DOI: 10.11817/j.ysxb.1004.0609.2020-36434

Mg-7Zn-0.3Mn-xCu镁合金半固态组织演变

黄晓锋1, 2,杨剑桥1,魏浪浪1,张乔乔1,尚文涛1,李旭娇1

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要:本文研究了Cu含量、重熔温度及等温时间对Mg-7Zn-0.3Mn镁合金半固态组织演变的影响。结果表明:Mg-7Zn-0.3Mn-1Cu合金的铸态组织由白色α-Mg基体和黑色共晶组织(α-Mg+Mg4Zn7+ MgZn2+CuMnZn)组成。在等温热处理过程中,Cu有加速非枝晶颗粒分离和球化的作用,且Cu含量(质量分数)为1.0%时效果最佳;Mg-7Zn-0.3Mn-1Cu镁合金通过适当提高保温温度或延长保温时间,能够得到细小且分布均匀的球状颗粒。然而当保温温度超过585 ℃或保温时间超过20 min时,半固态颗粒则会粗化长大。这种粗化长大现象是在合并长大机制与Ostwald熟化机制共同作用下产生的。在整个等温热处理过程中,半固态组织演变主要经历了初始粗化、组织分离、球化和最后粗化四个阶段。Mg-7Zn-0.3Mn-1Cu镁合金的最佳等温热处理工艺参数为保温温度585 ℃和保温时间20 min,其非枝晶颗粒的平均尺寸、形状因子和固相率分别为38.85 μm、1.39和53.38%。

关键词:Mg-7Zn-0.3Mn-1Cu镁合金;Cu含量;非枝晶组织;演变机理

文章编号:1004-0609(2020)-06-1238-11 中图分类号:TG145.2 文献标志码:A

21世纪是环保结构材料发展的时代,镁合金凭借其密度小,质量轻、比强与比刚度高、热传递快、优异的抗电磁干扰屏蔽性,尺寸稳定性及易于回收等优点,已经在航天航空、电子通讯产品、汽车和家电等领域中广泛应用[1-3]。然而,镁合金的综合性能较差,在一定程度上限制了其自身的应用,因此急需通过更加先进的成形技术及开发新型合金来提高镁合金的综合性能[4]。自20世纪70年代初问世以来,用于铸造加工的半固态成形技术趋于成熟。相较于传统技术,这种技术有许多优点,最显著的优点是节能高效、所需的成形温度低,成形的铸件精密度高、质量好,可近终成形等[5]。半固态成形技术主要包括流变成形和触变成形,在触变成形过程中,制备具有触变性的半固态浆料是首要环节[6-7]。目前,制备半固态金属浆料的方法主要有电磁搅拌法、机械搅拌法、应变诱导熔化激活法及半固态等温热处理法等。其中,本研究采用的半固态等温热处理法是将所用的铸态金属材料直接加热到半固态温度区间对其进行等温热处理,最终获得符合要求的半固态非枝晶组织,该方法工艺过程简单,成本低廉,是一种可快速获得半固态非枝晶组织的方法[8]。

Mg-Zn二元合金晶粒粗大,显微组织容易疏松导致其力学性能较差,在工业产品中很少应用。在Mg-Zn 二元合金的基础上,通过添加微量元素来细化晶粒、减少显微缩孔及缩松是解决上述问题的常见方法之一[9]。张丁菲等[10]研究了添加Mn元素对Mg-Zn基合金的显微组织和综合性能的影响,通过数据结果看出:添加微量Mn元素能够促使晶粒细化,阻碍晶粒长大,从而提高合金的力学性能。袁炜[11]报道了Mn元素在 Mg-Zn合金时效硬化的作用,发现时效过程中,弥散分布的Mn颗粒以单质形式在晶界处存在阻碍了晶界的迁移和晶粒的长大,起到了细晶和钉扎作用,提高了材料强度。此外,Cu元素可以提高Mg-Zn合金的固溶温度,提升固溶强化效果,进而增强了此后的时效强化[12],液态压铸件无法通过热处理进一步提高性能,而半固态压铸件是可以进行热处理的,因此,研究Mg-Zn-Cu-X合金有利于发挥这一优势。本文通过添加Cu元素,探究其对Mg-7Zn-0.3Mn镁合金基体的影响,确定了最优Cu含量并采用等温热处理的方法研究了Mg-7Zn-0.3Mn-1Cu合金半固态组织演变的形成过程及演变机理,获得最优的工艺参数,为镁合金半固态成形提供一定理论基础和实验依据。

1 实验

制备Mg-7Zn-0.3Mn-xCu镁合金所用的原材料为纯Mg锭、Zn锭、切成小块的Cu板(>99.99%)和Mg-5%Mn(质量分数)中间合金。熔炼过程中,熔炼装置为SG2-7.5 kW 型井式电阻炉,每次的下料量为(3000±100) g;先将干净的坩埚预热至200 ℃,并刷涂料,处理好的镁锭放入坩埚,撒上一层RJ-2覆盖剂作为熔剂。当温度升至500 ℃时,持续通入 Ar 气来进行防氧化保护。待Mg锭熔化之后,于680 ℃时加入 Cu和Zn,其中Cu含量(质量分数) 分别为0%、0.5%、1.0%和1.5%;继续升温,在700 ℃时加入易烧损的Mg-Mn合金;过热到750 ℃时停止加热并等待温度下降。温度降至730 ℃时,使用被锡箔纸包裹的C2Cl6(与合金质量比约 1:500)精炼除渣,整个过程持续2~3 min,直到液面光亮时停止;熔体静置12~15 min后,待炉温降至710 ℃时,准备浇注。

将合金试样切割加工成 d 15 mm×15 mm棒状坯料,在箱式电阻炉(温度误差±1 ℃)进行半固态重熔实验,试样经特定重熔工艺后迅速取出并立刻水淬,用金相试样预磨机进行打磨、抛光,随后用8%的硝酸水溶液(体积分数)侵蚀。用 Me F-3 金相显微镜、JSM-6700F 扫描电镜(SEM)及能谱仪(EDS)进行半固态组织形貌的观察。使用X 射线衍射仪(D/max-2400)进行合金的物相分析:Cu靶,电压40 kV,电流100 mA,扫描速度5 (°)/min、扫描角度2θ为10°~90°。用Image-Pro Plus软件分析其固相率S、形状因子F和颗粒平均尺寸D。计算所用的公式为[13]:

