DOI:10.19476/j.ysxb.1004.0609.2019.04.15

TP2铜管拉拔成形过程组织演变规律

王松伟1, 2,张士宏1,宋鸿武1,陈 岩1

(1.中国科学院 金属研究所,沈阳110016;

2.中国科学技术大学 材料科学与工程学院,合肥230026)

摘 要:为了研究铜管材游动芯头拉拔成形过程中组织结构及力学性能变化规律,采用OM和EBSD等试验方法对不同拉拔变形量的TP2管材进行分析。结果表明:经过拉拔变形后,晶粒沿着拉拔方向伸长形成纤维组织,管材显微硬度增加且轴向硬度值较高;经过第三道次拉拔变形量达到75%,晶粒沿轴向长度为80~100 μm,宽度为8~10 μm;经过拉拔变形,管材内部织构发生转变,随着变形量的提高,由原始轧制态{001}<110>、{111}<110>织构逐渐发生转动,经过三个道次后变为{110}<100>、{110}<111>织构。

关键词:铜管拉拔;织构转变;显微组织;EBSD

文章编号:1004-0609(2019)-04-0782-08 中图分类号:TG146.1 文献标志码:A

游动芯头拉拔工艺是精密铜管生产过程中一道关键工序,可实现管材连续减径减壁,具有变形量大、速度快、材料利用率高、工艺稳定和尺寸精度高等优点[1-4]。随着生产效率要求的提高,有必要对变形过程管材内部织构类型及演变进行研究,以便优化生产工艺。

关于铜及其合金织构方面研究较多,王雷等[5]研究发现冷轧纯铜变形量为92%时其轧制织构主要是{112}<111>铜型织构和{011}<112>黄铜型织构。LI等[6]对CuZr合金进行低温冷轧,发现低温可促进黄铜型织构向铜型织构转变。目前已有相关研究[7-9]表明,对于中高层错能FCC结构金属的轧制态组织主要为{123}<634>、{110}<112>、{112}<111>组分,而对于低层错能主要为{110}<112> 组分。陈亮维等[10]采取同步和异步轧制方法对纯铜深度塑性变形的织构组织均匀性进行了研究,发现异步叠轧铜样品表层变形织构为{100}<011>剪切织构,而同步叠轧是{211}<111>铜型织构。赵郅磊等[11]对Cu-3.6%Al2O3合金细丝冷拉拔变形织构进行研究,发现当变形量达到88%时,发生立方织构和铜型织构向黄铜织构、高斯织构和剪切织构的转变。李肖蓉[12]对铝铜合金进行了不同应变量的冷轧变形,发现形变量为60%时主要为高斯织构,变形量达到80%~90%时形成典型的轧制织构,其中黄铜型织构含量高于剪切织构和铜型织构。李红英等[13]对塑性变形单晶铜线材织构进行研究,发现工业单晶铜线材经过冷拉拔变形后主要产生<100>和<110>丝织构,随着变形量的增加<100>丝织构先减小后增加,而<110>丝织构先增加后减小,直到变形量为96.9%时几乎为零。目前,铜及合金织构的研究主要集中在丝材拉拔、轧制、挤压等变形方式[14],而在管材拉拔方面研究较少。本文对三个道次联拉过程管材取样分析,采取硬度测试、光学显微镜及EBSD试验对变形过程组织结构变化规律进行了研究。

