DOI: 10.11817/j.issn.1672-7207.2019.11.006

新型超高强度Ti-20Zr-6.5Al-4V合金热变形行为及热加工图

聂中奎1,杨秋月1,张文玮1,张雪1,杨洪艳1,张喜1,谭元标1,刘文昌2

(1. 贵州大学 材料与冶金学院,贵州 贵阳,550025;

2. 燕山大学 材料科学与工程学院,河北 秦皇岛,066004)

摘要:采用Gleeble 3500热模拟实验机对Ti-20Zr-6.5Al-4V合金进行等温热压缩实验,研究该合金在变形温度为750~1 050 ℃和变形速率为100~10-3 s-1条件下的热变形行为和热加工图。研究结果表明:在β单相区,低温高应变速率时,变形初期流变曲线会产生一个显著的应力降现象,随变形温度升高和应变速率降低,应力降现象逐渐消失;高温低应变速率时,流变曲线呈现出典型的动态再结晶特征;在α+β相区,高应变速率时,变形初期流变曲线也会产生一个显著的应力降;随着应变速率降低,应力降现象逐渐消失,流变曲线呈现出连续的流变软化现象;随着应变增大,Ti-20Zr-6.5Al-4V合金在α+β双相区的热变形激活能从414.2 kJ/mol降到173.8 kJ/mol,而在β单相区的热变形激活能从123.5 kJ/mol降到95.2 kJ/mol;Ti-20Zr-6.5Al-4V合金最优热加工参数范围分别为750~830 ℃和10-3~10-2 s-1以及925~ 1 020 ℃和5.6×10-3~1.2×10-1 s-1,最优热加工工艺参数组合为750 ℃和10-3 s-1以及950 ℃,10-2 s-1。

关键词:Ti-20Zr-6.5Al-4V合金;热变形;流变行为;显微组织;热加工图

中图分类号:TG146 文献标志码:A 文章编号:1672-7207(2019)11-2676-11

Hot deformation behavior and processing maps of new ultra-high strength Ti-20Zr-6.5Al-4V alloy

NIE Zhongkui1, YANG Qiuyue1, ZHANG Wenwei1, ZHANG Xue1,YANG Hongyan1, ZHANG Xi1, TAN Yuanbiao1, LIU Wenchang2

(1. College of Materials and Metallurgy, Guizhou University, Guiyang 550025, China;

2. College of Materials Science and Engineering, Yanshan University, Qinhuangdao 066004, China)

Abstract: To study the hot deformation behavior and processing maps of Ti-20Zr-6.5Al-4V alloy, the isothermal compression test was carried out at 750-1 050 °C and strain rates of 100-10-3 s-1 by Gleeble 3500 thermal simulator. The results show that at low temperatures and high strain rates, a significant stress drop is observed in the initial stage of deformation in single β phase region. With the increase of deformation temperature and decrease of strain rate, the phenomenon of stress drop is invisible. At higher temperature and lower strain rate, the flow curve illustrates a typical characterization of dynamic recrystallization. In the α+β phase region, the phenomenon of stress drop is also observed at high strain rates in the initial stage of deformation. With the decrease of strain rate, the phenomenon of stress drop disappears, and the flow curve exhibits a continuous flow softening phenomenon. With the increase of strain, the activation energy for hot deformation decreases from 123.5 to 95.2 kJ/mol in the single β phase region, and from 414.2 kJ/mol to 243.5 kJ/mol in the α+β phase region. The optimum processing parameter ranges are determined to be 750-830 ℃ and 10-3-10-2 s-1, and 925-1 020 ℃ and 5.6×10-3-1.2×10-1 s-1, respectively. The optimum processing parameters are evaluated to be 750 ℃, 10-3 s-1 and 950 ℃, 10-2 s-1.

Key words: Ti-20Zr-6.5Al-4V alloy; hot deformation; flow behavior; microstructure; processing map

钛及钛合金因其良好的耐热性和耐腐蚀性,高的疲劳寿命以及在高温条件下能够长期服役的特点而被广泛应用于航天航空领域。随着航天航空工业的发展,航空航天领域对材料的服役性能提出了更高的要求。钛合金作为航空航天结构材料在使用过程中依然存在不足,比如钛合金抗辐照性能差、膨胀系数大、高低温强辐射条件下耐磨性差、成形性能差,无法满足现阶段航空结构材料的要求。为了改善钛合金的力学性能,段静利等[1]以传统的Ti-6Al-4V合金为基体,通过添加Zr元素设计了一种新型的超高强度Ti-20Zr-6.5Al-4V合金。该合金具有优异的力学性能,在950 ℃固溶处理和450 ℃时效处理后,其抗拉强度为1 740 MPa,伸长率为2.3%,而700 ℃时效处理后其抗拉强度为1 437 MPa,伸长率为6.7%;在退火状态下,该合金抗拉强度可达1 300 MPa,伸长率大于10%[2-3]。作为一种新型的超高强度Ti-20Zr-6.5Al-4V合金,为了使其在航空航天领域尽快得到广泛应用,需要深入研究该合金的热加工成形性能。目前,金属结构件最主要的塑性加工方法为热锻成形、热轧成形和热挤压成形。金属结构件的力学性能取决于热加工过程中所形成的显微组织,并且受初始晶粒粒径、变形方式和热加工参数(如变形温度、应变速率和变形量等)的影响。因此,要获得力学性能优异的Ti-20Zr-6.5Al-4V合金航空结构件,需要深入研究该合金的热变形行为,阐明该合金热变形过程中显微组织的演变规律,掌握显微组织与流变应力之间的关系,以获得最优显微组织结构和最优的热加工参数。本文作者在变形温度为750~1 050 ℃,应变速率为10-3~100 s-1的条件下,对Ti-20Zr-6.5Al-4V合金进行热压缩实验,建立Ti-20Zr-6.5Al-4V合金的流变应力、应变、应变速率与温度的关系,预测该合金的高温流变行为,并基于动态材料模型建立热加工图,预测热加工过程中该合金的流变稳定区和流变不稳定区,从而获得最优的热加工参数。

