DOI:10.19476/j.ysxb.1004.0609.2017.03.006

Cu-3.6%Al2O3铜合金细丝加工过程中组织结构演变规律

赵郅磊1,李 周1,肖 柱1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 粉末冶金国家重点实验室,长沙 410083)

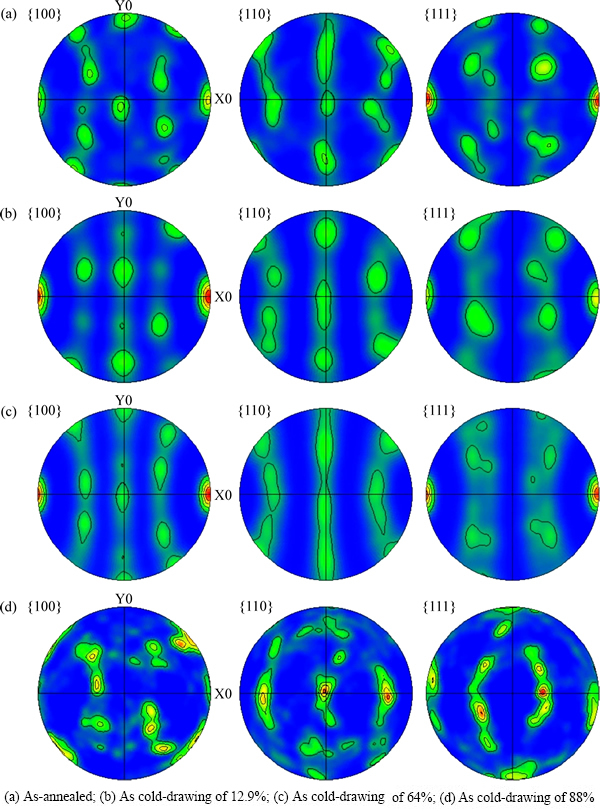

摘 要:通过TEM和EBSD等技术,研究Cu-3.6%Al2O3(体积分数)弥散强化铜合金细丝冷拉拔变形过程的显微组织和力学性能的演变规律。研究结果表明:Cu-3.6%Al2O3(体积分数)弥散铜合金基体内分布着大量的纳米级γ-Al2O3弥散强化相,形貌以近球状为主,还有少量尺寸为100~200 nm的呈棒状的γ-Al2O3粒子。在冷拉拔变形过程中,晶粒沿着拉拔方向拉长,硬度增加。随着拉伸的进行,合金的变形织构也在发生转变,当冷拉拔变形率达88%时,发生立方织构(Cube)和铜型织构(Copper)向黄铜织构(Brass)、高斯织构(Goss)和剪切织构(S)的转变;合金的显微组织为由位错缠结形成的带状组织和位错胞结构。

关键词:Cu-3.6%Al2O3铜合金;形变织构;显微组织

文章编号:1004-0609(2017)-03-0486-10 中图分类号:TG146.1 文献标志码:A

Cu-Al2O3弥散强化铜合金是一种具有优良的力学和物理性能的铜基复合材料[1]。弥散分布于铜合金基体中的纳米级的Al2O3强化相粒子对位错具有钉扎作用,阻碍位错的长程运动,而且Al2O3粒子硬度高、熔点高、高温稳定性能好[2-6],它们与时效强化型铜合金时效时析出的金属间化合物粒子不同,在温度接近铜基体的熔点时也不会溶解或粗化,因此可以十分有效地阻碍高温下的晶界迁移,提高合金室温和高温下的强度,同时合金的导电性能不会明显降低[7-8]。

随着微型特种电机的进一步发展,对电极丝材的耐磨、高温强度和电导率等性能提出了更高更苛刻的要求。Cu-Al2O3弥散强化铜合金因其特有的理化和力学特性,而成为微型特种电机最为理想的电极丝材。该合金随着纳米Al2O3强化相粒子的增加,其室温和高温强度会显著增大,而电导率下降幅度较小,但是随着纳米Al2O3强化相粒子的增加,其加工的难度也会进一步加大。

