DOI:10.19476/j.ysxb.1004.0609.2019.04.09

基于修正JC模型的TA12钛合金高温流变行为

叶建华1,陈明和1,王 宁1,谢兰生2

(南京航空航天大学 机电学院,南京 210001)

摘 要:为了研究TA12钛合金高温流变行为,构建能准确描述其高温流变行为的本构模型,对TA12钛合金进行了温度范围为700~850 ℃,应变速率为0.001~0.1 s-1的高温拉伸试验。结果表明:在所研究的变形条件下,流变应力随应变的增加而逐渐增大,达到峰值应力后又逐渐减小,直至材料发生断裂,并在850 ℃、0.001 s-1的变形条件下出现了稳态流动应力。综合考虑应变硬化效应、应变速率硬化效应和热软化效应的影响,提出一种修正的JC本构模型,可准确地描述TA12钛合金的高温流变行为。

关键词:TA12钛合金;高温流变行为;本构模型

文章编号:1004-0609(2019)-04-0733-09 中图分类号:TG146.4 文献标志码:A

TA12钛合金是我国研制的一种近α型高温钛合金,因其具有良好的高温强度、热稳定性和高温持久性能[1],广泛应用于航空发动机叶片、鼓筒、压气机机盘等零件的制造[2-3]。TA12钛合金在室温下成形时变形抗力大、回弹大,导致室温下无法成形,而采用热成形的方法能够很好地成形出TA12钛合金的结构件。为了确定材料热加工时合理的工艺参数以及为应用本材料结构件进行有限元模拟时提供基本参数,需要对材料的高温流变行为及其影响因素进行研究,构建材料的本构模型,确定材料在变形过程中流动应力与应变、温度以及应变速率之间的关系。

国内外的学者已经对材料的本构模型及其影响因素进行了很多的研究,并发展了多种类型的本构模型,主要有Arrhenius型[4-7]、Johnson-Cook型[6-9]以及Zerilli-Armstrong型[6-7]本构模型,但目前对钛合金本构模型的报道多是Arrhenius型。东赟鹏等[4]对TA7钛合金进行了不同温度和应变速率下的热压缩实验,建立了一种基于应变补偿的Arrhenius型本构模型,拟合误差较小,具有良好的预测能力。而崔志辉等[5]根据TC11钛合金在高温压缩实验条件下的应力应变数据变化趋势选择合适的分界点,建立了一种基于应变分段的Arrhenius双曲正弦的本构模型。而在国外期刊对材料本构模型的报道中,三种本构模型均有采用。LI等[6]则是建立了28CrMnMoV合金在高温条件下修正的Johnson-Cook、修正的Zerilli-Armstrong以及Arrhenius型本构模型,对比研究了三种本构模型对预测该合金高温流变行为的精度,其结果表明修正的Johnson-Cook和Arrhenius型本构模型拟合精度较高,误差小。

为了确定TA12钛合金的热成形工艺参数以及为材料结构件仿真提供基本参数,建立能准确描述其高温流变行为的本构方程具有重要意义。目前国内对TA12钛合金的研究主要集中在焊接、超塑成形方面[10-13],方波等[14]对其高温流变行为和本构模型的研究中,未能给出最后的验证结果,不能准确描述其高温流变行为,所以本文针对这方面展开了详细的研究,拟采用修正的Johnson-Cook本构模型来预测材料的高温流变行为。

1 实验

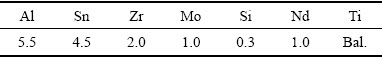

表1 TA12钛合金化学成分

Table 1 Chemical compositions of TA12 titanium alloy (mass fraction, %)