1 实验材料及方法

1.1 实验材料与样品的制备

本文采用海绵钛(质量分数为99.7%)、海绵锆(锆和铪质量分数≥99.5%)、工业纯铝(质量分数为99.5%)和钒(质量分数为99.9%)制备Ti-20Zr-6.5Al-4V合金,在真空自耗电弧炉中将该合金熔化3次以确保化学成分均匀。铸锭在1 000 ℃下均匀化12 h,随后冷却至室温。随后铸锭在1 050 ℃下保温1.5 h后,将该铸锭多次锻造以细化晶粒粒径。将锻后的合金坯在900 ℃下(α+β两相区)保温1.5 h,最后再热锻成直径为40 mm的棒材。

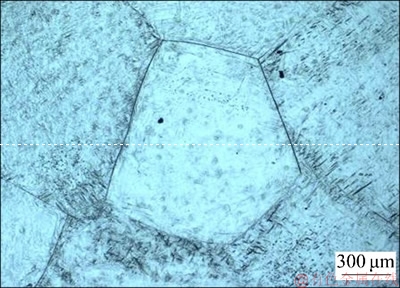

为了研究Ti-20Zr-6.5Al-4V合金的热变形行为,在带有氩气保护的管式真空热处理炉中,将合金棒材在1 050 ℃进行30 min的固溶处理,然后进行水淬。图1所示为经1 050 ℃固溶处理30 min后该合金的金相组织。从图1可以看出:β相的晶粒比较粗大,并且可以观察到晶粒中有少量针状的α"相。将热处理后的棒材加工成高度为12 mm和直径为8 mm的圆柱形试样并进行热压缩实验。

图1 Ti-20Zr-6.5Al-4V在1 050 ℃下固溶处理30 min后的显微结构图

Fig. 1 Microstructure of Ti-20Zr-6.5Al-4V alloy after solution-treatment at 1 050 ℃ for 30 min

1.2 热压缩实验

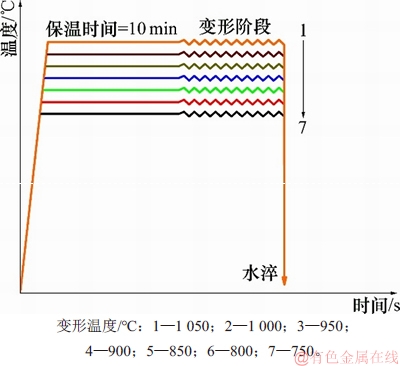

采用Gleeble-3500热模拟实验机在变形温度750~1 050 ℃和应变速率为10-3~100 s-1的实验条件下对Ti-20Zr-6.5Al-4V合金进行热压缩实验,热变形工艺如图2所示。温度由焊接在圆柱形试样圆弧表面中间部位的热电偶控制。为了减少试样在变形过程中的摩擦阻力,在试样两端分别涂上石墨润滑剂,再贴上钽片。整个热压缩实验是在氩气保护环境下进行的。实验过程中,以20 ℃/s的加热速度将试样加热至不同的变形温度,然后保温10 min以消除热变形前试样各部位的温度梯度。所有试样的真应变都为0.7。变形后,立即对试样喷水淬火冷却到室温,以保留高温变形结束时的显微组织。用线切割仪器将变形后的试样在中心处沿着试样的直径方向切成两半。用70%(体积分数,下同)CH3OH,20% C2H4(OH)2和10% HClO4的混合溶液进行电解抛光,然后用15% HF,20% HNO3和65% H2O的混合溶液进行化学腐蚀,制备金相试样。