由于Cu-Al2O3弥散强化铜合金优秀的性能,国内外越来越多的领域开始使用该合金来替代其他强化方式的铜合金,包括信息技术、制造业、精密仪器、导电材料、军工业以及航天航空业等众多领域[9-10],越来越多的科研工作者投入对Cu-Al2O3弥散强化铜合金的研究,目前,对Al2O3含量较高的弥散强化铜合金的冷加工性能的研究报道很少,而国内外的研究主要集中在对于弥散强化铜合金的力学性能和显微组织的分析,本文作者利用TEM和EBSD手段研究了Cu-3.6%Al2O3(体积分数)弥散强化铜合金在冷拉丝过程中的微观组织结构的演变规律,以期为该系合金丝材的制备提供指导。

1 实验

实验合金制备流程如下:Cu-Al(0.8%,质量分数)合金中频感应熔炼→氮气雾化制粉→筛分后与适量氧化剂混合→N2气体保护下,900 ℃、1 h内氧化→内氧化粉末900 ℃、1 h氢气退火→冷等静压→包套→920 ℃热挤压成棒材,挤压比为20:1→旋锻至d4.5 mm丝材→900 ℃、1 h氢气退火→多道次冷拉拔至d 0.3 mm丝材(中间不退火)(样品如图1)[11-13]。样品道次拉拔尺寸和道次变形率如表1所示。

图1 0.3 mm丝材

Fig. 1 0.3 mm fine wire

硬度测试样品、金相显微组织观察样品、扫描电镜样品均先用砂纸打磨, 再进行机械抛光。硬度测试是在HV-5型小负荷维氏硬度计上测量;金相显微组织观察在Leica DM光学显微镜上进行;扫描电镜实验在FEI公司产Helios Nanolab 600i 双束扫描电镜上进行,工作电压为15 kV。透射电镜和EBSD样品采用常规双喷电解抛光的制样方法制备,实验在FEI公司产Tecnai G2 F20电镜上进行,工作电压为200 kV;EBSD实验在扫描电镜配以英国牛津公司产HKL Nordlys EBSD探头进行,工作电压为20 kV。

2 结果与讨论

2.1 旋锻退火态合金的显微组织结构

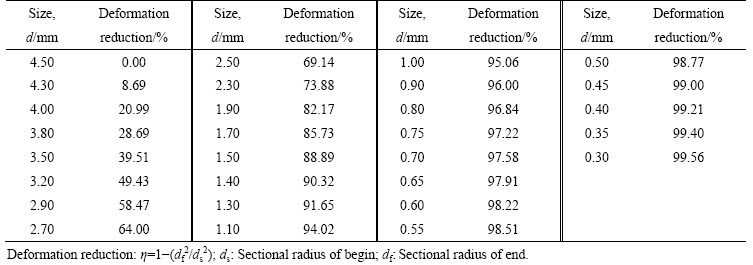

经过旋锻并退火处理的Cu-3.6%Al2O3弥散强化铜合金的元素面分布图如图2所示。其中,图2(a)所示为合金的典型二次电子像,弥散分布着尺寸为1~2 μm的黑色衬度相,图2(b)、(c)和(d)所示分别为Cu元素、Al元素和O元素的面分布图。在图2(b)、(c)和(d)中红色表示此元素富集,蓝色为其他元素,则对应于图2(a)黑色衬度相,出现了氧元素和铝元素的富集,说明黑色衬度相为Al2O3强化相粒子,也说明内氧化法制备的高Al2O3含量的Cu-3.6%Al2O3弥散强化铜合金,基体内存在少量的较大颗粒Al2O3强化相粒子。