1 实验

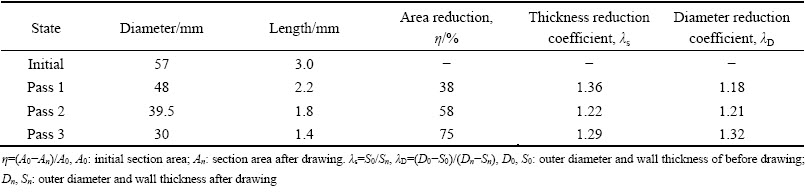

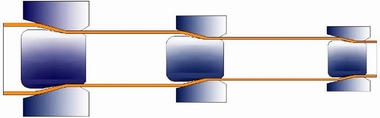

样品取自实际生产管材,由水平连铸获得d96 mm×24 mm管坯,经过三辊行星轧制后得到初始管材尺寸为d57 mm×3.0 mm。变形量可达到90%以上,温度可升高至680~700 ℃,发生再结晶,因此可消除铸造组织而得到等轴晶组织,便于后续拉拔工艺进行。随后进行室温下三个道次的游动芯头拉拔变形,图1所示为管材联拉示意图,经数值模拟[2]和现场示温涂料测试三个道次变形后温度分别为117、148和172 ℃,三个道次拉拔速度分别为40、60和90 m/min。模具与管坯之间润滑较好,摩擦因数控制在0.05,从而保证铜管表面质量。各道次相应尺寸和变形率如表1所列。

表1 TP2铜管样品道次拉拔尺寸和变形率

Table 1 Deformation and deformation reduction

图1 三道次联合拉拔示意图

Fig. 1 Schematic diagram of three passes of joint drawing

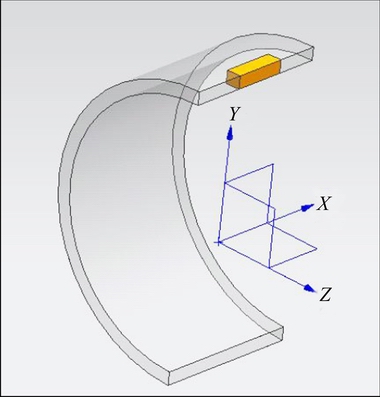

显微硬度测试样品、金相显微组织观察样品、扫描电镜样品均先经过砂纸粗磨,细磨,机械抛光。显微硬度测试在FM-700型显微硬度仪上进行;金相显微组织观察在ZMEF4A型金相显微镜和SSX-550型扫描电镜上进行;EBSD样品经过常规磨抛后再进行振动抛光12 h,立刻利用超声波振动清洗,实验在FEINanoSEM Nova430场发射扫描电镜上进行,测试步长为0.75μm,利用Oxford Instrument的HKL Channel 5 EBSD系统提取数据信息,设置2°为噪点,进行去燥处理。EBSD样品选取的观察面为沿拉拔方向纵切面,选取位置为沿径向管壁中心部位,拉拔方向为X0,径向为Y0,周向为Z0,如图2所示。

图2 取样位置示意图

Fig. 2 Diagram of sampling point

2 结果与讨论

2.1 轧制态管材显微组织

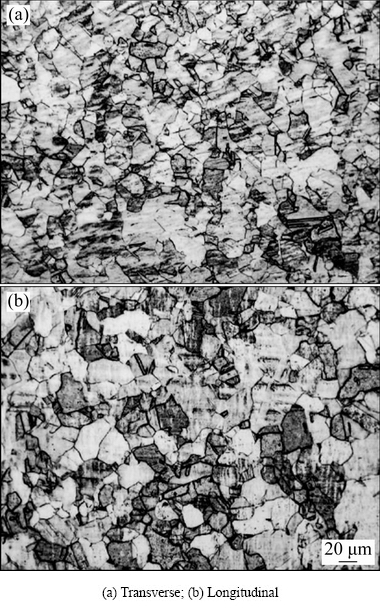

水平连铸管坯经过三辊行星轧制过程,变形量可达到90.6%,在此剧烈变形过程下轧辊摩擦生热和塑性变形热可使管坯温度迅速升高至700°左右并发生动态再结晶,使铸态组织转变为均匀的等轴晶组织,为后续拉拔过程提供良好的组织条件。图3所示为轧制变形后铜管金相组织,晶粒尺寸在15~20 μm,且沿着管材轴向(见图3(b))晶粒尺寸稍大。可以观察到在晶界边部产生细小的动态再结晶晶粒,说明已存在的晶界往往是动态再结晶的形核地,轧制过程超过临界变形量而凸出形核长大。再结晶晶粒在长大的同时,变形在持续进行,因而形成的新晶粒中有一定程度的应变,会出现位错缠结的亚结构以及晶粒内部出现少量孪晶。