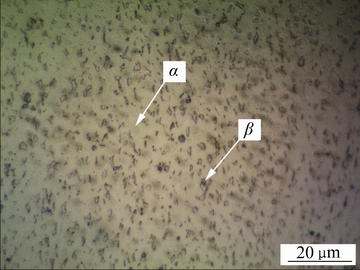

图1 TA12钛合金显微组织

Fig. 1 Microstructures of TA12 titanium alloy

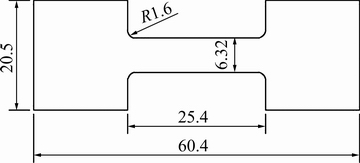

实验材料为宝鸡钛业提供的退火态TA12钛合金板材,厚度为1.5 mm,其化学成分如表1所示。TA12钛合金是一种近α型钛合金,其金相组织如图1所示。高温拉伸试样采用慢走丝电火花线切割加工而成,其形状尺寸如图2所示。实验设备为深圳三思纵横UTM5504X万能试验机和三段式高温加热炉,力传感器量程为0~10000 N,加热温度精度为±3 ℃。实验采用的温度为700、750、800、850 ℃,应变速率为0.001、0.01、0.1 s-1。所有试样加热到设定温度后保温10 min进行实验,保证试样内部温度分布均匀,实验完成后取出试样水冷。实验过程中由计算机自动采集变形过程中的位移与载荷。

图2 高温拉伸试样

Fig. 2 Dimension of high temperature tensile sample (Unit: mm)

2 结果与讨论

2.1 流变行为

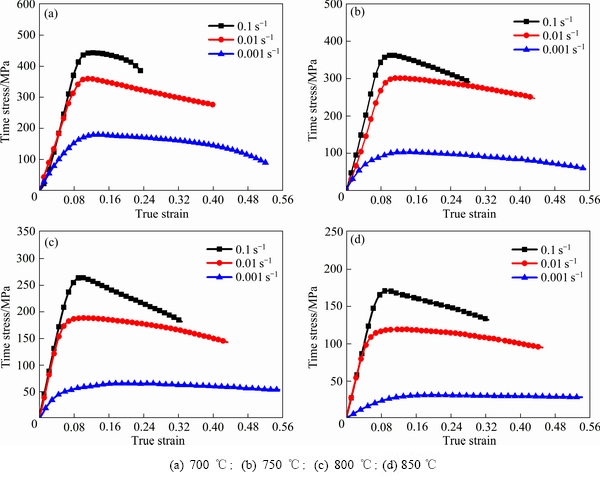

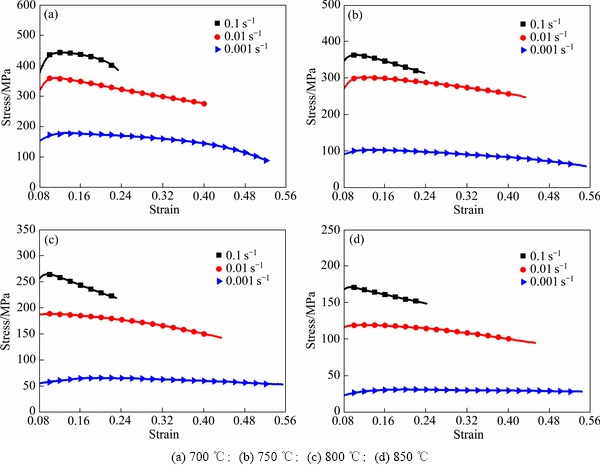

图3 TA12钛合金不同温度下的真应力—真应变曲线

Fig. 3 True stress—true strain curves of TA12 titanium alloy at different temperatures

TA12钛合金在不同实验条件下的流变应力曲线如图3所示。从图3中可以看出,TA12钛合金的高温流变行为明显受到变形温度和应变速率的影响。在700 ℃和0.1 s-1的变形条件下,在变形的初始阶段,材料的加工硬化现象占主导地位,流变应力随应变的增加而逐渐增大,达到峰值应力后又逐渐减小,直至材料发生断裂。当温度升高或应变速率减小时,在相同的变形程度下,材料流变应力逐渐下降。这是由于当变形量相同时,应变速率越低,变形时间越长,动态再结晶引起的软化过程可以充分进行;而较高的温度能够促进动态再结晶晶粒的形核,有利于再结晶的进行[15]。在较高温度或较低应变速率的变形条件下,动态软化机制的作用增强,导致材料的流变应力曲线逐渐下降。在850 ℃和0.001 s-1的变形条件下,材料能保持较长时间的软化流动阶段,呈现出了一个应力几乎不变的稳定状态。考虑到材料在不同实验条件下的伸长率不同以及模型的适用范围,本文所取的应变范围为材料拉伸失稳前塑性阶段的实验数据。