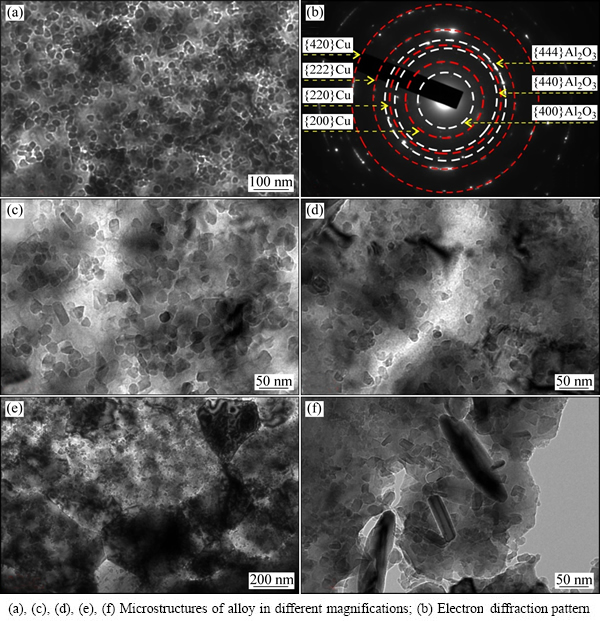

表1 样品道次拉拔尺寸和变形率

Table 1 Deformation and deformation reduction

图2 Cu-3.6%Al2O3铜合金元素面分布图

Fig. 2 Element area distribution profiles of Cu-3.6%Al2O3 alloy

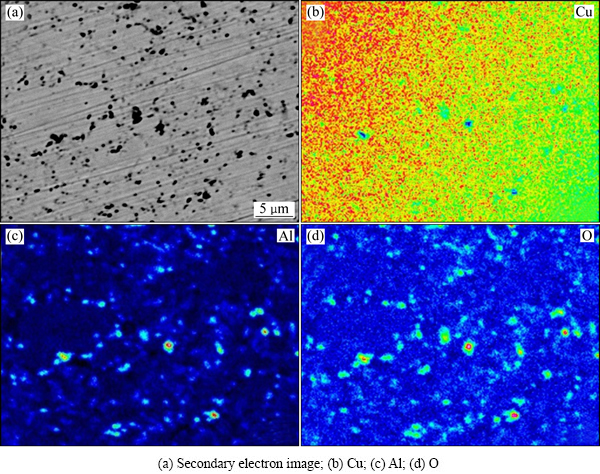

图3所示为旋锻退火态合金典型的透射电镜照片。从图3中可以看出,合金基体中弥散分布着高体积百分含量的纳米级Al2O3强化相粒子,形貌以近球状为主,少数为三角状和棒状等形状,尺寸介于30~60 nm(见图3(a)、(c)、(d));图3(b)所示为图3(a)的选取电子衍射,由于析出相弥散而且体积分数多,析出相的衍射花样以衍射环的形状出现,标定结果示于图上,弥散析出相为γ-Al2O3。从图3(f)可见,合金中也分布着少量尺寸介于100~200 nm,形状为针棒状的Al2O3强化相粒子,这一结果与图2(a)的观察结果一致。从图3(e)可以发现,经过900 ℃退火态的样品,合金发生了高温回复,亚晶粒尺寸为0.4~1.0 μm。

2.2 冷拉态合金的硬度变化

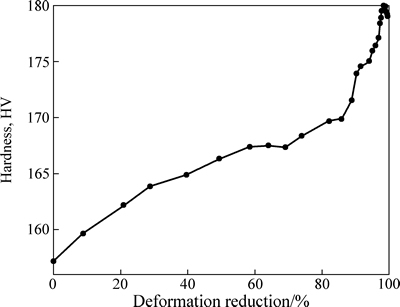

图4所示为Cu-3.6%Al2O3弥散强化铜合金经不同变形率拉拔变形后的硬度变化曲线。由图4可知,随着变形率的增加,合金的硬度增加;当冷拉变形率小于80%时,硬度以抛物线状增长,较为平缓;当变形率超过85%时,硬度增加的幅度显著增大;当变形率达到99%时,硬度达180 HV。这是由于弥散强化铜合金出现加工硬化的现象,冷拉拔变形使铜合金内部出现大量的位错,同时,由于均匀弥散分布的Al2O3强化相粒子对位错有强烈钉扎作用, 导致位错难以聚集和抵消。而当变形量达到95%后,则硬度略有下降,出现了加工软化的现象。