(1)

(1)

(2)

(2)

(3)

(3)

式中:A0为单个固相颗粒面积;As固液相总面积;N为固相颗粒数量;P0为单个固相颗粒周长;F为形状因子,取值范围为[1, ∞),若F越趋近于1,则获得的半固态颗粒越圆整。

2 结果与分析

2.1 铸态合金显微组织

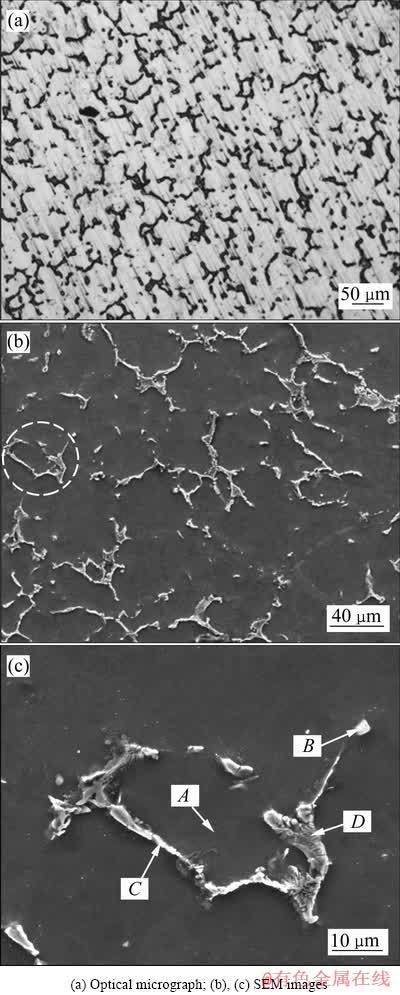

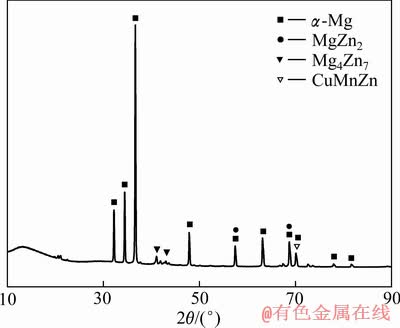

图1和2所示分别为铸态Mg-7Zn-0.3Mn-1Cu镁合金显微组织和XRD谱。

图1 Mg-7Zn-0.3Mn-1Cu合金的铸态显微组织

Fig. 1 As-cast microstructures of Mg-7Zn-0.3Mn-1Cu alloy

图2 Mg-7Zn-0.3Mn-1Cu铸态合金的XRD谱

Fig. 2 XRD pattern of as-cast Mg-7Zn-0.3Mn-1Cu alloy

如图1(a)所示,Mg-7Zn-0.3Mn-1Cu合金主要由呈现白色的α-Mg基体和呈黑色沿晶界分布的共晶组织组成,结合XRD谱(见图2)可知,共晶组织主要由α-Mg+CuMnZn+MgZn2+Mg4Zn7组成。CuMnZn相的衍射峰很少且峰值较低,这可能是与合金成分中加入的Mn元素含量较少有关。如图1(b)所示,通过对合金铸态组织的SEM分析,共晶组织呈现孤点状和半连续或不连续的网状分布,这与非平衡冷却和成分过冷有关[14]。在非平衡凝固过程中,当温度降至液相线温度时α-Mg相会先析出,随着初生相的生长,Zn、Cu和Mn原子会持续地从凝固界面前沿排出,富集在晶界或枝晶边界处,形成了沿晶界分布的粗大共晶组织[15]。通过对图1(c)中各点进行EDS点扫描,结合扫描结果表1可知:除基体A点外,B、C、D点均检测出到Mg、Zn、Cu元素的存在,B、D两点存在微量Mn元素,可认为合金的晶界是由α-Mg+CuMnZn+ MgZn2+ Mg4Zn7组成,这与XRD检测结果一致。

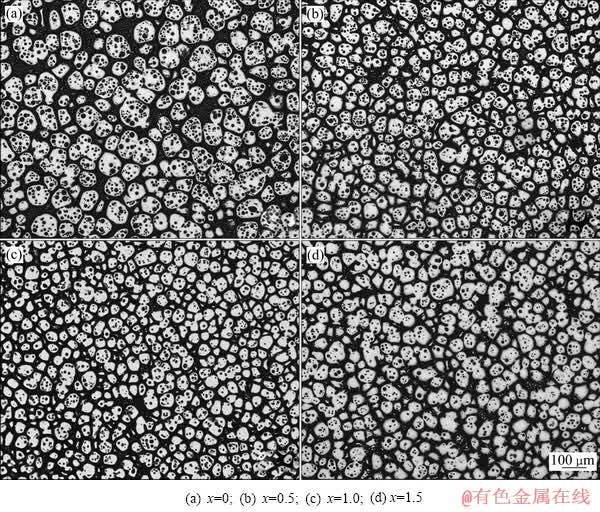

表1 图1(b)中各点的EDS分析结果

Table 1 EDS analysis results of points in Fig. 1(b)

2.2 半固态非枝晶组织演变

2.2.1 Cu含量对Mg-7Zn-0.3Mn镁合金半固态非枝晶组织的影响

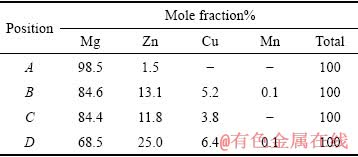

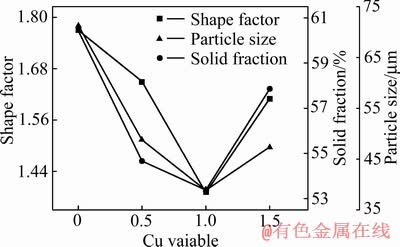

图3所示为Cu含量对Mg-7Zn-0.3Mn镁合金半固态非枝晶组织的影响。图4所示为Mg-7Zn-0.3Mn-xCu在此工艺下非枝晶颗粒的平均尺寸、形状因子和固相率的变化曲线。