2.2 本构模型的建立

2.2.1 Johnson Cook本构模型

Johnson Cook(JC)本构模型是一种常用来描述材料在高温下静态和动态流动应力行为的经验本构方程。原始的JC模型[8]如式(1)所示:

(1)

(1)

式中: 为真实应力,MPa;

为真实应力,MPa; 为真实应变;

为真实应变; 为应变速率,s-1;

为应变速率,s-1; 为参考应变速率,s-1;T为温度,K;Tref为参考温度,K;TMelt为熔点温度,K;A为在参考温度和参考应变速率下的屈服应力,MPa;B为应变硬化系数,MPa;n为应变硬化指数;C为应变速率硬化系数;m为温度软化系数。

为参考应变速率,s-1;T为温度,K;Tref为参考温度,K;TMelt为熔点温度,K;A为在参考温度和参考应变速率下的屈服应力,MPa;B为应变硬化系数,MPa;n为应变硬化指数;C为应变速率硬化系数;m为温度软化系数。

原始的JC本构模型形式较简单,需要确定的材料参数较少,只需做一部分实验即可确定上述参数,它由应变硬化影响部分、应变速率影响部分和温度影响部分组成,将应变硬化、应变速率硬化和热软化效应三者单独考虑,没有考虑三者相互影响的效应,导致预测精度不高[7, 9]。LIN等[16]采用二次多项式函数用以描述应变硬化部分,耦合了应变速率和温度的影响,提出了一种改进的JC本构模型如式(2)所示,一些学者[6, 17]应用此改进的JC本构模型成功地预测了几种合金的高温流变行为。

(2)

(2)

式中:A1、B1、B2、C1、 和

和 是材料参数,

是材料参数, ,

, ,其余参数意义与式(1)相同。

,其余参数意义与式(1)相同。

本小节拟先采用上述改进的JC本构模型来预测TA12钛合金高温下的流动应力。李建光等[18]指出JC本构模型中参考应变速率一般取0.1~0.0001 s-1,在材料的动态力学行为研究中,常选取应变速率较低的准静态应变速率作为参考应变速率。而对TA12钛合金板材成形过程中高温流变行为来说,实际成形条件下应变速率相对较慢,应选取较低的应变速率作为参考应变速率。本文选取参考温度973 K(700 ℃),参考应变速率0.001 s-1来确定式(2)中的各参数,主要步骤如下:

1) 当变形温度为973 K(700 ℃),变形应变速率为0.001 s-1时,式(2)可转换成式(3):

(3)

(3)

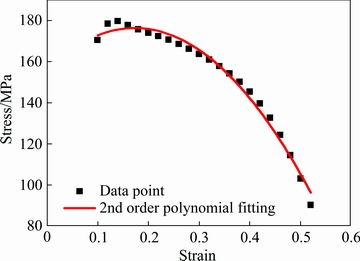

将此变形条件下所取的应力应变数据点绘制散点图,采用二次多项式进行拟合,如图4所示,根据多项式的拟合系数可以确定A1、B1和B2。

图4 在参考温度和参考应变速率下应力与应变的拟合

Fig. 4 Fitting curve of stress and strain at reference temperature and reference strain rate

2) 当变形温度为973 K(700 ℃)时,式(2)可以转换成式(4):

(4)

(4)

变换式(4)为

(5)

(5)

