文章编号:1004-0609(2013)S1-s0011-04

冷拉拔变形量和时效温度对TB9钛合金丝材组织和性能的影响

黄鎏杰,王 健,张慧博,金 伟

(中国科学院 金属研究所,沈阳 110016)

摘 要:采用拉伸性能测试和扫描电镜观察等方法,研究了冷拉拔变形量和时效温度对TB9合金丝材显微组织和力学性能的影响。结果表明:冷拉拔变形可以促进α相的弥散析出,随冷拉拔变形量增大,强度上升,塑性先升后降;经过30%冷拉拔变形的TB9合金具有良好的综合力学性能;在480~580 ℃时效,随时效温度升高,α相粗化,强度随之下降。

关键词:TB9钛合金;冷拉拔;时效处理;显微组织;力学性能

中图分类号:TG146.2 文献标志码:A

Effects of cold drawing deformation and aging temperature on microstructure and mechanical properties of TB9 titanium alloy

HUANG Liu-jie, WANG Jian, ZHANG Hui-bo, JIN Wei

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The effects of cold drawing deformation and aging temperature on microstructures and tensile properties of TB9 titanium alloy wire were studied using tensile test and scanning electron microscopy. It is shown that cold drawing promotes the dispersed precipitation of α phase, and the strength increases while the plasticity rises at first and then decreases with rising the cold drawing deformation. Good mechanical property of TB9 alloy is obtained after 30% cold drawing deformation. α phase is coarsened and the strength decreases with increasing the aging temperature in the range of 480-580 ℃.

Key words: TB9 titanium alloy; cold drawing; aging; microstructure; mechanical property

TB9钛合金是20世纪60年代美国RMI研发的亚稳β商业钛合金,美国牌号为β-C[1]。该合金是在Ti-13V-11Cr-3Al(13-11-3)的基础上发展而来,解决了13-11-3合金由于Cr含量过高而出现的熔炼问题。Mo元素的大量加入使得该合金在酸性和氯化物介质中比其他高强钛合金具有更好的抗缝隙腐蚀性能[2]。TB9钛合金具有良好的冷加工性能,通过合理的热处理,抗拉强度可以达到1 600 MPa,主要应用于航空弹簧、紧固件、扭杆以及天然气和石油井下管道系统[3-7]。

TB9钛合金在普通时效过程中易出现α相分布不均匀,形成无α相析出的区域,被称为未沉淀区[8]或β斑(β fleck)[4-5]。α相无析出区对合金的力学性能特别是疲劳性能有显著影响,国内外大多采用双级时效来使α相均匀弥散析出[4-5]。冷变形产生的缺陷有利于α相的均匀析出[9],而这方面的研究在国内鲜有涉及。本文作者研究了冷拉拔变形量和冷变形后的时效处理温度对TB9合金组织及性能的影响。

1 实验

按TB9名义成分(Ti-3Al-8V-6Cr-4Mo-4Zr)配料、压制电极,电极经3次真空自耗熔炼制成合金铸锭,铸锭经过开坯、锻造、轧制、拉拔,制成d 5.0 mm的盘圆丝材。丝材在820 ℃固溶30 min后分别采取以下处理方式:1) 经过0%、16%、30%、39%、49%、57%、64%不同拉拔变形后,在真空炉中540 ℃时效8 h,空冷;2) 经过30%冷拉拔变形,分别在480、500、520、540、560、580 ℃温度下真空时效8 h,空冷。

采用Shimudz电子万能试验机测量不同冷拉拔变形量和不同热处理TB9丝材的室温拉伸性能;采用岛津SSX-550钨丝扫描电子显微镜观察不同冷拉拔变形量和不同热处理TB9丝材的显微组织。

2 结果与分析

2.1 冷拉拔变形量对时效后TB9钛合金性能及组织的影响

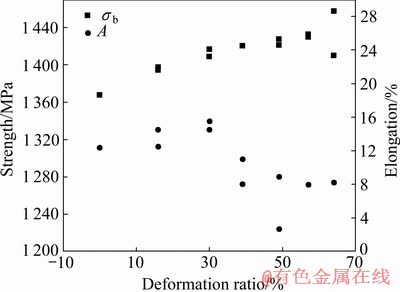

图1所示为TB9丝材经不同冷拉拔变形量540 ℃,8 h时效后的室温拉伸性能。可以看出,随着冷拉拔变形量的增加,强度逐渐升高,塑性先升后降。冷拉拔变形量从0%增大至64%,抗拉强度从1 368 MPa提高到1 458 MPa,伸长率从12.4%先升高到15%再下降至8%。而未经过时效的试样,抗拉强度从1 025 MPa提高到1 247 MPa,伸长率从16%降至3%。对比后发现,时效处理消除了加工硬化的部分影响。当拉拔量超过30%时,强化效果明显,伸长率显著下降,降至10%以下。拉拔量30%时强度和塑性配比适中,具有良好的拉伸性能。