由图3可知,当在585 ℃保温20 min的时,不同Cu含量对Mg-7Zn-0.3Mn镁合金半固态非枝晶组织产生了显著影响。当不含Cu时,Mg-7Zn-0.3Mn合金中出现了近球状非枝晶颗粒,此时大部分非枝晶颗粒仍连在一起,分离不够彻底,非枝晶颗粒尺寸较大且不圆整,球化效果不好(见图3(a))。随着Cu含量以0.5%等梯度增加的时候(含量分别为0.5%、1.0%和1.5%),非枝晶颗粒明显变的细小圆整,球化效果显著提升(见图3(b)、(c)和(d))。所以Cu的添加对于非枝晶颗粒的分离和球化有促进作用;当Cu含量增加到 1.5%时,相比Cu含量为1.0%时,不难发现非枝晶颗粒有变大的趋势,主要原因是铸态合金晶粒的大小不同造成的。

图3 Mg-7Zn-0.3Mn-xCu 合金585 ℃保温 20 min 的组织

Fig. 3 Microstructures of Mg-7Zn-0.3Mn-xCu alloy (mass fraction, x%) at 585 ℃ for 20 min

图4 Mg-7Zn-0.3Mn-xCu合金在585 ℃保温20 min的颗粒平均尺寸、形状因子和固相率

Fig. 4 Particle size, solid fraction and shape factor of Mg-7Zn-0.3Mn-xCu alloy treated at 585 ℃ for 20 min

Cu含量为1.0%时,非枝晶颗粒尺寸和形状因子最小,分别为 38.85 μm和1.39(见图4),其符合半固态成形对组织的要求(细小、均匀、近球状),综上所述,本文选择Mg-7Zn-0.3Mn-1Cu的半固态组织作为研究对象。

2.2.2 保温温度对Mg-7Zn-0.3Mn-1Cu半固态非枝晶组织的影响

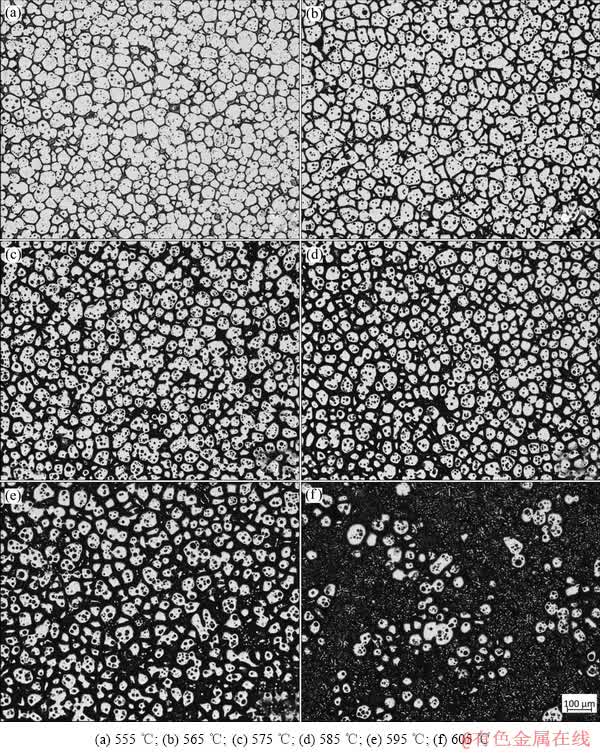

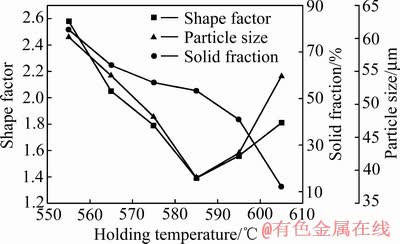

图5和6所示分别为Mg-7Zn-0.3Mn-1Cu合金在不同温度下保温20 min的半固态组织形貌及其半固态非枝晶颗粒平均尺寸、形状因子和固相率随保温温度的变化规律曲线。

图5 Mg-7Zn-0.3Mn-1Cu合金在不同温度下保温20 min的半固态组织

Fig. 5 Semi-solid microstructures of Mg-7Zn-0.3Mn-1Cu alloy treated at different temperatures for 20 min

图6 Mg-7Zn-0.3Mn-1Cu合金在不同温度保温20 min的颗粒平均尺寸、形状因子和固相率

Fig. 6 Particle size, solid fraction and shape factor of Mg-7Zn-0.3Mn-1Cu alloy treated at different temperatures for 20 min

由图5(a)及图6可知,在保温时间为20 min,保温温度为555 ℃时,原铸态枝晶组织完全消失,出现了紧密相连且不规则的非枝晶颗粒状组织,颗粒有明显的分离现象和球化倾向,但此时其非枝晶颗粒平均尺寸较大为60.21 μm,颗粒圆整度比较低,形状因子为2.58,固相率高达79.61%,并且在不规则的初生颗粒内部已有许多形状各异的小液滴生成。结合图5(b)、(c)和图6可知,随着保温温度继续升高,液相明显增多,非枝晶颗粒逐渐向椭圆状转变,颗粒彼此分离,尺寸逐渐减小并且球化现象趋于明显。此时,在颗粒上的点状小液滴也逐渐增多。当保温温度为585 ℃时(见图5(d)),半固态组织近似为球状且固相颗粒分布最为均匀,其平均尺寸及形状因子分别优化至38.85 μm和1.39,固相率降至53.38%。这是因为固相颗粒受已生成的液相侵蚀作用而加速溶解,同时固相颗粒内部的液相与晶界处液相相通,使得固相颗粒分离的细小圆整[16]。当保温温度升高至595 ℃时,组织中液相体积分数进一步升高,颗粒之间出现团聚倾向,颗粒圆整度变得较差,导致其形状因子和颗粒尺寸相较于585 ℃时有所上升。当温度为605 ℃时,Mg-7Zn-0.3Mn-1Cu合金组织中液相体积分数显著增加,固相率仅为12.11%,颗粒之间团聚现象显著,固相颗粒尺寸增加,并且颗粒周围有“毛刺”状组织出现,出现这一现象的原因是在高温状态下原子的迁移活动能力得到提高,加快了固相颗粒的熔化速度,使得固相颗粒中的部分原子从固相中脱离进入液相。同时,在Ostwald 熟化作用下[17],为了降低体系界面能,较小的颗粒消失,较大的非枝晶颗粒之间的合并长大导致其平均尺寸增加,合并后的非枝晶颗粒形状并不规则,引起了形状因子的增大。