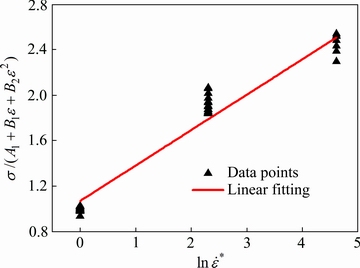

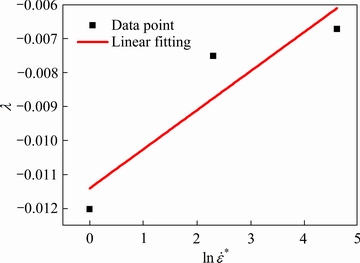

根据上一步得到的A1、B1、B2和3个应变速率下应力应变数据点,绘制 -

- 散点图,采用一次多项式进行线性拟合如图5所示,即可确定C1。

散点图,采用一次多项式进行线性拟合如图5所示,即可确定C1。

图5  -

- 线性拟合曲线

线性拟合曲线

Fig. 5  -

- linear fitting curve

linear fitting curve

3) 将公式(2)转换成如下形式:

(6)

(6)

对式(6)两边取对数:

(7)

(7)

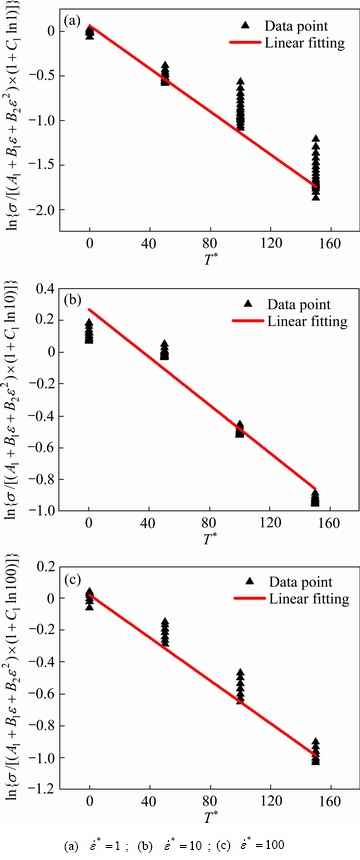

将3个应变速率与4个变形温度下的所有应力应变数据点代入式(7),绘制每个应变速率下的 -T*散点图,采用一次多项式进行线性拟合如图6所示,可确定

-T*散点图,采用一次多项式进行线性拟合如图6所示,可确定 在3个应变速率下的值。绘制

在3个应变速率下的值。绘制 -

- 散点图,进行线性拟合如图7所示,可确定

散点图,进行线性拟合如图7所示,可确定 和

和 。根据上述步骤得到的材料参数如表2所示。

。根据上述步骤得到的材料参数如表2所示。

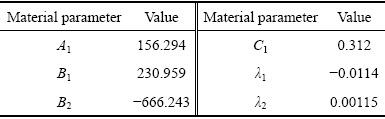

表2 改进JC模型的材料参数[16]

Table 2 Material parameters of improved JC model[16]

改进的JC本构模型如下:

图6 在不同应变速率下 - T*线性拟合曲线

- T*线性拟合曲线

Fig. 6  -T* linear fitting curves at different strain rates: (a)

-T* linear fitting curves at different strain rates: (a)  ; (b)

; (b)  ; (c)

; (c)

2.2.2 本文修正的Johnson Cook本构模型

图7 λ- 线性拟合曲线

线性拟合曲线

Fig. 7 λ- linear fitting curve

linear fitting curve

原始的JC本构模型和LIN等[16]改进的模型在给定的参考应变速率和温度下确定了应变项常数,该方法限制了材料常数在不同变形条件下的适用性。基于LIN等[16]改进的JC本构模型的应变硬化项,本文将每个条件下的塑性变形阶段的流动应力曲线用如下公式进行拟合:

(8)

(8)

式中: 为真实应力,MPa;

