文章编号:1004-0609(2013)S1-s0566-05

应变对TB9钛合金热变形行为及显微组织的影响

许 鑫,董利民,张志强,巴宏波,胡 明,关少轩,杨 锐

(中国科学院 金属研究所,沈阳 110016)

摘 要:采用Gleeble-3800热模拟试验机对TB9钛合金进行等温压缩试验,变形温度分别为850和950 ℃,应变速率为1 s-1,真应变分别为0.3,0.5,0.7,0.9和1.2,研究应变对TB9合金热变形行为及显微组织的影响。结果表明:温度越高,流变应力越小;在较小应变下,显微组织主要发生动态回复,随着应变增大,动态回复、动态再结晶增强,同时,出现几何动态再结晶现象;变形温度为950℃时,合金易发生动态再结晶,但变形量不能过大,否则会形成粗大的再结晶晶粒,造成显微组织不均匀,合适的真应变为0.7~0.9。

关键词:TB9钛合金;热变形;应变;显微组织;动态再结晶

中图分类号:TG146.2 文献标志码:A

Effect of strain on hot deformation behavior and microstructure of TB9 titanium alloy

XU Xin, DONG Li-min, ZHANG Zhi-qiang, BA Hong-bo, HU Ming, GUAN Shao-xuan, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The effect of strains on hot deformation behavior and microstructure of TB9 titanium alloy were investigated by isothermal compression tests on a Gleeble-3800 thermomechanical simulator at deformation temperatures of 850 ℃ and 950 ℃, the strain rate of 1 s-1 and true strains of 0.3, 0.5, 0.7, 0.9 and 1.2, respectively. The results show that the flow stress decreases with increasing temperature. The microstructure undergoes dynamic recovery mainly at small strains. With strains increasing, dynamic recovery and dynamic recrystallization are enhanced and geometrical dynamic recrystallization occurs at high strains. At 950 ℃, dynamic recrystallization happens more easily but large recrystallization grains can be generated at high strains, which causes inhomogeneous microstructure. Beneficial true strains are 0.7-0.9 when TB9 alloy is deformed at 950 ℃ and 1 s-1.

Key words: TB9 titanium alloy; hot deformation; strain; microstructure; dynamic recrystallization

亚稳β钛合金TB9(Beta C)名义成分为Ti-3Al-8V-6Cr-4Mo-4Zr(质量分数,%),是由美国RMI公司于20世纪60年代研发[1]。TB9合金属于高强钛合金,通过合适的热处理,其室温抗拉强度可超过1 500 MPa,并且具有良好抗腐蚀性、淬透性以及室温变形能力[2-3]。该合金是制造紧固件及弹簧的理想材料,另外,在深海探测器用缆绳及石油化工等领域也有广泛的应用[4-5]。

TB9合金显微组织受锻造、轧制等热变形过程影响,热加工过程形成的显微组织决定了产品的最终性能。为了获得合适的热加工参数,本文作者对TB9合金进行了等温压缩试验,研究了不同的应变对其热变形行为和显微组织的影响。

1 实验

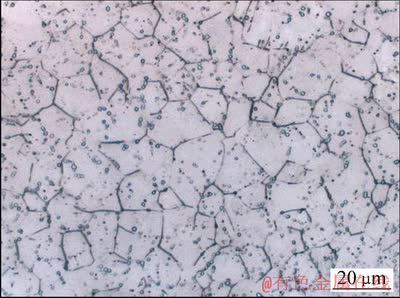

所使用的TB9合金原始显微组织如图1所示。可见,原始显微组织由等轴β晶粒组成,晶粒尺寸为10~30 μm。

图1 用于等温压缩试验的TB9合金原始显微组织

Fig. 1 Initial microstructure of TB9 alloy used in isothermal compression tests

合金加工成尺寸(直径×长度)为6 mm×9 mm的圆柱试样。等温压缩试验在Gleeble-3800热模拟试验机上进行。在变形温度为850 ℃和950 ℃,应变速率为1 s-1条件下对样品进行不同应变的等温压缩试验,真应变ε分别为0.3(压下量为26%)、0.5(压下量为40%)、0.7(压下量为51%)、0.9(压下量为60%)和1.2(压下量为70%)。试验前,样品两端涂抹含镍粉和石墨的润滑剂,样品端部和压头之间放有0.05 mm厚的钽片,以减小摩擦保证变形的均匀性。沿轴向,样品表面的中间部位焊接了铂铑-铂热电偶以测定压缩过程中样品的瞬时温度。样品以5 ℃/s的升温速率加热到试验温度并保温2 min使样品温度均一,然后压缩至指定变形量。压缩完成后样品空冷至室温。