由图5和6可知:在相同保温时间内,随着等温温度的升高,半固态组织的液相体积分数一直升高,颗粒的形状因子和平均尺寸呈现先减小后变大的规律,这个过程中伴随着共晶组织的重熔,形成了类球状或球状的颗粒组织。半固态组织这种变化现象,一是由于随着保温温度的升高,会使得颗粒晶内成分均匀化及固溶度提高;二是由于不同枝晶臂微观结构存在区别,枝晶曲率有所不同,导致枝晶周围溶质浓度存在差别,半径小的枝晶其周围溶质浓度比较低,所以在曲率半径不同的枝晶间(一次枝晶与二次枝晶或二次枝晶之间)就会形成扩散偶,使得不同浓度的溶质原子在浓度梯度的作用下,沿着粗大的枝晶处向细小枝晶处扩散,造成细枝熔化或从其根部熔断[18];最后,由于共晶组织成分不同,导致各相的熔点也会有差别,熔点低的相在先前的凝固过程中后发生凝固,并存在晶粒或枝晶之间,等温重熔时这些低熔点相会优先发生熔化。

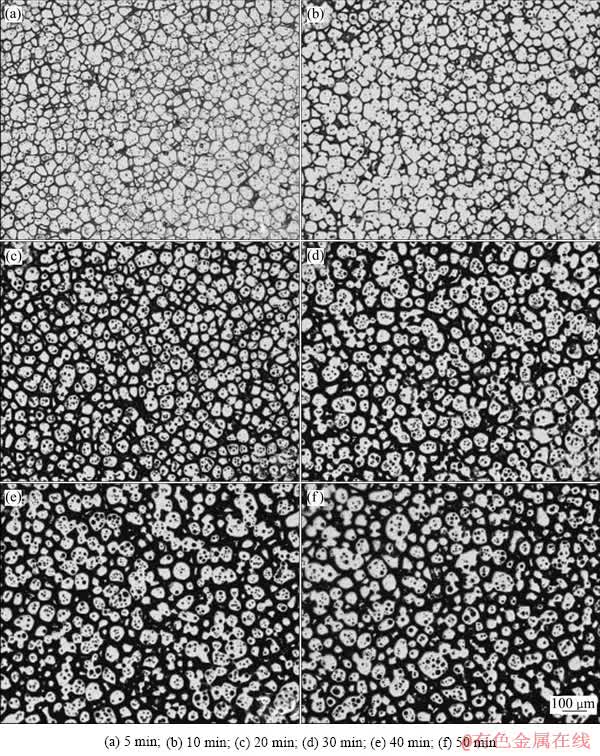

2.2.3 保温时间对半固态非枝晶组织的影响

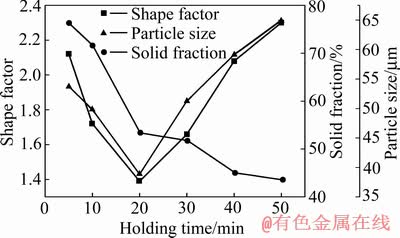

基于上述分析可知,Mg-7Zn-0.3Mn-1Cu合金在585 ℃保温20 min的半固态组织细小、均匀、近球状,因此选择保温温度在585 ℃下来探究不同等温时间对半固态组织演变的影响。图7和8所示分别为该温度下不同等温时间的半固态组织形貌演变以及合金颗粒平均尺寸、形状因子及固相率随等温时间的变化规律曲线。

由图7(a)可见,在保温5 min以后,共晶组织向α-Mg 基体中固溶,曲率较大的二次枝晶臂已被熔断,与主干组织分离,得到了部分液相相连的组织,组织中出现较为明显颗粒边界,但固相颗粒形状不规则且分布不均匀,形状因子高达2.12。由图7(b)可见,当保温时间为10 min时,组织中出现了较多的液相,组织进一步分离,形状不规则的α-Mg基体逐渐球化,大小趋于均匀,圆整度得到较大提升,形状因子达到1.72。由图7(c)可见,当等温时长延至20 min时,液相明显增多,非枝晶颗粒基本完全分离,呈现球状或近球状,均匀分布在液相中,同时在颗粒内部出现了明显大小不一的“小液池”,在此工艺条件下可获得的半固相颗粒尺寸细小且圆整。如图7(e)所示,当保温时间进一步延长时,颗粒之间开始出现合并和粗化长大现象,又由于在颗粒内部形成的“小液池”进一步增加,使得组织中的总液相占比升高。如图7(f)所示,进一步增加保温时间至50 min时,小颗粒被大颗粒吞并消失,使得固相颗粒平均尺寸急剧增加,达到65 μm;其原因是由于在重熔过程中,当保温时间较短的状况下,初生固相颗粒的尺寸主要受熔化的影响,当保温时间适当延长后,固相颗粒尺寸逐渐下降。但当保温时间过长时,颗粒的粗化机制开始发挥作用,导致固相颗粒粗化长大[19]。这种粗化现象,是在合并长大和 Ostwald 熟化机制共同作用下出现的[20]。

根据本实验结果及文献[21]得出以下结论:等温时间相同时,温度对合金半固态组织中的液相率有较大的影响;等温温度相同时,时间对合金半固态非枝晶颗粒的形貌及尺寸起决定性的影响。总之,Mg-7Zn-0.3Mn-1Cu合金在半固态等温热处理过程中,经历了由共晶组织固溶和熔化造成树枝晶的初始粗化、组织分离、球化以最后的粗化 4 个阶段[22]。通过本部分实验,在工艺条件为(585 ℃,20 min)下可获得较理想的半固态非枝晶组织。