为真实应力,MPa; 为真实应变。

为真实应变。

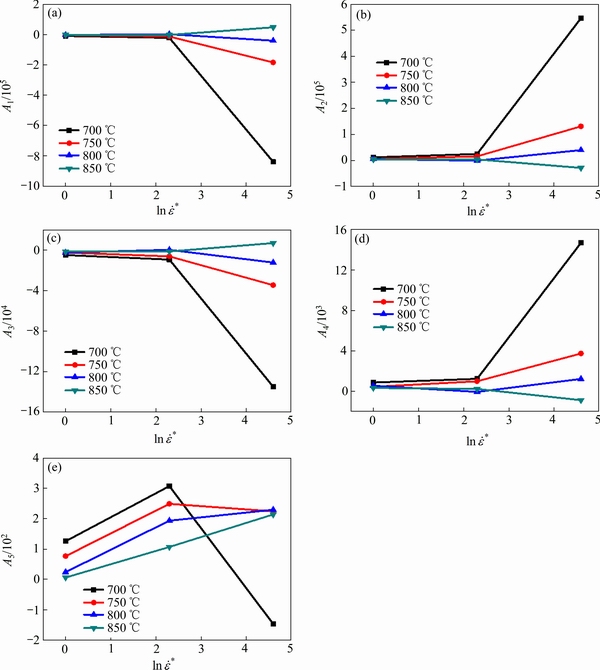

公式(8)中的参数Ai可以用于表征应变速率硬化效应和热软化效应。取0.001 s-1为参考应变速率,可得每个参数Ai与 的关系图如图8所示,其中

的关系图如图8所示,其中 。

。

在每个温度下,采用多项式方程拟合Ai与 的数据点,Ai可以被描述成下式:

的数据点,Ai可以被描述成下式:

(9)

(9)

取参考温度为973 K(700 ℃),熔点温度为1941 K, 可以计算每个温度下的

。

。

图8 Ai- 曲线

曲线

Fig. 8 Ai- curves

curves

式(9)中的参数Aij可看作是关于温度的函数,用式(10)进行描述:

(10)

(10)

从上述可看出,应变硬化效应、应变速率硬化效应和热软化效应得到耦合,本文提出的修正的JC本构模型可描述如下:

,

, ,

, (11)

(11)

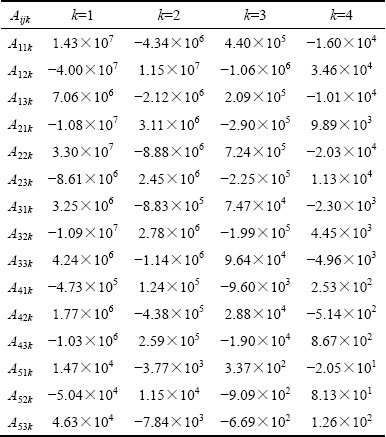

根据上述提出修正的JC本构模型,采用Matlab软件进行编程,将实验得到的应力应变数据输入到程序中,得到的材料参数如表3所示。

2.3 模型的准确性分析

表3 修正的JC本构模型的材料参数

Table 3 Material parameters of modified JC constitutive model

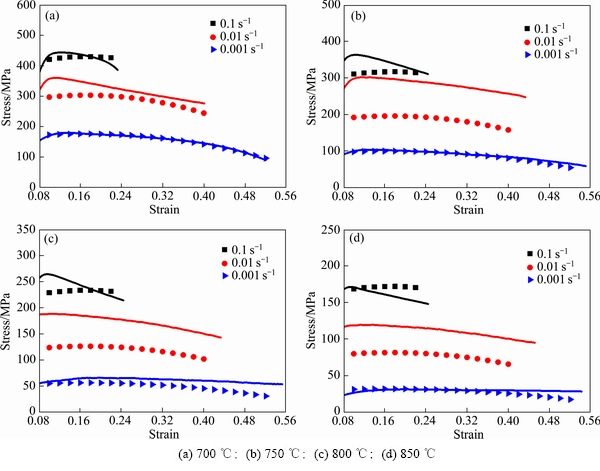

图9 采用LIN等[16]改进的JC本构模型的预测结果(点)与实验数据(曲线)的对比

Fig. 9 Comparison of prediction results (points) and experimental data (curves) of improved JC constitutive model by LIN et al[16]