图2 热变形实验示意图

Fig. 2 Schematic diagram of hot deformation tests

2 实验结果与讨论

2.1 真应力-真应变曲线

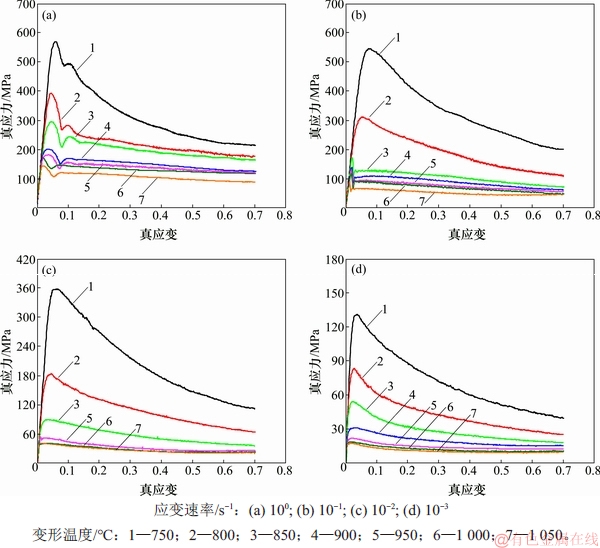

图3所示为Ti-20Zr-6.5Al-4V合金在不同变形温度和应变速率下的真应力-真应变曲线。由图3可以看出:当温度低于950 ℃,应变速率为100 s-1时,变形初始阶段出现显著的应力降现象(如图3(a)所示),即在较低的塑性应变下,流变应力急剧上升到一个峰值,然后随着应变的增加,流变应力迅速下降到一个较低值。在其他钛合金的单β相区热变形过程中普遍观察到这种应力降现象。本文所研究的Ti-20Zr-6.5Al-4V合金在温度低于789 ℃时为α单相区,789~946 ℃为α+β双相区。当温度低于950 ℃和应变速率为100 s-1时,应力降现象的产生可能与较快的应变速率有关。应变速率过快,变形时间较短,合金在变形过程中来不及析出α相,因此依然保持着β相的变形特征。当变形温度低于950 ℃时,随着应变速率的降低,应力降现象逐渐消失(见图3(b)~(d))。这是由于应变速率降低,变形时间增长,合金在变形过程将析出α相。α相为密排六方结构,不易发生塑性变形,从而导致应力降现象逐渐消失。

当变形温度高于950 ℃时(β单相区),应变速率为100 s-1和10-1 s-1时的真应力-真应变曲线在变形初期也出现显著的应力降现象(见图3(a)和(b))。PHILIPPART等[4]认为在变形过程中,由于晶界的阻碍作用,使得产生的大量位错在晶界处发生位错塞积,导致流变应力急剧升高,随后由于与热激活相关的一些机制(如攀移等)的作用,导致位错突然从晶界向晶内扩展,从而使流变应力大幅度下降,出现应力降现象。本文Ti-20Zr-6.5Al-4V合金应力降幅明显大于其他钛合金中观察到的应力降幅,并且与47Zr-45Ti-5Al-3V合金的应力降幅相近。因此,应力降可能是由在晶界附近因塑性变形产生的可动位错在晶界处快速消失引起的[5]。随着应变速率进一步降低,流变曲线表现出典型动态再结晶特征。

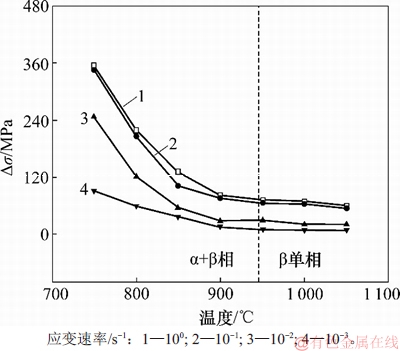

在应力降之后,随着应变的增加,流变应力逐渐降低,展现出连续的流变软化现象。为了定量分析流变曲线的流变软化程度,本文把峰值应力与真应变为0.7时的流变应力的差值△σ与峰值应力σp的比值定义为热变形过程中该合金的流变软化程度,即△σ/σp(△σ=σp-σ0.7)。图4所示为在不同应变速率下Ti-20Zr-6.5Al-4V合金流变软化程度随变形温度的变化曲线。由图4可以看出:在750 ℃时流变软化程度最大,随着温度升高流变软化程度逐渐减小。在给定变形温度情况下,流变软化程度随着应变速率的增加而增大。这可能归因于变形热、片状α相的球化和β相的动态再结晶等微观组织变化[6-8]。在低温高应变速率条件下,流变软化主要是由变形热引起的,而在高温低应变速率条件下,流变软化主要是由热变形过程中合金内部的组织结构变化引起的[9]。但值得注意的是,在β单相区,流变软化程度随变形温度的变化不明显,而在α+β双相区流变软化程度随变形温度变化较大,这可能与析出的α相体积分数有关。在两相区,变形温度越低,越有利于片状α相的析出。在变形过程中,片状α相将发生球化,α相体积分数越多,发生球化的α相也越多,因此,流变软化程度较大。

图3 Ti-20Zr-6.5Al-4V合金在等温变形及不同应变速率条件下的流变曲线

Fig. 3 True stress-ture strain curves for Ti-20Zr-6.5Al-4V alloy deformed at different strain rates under condition of isothermal deformation

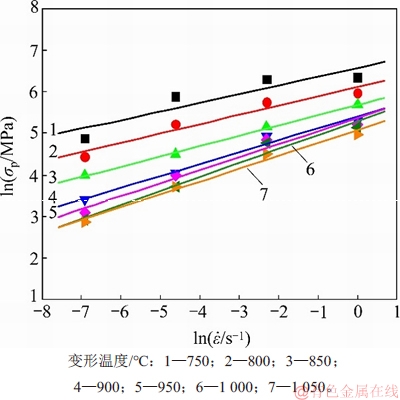

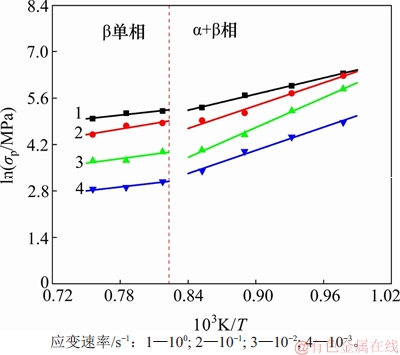

2.2 动力学分析

真应力-真应变曲线表明应变速率和变形温度对流变应力影响显著。为了分析流变应力、应变速率和变形温度之间的关系,可选择峰值应力作为各流变曲线的代表应力,图5和图6所示分别为峰值应力σp与应变速率 和变形温度T的关系。由图5和图6可以看出:峰值应力随着变形温度的降低和应变速率的增大而增大。值得注意的是,当给定应变速率时,α+β两相区的峰值应力随变形温度变化的斜率显著大于β单相区的斜率,说明在α+β双相区和β单相区变形机制不同。峰值应力、变形温度和应变速率之间的关系可用双曲正弦Arrhenius方程表示[10]:

和变形温度T的关系。由图5和图6可以看出:峰值应力随着变形温度的降低和应变速率的增大而增大。值得注意的是,当给定应变速率时,α+β两相区的峰值应力随变形温度变化的斜率显著大于β单相区的斜率,说明在α+β双相区和β单相区变形机制不同。峰值应力、变形温度和应变速率之间的关系可用双曲正弦Arrhenius方程表示[10]:

图4 Ti-20Zr-6.5Al-4V合金变形的流变软化程度(△σ/σp)随应变速率和变形温度的变化

Fig. 4 Changes of flow softening degree (△σ/σp) of deformation of Ti-20Zr-6.5Al-4V alloy with strain rate and deformation temperature

图5 Ti-20Zr-6.5Al-4V合金峰值应力与应变速率的关系

Fig. 5 Relationship between peak-stress and strain rate for Ti-20Zr-6.5Al-4V alloy

图6 Ti-20Zr-6.5Al-4V合金峰值应力与变形温度的关系

Fig. 6 Relationship between peak-stress and deformation temperature for Ti-20Zr-6.5Al-4V alloy

(1)

(1)

式中:A,α1和n为实验测定的与温度无关的材料常数;Q为热变形表面激活能;R为理想气体常数,R=8.314 J/(k·mol)-1; 为应变速率;T为变形温度。

为应变速率;T为变形温度。

对式(1)两边取自然对数可得

(2)

(2)

从式(2)可以看出:式中有4个常数,因此,线性回归统计方法不能够直接用来确定α1,A,n和Q。α1取值范围为0~1 MPa-1,并且与式(2)中的线性拟合相关系数之间呈抛物线分布。当线性拟合相关系数达到最大时,所对应的α1即为最优解。为了确定这些与温度无关的材料常数的值,首先,给定一系列介于0和1之间对称的α1;然后,根据式(2)采用1st0pt线性回归软件对不同的应变速率、变形温度以及所对应的流变应力进行线性拟合,得出给定的α1所对应的A,n,Q和相关系数。根据线性拟合相关系数与α1之间的关系,当线性拟合相关系数达到最大时,所对应的α1即为最优的α1。本文求得的最优α1在α+β双相区为0.003 44 MPa-1,在β单相区为0.01 MPa-1,然后可以确定A,n和Q在α+β双相区分别为7.9×1018 s-1,3.45和414.2 kJ/mol;在β单相区分别为8.1×103 s-1,3.35和123.0 kJ/mol。则在α+β双相区,式(1)可表示为

(3)

(3)

在β单相区:

(4)

(4)

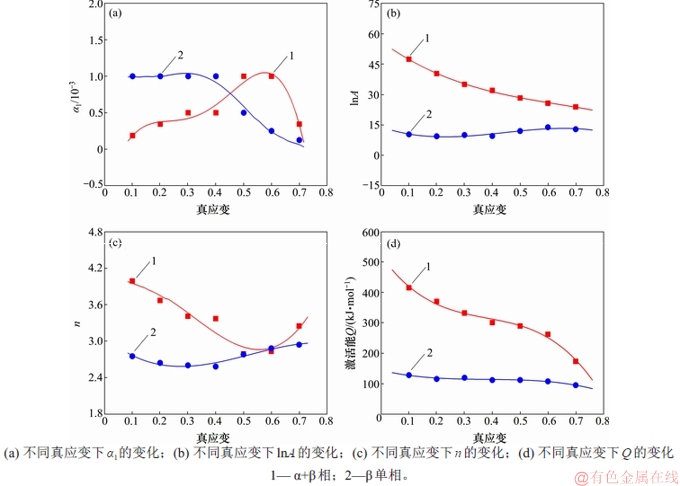

近年来,大量文献报道应变对热变形激活能和材料常数有显著影响[11-12]。为了更好地理解该合金的高温流变行为,计算出在不同应变下α1, ln A,n和Q在α+β双相区和β单相区的取值。图7所示为α1,ln A,n和Q在不同真应变下的取值。由图7可见:在α+β双相区,α1首先随着应变的增大而增大到最大值,然后降低;ln A和Q随着应变的增大逐渐减小,而n随应变的增大先减小到最小值然后增大。值得注意的是,Ti-20Zr-6.5Al-4V在α+β两相区的热变形激活能高于在α-Ti中的自扩散激活能(150 kJ/mol)[13],这表明变形机制可能和β相的动态回复、动态再结晶或者是层片状α相的动态回复和球化有关[14]。在β单相区,α1随着应变的增大而减小,而lnA随着应变的增大而缓慢增加;n随应变的增大先减小后增大,Q先随应变的增大而减小,然后在应变大约为0.4时趋向于一个稳定值。在β单相区的热变形激活能略微低于β-Ti中的自扩散激活能(153 kJ/mol)[15],这表明在β单相区合金的变形机制可能是以扩散回复型变形机制为主,只有在低应变速率条件下才发生动态再结晶。