用于显微组织观察的金相样品取自压缩试样的纵剖面,经机械磨光、抛光,用Kroll试剂蚀刻得到。所使用的光学显微镜和扫描电镜分别为ZEISS Axiovert 200MAT金相显微镜和Shimadzu SSX-550 型扫描电子显微镜。

2 结果与分析

2.1 不同应变下的流变行为

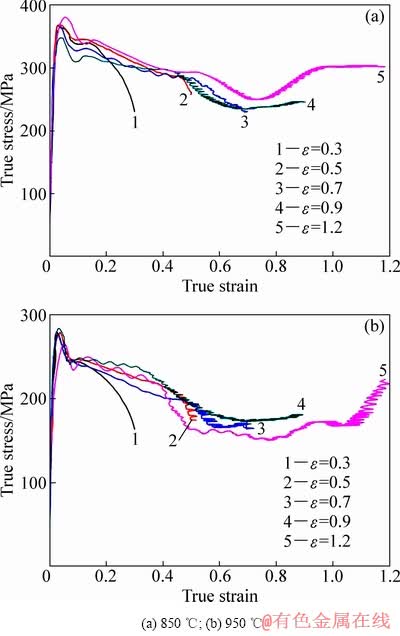

图2所示为在恒定变形温度和应变速率下,不同应变的真应力—真应变曲线(流变曲线)。在同一应变速率下,温度越高,流变应力越小,说明流变应力对温度较敏感。在所有变形温度下,流变应力在很小的真应变下迅速增大到峰值,随后立即降低,流变曲线上出现一个尖锐的峰,即出现了不连续屈服现象,在许多β钛合金中都观察到了这种现象[6],当变形温度和应变速率一定时,不同应变下的屈服强度变化不大。随后,材料发生连续软化,直到真应变为0.6时,达到稳态流变,硬化过程和软化过程达到平衡。流变软化的原因可能是变形温升、超塑性变形、动态再结晶、动态回复等过程[7-9],其中动态再结晶能细化晶粒并且降低流变应力,因此,对材料的热加工有利[10]。真应变超过0.9合金出现表观加工硬化现象,说明加工硬化速率超过了流变软化速率,应变加大,加工硬化起主导作用。

图2 应变速率为1 s-1时,不同应变下的等温压缩真应力—真应变曲线

Fig. 2 Flow curves of TB9 alloy deformed at 1 s-1 with different true strains

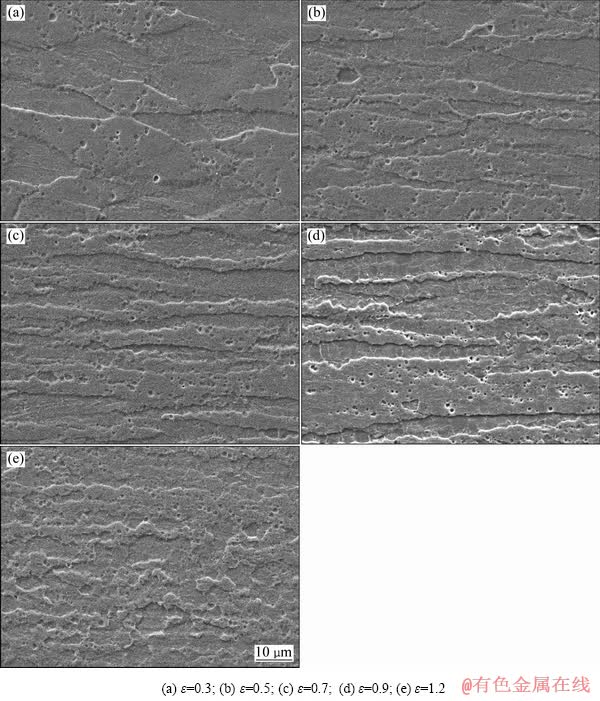

图3 TB9合金在850 ℃、应变速率为1 s-1时等温压缩至不同变形量后的显微组织

Fig. 3 Microstructure of TB9 alloy deformed at 850 ℃, 1 s-1 with different true strains