图7 Mg-7Zn-0.3Mn-1Cu合金在585 ℃下半固态等温热处理过程中不同保温时间的组织演变

Fig. 7 Microstructural evolution of Mg-7Zn-0.3Mn-1Cu alloy after isothermal heat-treatment at 585 ℃ for different time

图8 Mg-7Zn-0.3Mn-1Cu合金在585 ℃保温不同时间的颗粒平均尺寸、形状因子和固相率

Fig. 8 Particle size, solid fraction and shape factor of Mg-7Zn-0.3Mn-1Cu alloy treated at 585 ℃ for different time

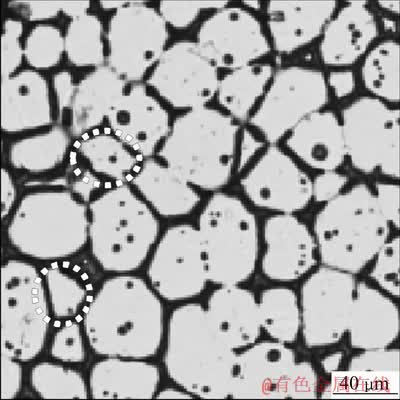

2.3 非枝晶组织的特征分析

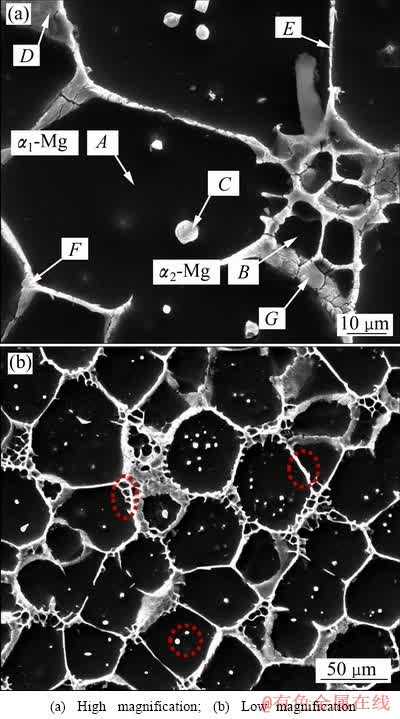

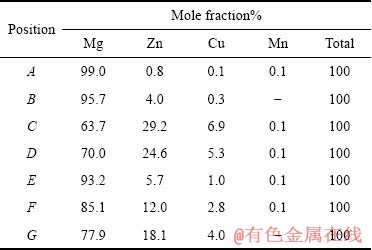

为了进一步确定Mg-7Zn-0.3Mn-1Cu合金的半固态组织的特征及成分,通过SEM和EDS对等温热处理条件为585 ℃、20 min的试样进行分析,探究其组织的形貌及相的成分。图9所示为合金的SEM像,表2为图9(a)中显微组织的EDS分析数据。

图9 Mg-7Zn-0.3Mn-1Cu合金在585 ℃保温20 min的SEM像

Fig. 9 SEM images of Mg-7Zn-0.3Mn-1Cu alloy treated at 585 ℃ for 20 min

表2 图9(a)中显微组织的EDS分析结果

Table 2 EDS analysis results of microstructure in Fig. 9(a)

由图9可知,非枝晶组织的边缘呈现锯齿状,其周围的共晶组织整体上表现为蜂窝状。较大的固相颗粒的形貌呈球状或椭球状,同时存在一些不规则形状,液相组织包含着较小的固相颗粒。在半固态组织中,水淬后凝固的液相由三部分组成,即线性形状的液态薄膜、熔池和颗粒内部包裹的“小液池”(如图9(b)圈出所示)。非枝晶组织主要是由初生的α1-Mg颗粒、次生的α2-Mg颗粒构成,分别对应于图 9(a)中的A、B两点。结合表2可得,次生α2-Mg 颗粒中的Zn、Cu含量多于初生 α1-Mg 颗粒中的Zn、Cu含量。这种现象产生的原因是在半固态等温热处理的过程中,重熔和结晶是在动态变化中进行的,熔化一般先在Zn、Cu溶质元素富集区和低熔点的第二相中发生,初生α1-Mg的晶界上溶质富集程度高优先熔化,形成扩散浓度梯度,沿晶界扩散,此时晶界处合金元素高于晶内,有利于晶界处的原子向晶体内部迁移,使得次生组织α2-Mg中Zn、Cu含量增加。此外,初生共晶组织在重熔过程中其原子能够获得足够多的能量,利于长程扩散向晶内迁移[23]。促使以上结果的出现。

通过EDS分析发现,呈点状的C点处的Zn、Cu含量高于其他点,这是由于在晶界处浓度较高的原始共晶组织,在等温热处理时,因枝晶包裹,使其在后续的二次凝固过程中,溶质原子无法继续扩散所致。此外,E点处的Zn、Cu含量明显低于C、D、F、G四点的Zn、Cu含量,这是因为在等温重熔过程中,C、D、F、G四点的组织皆为二次凝固时形成,而E点扩散程度较高,使得少量Zn、Cu原子进入基体造成的。

3 半固态等温热处理过程中组织演变分析

在半固态等温热处理过程中,Mg-7Zn-0.3Mn-1Cu合金经历了由共晶组织固溶和熔化造成树枝晶的初始粗化、组织分离、球化以及最后粗化四个阶段。

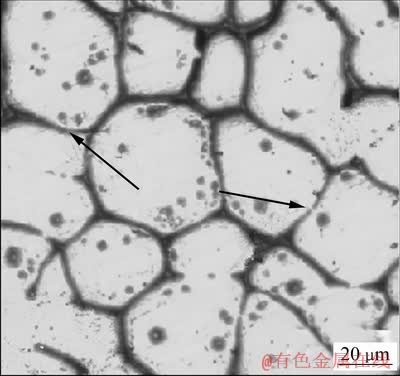

3.1 枝晶组织的初始粗化

在等温热处理初始阶段,初生α1-Mg之间只存在少量的共晶液体(如图 10箭头所示)。随着温度的升高和时间的延长,溶质原子的扩散能力逐渐增强,固溶体对Zn、Cu和Mn 的固溶度增加。因相起伏、能量起伏以及溶质浓度梯度的存在,促使晶界处含有Zn、Cu和Mn的粗大共晶组织向α-Mg中固溶扩散,导致α-Mg明显粗化,枝晶组织消失,枝晶臂出现了的合并搭接,形成块状或椭球状的颗粒。总而言之,该阶段粗化机制主要是受升温过程中溶质原子扩散控制的过程。