图10 采用修正的JC本构模型的预测结果(点)与实验数据(曲线)的对比

Fig. 10 Comparison of prediction results (points) and experimental data (curves) of modified JC constitutive model in this work

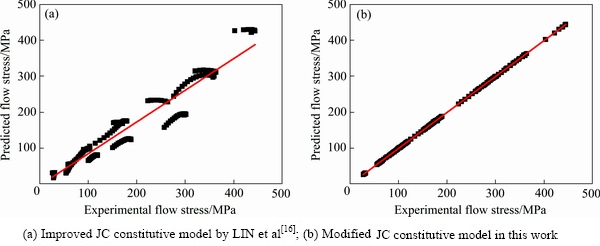

图11 实验与预测应力关系图

Fig. 11 Correlation between experimental and predicted stresses

为了说明LIN等[16]改进的JC本构模型与本文修正的JC本构模型的预测精度,将两种模型的预测应力与实验获得的应力应变曲线进行对比,如图9和10所示。从图9中可以看出,LIN等[16]改进的JC本构模型由于限制了应变项常数在不同变形条件下的适用性,导致只有在参考温度和参考应变速率下有较高的预测精度:随着温度的升高和应变速率的增大,预测结果和该条件下的应力应变曲线之间均出现不同程度的偏差。而本文修正的JC本构模型,综合考虑了应变硬化效应、应变速率硬化效应和热软化效应的影响,不同变形条件下的预测结果与该条件下的应力应变曲线之间吻合度较高。为了进一步说明两种模型的精度,将模型预测的应力与实验所得的应力绘制在同一坐标系下,如图11所示,并采用相关系数R2(见式(12))和平均相对误差 (见式(13))来衡量模型相对于实际实验结果的准确性。LIN等[16]改进的JC本构模型R2和

(见式(13))来衡量模型相对于实际实验结果的准确性。LIN等[16]改进的JC本构模型R2和 分别为0.92754和0.15159,而本文修正的JC本构模型R2和

分别为0.92754和0.15159,而本文修正的JC本构模型R2和 分别为0.9995和0.002995。对比以上结果和图9~11可以看出,本文修正的JC模型的预测结果更准确,得到的预测结果相对于LIN等[16]改进的JC本构模型更为可靠。

分别为0.9995和0.002995。对比以上结果和图9~11可以看出,本文修正的JC模型的预测结果更准确,得到的预测结果相对于LIN等[16]改进的JC本构模型更为可靠。

(12)

(12)

(13)

(13)

3 结论

1) TA12钛合金在700~850 ℃范围内,应变速率为0.001~0.1 s-1的条件下,在变形的初始阶段,材料的加工硬化现象占主导地位,流变应力随应变的增加而逐渐增大,达到峰值应力后又逐渐减小,直至材料发生断裂,并在850 ℃和0.001 s-1的变形条件下,出现了稳态流动应力。

2) TA12钛合金的高温流变行为明显受到变形温度和应变速率的影响,在相同的变形程度下,材料的流变应力随着温度的升高和应变速率的减小而减小。

3) 综合考虑应变硬化效应、应变速率硬化效应和热软化效应的影响,提出了一种修正的JC本构模型:

,

, ,

,

该模型的预测结果与实验得到的TA12钛合金应力应变曲线吻合度较高,其相关系数达到0.9995,平均相对误差为0.002995,优于LIN等[16]提出的改进的JC模型,预测结果更为可靠。

REFERENCES

[1] 王清江, 刘建荣, 杨 锐. 高温钛合金的现状与前景[J]. 航空材料学报, 2014, 34(4): 1-26.

WANG Qing-jiang, LIU Jian-rong, YANG Rui. High temperature titanium alloys: Status and perspective[J]. Journal of Aeronautical Materials, 2014, 34(4): 1-26.