图1 不同拉拔量的TB9合金时效后的室温拉伸性能

Fig. 1 Room temperature tensile properties of TB9 alloy with different cold drawing deformation after aging

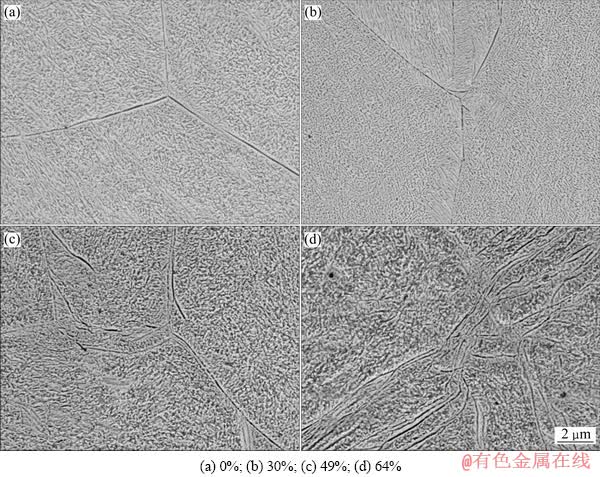

图2 不同冷拉拔变形量TB9合金时效后的SEM像

Fig. 2 SEM images of TB9 alloy with different cold drawing deformation after aging

图2所示为不同拉拔变形量时效后TB9合金的显微组织。可以看出,TB9合金经过冷变形后,原始β晶粒破碎,晶界严重变形扭曲,内部产生大量缺陷,储存很高的畸变能。经过冷变形金属再加热到时效温度时,析出与回复过程同时发生。析出将因冷加工而加速,析出相质点将因冷变形而更加弥散分布。与此同时,析出相也阻碍多边形化等回复过程[10]。因此,α相在β相中均匀弥散析出。随着冷拉拔变形量的增加,α相有明显长大趋势。这是由于冷拉拔储存大量的畸变能,为相变提供驱动力,促进α相的形核和长大。而时效过程中变形量大的样品回复更加明显,所以时效后抗拉强度的提高要明显低于未时效前抗拉强度的提高。由图2(c)和(d)可以看出,变形量超过30%,晶界变形严重,回复过程不能消除加工硬化的影响,伸长率下降严重。

2.2 时效温度对TB9钛合金性能及组织的影响

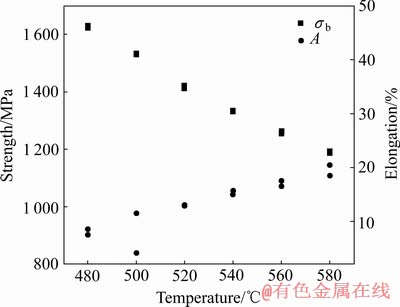

TB9合金力学性能对时效温度非常敏感,图3所示为TB9合金经过不同温度时效后的拉伸性能。在480~580 ℃时效后,抗拉强度随时效温度的升高明显下降。强度从480 ℃的峰值1 626 MPa下降到580 ℃的1 191 MPa,下降约27%。伸长率随时效温度的升高从8%升高到19.5%。抗拉强度随温度的变化基本上呈线性规律,从480 ℃开始每提高10 ℃,强度下降约35 MPa。