图3 TP2铜管轧制态金相组织

Fig. 3 Metallographic of copper tube after rolling

2.2 拉拔变形铜管组织结构的演变

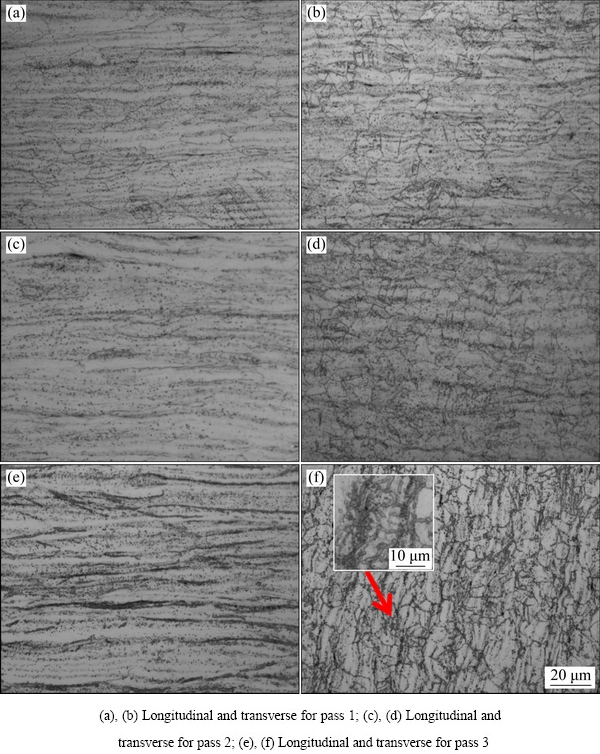

图4所示为不同拉拔道次后铜管金相组织。由图4可见,沿拉拔方向晶粒形貌尺寸发生显著变化,随着变形量的增加,晶界趋于平行拉拔方向并形成纤维流线且晶界宽度增加,晶粒破损严重;周向晶粒尺寸逐渐减小,在原有晶界附近形成新的亚结构组织。由图4(f)可见,晶界堆积缠结,在后续取向差角结果中可知形成大量小角度晶界。

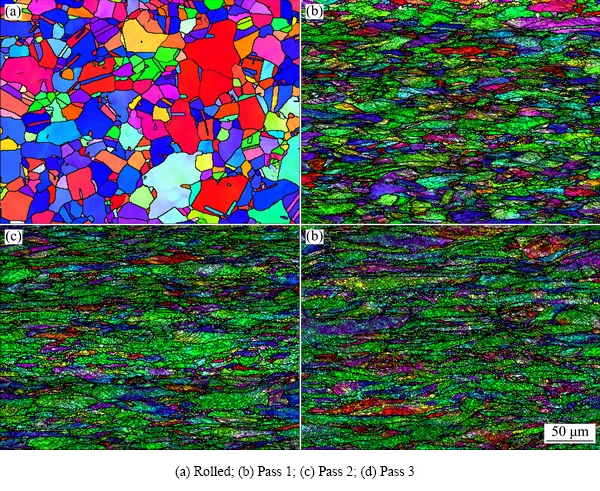

图5所示为Channel5软件重构得到的各道次变形条件下取向成像图(IPF),图中细实线标记为晶界角度在2°~10°之间。由图5可见,拉拔过程中铜管内部产生大量小角度晶界,随着变形的不断积累,原始轧制态再结晶晶粒被拉长并破碎,内部分裂形成细长小晶粒。经过第三道次拉拔变形量达到75%,变形方向上细长晶粒长度为80~100 μm,而晶粒宽度为8~10 μm。