2.3 冷拉变形合金的组织结构的演变

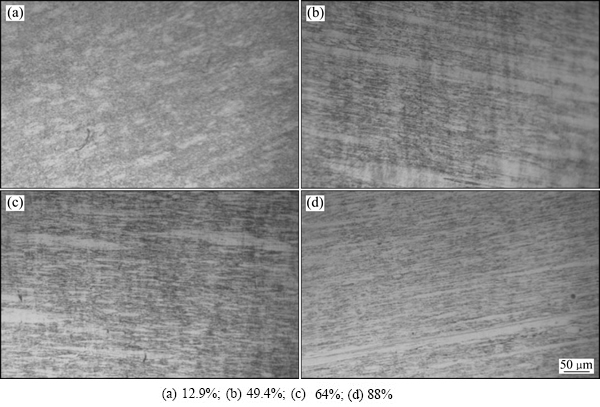

图5所示为弥散强化铜合金经冷拉变形12.9%、49.4%、64%和88%后的典型纵向金相组织形貌。从图5可以看出,平行于拉拔方向的晶粒随着拉拔量的增加显著拉长,当拉拔变形足够大时呈加工纤维状组织,经64%后变形后,晶粒的长宽比大于20。

图3 Cu-3.6%Al2O3铜合金的TEM像

Fig. 3 TEM images of Cu-3.6%Al2O3 alloy

图4 Cu-3.6%Al2O3合金样品在不同变形率下的硬度变化分布图

Fig. 4 Hardness change of Cu-3.6%Al2O3 Alloy in different deformation reductions

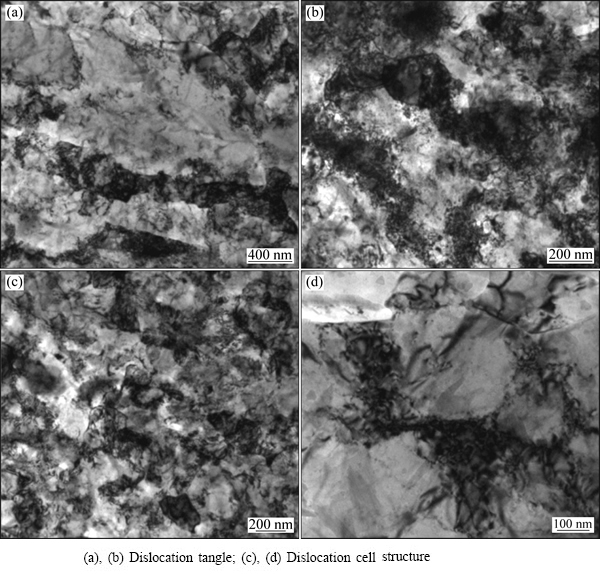

图6所示为Cu-3.6%Al2O3合金冷拉变形64%的典型透射电镜下的组织形貌,不同取向的晶粒经冷拉变后的组织差异较大[14-15]。一些晶粒变形不均匀,晶粒中形成了由位错缠结形成的界面,进而形成了带状组织(见图6(a)和(b));另一些晶粒变形均匀,晶粒中形成均匀的位错缠结,进而形成位错胞结构(见图6(c)和(d))[16]。