图7 不同应变条件下α1, ln A, n 和Q的变化

Fig. 7 Variation of α1, ln A, n and Q with true strain

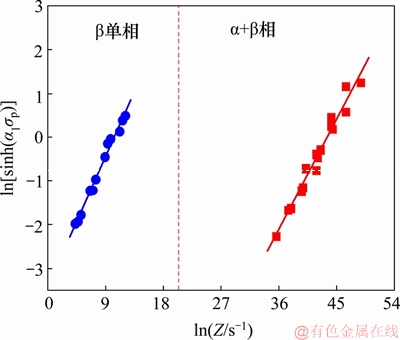

通常用温度补偿的应变速率因子,即Zener-Hollomon参数(Z= exp[Q/(RT)])表征变形温度与应变速率对变形过程特别是形变抗力的综合作用。图8所示为α+β双相区和β单相区峰值应力和Z参数的关系。由图8可以看出:α+β两相区和β单相区的峰值应力随Z增大而增大,呈现出良好的线性关系。所以利用双曲正弦函数建立的热变形本构方程是合理的。

exp[Q/(RT)])表征变形温度与应变速率对变形过程特别是形变抗力的综合作用。图8所示为α+β双相区和β单相区峰值应力和Z参数的关系。由图8可以看出:α+β两相区和β单相区的峰值应力随Z增大而增大,呈现出良好的线性关系。所以利用双曲正弦函数建立的热变形本构方程是合理的。

图8 在α+β两相区和β单相区中峰值应力(σp)随Zener-Hollomon参数的变化

Fig. 8 Variation of peak-stress (σp) with Zener-Hollomon parameter in α+β and single β phase fields

2.3 热加工图

动态材料模型(dynamic materials model,DMM)理论认为[16],合金在变形过程中具有能量耗散性,合金热变形吸收的功一部分是通过塑性变形以热量形式耗散,另一部分则是由显微组织变化引起的功率消耗[17],可以表示为

(5)

(5)

式中:P为合金在热变形过程中从外界吸收的热量;σ为瞬时流变应力;G为金属塑性变形而消耗的功率;J为与合金变形显微组织变化有关的功率消耗。由不可逆热力学可知在给定变形温度和应变条件下,流变应力和应变速率之间的关系可表示为

(6)

(6)

式中:a,b,c和d均为材料常数,可以利用应变速率敏感系数m描述G与J的变化。

(7)

(7)

联合式(6)和(7)可知m可以通过下式计算:

(8)

(8)

对于理想的线性耗散(m=1),J取最大值Jmax=P/2。这将引入1个量纲一非线性耗散参数即能量耗散系数(η):

(9)

(9)

根据合金在大应变塑性变形过程中的极大值原理,可以得出材料发生流动失稳的判据:

(10)

(10)

式中: 为量纲一不稳定参数,

为量纲一不稳定参数, 随温度和应变速率变化的等高线图构成了流变失稳图,当

随温度和应变速率变化的等高线图构成了流变失稳图,当 为负值时,意味着变形发生了流变不稳定。将流变失稳图和能量耗散图叠加到一起就构成了合金热变形过程中的热加工图。

为负值时,意味着变形发生了流变不稳定。将流变失稳图和能量耗散图叠加到一起就构成了合金热变形过程中的热加工图。

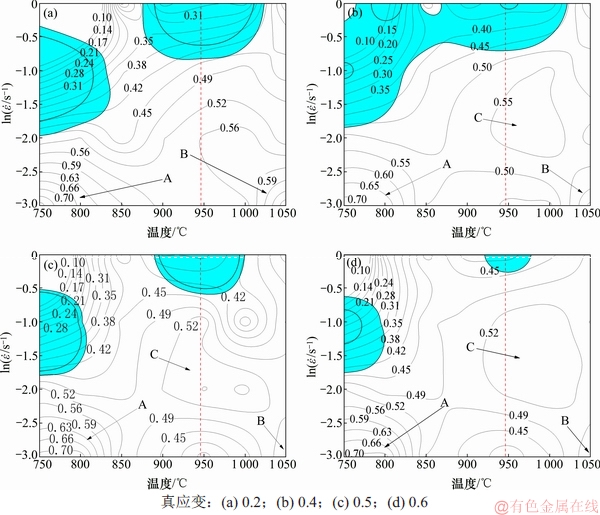

图9所示为Ti-20Zr-6.5Al-4V合金在应变分别为0.2,0.4,0.5和0.6时的热加工图,其中等高线的数值代表能量耗散系数η,图中深色区域代表流变不稳定区域,其他区域则为热加工安全区域。对于金属材料而言,在安全区内,η越大,越利于材料的加工;在失稳区内,外力对材料做的功大部分转变成塑性变形的能量,功率耗散系数比较小,宏观上表现为试样开裂、孔洞、流变局部带等,不适合材料的热加工。从图9(a)可以看出:在真应变为0.2时热加工图有2个失稳区。当应变增加到0.4时,第1个失稳区向着高温高应变方向扩展;随着应变不断增加,2个失稳区的面积逐渐减小,安全区域增大;当真应变为0.2时,热加工图中有2个加工区域,即A和B区域;当应变大于0.2时,热加工图有3个区域即A,B和C区域;区域A位于α+β双相区,发生在变形温度为750~830 ℃和应变速率为10-3~10-2 s-1范围内;区域B位于β单相区,发生在变形温度为1 025~1 050 ℃和应变速率为10-3~3.16×10-3 s-1范围内;区域C位于α+β双相区和β单相区交界处,发生在变形温度为925~1 020 ℃和应变速率为5.6×10-3~1.2×10-1 s-1范围内;随着应变的增加,A区域的范围没有发生明显变化,B区域的范围逐渐减小,C区域的范围逐渐增大。