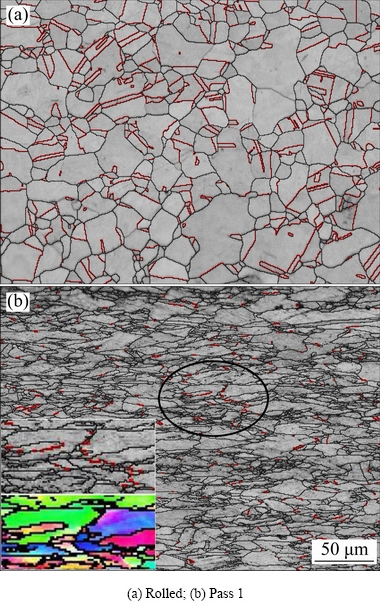

在IPF图中可见,初始轧制态再结晶晶粒取向较均匀,有明显的孪晶在晶内出现,细小再结晶晶粒在初始晶界处生长和聚集。图6所示为拉拔变形前后孪晶变化。由图6可见,经过一次拉拔后,孪晶显著减少,原始晶粒内部孪晶取向发生转变,并演变为具有独立取向的晶粒;由图5(b)、(c)和(d)可见,随着变形道次进行,晶粒沿着拉拔方向伸长并发生转动,择优取向明显,织构逐渐加强;由图6(b)可见,{101}晶面逐渐趋向于平行观察面,成为主要取向。