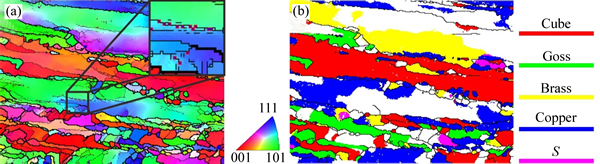

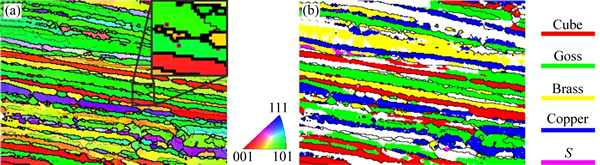

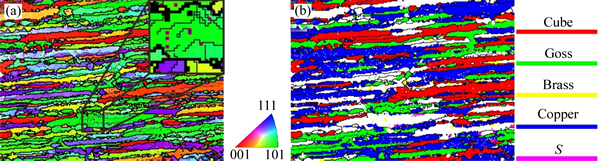

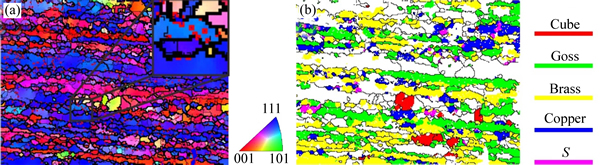

利用Channel 5软件重构出Cu-3.6%Al2O3弥散强化铜合金不同变形量下的取向成像图(IPF)[17-18]。图7、8、9和10所示分别为旋锻退火、冷拉变形12.9%、冷拉变形64%和冷拉变形88%状态的IPF像和OIM像。由图7(a)、8(a)、9(a)和10(a)可见,随着冷拉拔变形率的增大,晶粒沿着拉拔方向被拉长,大晶粒最后被拉长成细长晶粒,同时大量晶粒开始分裂,内部出现大量的亚结构(黑色细线)。通过使用HKL Channel 5软件将晶粒结构重新计算,去掉影响计算结果的取向噪音后,当Cu-3.6%Al2O3弥散强化铜合金变形率达到60%以上后,其晶粒长度为15~20 μm左右,而晶粒的宽度为1~2 μm左右(见图 9(a)和10(a))。同时还可以观察到,在Cu-3.6%Al2O3弥散强化铜合金基体内分布着大量的弥散强化相Al2O3粒子(红色细线圈出),形貌以近球状为主,直径约为30~50 nm左右;晶界处有少量尺寸粗大的Al2O3强化相粒子存在,直径约为 100 nm。

图5 Cu-3.6%Al2O3铜合金经不同冷拉变形后的典型纵向金相组织形貌

Fig. 5 Typical longitudinal metallographs of Cu-3.6%Al2O3 alloy after different cold-drawing degrees

图6 Cu-3.6%Al2O3铜合金冷拉变形率64%的TEM像

Fig. 6 TEM images of Cu-3.6%Al2O3 alloy in 64% deformation reduction

图7 旋锻退火态样品的IPF图和OIM像

Fig. 7 IPF (a) and OIM (b) images as-annealed sample (Bar is 5 μm)

图8 冷拉变形12.9%样品的IPF图和OIM像

Fig. 8 IPF (a) and OIM (b) images of alloy after 12.9% cold-drawing degree (Bar is 5 μm)

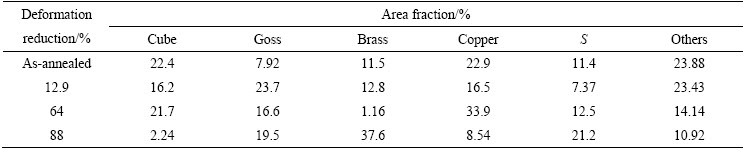

在OIM像中,FCC金属中常出现的典型织构取向有立方织构(Cube){100}<100>、高斯织构(Goss){011}<100>、黄铜织构(Brass){011}<211>、铜型织构(Copper)、剪切织构(S){123}<412>或{123}<634>等[19]。图7(b)(OIM像)所示为Cu-3.6%Al2O3弥散强化铜合金旋锻退火态后典型的织构分布特征,其中立方织构(Cube)取向和铜型织构(Copper)取向所含比例较高,分别超过15%以上(见表2)。图8(b)、9(b)和10(b)的OIM像示出了Cu-3.6%Al2O3弥散强化铜合金分别进行12.9%、64%和88%的冷拉拔变形后的织构分布特点,随着变形率的增加,立方织构(Cube)取向含量迅速减少,铜织构(Copper)取向也同时减少,而黄铜织构(Brass)取向显著增加,同时,高斯织构(Goss)取向和剪切织构(S)取向微幅增加。与轧制不同[20],Cu-3.6%Al2O3弥散强化铜合金经大变形量的冷拉拔变形后样品中黄铜织构(Brass)取向、高斯织构(Goss)取向和剪切织构(S)取向占主要组分,而其他非经典织构取向只有10%左右。

表2所列为Cu-3.6%Al2O3弥散强化铜合金不同冷拉变形量下的不同状态的织构组分。由表2可以看出,在大变形量的冷拉拔变形下发生了立方织构(Cube)取向和铜型织构(Copper)取向往黄铜织构(Brass)取向、高斯织构(Goss)取向和剪切织构(S)取向的转变趋势;同时退火态的其他非经典织构取向成分转变为FCC织构取向。

同时,为了研究晶粒在不同变形量下的样品中的取向分布,晶粒的取向利用EBSD分析软件在极图上表示出来,如图11示。图11(a)所示为旋锻退火态样品的晶粒(对应于图7(b)取向),图11(b)~(d)所示为所有冷拉拔变形态样品的晶粒(分别对应于图8(b)、9(b)和10(b)取向)。由图11(a)所示,旋锻退火态Cu-3.6%Al2O3弥散强化铜合金在(100)极图上立方织构(Cube)取向和铜型织构(Copper)取向强度最高。而样品经12.9%、64%、88%冷拉拔变形后,分别如图11(b)~(d) 所示,呈现典型的黄铜织构(Brass)取向、高斯织构(Goss)取向和剪切织构(S)取向,而取向强度在(110)及(111)极图上最强。