图4 TB9合金在950 ℃、应变速率为1 s-1时经不同变形量的等温压缩后的显微组织

Fig. 4 Microstructure of TB9 alloy deformed at 950 ℃, 1 s-1 with different true strains

2.2 不同应变下的显微组织演变

在850 ℃,1 s-1,不同真应变下变形后,样品中心的显微组织如图3所示。从图3可以看出,随着变形量的增大,晶粒越来越细小,原始β晶粒变形越来越严重。当ε=0.3时,晶粒沿着压缩轴方向被略微压扁,在垂直于压缩轴方向,晶粒被略微拉长,显微组织中出现亚结构,说明发生了动态回复,但亚晶轮廓模糊。一些原始β晶粒的晶界变为锯齿状,部分晶界附近出现少量动态再结晶晶粒。

当ε=0.5时,显微组织亚结构逐渐清晰,说明发生了更大程度的动态回复,组织中形成了大小不一的动态再结晶晶粒。由于变形温度低,变形速率快,部分原始β晶粒被压缩到很细小,对边的晶界相互接触,剪断了原始β晶粒,形成细小晶粒,而附近的原始β晶粒变粗大,即出现了几何动态再结晶现象[11]。在这些软化机制的作用下,流变曲线表现出软化现象。

当ε=0.7时,动态再结晶、动态回复、几何动态再结晶现象明显,但由于变形量的加大,加工硬化效果也增大,软化和硬化过程达到平衡,变形进入稳态阶段。

当真应变超过0.9时,动态再结晶、动态回复、几何动态再结晶继续进行。大部分原始β晶粒已经压缩至很小尺寸,晶界和晶粒内部承担的变形量相近,并且晶界和晶内位错密度达到非常高的水平,使位错滑移等运动较难进行,进一步变形难度增大,加工硬化效果明显,因此,流变曲线上表现出加工硬化特点,如图2(a)所示。

当ε=1.2时,显微组织中出现许多细小晶粒,这些晶粒是通过动态再结晶和几何动态再结晶形成的。由于晶粒被压缩到很小尺寸,晶内亚结构已经无法辨认,如图3(e)所示。

当变形条件为950 ℃、1 s-1,不同真应变下,样品中心的显微组织如图4所示。在对应的变形量下,950 ℃的合金晶粒尺寸均比850 ℃、1 s-1条件下的大。当ε=0.3时,在一些变形的原始β晶粒晶界处形成了一连串的细小动态再结晶晶粒,这是在动态再结晶条件下,晶界作为再结晶优先形核位置所造成的项链状(Necklace)动态再结晶晶粒层(图4(a)),在Ni-20%Cr合金中也发现了这种现象[12]。在850 ℃时未发现这种现象,说明要形成项链状动态再结晶晶粒层需要合适的温度。当ε=0.5时,出现了许多尺寸不同(晶粒粒径为2~13 μm)的未变形晶粒,且原始β晶粒内出现大量轮廓清晰的亚结构,如图4(b)所示。说明动态再结晶形核、长大及动态回复同时在进行并且在加剧。当ε=0.7时,动态再结晶、动态回复继续进行,同时,出现了几何动态再结晶现象(图4(c))。当ε=0.9时,晶内的亚晶更清晰、尺寸更大,如图4(d)所示。当ε=1.2时,出现尺寸超过20 μm的未变形晶粒(图4(e)),而原始β晶粒已经被压缩拉长,宽度小于20 μm,多数原始β晶粒宽度已经在10 μm左右。这些晶粒是动态再结晶晶粒异常长大形成的,这可能与变形温度、变形速率和大变形量下形成织构有关[13]。