图4 不同拉拔道次铜管金相组织

Fig. 4 Metallographs of copper tube after drawing passes

图5 不同状态铜管样品取向成像图

Fig. 5 IPF images of copper tube at different states

图6 拉拔变形前后孪晶变化

Fig. 6 Twining changes of twin before and after drawing deformation

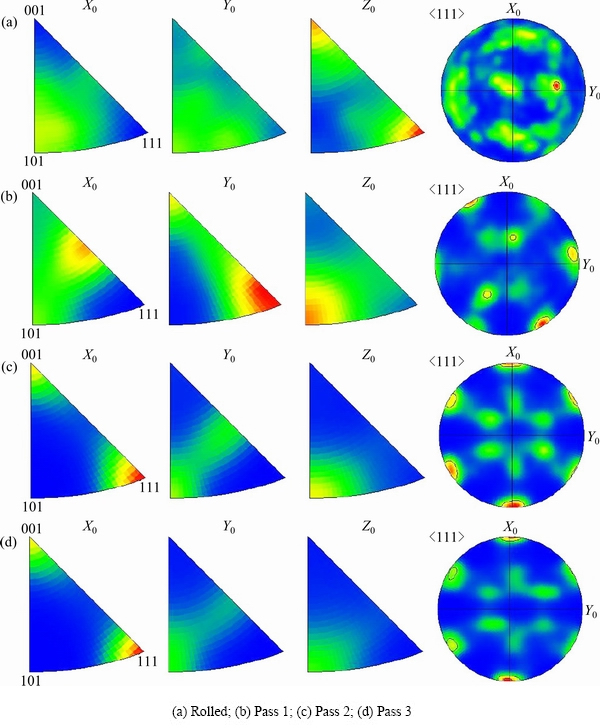

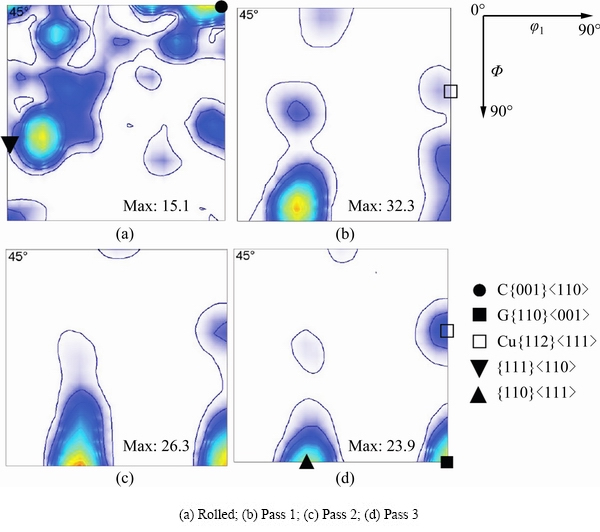

图7所示为各道次变形样品反极图与极图。由图7(a)所示铜管轧制态反极图可见,{001}和{111}晶面与观察面平行,<110>晶向与拉拔方向平行。对比极图分析[15]可知,轧制后铜管内含有少量旋转立方织构{001}<110>和退火织构{111}<110>。如图7(b)所示,经过一道次拉拔后,{110}晶面趋向于平行观察面即管材纵切面,<112>晶向转向拉拔方向。由图7(c)和(d)可见,随着第二和第三道次拉拔,变形量逐渐提高,主要织构类型转向高斯织构{110}<100>及较强的{110}<111>织构。图8所示为各道次变形后样品ψ2=45°三维取向(ODF)图及主要织构取向。已有研究表明[7-9],FCC结构金属在轧制变形过程中,其黄铜型织构{011}<112>和铜型织构{112}<111>为稳定取向,晶粒会向这两个方向发生偏转。而对于管材拉拔变形可见随着道次增加,织构类型逐渐转向{110}<100>和{110}<111>,而黄铜型织构和铜型织构含量则较少,这主要与变形方式及应力状态有关。

轧制态管材内部含有少量动态再结晶过程形成的退火织构和轧制变形产生的剪切织构,以<110>//X0为主;经过拉拔变形处理后,晶粒发生转动,转变为<001>和<111>//X0,其中{110}晶面平行于观察面。由此可见,对于FCC铜管材的拉拔过程,其织构类型不同于已有的轧制、挤压等变形方式;经过三个道次拉拔后,当累计变形量达到75%时,其主要织构类型为{110}<100>和{110}<111>。

图7 不同状态铜管样品的反极图和极图

Fig. 7 Pole figures of copper tube at different states

2.3 拉拔变形过程中晶界的变化

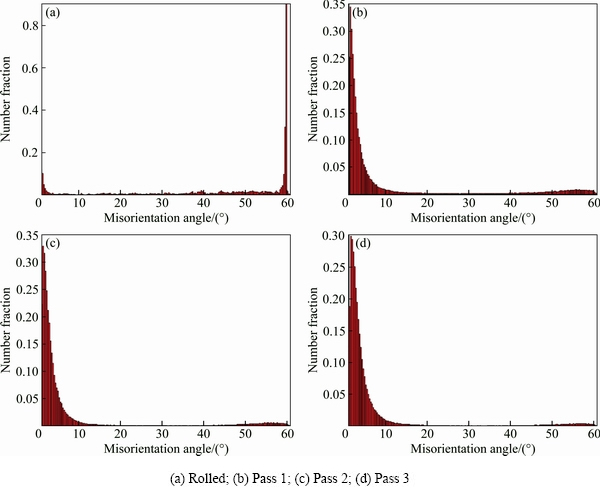

经过较大塑性变形处理后,一般会发生晶粒破碎,晶界数量显著增加,而晶界角度是表征晶界特性的手段之一[16]。图9所示为各道次变形量下不同取向差角度所占比例。由图9可知,轧制态晶界角度较均匀,晶界角度为50°~60°之间含量稍多,这主要是孪晶取向(60°//<111>);当变形一次后,孪晶显著减少,小角度(2°~10°)晶界迅速增多;随着变形量的增加,晶粒破碎严重,且随着晶粒转向织构方向。

2.4 拉拔态管材力学性能变化

图8 不同状态铜管ψ2=45°三维取向(ODF)图及主要织构取向

Fig. 8 ψ2=45° section of ODF and typical texture of different states

图9 不同状态铜管试样取向差角分布

Fig. 9 Distribution of misorientation angle of copper tube at different states

图10 不同状态铜管显微硬度变化

Fig. 10 Micro-hardness of copper tube at different states

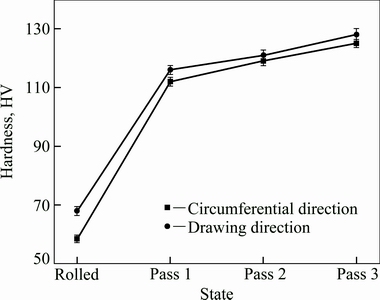

图10所示为不同道次铜管拉拔变形后横向切面和轴向切面测得显微硬度变化曲线。由图10可知,经过一道次拉拔变形,铜管硬度较轧制态相比提高了近一倍;随着拉拔道次的增加,铜管周向和拉拔方向硬度均逐渐增加,且轴向硬度平均值稍高于周向。对比金相组织分析可知,硬度值与变形后晶粒取向有关。对于TP2铜来说,基体内无其他析出相,硬度提高主要归因于变形过程的加工硬化及晶粒细化,内部晶粒破碎严重,产生大量小角度晶界阻碍位错运动。由于拉拔铜管晶粒沿轴向晶粒被拉长,因此呈现出力学性能的变化。