图9 冷拉变形64%样品的IPF图和OIM像

Fig. 9 IPF (a) and OIM (b) images of alloy after 64% cold-drawing degree (Bar is 10 μm)

图10 冷拉变形88%样品的IPF图和OIM像

Fig. 10 IPF (a) and OIM (b) images of alloy after 88% cold-drawing degree (Bar is 5 μm)

表2 Cu-3.6Al2O3铜合金不同状态的织构组分

Table 2 Texture composition of Cu-3.6%Al2O3 alloy in different states

图11 Cu-3.6%Al2O3铜合金样品不同状态的极图

Fig. 11 Pole figures of Cu-3.6%Al2O3 alloy in different states

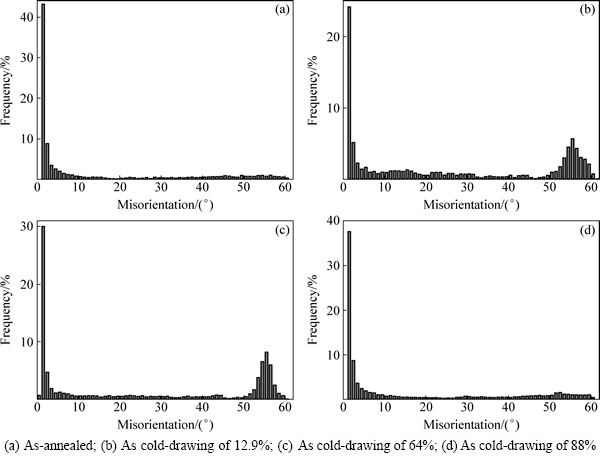

通过EBSD微结构分析,可以得到组织形貌与取向之间的对应关系。通过对比定义的基准值θ和相邻晶粒间的取向差的大小,将大于基准值θ的界限相连,就构成了EBSD取向差角分布图,可反映出晶界角度,如图12所示为不同变形率下样品显微组织的取向差分布图。从图12可看出,随着变形率逐渐增加,小角度晶界(<15°)占据主要含量,取向差角在大小为2°左右的小角度晶界分布最高并呈现单峰值,而取向差角大于15°的大角度晶界几乎为0。由此说明Cu-3.6%Al2O3弥散强化铜合金在发生大变形量的冷拉拔时大量的滑移线及亚结构在晶粒内部堆积,造成小角度晶界的数量急剧上升。而图12中出现取向差角度出现先增加后降低的现象,有研究认为[21],金属在塑性变形时,当变形量在一定范围里时,在金属微观组织结构中可能会形成一种新的界面结构,多层条状带(Lamellar bands)组成的层片状组织,这些层片结构界面与相邻晶粒间的取向差一般都在10°以内,但是在不同的晶粒中,变形组织存在着很大的差异,取向差角度分布就可能出现先增后减的现象。

图12 Cu-3.6%Al2O3铜合金样品不同状态的取向差分布图

Fig. 12 Misorientation distribution of Cu-3.6%Al2O3 Alloy in different states

3 结论

1) 内氧化法制备的Cu-3.6%Al2O3弥散强化铜合金中分布着高体积含量的纳米级的γ-Al2O3强化相粒子,近球状居多,其余少量为不规则形状,尺寸介于30~60 nm之间;同时,在晶界处存在少量的粗大γ-Al2O3强化相粒子,尺寸最大为100~200 nm。

2) Cu-3.6%Al2O3弥散强化铜合金经冷拉拔变形过程中,随着变形的增加,沿拉拔方向形成加工纤维,长宽比大于20;不同晶粒的变形不一致,一些晶粒变形不均匀,形成高密度位错的带状组织;另一些晶粒变形均匀,晶粒中形成位错胞结构。

3) Cu-3.6%Al2O3弥散强化铜合金在大变形量下的冷拉拔变形后存在大量的小角度晶界(<15°)。同时其在88%变形率的冷拉拔后织构含量主要为黄铜织构(Brass),含量37.6%;高斯织构(Goss),含量19.5%;剪切织构(S),含量21.2%,发生了立方织构(Cube)和铜型织构(Copper)向黄铜织构(Brass)、高斯织构(Goss)和剪切织构(S)的转变。

REFERENCES

[1] 申玉田, 崔春翔, 孟凡斌, 吴人洁. 高强度高电导率Cu-Al2O3复合材料的制备[J]. 金属学报, 1999, 35(8): 888-892.