图9 不同真应变下Ti-20Zr-6.5Al-4V合金α + β相和β相的热加工图

Fig. 9 Processing maps for Ti-20Zr-6.5Al-4V alloy at different true strains in α+β and β phase fields

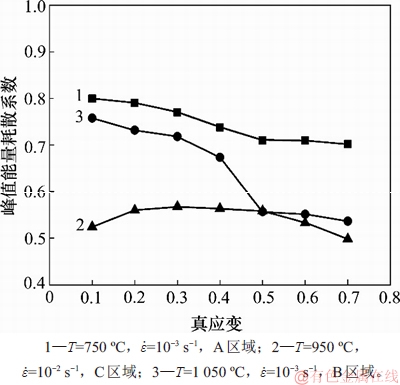

图10所示为A,B和C区域峰值能量耗散系数随真应变的变化情况。从图10可看出:在A区域,当变形温度为750 ℃和应变速率为10-3 s-1时能量耗散系数最大,能量耗散系数随应变的增加缓慢减小,这可能是片状α相发生球化所致。通常球状的α相表现出优异的热加工性能,因此,Ti-20Zr-6.5Al-4V合金在α+β两相区进行热加工时,可将片状α相发生完全球化的热加工参数作为Ti-20Zr-6.5Al-4V合金的热加工参数;在B区域,当变形温度为1 050 ℃和应变速率为10-3 s-1时能量耗散系数最大,能量耗散系数先随应变的增加逐渐从0.76下降到0.55,随后小幅度降低。

图10 Ti-20Zr-6.5Al-4V合金在A,B和C区域峰值能量耗散系数随真应变的变化

Fig. 10 Variations of peak power dissipation coefficient of Ti-20Zr-6.5Al-4V alloy with true strain in regions of A, B and C

能量耗散系数的下降,可能是由发生再结晶的β相晶粒随应变的增加而发生粗化导致的[18],β相晶粒的粗化会降低Ti-20Zr-6.5Al-4V合金的力学性能,因此,该区域不适合用于Ti-20Zr-6.5Al-4V合金的热加工。对于C区域,当变形温度为950 ℃和应变速率为10-2 s-1时能量耗散系数最大。能量耗散系数先随应变的增加而略微增加,随后轻微降低,总体变化不大,因此,可以认为该变形参数是Ti-20Zr-6.5Al-4V合金最优的热加工参数。该区域位于α+β双相区和β单相区交界处,位于近β锻造温度范围内。ZHOU等[19]发现经近β锻造处理的钛合金具有高的低周疲劳性能,高断裂韧性,优良的延展性,因此,可认为C区域为Ti-20Zr-6.5Al-4V合金最佳的热加工区域。

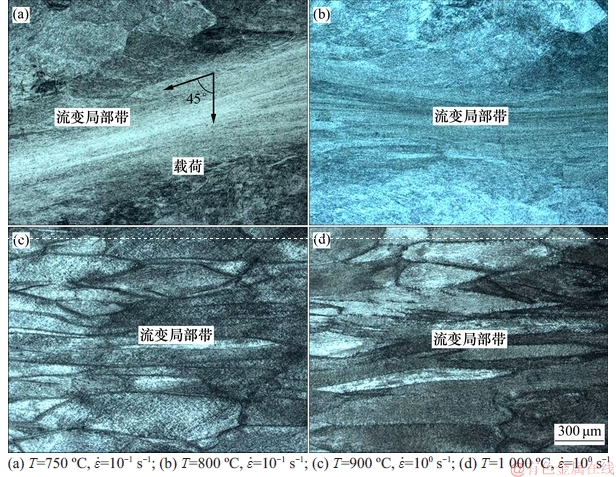

2.3 热变形组织

热加工图中不同区域的变形机制是不同的,为了进一步阐明Ti-20Zr-6.5Al-4V在不同加工参数下的变形机制,需要结合合金热变形的显微组织进一步分析。图11所示为Ti-20Zr-6.5Al-4V合金在流变失稳区的显微组织。由图11(a)可以看出:在变形温度为750 ℃和应变速率为10-1 s-1时,会在与径向成45°方向上形成流变局部绝热剪切带。通常来说,流变局部绝热剪切带容易在相对较低的温度和高应变速率的热加工过程中产生。这是由于应变速率太高,变形时间太短,由塑性变形产生的大量的热量不能够及时释放出去,这将会导致材料局部温度上升[20],从而使塑性变形沿着与径向成45°的切应力最大方向进行。此外,流变局部绝热剪切带的形成还与合金低的热导率有关。随着变形温度升高,流变局部绝热剪切带与径向方向的角度减小,如图11(b)和(c)所示。当变形温度增加到1 000 ℃时,流变局部绝热剪切带与径向几乎平行,此时,原始晶粒沿变形方向被拉长,这会导致位错密度增大以及应力集中、材料的微观组织不均匀,造成流变失稳。在钛合金的热加工过程中,流变局部绝热剪切带不利于合金的力学性能和加工性能,应避免在出现流变局部绝热剪切带的热加工参数下进行热加工。