图10 ZC71-0.3Mn合金585 ℃短时保温的组织

Fig. 10 Microstructure of ZC71-0.3Mn alloy treated at 585 ℃ for short times (5 min)

3.2 枝晶组织的分离和球化

枝晶组织的分离和球化过程决定了固相颗粒大小和形态的好坏。随着保温温度的升高或是保温时间的进一步延长,枝晶的粗化机制作用减弱,由溶质再分配理论可知,熔化首先会在二次枝晶溶质浓度很高但熔点较低的根部进行,形成颈部熔缩直至断裂,使得椭球状或块状组织颗粒逐渐分离为小块状固相颗粒(如图11红圈所示)。分离后的固相颗粒表面凹凸不平,故其表面上各位置的曲率也不同,曲率不同导致了平衡熔点的不同,二者的关系式为[24]:

(4)

(4)

式中:Tr表示半径为r的曲面的平衡熔点;σ为固液界面张力;Tm为固液界面的熔点;Vs为固相摩尔体积;k为固液界面曲率;△Hm为固-液转变时的摩尔焓变。此式表明:固液界面曲率与平衡熔点之间是反比关系,即曲率越大,熔点越低,在等温热处理过程中越易熔化。因此,在固相颗粒表面不规则处(例如固相颗粒表面凸出或边角处),由于其曲率高而导致其熔点低,与其他位置相比,重熔时更易熔化,加快非枝晶颗粒的球化进程,使分离后的块状或椭球状颗粒逐渐转变为细小的球状颗粒。

图11 Mg-7Zn-0.3Mn-1Cu合金585 ℃保温 10 min 的显微组织

Fig. 11 Microstructure of Mg-7Zn-0.3Mn-1Cu alloy treated at 585 ℃ for 10 min

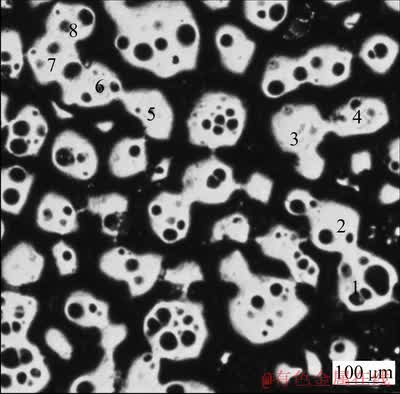

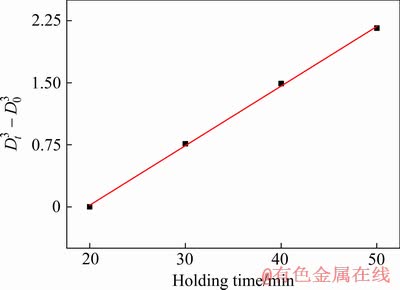

3.3 枝晶组织的最后粗化

枝晶的最后粗化发生在保温后期,随着保温温度的升高或保温时间的延长,此时液相率较高,大部分固相颗粒处于游离状态,而小颗粒最终会熔化或粘附到一起,促使形成粗大不圆整的固相颗粒,出现合并长大现象。一方面,是因为固相颗粒的合并取决于其之间的晶界及晶体学取向。当固相颗粒发生合并时,系统的能量将会降低,对系统的稳定有利[25]。普遍情况是较少数量的固相颗粒之间发生合并,如图12所示,标出的颗粒1与2,颗粒3与4。但也有类似于标示颗粒5、6、7和8,多个颗粒团聚在一起同时发生合并的现象,这种合并对降低系统的能量更有利[26]。另一方面,当系统中固/液两相达到平衡时,界面能的降低要通过固相颗粒之间的合并来完成,这种机制就是Ostwald熟化[27],即

(5)

(5)

式中:Dt为t时刻的晶粒平均尺寸;D0为球化时的平均尺寸;K为粗化常数。对Mg-7Zn-0.3Mn-1Cu合金在585 ℃保温20~50 min的颗粒尺寸使用上述机制进行拟合,结果如图13所示,合金固相颗粒的粗化完全符合该机制;当合金固相体积分数低于50%时,随着固相体积分数的减小,粗化常数也在减小,但颗粒平均尺寸仍在增大。这是因为较小的固相颗粒其界面能较高,处于不稳定的状态,当保温时间足够长时,界面能得到下降,固相颗粒将熔化甚至消失,溶质原子通过扩散和迁移至大晶粒表面沉积,使颗粒“生长变大”,平均尺寸明显增加。保温时间达到50 min时,固相颗粒的平均尺寸长大至65 μm。

图12 Mg-7Zn-0.3Mn-1Cu合金585 ℃保温50 min的显微组织

Fig. 12 Microstructure of Mg-7Zn-0.3Mn-1Cu alloy treated at 585 ℃ for 50 min

图13 Mg-7Zn-0.3Mn-1Cu合金的( )与保温时间的关系

)与保温时间的关系

Fig. 13 Relationship between ( ) and holding time of Mg-7Zn-0.3Mn-1Cu alloy

) and holding time of Mg-7Zn-0.3Mn-1Cu alloy

综上所述,合并长大机制与Ostwald熟化机制都能促使系统能量降低,维持稳定状态,同时也共同决定了最后粗化阶段中颗粒的形态与大小。

4 结论

1) Mg-7Zn-0.3Mn-1Cu合金的铸态组织由白色α-Mg基体和黑色α-Mg、Mg4Zn7、MgZn2和CuMnZn共晶组织组成。在非枝晶组织中,固相的组成成分是初生α1-Mg相和次生α2-Mg相。液相主要由固相颗粒边界处的液态薄膜、固相颗粒周围的熔池和固相颗粒内部的“小液池”组成。