SHEN Yu-tian, CUI Chun-xiang, MENG Fan-bin, WU Ren-jie. Fabrication of Cu-Al2O3 composites with high strength and electric conductivity[J]. Acta Metallurgica Sinica, 1999, 35(8): 888-892.

[2] 申 坤, 汪明朴, 郭明星, 李树梅. Cu-0.23%Al2O3弥散强化铜合金的高温变形特性研究[J]. 金属学报, 2009, 45(5): 597-604.

SHEN Kun, WANG Min-pu, GUO Ming-xing, LI Shu-mei. Study on high temperature deformation characteristics of Cu-0.23%Al2O3 dispersion-strengthened copper ally[J]. Acta Metallurgica Sinica, 2009, 45(5): 597-604.

[3] 向紫琪, 雷 前, 肖 柱, 庞 咏. Cu-2.7%Al2O3弥散强化铜合金的微观组织和力学性能研究[J]. 矿冶工程, 2014, 34(6): 132-137.

XIANG Zi-qi, LEI Qian, XIAO Zhu, PANG Yong. Investigation on the microstructure and mechanical properties of Cu-2.7% Al2O3 dispersion strengthened copper alloy[J]. Mining Metallurgical Engineering, 2014, 34(6): 132-137.

[4] 程建奕, 汪明朴. 高强高导高耐热弥散强化铜合金的研究现状[J]. 材料导报, 2004, 18(2): 38-41.

CHENG Jian-yi, WANG Min-pu. Progress in research on high-strength high-conductivity and high-heat resistance dispersion strengthened copper alloy[J]. Materials Review, 2004, 18(2): 38-41.

[5] GROZA J. Heat-resistant dispersion strengthened copper alloys[J]. Journal of Materials Engineering and Performance, 1992, 1(1): 113-118.

[6] JENA P K, BROCCHI E A, MOTTA M S. In-situ formation of Cu-Al2O3 nano-scale composites by chemical routes and studies on their microstructure[J]. Materials Science and Engineering A, 2001, 313(00): 180-186.

[7] LIANG S, FAN Z, XU L, FANG L. Kinetic analysis on Al2O3/Cu composite prepared by mechanical activation and internal oxidation[J]. Composites Part A, 2004, 35(12): 1441-1446.

[8] PLASCENCIA G, UTIGARD T A. High temperature oxidation mechanism of dilute copper aluminum alloys[J]. Corrosion Science, 2005, 47(5): 1149-1163.

[9] CHENG J Y, WANG M P, LI Z, WANG Y H, XIAO C W, HONG B. Fabrication and properties of low oxygen grade A12O3 dispersion strengthened copper alloy[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(1): 121-126.

[10] 程建奕, 敖学文, 汪明朴, 郭明星. Al2O3弥散粒子对Cu-Al2O3合金高温退火显微组织的影响[J]. 中国有色金属学报, 2009, 19(11): 1928-1933.

CHENG Jian-yi, AO Xue-wen, WANG Ming-pu, GUO Ming-xing. Effect of Al2O3 disperoid on microstructure of Cu-Al2O3 alloy annealed at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1928-1933.

[11] 于艳梅, 杨根仓, 李华伦. 内氧化制备Cu-Al2O3复合材料新工艺的研究[J].粉末冶金技术, 2000, 18(4): 252-256.

YU Yan-mei, YANG Gen-cang, LI Hua-lun. A new method for fabrication of Cu-Al2O3 composite by internal oxidation[J]. Powder Metallurgy Technology, 2000, 18(4): 252-256.

[12] PRESTON O, GRANT N J. Dispersion strengthening of copper by internal oxidation[J]. Transaction of the Metallurgical society of AIME, 1961, 221: 164-172.