图11 当真应变为0.7时不同变形条件下Ti-20Zr-6.5Al-4V合金流变不稳定区的光学显微组织

Fig. 11 Optical microstructures of Ti-20Zr-6.5Al-4V alloy in flow instability region at strain of 0.7 and different deformation conditions

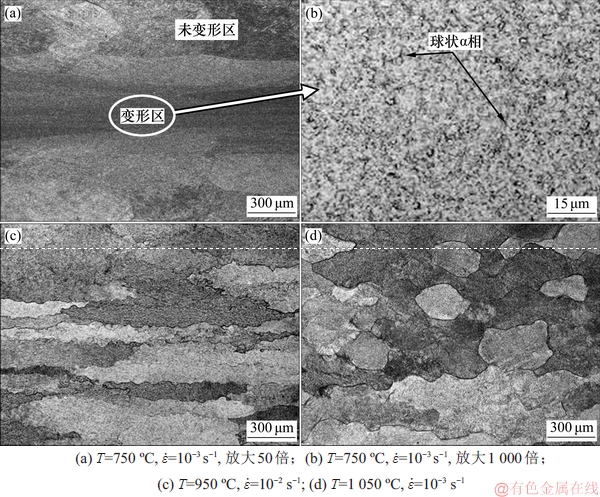

图12所示为Ti-20Zr-6.5Al-4V合金在流变稳定区的金相显微组织,从图12(a)可以看出:在变形温度为750 ℃和应变速率为10-3 s-1时,初始的β相晶粒沿着变形方向被拉长,仅仅发生动态回复;在未变形区,能够看到片层状α相,而在变形区域,以球状α相形式存在(见图12(b)),这表明合金在该变形条件下变形过程中片层状α相发生了球化转变;在变形温度为950 ℃和应变速率为10-2 s-1时,初始β相晶粒的晶界呈锯齿状,且在晶界处的局部区域可以观察到一些细小的再结晶晶粒,如图12(c)所示,这表明在该变形条件下合金发生了动态再结晶,此时,合金热变形过程的热变形机制主要为α相的球化和β相的动态再结晶,因此,该热变形参数有利于Ti-20Zr-6.5Al-4V合金进行热加工。当变形温度为1 050 ℃和应变速率为10-3 s-1时,可观察到大量粗化的β相再结晶晶粒,如图 12(d)所示。这表明合金发生了完全再结晶,且再结晶晶粒发生了粗化。此时,合金的热变形机制为β相的动态再结晶。通常发生动态再结晶的热变形参数有利于合金热加工,但此时再结晶晶粒发生了粗化,粗化的晶粒导致能量耗散系数较低,这对于材料的加工性和机械性能都是不利的。

图12 当真应变为0.7时Ti-20Zr-6.5Al-4V合金流变稳定区中出现能量耗散系数峰值的热变形条件对应的光学显微组织

Fig. 12 Optical microstructures of Ti-20Zr-6.5Al-4V alloy in stability region corresponding to peak coefficient of power dissipation at strain of 0.7 and different deformation conditions

3 结论

1) 在β单相区,在低温高应变速率时,变形初期流变曲线会产生显著的应力降现象;随着变形温度的增加和应变速率的降低,应力降现象逐渐消失。在高温低应变速率时,流变曲线呈现出典型的动态再结晶特征。在α+β相区,高应变速率时,变形初期流变曲线也会产生显著的应力降;随着应变速率的降低,应力降现象逐渐消失,流变曲线呈现出连续的流变软化现象。

2) 峰值应力随变形温度降低和应变速率增加而增大。在α+β相区, =7.9×1018[sinh(0.003 44

=7.9×1018[sinh(0.003 44 σp)]3.55exp[-414 200/(RT)];在β单相区,

σp)]3.55exp[-414 200/(RT)];在β单相区, =8.1×103

=8.1×103 [sinh(0.01σp)]2.62exp[-123 500/(RT)]。

[sinh(0.01σp)]2.62exp[-123 500/(RT)]。

3) 随着应变的增加,Ti-20Zr-6.5Al-4V合金在α+β双相区的热变形激活能从414.2 kJ/mol降到173.8 kJ/mol,其热变形机制是β相动态回复和动态再结晶以及片状α相的球化;而在β单相区,合金热变形激活能从123.5 kJ/mol降到95.2 kJ/mol,其热变形机制为β相的动态回复和动态再结晶。

4) 根据Ti-20Zr-6.5Al-4V合金的热加工图分析可知,该合金的最优热加工参数范围为750~830 ℃和10-3~10-2 s-1以及925~1 020 ℃和5.6×10-3~1.2×10-1 s-1。最优热加工工艺参数为750 ℃和 10-3 s-1以及950 ℃和10-2 s-1。

参考文献:

[1] 段静利. 热处理工艺和热变形参数对Ti-20Zr-6.5Al-4V合金组织与性能的影响[D]. 秦皇岛: 燕山大学材料科学与工程学院, 2015: 1-2.

DUAN Jingli. Effect of heat treatment process and hot deformation parameters on microstructure and properties of Ti-20Zr-6.5Al-4V alloy[D]. Qinhuangdao: Yanshan University. College of Materials Science and Engineering, 2015: 1-2.