2) Cu的添加对Mg-7Zn-0.3Mn镁合金半固态非枝晶组织产生了显著影响,当Cu含量为1.0%时,促进非枝晶颗粒分离和球化的作用效果最佳。

3) Mg-7Zn-0.3Mn-1Cu合金在585 ℃保温20 min时可获得较理想的半固态组织,其颗粒平均尺寸、形状因子、固相率分别为38.85 μm、1.39和53.38%。

4) Mg-7Zn-0.3Mn-1Cu镁合金在非枝晶组织演变中,经历了初始粗化、组织分离、球化以最后粗化四个阶段。合并长大机制与Ostwald熟化机制共同决定了最后粗化阶段中颗粒的形态与大小。

REFERENCES

[1] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[2] MORDIKE B L, EBERT T. Magnesium properties applications potential[J]. Materials Science and Engineering A, 2001, 302(1): 37.

[3] 陈先华, 耿玉晓, 刘 娟. 镁及镁合金功能材料的研究进展[J]. 材料科学与工程学报, 2013, 31(1): 148-152.

CHEN Xian-hua, GENG Yu-xiao, LIU Juan. Research status of magnesium alloys as functional materials[J]. Journal of Materials Science and Engineering, 2013, 31(1): 148-152.

[4] BUHA J. The effect of Ba on the microstructure and age hardening of an Mg-Zn alloy[J]. Materials Science and Engineering A, 2008, 491(1/2): 70-79.

[5] 邓 辉, 郭学锋, 黄 丹, 崔红保. 镁合金半固态成形技术的研究和发展[J]. 热加工工艺, 2011, 40(23): 9-13.

DENG Hui, GUO Xue-feng, HUANG dan, CUI Hong-bao. Research and development of semi-solid forming technology for magnesium alloys[J]. Hot working process, 2011, 40(23): 9-13.

[6] FAN Z, LIU G, WANG Y, Microstructure and mechanical properties of rheo-diecast AZ91D magnesium alloy[J]. Journal of Materials Science, 2006, 41(12): 3631-3644.

[7] FLEMINGS M C. Behavior of metal alloys in the semisolid state[J]. Metallurgical and Materials Transactions A, 1991, 22(5): 957-981.

[8] 程健杰. 压缩形变AZ91D镁合金半固态加热及凝固组织研究[D]. 西安: 西安理工大学, 2005.

CHENG Jian-jie. Study on semi-solid heating and solidification structure of compressive deformation AZ91D magnesium alloy[D]. Xi’an: Xi’an University of Technology, 2005.

[9] 陈晓强, 刘江文, 罗承萍. 高强度Mg-Zn系合金的研究现状与发展趋势[J]. 材料导报, 2008, 22(5): 58-62.

CHEN Xiao-qiang, LIU Jiang-wen, LUO Cheng-ping. Research status and development trend of Mg-Zn alloys with high strength[J]. Materials Review, 2008, 22(5): 58-62.

[10] 张丁非, 齐福刚, 石国梁, 戴庆伟. Mn含量对Mg-Zn-Mn变形镁合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2010, 39(12): 2205-2210.

ZHANG Ding-fei, QI Fu-gang, SHI Guo-liang , DAI Qing-wei. Effect of Mn content on microstructure and mechanical properties of Mg-Zn-Mn wrought magnesium alloy[J]. Rare Metal Materials and Engineering, 2010, 39(12): 2205-2210.

[11] 袁 炜. 新型Mg-6Zn-1M变形镁合金组织与性能研究[D]. 重庆: 重庆大学, 2007.

YUAN Wei. Study on microstructure and properties of new Mg-6Zn-1M wrought magnesium alloy[D]. Chongqing: Chongqing University, 2007.

[12] 李 萧, 刘江文, 罗承萍. 铸造ZC62镁合金的时效行 为[J]. 金属学报, 2006, 42(7): 733-738.

LI Xiao, LIU Jiang-wen, LUO Cheng-ping. Precipitation behavior of cast ZC62 magnesium alloy[J]. Acta Metallurgica Sinica, 2006, 42(7): 733-738.

[13] FAN Z. Semisolid metal processing[J]. International Materials Reviews, 2002, 47(2): 49-85.

[14] 李爱文, 刘江文, 伍翠兰, 罗承萍, 焦东玲, 朱红梅. Cu含量对铸造Mg-3Zn-xCu-0.6Zr镁合金时效析出行为的影 响[J]. 中国有色金属学报, 2010, 20(8): 1487-1494.

LI Ai-wen, LIU Jiang-wen, WU Cui-lan, LUO Cheng-ping, JIAO Dong-ling, ZHU Hong-mei. Effects of Cu addition on aging precipitation behavior of cast Mg-3Zn-xCu-0.6Zr magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(8): 1487-1494.

[15] 冯 凯, 黄晓锋, 马颖, 阎峰云, 郝 远. ZA74镁合金非枝晶组织的演变过程及机理[J]. 中国有色金属学报, 2013, 23(3): 635-644.

FENG Kai, HUANG Xiao-feng, MA Ying, YAN Feng-yun, HAO Yuan. Non-dendritic microstructure evolution process and mechanism of ZA74 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 635-644.

[16] 黄晓锋, 张玉, 秦牧岚, 郝 远. 等温热处理对Mg-6Zn-3Cu合金半固态组织演变的影响[J]. 材料热处理学报, 2016, 37(8): 53-59.

HUANG Xiao-feng, ZHANG Yu, QIN Mu-lan, HAO Yuan. Effects of isothermal heat treatment on microstructural evolution of Mg-6Zn-3Cu alloy[J]. Transaction of Materials and Heat Treatment, 2016, 37(8): 53-59.

[17] KANG M K, KIM D Y, NONG M H. Ostwald ripening kinetics of angular grains dispersed in a liquid phase by two-dimensional nucleation and abnormal grain growth[J]. Journal of the European Ceramic Society, 2002, 22(5): 603-612.