[13] LEE J, YONG C K, LEE S, KIM N J, AHN S. Correlation of the microstructure and mechanical of oxide-dispersion-strengthened coppers fabricated by internal oxidation[J]. Metallurgical and Materials Transactions A, 2004, 35: 493-502.

[14] BAY B, HANSEN N, HUGHES D A, KUHLMANN-WILSDORF D. Overview No. 96 evolution of f.c.c. deformation structures in polyslip[J] Acta Metallurgica et Material, 1992, 40(2): 205-219.

[15] SEEFELDT M, DELANNAY L, PEETERS B, KALIDINDI S R, HOUTTE P V. A disclination-based model for grain subdivision[J] Materials Science and Engineering A, 2001, 319(1): 192-196.

[16] HUANG X. Grain orientation effect on microstructure in tensile strained copper[J]. Scripta Materialia, 1998, 38: 1697-1703.

[17] 黄光杰, 陈江波, 黄天林, 邹 彬. 超高纯Al-0.5%Cu合金溅射靶材微观组织与织构的EBSD分析[J]. 电子显微学报, 2010, 29(1): 750-753.

HUANG Guang-jie, CHEN Jiang-bo, HUANG Tian-lin, ZOU Bin. EBSD analysis of microstructure and texture of ultra-high pure Al-0.5% Cu alloy sputtering target[J] Journal of Chinese Electron Microscopy Society, 2010, 29(1): 750-753.

[18] 陈绍楷, 李晴宇, 苗 壮, 许 飞. 电子背散射衍射(EBSD)及其在材料研究中的应用[J]. 稀有金属材料与工程, 2006, 35(3): 500-504.

CHEN Shao-kai, LI Qing-yu, MIAO Zhuang, XUu Fei. EBSD and Its applications in materials research rare[J]. Rare Metal Materials and Engineering, 2006, 35(3): 500-504.

[19] 杨 钢, 陈亮维, 王剑华, 王军丽, 史庆南. FCC 金属的织构对力学性能的影响[J]. 昆明理工大学学报(自然科学版), 2012, 37(5): 24-34.

YANG Gang, CHEN Liang-wei, WANG Jian-hua, WANG Jun-li, SHI Qing-nan. Influences of texture of FCC metals on their mechanical properties[J]. Journal of Kunming University of Science and Technology (Natural Science Edition), 2012, 37(5): 24-34

[20] 毛卫民, 余永宁, 李波涛. 极图数据与板材织构信息[J]. 北京科技大学学报, 1995, 17(5): 434-438.

MAO Wei-min, YU Yong-ning, LI Bo-tao. Pole figure data and texture informations of metal sheets[J]. Journal of University of Science and Technology Beijing, 1995, 17(5): 434-438.

[21] HUGHES D A, HANSEN N. High angle boundaries formed by grain subdivision mechanisms[J]. Acta Materialia, 1997, 45(9): 3871-3886.

Structure evolution of Cu-3.6%Al2O3 alloy fine wire during cold drawing

ZHAO Zhi-lei1, LI Zhou1, XIAO Zhu1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The microstructure and mechanical property evolution of Cu-3.6%Al2O3 (volume fraction) alloy fine wire during cold drawing were studied by TEM and EBSD. The results show that the massive nano-scale γ-Al2O3 particles with near spherical like dispersively distribute on the matrix of the alloy strengthening phase, meanwhile, some rod-like particles with size of 100-200 nm also appear. During cold drawing, the grains are elongated and the hardness increases. With drawing process, the deformation texture of alloy changes, as the deformation reduction approaches 88%, the cube texture and copper texture transform to Brass texture, Goss texture and S texture. The microstructures of alloy are composed of banded structure and dislocation cell one formed by dislocation.

Key words: Cu-3.6%Al2O3 alloy; deformation texture; microstructure

Foundation item: Project (U1637210) supported by the National Natural Science Foundation of China

Received date: 2016-03-18; Accepted date: 2016-10-25

Corresponding author: LI Zhou; Tel: +86-731-88830264; E-mail: lizhou6931@csu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(U1637210)

收稿日期:2016-03-18;修订日期:2016-10-25

通信作者:李 周,教授,博士;电话:0731-88830264;E-mail:lizhou6931@csu.edu.cn