[2] JING R, LIANG S X, LIU C Y, et al. Aging effects on the microstructures and mechanical properties of the Ti-20Zr-6.5Al-4V alloy[J]. Materials Science and Engineering: A, 2013, 559: 474-479.

[3] JING R, LIANG S X, LIU C Y, et al. Effect of the annealing temperature on the microstructural evolution and mechanical properties of TiZrAlV alloy[J]. Materials & Design, 2013, 52: 981-986.

[4] PHILIPPART I, RACK H J. High temperature dynamic yielding in metastable Ti-6.8Mo-4.5F-1.5Al[J]. Materials Science and Engineering: A, 1998, 243(1/2): 196-200.

[5] 谭元标. ZrTiAlV 合金热变形行为及组织与力学性能的研究[D]. 秦皇岛: 燕山大学材料科学与工程学院, 2016: 29-30.

TAN Yuanbiao. Study on hot deformation behavior, microstructure and mechanical properties of ZrTiAlV alloy [D]. Qinhuangdao: Yanshan University. College of Materials Science and Engineering, 2016: 29-30.

[6] PARK C H, KIM J H, HYUN Y T, et al. The origins of flow softening during high-temperature deformation of a Ti-6Al-4V alloy with a lamellar microstructure[J]. Journal of Alloys and Compounds, 2014, 582: 126-129.

[7] MA Xiong, ZENG Weidong, WANG Kaixuan, et al. The investigation on the unstable flow behavior of Ti17 alloy in α+β phase field using processing map[J]. Materials Science and Engineering: A, 2012, 550: 131-137.

[8] LI Chao, ZHANG Xiaoyong, LI Zhiyou, et al. Hot deformation of Ti-5Al-5Mo-5V-1Cr-1Fe near β titanium alloys containing thin and thick lamellar α phase[J]. Materials Science and Engineering: A, 2013, 573: 75-83.

[9] SEMIATIN S L, SEETHARAMAN V, WEISS I. Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure[J]. Materials Science and Engineering: A, 1999, 263(2): 257-271.

[10] SELLARS C M, TEGART W J M. Relationship between strength and structure in deformation at elevated temperatures [J]. Memoires Scientifiques De La Revue De Metallurgie, 1966, 63: 731-746.

[11] LEE W S, LIN Mingtong. The effects of strain rate and temperature on the compressive deformation behaviour of Ti-6Al-4V alloy[J]. Journal of Materials Processing Technology, 1997, 71(2): 235-246.

[12] CAI Jun, LI Fuguo, LIU Taiying, et al. Constitutive equations for elevated temperature flow stress of Ti-6Al-4V alloy considering the effect of strain[J]. Materials & Design, 2011, 32(3): 1144-1151.

[13] DYMENT F, LIBANATI C M. Self-diffusion of Ti, Zr, and Hf in their hcp phases, and diffusion of Nb95 in hcp Zr[J]. Journal of Materials Science, 1968, 3(4): 349-359.

[14] TAN Y B, DUAN J L, YANG L H, et al. Hot deformation behavior of Ti-20Zr-6.5Al-4V alloy in the α+β and single β phase field[J]. Materials Science and Engineering: A, 2014, 609: 226-234.

[15] GRIFFITHS M. A review of microstructure evolution in zirconium alloys during irradiation[J]. Journal of Nuclear Materials, 1988, 159: 190-218.

[16] PRASAD Y V R K, GEGEL H L, DORAIVELU S M, et al. Modeling of dynamic material behavior in hot deformation: forging of Ti-6242[J]. Metallurgical Transactions A, 1984, 15(10): 1883-1892.

[17] JAYARAMAN A, KLEMENT W, KENNEDY G C. Solid-solid transitions in titanium and zirconium at high pressures[J]. Physical Review, 1963, 131(2): 644.

[18] BALASUBRAHMANYAM V V, PRASAD Y V R K. Deformation behaviour of beta titanium alloy Ti-10V-4.5Fe-1.5Al in hot upset forging[J]. Materials Science and Engineering: A, 2002, 336(1/2): 150-158.

[19] ZHOU Y G, ZENG W D, YU H Q. An investigation of a new near-beta forging process for titanium alloys and its application in aviation components[J]. Materials Science and Engineering: A, 2005, 393(1/2): 204-212.

[20] MA Xiong, ZENG Weidong, XU Bin, et al. Characterization of the hot deformation behavior of a Ti-22Al-25Nb alloy using processing maps based on the Murty criterion[J]. Intermetallics, 2012, 20(1): 1-7.

(编辑 伍锦花)

收稿日期: 2019 -03 -15; 修回日期: 2019 -05 -24

基金项目(Foundation item):国家自然科学基金资助项目(51804087);贵州省基础研究计划资助项目([2019]1091);贵州省教育厅青年人才成长资助项目(KY[2018]107);贵州大学大学生创新创业训练计划资助项目([2018]003)(Project(51804087) supported by the National Natural Science Foundation of China; Project([2019]1091) supported by the Basic Research Program of Guizhou Province; Project(KY[2018]107) supported by the Youth Science and Technology Talent Growth Program of Guizhou Education Bureau; Project([2018]003) supported by Students Innovation and Entrepreneurship Training Program of Guizhou University)

通信作者:谭元标,博士,副教授,从事金属材料热变形行为及组织与力学性能研究;E-mail: ybtan1@gzu.edu.cn