[18] CHEN T J, MA Y, LI Y D, LU G X, HAO Y. Microstructural evolution of equal channel angular pressed AZ91D magnesium alloy during partial remelting[J]. Metal Science Journal, 2013, 26(10): 1197-1206.

[19] 胡 勇, 饶 丽, 黎秋萍, 万 强. 等温热处理对AZ91D+Ce镁合金半固态组织的影响[J]. 稀有金属材料与工程, 2016, 45(2): 493-497.

HU Yong, RAO Li, LI Qiu-ping, WAN Qiang. Effect of isothermal heat treatment on the microstructure of semi-solid AZ91D+Ce magnesium alloy[J]. Rare Metal Materials and Engineering, 2016, 45(2): 493-497.

[20] CAO Li-jie, MA Guo-rui, TANG Chun-chong. Effects of isothermal process parameters on semisolid microstructure of Mg-8%Al-1%Si alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2364-2369.

[21] 王顺成, 李元元, 陈维平, 潘国如,王俊文. 升温速率对半固态2024铝合金部分重熔组织的影响[J]. 金属学报, 2008, 44(8): 905-910.

WANG Shun-cheng, LI Yuan-yuan, CHEN Wei-ping, PAN Guo-ru, WANG Jun-wen. Effect of heating rare on microstructure of semi-solid 2024 aluminum alloy during partial remelting[J]. Acta Metallurgica Sinica, 2008, 44(8): 905-910.

[22] 王瑞权, 姜向东. SiC对等温热处理AZ91D镁合金组织的影响[J]. 材料研究与应用, 2009, 3(4): 234-238.

WANG Rui-quan, JIANG Xiang-dong. Effect of SiC on microstructure of AZ91D magnesium alloy after isothermal heat treatment[J]. Material Research and Application, 2009, 3(4): 234-238.

[23] 黄晓锋, 马亚杰, 张 玉, 张乔乔, 郭 峰, 杨健长. 等温热处理对ZC61-0.3Cr镁合金半固态组织演变的影响[J]. 中国有色金属学报, 2018, 28(10): 1962-1971.

HUANG Xiao-feng, MA Ya-jie, ZHANG Yu, ZHANG Qiao-qiao, GUO Feng, YANG Jian-chang. Effects of isothermal heat treatment on the semi-solid microstructure evolution of ZC61-0.3Cr magnesium alloy[J]. Chinese Journal of Nonferrous Metals, 2018, 28(10): 1962-1971.

[24] 乐启炽, 张新建, 崔建忠, 路贵民, 欧 鹏. 镁合金近液相线铸造半固态坯料的部分重熔[J]. 金属学报, 2002, 38(12): 1266-1272.

LE Qi-chi, ZhANG Xin-jian, CUI Jian-zhong, LU Gui-min, OU Peng. Partial remelting of semi-solid billets of near- liquidus casting in magnesium alloys[J]. Acta Metallurgica Sinica, 2002, 38(12): 1266-1272.

[25] ZHANG Yu, HUANG Xiao-feng, MA Ying, CHEN Ti-jun, HAO Yuan. Effects of Sm addition on microstructural evolution of Mg-6Zn-0.4Zr alloy during semi-solid isothermal heat treatment[J]. China Foundry, 2017, 14(2): 433-440.

[26] KATTAMIS T Z, PICCONE T J. Rheology of semisolid Al-4.5%Cu-1.5% Mg alloy[J]. Materials Science and Engineering A, 1991, 131(2): 265-272.

[27] 杜 磊, 闫 洪. 等温热处理对AZ61稀土镁合金半固态组织的影响[J]. 材料研究学报, 2012, 26(2): 169-174.

DU Lei, YAN Hong. Effect of isothermal heat-treated on the microstructure of AZ61 rare earth magnesium alloy[J]. Chinese Journal of Materials Research, 2012, 26(2): 169-174.

Semi-solid microstructure evolution of Mg-7Zn-0.3Mn-xCu alloy

HUANG Xiao-feng1, 2, YANG Jian-qiao1, WEI Lang-lang1, ZHANG Qiao-qiao1, SHANG Wen-tao1, LI Xu-jiao1

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys and Processing, Ministry of Education, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The effects of Cu content (0%, 0.5%, 1.0%, 1.5%), remelting temperature and holding time on the evolution of semi-solid non-dendrites of Mg-7Zn-0.3Mn magnesium alloy were studied. The results show that the cast microstructure of the Mg-7Zn-0.3Mn-1Cu alloy is composed of white α-Mg matrix and black eutectic phase (α-Mg+Mg4Zn7+ MgZn2+CuMnZn). And Cu accelerated the separation and spheroidization of non-dendritic particles during isothermal heat treatment, and the effect is optimal when the Cu content (mass fraction) is 1.0%. By properly raising the holding temperature or extending the holding time, Mg-7Zn-0.3Mn-1Cu can obtain finer and more uniform spherical particles. However, when the holding temperature exceeds 585 ℃ or the holding time exceeds 20 min, semi-solid particles will gradually coarsene. This coarsening growth phenomenon is generated by the combined growth mechanism and Ostwald maturation mechanism. During the whole isothermal heat treatment process, the semi-solid microstructure evolution mainly experiences four stages: initial coarsening, tissue separation, spheroidization and final coarsening. The best parameters of isothermal heat treatment of Mg-7Zn-0.3Mn-1Cu are 585 ℃ in holding temperature, 20 min in holding time, and the average particle size, shape factor and solid fraction are 38.85 μm, 1.39 and 53.38%, respectively.

Key words: Mg-7Zn-0.3Mn-1Cu magnesium alloy; Cu content; non-dendritic microstructure; evolution mechanism

Foundation item: Project(51464032) supported by the National Natural Science Foundation of China

Received date: 2019-06-26; Accepted date: 2019-10-20

Corresponding author: HUANG Xiao-feng; Tel: +86-931-2976688; E-mail: huangxf_lut@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51464032)

收稿日期:2019-06-26;修订日期:2019-10-20

通信作者:黄晓锋,副教授,博士;电话:0931-2976688;E-mail:huangxf_lut@163.com