3 结论

1) TP2铜管经过游动芯头拉拔变形后,显微硬度显著提高且轴向硬度值稍高于周向;晶粒沿着拉拔方向伸长形成纤维组织,小角度晶界大量增加;经过第三道次拉拔变形量达到75%,变形方向上细长晶粒长度为80~100 μm,而晶粒宽度为8~10 μm。

2) 经过拉拔变形后,管材内部由轧制态少量{001}<110>和{111}<110>织构逐渐发生转动,且孪晶显著减少,经过三个道次拉拔累计变形量达到75%时,以{110}<100>和{110}<111>为主要织构类型。

REFERENCES

[1] 张士宏, 刘劲松, 程 明. 精密铜管铸轧加工技术[M]. 北京: 国防工业出版社, 2016: 76-85.

ZHANG Shi-hong, LIU Jin-song, CHENG Ming. Cast and roll technology of precision copper tubes[M]. Beijing: National Defend Industry Press, 2016: 76-85.

[2] 陈大勇. 基于TP2铜管材性能控制的拉拔工艺研究[D]. 沈阳: 沈阳理工大学, 2015: 9-20.

CHEN Da-yong. The research of the drawing processes based on property controlling of TP2 copper tube[D]. Shenyang: Shenyang Ligong University, 2015: 9-20.

[3] 王祝堂, 田荣璋. 铜合金及其加工手册[M]. 长沙: 中南大学出版社, 2002: 130-190.

WANG Zhu-tang, TIAN Rong-zhang. Copper alloy and processing manual[M]. Changsha: Central South University Press, 2002: 130-190.

[4] 李耀群, 易茵菲. 现代铜盘管生产技术[M]. 北京: 冶金工业出版社, 2005: 20-60.

LI Yao-qun, YI Yin-fei. The modern production technology of copper tube[M]. Beijing: Metallurgical Industry Press, 2005: 20-60.

[5] 王 雷, 李 凡, 蒋建清. 冷轧纯铜微观组织及织构演变的特征[J]. 理化检验, 2008, 44(8): 405-407.

WANG Lei, LI Fan, JIANG Jian-qing. Microstructure and micro-texture evolution of cold rolling copper[J]. Physical Testing and Chemical Analysis, 2008, 44(8): 405-407.

[6] LI Ren-geng, ZHANG Shao-jian, KANG Hui-jun, CHEN Zong-ning, YANG Fen-fen, WANG Wei, ZOU Cun-lei, LI Ting-ju, WANG Tong-min. Microstructure and texture evolution in the cryorolled CuZr alloy[J]. Journal of Alloys and Compounds, 2017, 693: 592-600.

[7] SIDOR J J, KESTENS L A I. Analytical description of rolling textures in face-centred-cubic metals[J]. Scripta Materialia, 2013, 68(5): 273-276.

[8] ANAND G, BARAI K, MADHAVAN R, CHATTOPADHYAY P P. Evolution of annealing texture in cryo-rolled copper[J]. Material Science and Engineering A, 2015, 638: 114-120.

[9] HIRSCH J, LUCKE K. Mechanism of deformation and development of rolling texture in polycrystalline FCC metals[J]. Acta Metallurgica, 1988, 36(11): 2863-2927.

[10] 陈亮维, 韩 波, 史庆南, 起华荣, 王效琪. 纯铜深度塑性变形的织构组织均匀性研究[J]. 材料科学与工艺, 2010, 18(3): 391-394.