[2] 方 波, 程 明, 陈仲强, 刘军和, 刘 艳, 冯贞伟, 宋玺玉, 魏明霞, 胡井祥. TA12钛合金板材成形性能试验[J]. 精密成形工程, 2011(4): 1-3.

FANG Bo, CHENG Ming, CHEN Zhong-qiang, LIU Jun-he, LIU Yan, FENG Zhen-wei, SONG Xi-yu, WEI Ming-xia, HU Jing-xiang. Research on the formability of TA12 titanium alloy sheet[J]. Netshape Forming Engineering, 2011(4): 1-3.

[3] 龚志强, 刘 宇. Ti55钛合金机械加工性能研究[C]// “航空航天先进制造技术”学术交流论文集. 南京: 江苏省科学技术协会学会学术部, 2010: 29-32.

GONG Zhi-qiang, LIU Yu. Research on mechanical machinability of Ti55 titanium alloy[C]// “Aerospace Advanced Manufacturing Technology” Academic Exchange Proceedings. Nanjing: Acadamic Department of Jiangsu Association of Science and Technology, 2010: 29-32.

[4] 东赟鹏, 于秋颖, 方 爽, 王淑云, 王超渊, 宋晓俊. TA7钛合金高温流变行为研究[J]. 航空材料学报, 2015, 35(1): 13-19.

DONG Yun-peng, YU Qiu-ying, FANG Shuang, WANG Shu-yun, WANG Chao-yuan, SONG Xiao-jun. Plastic deformation behavior of TA7 titanium alloy[J]. Journal of Aeronautical Materials, 2015, 35(1): 13-19.

[5] CUI Jun-hui, YANG He, SUN Zhi-zhao, LI Hong-wei, LI Zhi-jun, SHEN Chang-wu. Flow behavior and constitutive model using piecewise function of strain for TC11 alloy[J]. Rare Metal Materials & Engineering, 2012,41(3): 397-401.

[6] LI Hong-yi, LI Yang-hua, WANG Xiao-feng, LIU Jiao-jiao, WU Yue. A comparative study on modified Johnson Cook, modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict the hot deformation behavior in 28CrMnMoV steel[J]. Materials & Design, 2013, 49(Complete): 493-501.

[7] GUPTA A K, ANIRUDH V K, SINGH S K. Constitutive models to predict flow stress in Austenitic Stainless Steel 316 at elevated temperatures[J]. Materials & Design, 2013, 43: 410-418.

[8] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures[C]// Proceedings of the 7th International Symposium on Ballistics. The Hague, 1983: 541-547.

[9] LI Hong-ying, WANG Xiao-feng, DUAN Jun-ying, LIU Jiao-jiao. A modified Johnson Cook model for elevated temperature flow behavior of T24 steel[J]. Materials Science & Engineering A, 2013, 577: 138-146.

[10] 赵子博, 葛敬鲁, 陈志勇, 王清江, 刘建荣. Ti-55钛合金板材的超塑性变形行为[J]. 中国有色金属学报, 2010, 10(S1): s847-s851.

ZHAO Zi-bo, GE Jing-lu, CHEN Zhi-yong, WANG Qing-jiang, LIU Jian-rong. Superplastic deformation of Ti-55 alloy Sheet[J]. The Chinese Journal of Nonferrous Metals, 2010, 10(S1): s847-s851.

[11] 刘章光, 李建辉, 李培杰, 高海涛, 熊亮同. Ti-55钛合金板材的超塑性变形及组织演变[J]. 稀有金属, 2017, 41(12): 1285-1292.

LIU Zhang-guang, LIJian-hui, LI Pei-jie, GAO Hai-tao, XIONG Liang-tong. Superplastic deformation and microstructure evolution of Ti-55 alloy sheet[J]. Chinese Journal of Rare Metals, 2017, 41(12): 1285-1292.