由上述分析可知,应变速率为1 s-1时,TB9合金在950 ℃比在850 ℃下更易进行动态再结晶,所以变形温度应选择950 ℃。但在此温度下变形,变形量不宜过大,真应变应控制在0.9以内,否则会形成大尺寸动态再结晶晶粒,造成组织不均匀。

3 结论

1) 在同一应变速率下,温度越高,流变应力越小。随着变形量增大,真应力—真应变曲线上出现不连续屈服、流变软化、稳态流变和加工硬化等现象。

2) 不同变形量下,显微组织的演变机制不同,通常,在较小变形量下,显微组织主要发生动态回复,随着变形量增大,动态回复进行彻底并且出现动态再结晶现象并增强,在大应变下同时出现几何动态再结晶现象。

3) 应变速率为1 s-1时,950 ℃下TB9合金比850 ℃下的更易进行动态再结晶,但在此温度下变形,变形量不宜过大,否则会形成粗大的再结晶晶粒,造成组织不均匀,应避免。TB9合金以1 s-1变形速率热变形的有利条件为变形温度950 ℃,ε=0.7~0.9。

REFERENCES

[1] EYLON D, VASSLE A, COMBRES Y, BOYER R R, BANIA P J, SCHUTZ R W. Issues in the development of beta titanium alloys[J]. Journal of the Minerals, Metals and Materials Society, 1994, 46(7): 14-15.

[2] SCHMIDT P, EL-CHAIKH A, CHRIST H J. Effect of duplex aging on the initiation and propagation of fatigue cracks in the solute-rich metastable β titanium alloy Ti 38-644[J]. Metallurgical and Materials Transactions A, 2011, 42: 2652-2667.

[3] EL-CHAIKH A, SCHMIDT P, CHRIST H J. Fatigue properties of duplex-aged Ti 38-644 metastable beta titanium alloy[J]. Procedia Engineering, 2010, 2: 1973-1982.

[4] BOYER R R, BRIGGS R D. The use of β titanium alloys in the aerospace industry[J]. Journal of Materials Engineering and Performance, 2005, 14(6): 681-685.

[5] YAMASHITA Y, IRIE N, ISHIOU S, MURAYAMA Y, TSUCHIYA K, YAMADA N, MORII A. Manufacturing technology and application of titanium alloy wire rod to deep-sea cable[J]. Nippon Steel Technical Report, 1994, 62: 52-56

[6] WEISS I, SEMIATIN S L. Thermomechanical processing of beta titanium alloys—An overview[J]. Materials Science and Engineering A, 1998, 243: 46-65.

[7] DING R, GUO Z X, WILSON A. Microstructural evolution of a Ti-6Al-4V alloy during thermomechanical processing[J]. Materials Science and Engineering A, 2002, 327: 233-245.

[8] SEMIATIN S L, SEETHARAMAN V, WEISS I. Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure[J]. Materials Science and Engineering A, 1999, 26: 257-271.

[9] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Hot Working of Commercial Ti-6Al-4V with an Equiaxed α-β Microstructure: Materials Modeling Considerations[J]. Materials Science and Engineering A, 2000, 284: 184-194.

[10] PRASAD Y V R K, SASIDHARA S. Hot working guide: A compendium of processing maps [M]. USA: ASM International, 1997: 9.

[11] MCQUEEN H J. Development of dynamic recrystallization theory[J]. Materials Science and Engineering A, 2004, 387/389: 203-208.

[12] DUDOVA N, BELYAKOV A, SAKAI T, KAIBYSHEV R. Dynamic recrystallization mechanisms operating in a Ni-20%Cr alloy under hot-to-warm working[J]. Acta Materialia, 2010, 58(10): 3624-3632.

[13] LEYENS C, PETERS M. Titanium and titanium alloys[M]. Weinheim: Wiley-VCH, 2003: 11-54.

(编辑 赵 俊)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:董利民,副研究员;电话:024-23971265;E-mail:lmdong@imr.ac.cn