CHEN Liang-wei, HAN Bo, SHI Qing-nan, QI Hua-rong, WANG Xiao-qi. Unformity of texture microstructure of pure copper sheets with severe plastic deformation[J]. Material Science and Technology, 2010, 18(3): 391-394.

[11] 赵郅磊, 李 周, 肖 柱. Cu-3.6%Al2O3铜合金细丝加工过程中组织结构演变规律[J]. 中国有色金属学报, 2017, 27(3): 486-493.

ZHAO Zhi-lei, LI Zhou, XIAO Zhu. Structure evolution of Cu-3.6%Al2O3 alloy fine wire during cold drawing[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(3): 486-493.

[12] 李肖蓉. 铝铜合金形变与退火过程中微观组织与织构研究[D]. 重庆: 重庆大学, 2016: 18-26.

LI Xiao-rong. Investigation on microstructure and texture of Al-Cu alloy during deformation and recrystallization[D]. Chongqing: Chongqing University, 2016: 18-26.

[13] 李红英, 严 文, 陈 建, 范新会, 王雪艳. 塑性变形单晶铜线材织构的研究[J]. 西安工业学院学报, 2006, 26(1): 64-67.

LI Hong-ying, YAN Wen, CHEN Jian, FAN Xin-hui, WANG Xue-yan. Study of texture in deformed single crystal copper wires[J]. Journal of Xi’an Institute of Technology, 2006, 26(1): 64-67.

[14] 杨 钢, 陈亮维, 王剑华, 王军丽, 史庆南. FCC金属的织构对力学性能的影响[J]. 昆明理工大学学报(自然科学版), 2012, 37(5): 24-34.

YANG Gang, CHEN Liang-wei, WANG Jian-hua, WANG Jun-li, SHI Qing-nan. Influences of texture of fcc metals on their mechanical properties[J]. Journal of Kunming University of Science and Technology ( Natural Science Edition), 2012, 37(5): 24-34.

[15] 毛卫民. 金属材料的晶体学织构与各向异性[M]. 北京: 科学出版社, 2002: 33.

MAO Wei-min. Crystallographic texture and anisotropy of metal materials[M]. Beijing: Science Press, 2002: 33.

[16] 史庆南, 陈亮维, 王效琪. 大塑性变形及材料微结构表征[M]. 北京: 科学出版社, 2016: 101-116.

SHI Qing-nan, CHEN Liang-wei, WANG Xiao-qi. Characterization of sever plastic deformation and microstructure of materials[M]. Beijing: Science Press, 2016: 101-116.

Evolution of microstructure of TP2 copper tube during drawing process

WANG Song-wei1,2, ZHANG Shi-hong1, SONG Hong-wu1, CHEN Yan1

(1. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. School of Materials Science and Engineering, University of Science and Technology of China, Hefei 230026, China)

Abstract: In order to study the changes of microstructure and mechanical properties of copper tubes during floating plug drawing process, OM and EBSD methods were used to analyze the tube with different drawing deformations. The results show that the grains were elongated along the drawing direction and form fibrous tissue after drawing, the micro-hardness of tube increases and is higher along the transverse than that along the longitudinal; after the third pass deformation amount to 75%, the grain sizes are 80-100 μm in length and 8-10 μm in width. With the deformation increasing, the type of texture transforms from {001}<110> and {111}<110> texture, which is formed in original rolling, into {110}<100> and {110}<111> texture.

Key words: tube drawing; texture transform; microstructure; EBSD method

Foundation item: Project(17-32-6-00) supported by the Shenyang Key Science and Technology Research and Development Program, China

Received date: 2018-04-09; Accepted date: 2018-07-30

Corresponding author: ZHANG Shi-hong; Tel: +86-13709887696; E-mail: shzhang@imr.ac.cn

(编辑 何学锋)

基金项目:沈阳市重点科技研发计划资助项目(17-32-6-00)

收稿日期:2018-04-09;修订日期:2018-07-30

通信作者:张士宏,教授,博士;电话:13709887696;E-mail:shzhang@imr.ac.cn