[12] 张秉刚, 陈国庆, 郭栋杰, 刘成来. 高温钛合金Ti55/Ti60真空电子束焊接[J]. 焊接学报, 2009, 30(12): 5-8.

ZHANG Bing-gang, CHEN Guo-qing, GUO Dong-jie, LIU Cheng-lai. High temperature titanium alloy Ti55/Ti60 vacuum electron beam welding[J]. Transactions of the China Welding Institution, 2009, 30(12): 5-8.

[13] LIU Zhang-guang, LI Pei-jie, XIONG Liang-tong, LIU Tai-yi, HE Liang-ju. High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy[J]. Materials Science & Engineering A, 2017, 680: 259-269.

[14] 方 波, 程 明, 陈仲强, 王清江, 冯贞伟, 孙铁峰, 刘 艳, 宋玺玉, 魏明霞, 胡井祥, 吕晶晶. Ti55钛合金的热压缩变形及其本构方程[J]. 中国有色金属学报, 2013, 12(s1): 600-604.

FANG Bo, CHEN Zhi-yong, CHEN Zhong-qiang, WANG Qing-jiang, FENG Zhen-wei, SUN Tie-feng, LIU Yan, SONG Xi-yu, WEI Ming-xia, HU Jing-xiang, LU Jing-jing. Hot compression deformation and its constitutive equation of Ti55 alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 12(s1): 600-604.

[15] 袁武华, 卢 政, 齐占福, 熊运森. TA15钛合金热变形本构方程及热加工图[J]. 热加工工艺, 2017, 46(17): 41-45, 50.

YUAN Wu-hua, LU Zheng, QI Zhan-fu, XIONG Yun-sen. Constitutive equation and hot processing map for hot deformation of TA15 titanium alloy[J]. Hot Working Technology, 2017, 46(17): 41-45, 50.

[16] LIN Y C, CHEN X M, LIU G. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel[J]. Materials Science & Engineering A, 2010, 527(26): 6980-6986.

[17] HE An, XIE Gan-lin, ZHANG Hai-long, WANG Xi-tao. A comparative study on Johnson-Cook, modified Johnson-Cook and Arrhenius-type constitutive models to predict the high temperature flow stress in 20CrMo alloy steel[J]. Materials & Design, 2013, 52(24): 677-685.

[18] 李建光, 施 琪, 曹结东. Johnson-Cook本构方程的参数标定[J]. 兰州理工大学学报, 2012, 38(2): 164-167.

LI Jian-guang, SHI Qi, CAO Jie-dong. Parameters calibration for Johnson-Cook constitutive equation[J]. Journal of Lanzhou University of Technology, 2012, 38(2): 164-167.

Flow behavior of TA12 titanium alloy based on modified JC model at high temperature

YE Jian-hua1, CHEN Ming-he1, WANG Ning1, XIE Lan-sheng2

(College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210001, China)

Abstract: In order to study the flow behavior of TA12 titanium alloy at high temperature and set up the constitutive model that accurately describes its flow behavior at high temperature, the tensile tests at the temperatures of 700-850 ℃ and at strain rates of 0.001-0.1 s-1 were carried out. The results show that, under the deformation conditions, the flow stress increases with the increase of strain, and then decreases gradually after reaching the peak stress until the material breaks and the steady flow stress occurs at 850 ℃ and 0.001 s-1. Considering the effects of strain hardening, strain rate hardening and thermal softening, a modified JC constitutive model was proposed. It can accurately describe the flow behavior of TA12 titanium alloy at high temperature.

Key words:TA12 titanium alloy; high temperature flow behavior; constitutive model

Received date: 2018-04-11; Accepted date: 2018-06-11

Corresponding author: CHEN Ming-he; Tel: +86-13951809276; E-mail: meemhchen@nuaa.edu.cn

(编辑 李艳红)

收稿日期:2018-04-11;修订日期:2018-06-11

通信作者:陈明和,教授,博士;电话:13951809276;E-mail:meemhchen@nuaa.edu.cn