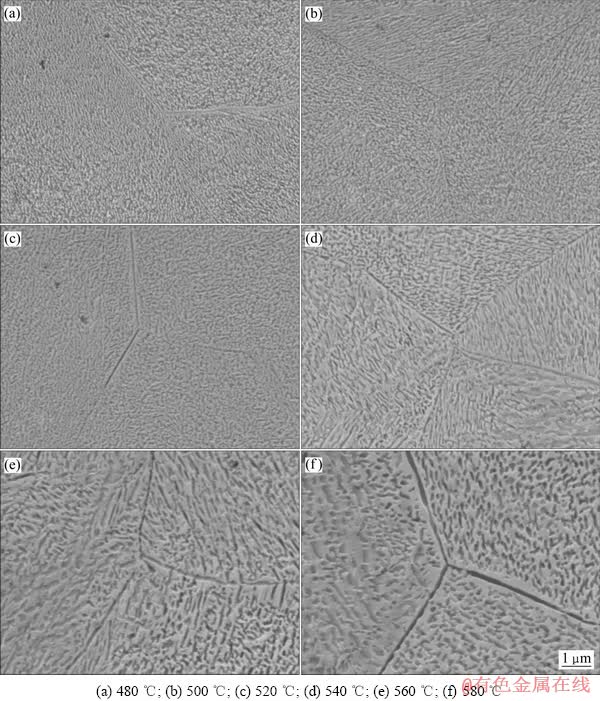

TB9合金在不同温度时效后的组织如图4所示。

图3 不同时效温度TB9合金的室温拉伸性能

Fig. 3 Room temperature tensile properties of TB9 alloy with different aging temperatures

图4 不同时效温度TB9合金的SEM像

Fig. 4 SEM images of TB9 alloy with different aging temperatures

经过30%冷变形,在480~580 ℃时效后,α相在β晶粒中均匀弥散析出。随时效温度升高,α相长大明显,长度从纳米级长大到约0.5 μm,析出量同时减小。较低温时效时,α相尺寸小且密集分布在β晶粒内,对位错有钉扎作用,阻碍位错的滑移,形成第二相粒子强化,强度达到1 400 MPa以上,塑性较差,如图4(a),(b)和(c)所示。较高温时效时,α相较粗大,间距增大,对位错钉扎作用减弱,位错更易滑移,所以强度下降,伸长率升高,如图4(d),(e)和(f)所示。

3 结论

1) 冷拉拔变形可以促进α相在β相中均匀弥散析出,提高抗拉强度,但是,随着拉拔量的增大,塑性先升后降。拉拔量达到30%时合金具有良好的拉伸性能。

2) α相在480~580 ℃随时效温度升高粗化明显,抗拉强度随之降低。

REFERENCES

[1] C. 莱恩斯, M. 皮特尔斯. 钛与钛合金[M]. 陈振华, 译. 北京: 化学工业出版社, 2005: 32-51.

LEYENS C, PETERS M. Titanium and titanium alloys[M]. CHEN Zhen-hua, trans. Beijing: Chemical Industry Press, 2005: 32-51.

[2] BOYER R, WELSCH G, COLLINGS E W. Materials properties handbook: Titanium alloys[M]. America: ASM International, 1994: 797-827.

[3] BOYER R R, BRIGGS R D. The use of β titanium alloys in the aerospace industry[J]. Journal of Materials Engineering and Performance, 2005, 14(6): 681-685.

[4] SCHMIDT P, EI-CHAIKH A, CHRIST H J. Effect of duplex aging on the initiation and propagation of fatigue cracks in the solute-rich metastable β titanium alloy Ti 38-644[J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2011, 42A(9): 2652-2667.

[5] EI-CHAIKH A, SCHMIDT P, CHRIST H J. Fatigue properties of duplex-aged Ti 38-644 metastable beta titanium alloy[J]. Procedia Engineering, 2010, 2(1): 1973-1982.

[6] BUZOLITS S. Tough titanium fasteners[J]. Advanced Materials and Processes, 2003, 161(11): 53.

[7] 郑 勇. 钛合金弹簧发展动态研究[J]. 飞机设计, 2012, 32(3): 46-49.

ZHENG Yong. A dynamic study of development for titanium alloy spring[J]. Aircraft Design, 2012, 32(3): 46-49.

[8] 林永新, 张国新, 陈 军, 杨冠军, 邓 炬. 热处理参数对βC钛合金显微组织与机械性能的影响[J]. 稀有金属材料与工程, 1998, 27(2): 75-78.

LIN Yong-xin, ZHANG Guo-xin, CHEN Jun, YANG Guan-jun, DENG Ju. Effects of heat treatment on the microstructures and mechanical properties of βC titanium alloy[J]. Rare Metal Materials and Engineering, 1998, 27(2): 75-78.

[9] 张 翥, 王群骄, 莫 畏. 钛的金属学和热处理[M]. 北京: 冶金工业出版社, 2009: 255-256.

ZHANG Zhu, WANG Qun-jiao, MO Wei. Metal science and heat treatment of titanium[M]. Beijing: Metallurgical Industry Press, 2009: 255-256.

[10] 李松瑞, 周善初. 金属热处理[M]. 长沙: 中南大学出版社, 2003: 395-398.

LI Song-rui, ZHOU Shan-chu. Heat treatment of metals[M]. Changsha: Central South University Press, 2003: 395-398.

(编辑 杨 兵)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:金 伟,研究员,博士;电话:024-23971956;E-mail: wjin@imr.ac.cn