基于Fluent非稳态模型工作辊精细冷却参数研究

曹建国1,覃业均1,张杰1,宋木清2,宫贵良2,彭强 2

(1. 北京科技大学 机械工程学院,国家板带生产先进装备工程技术研究中心,北京,100083;

2. 武汉钢铁(集团)公司,湖北 武汉,430083)

摘要:为了提高宽幅冷轧薄板板形尤其是边中复合浪等高次复杂浪形的控制能力,研究工作辊精细冷却喷射梁的结构参数及其安装尺寸对精细冷却效果的影响。采用流体建模软件ANSYS Fluent建立工作辊精细冷却的三维VOF非稳态模型,分析精细冷却喷嘴孔口特征比、喷嘴到工作辊距离和喷嘴之间的距离对工作辊冷却效果的影响。仿真结果表明:喷嘴孔口特征比较小时,射流轴线速度衰减慢;利用射流在特征衰减区的特性合理控制冷却喷射梁喷嘴与工作辊之间的距离可提高精细冷却效率;喷嘴间距适度减小可使控制区域的工作辊温度场冷却效果更均匀并提高精细冷却效率。

关键词:冷轧;轧辊;板形;精细冷却;有限元分析;数学模型

中图分类号:U441+4 文献标志码:A 文章编号:1672-7207(2011)12-3742-06

Numerical study on parameters of multi-zone cooling for work roll based on unsteady VOF model of Fluent

CAO Jian-guo 1, QIN Ye-jun1, ZHANG Jie1, SONG Mu-qing2, GONG Gui-liang2, PENG Qiang2

(1. National Engineering Research Center of Flat Rolling Equipment, School of Mechanical Engineering,

University of Science and Technology Beijing, Beijing 100083, China;

2. Wuhan Iron & Steel (Group) Corp., Wuhan 430083, China)

Abstract: In order to enhance the controllability of profile and flatness for ultra-wide cold-rolled strip, especially the complex waves such as the center buckle with edge wave, the effect of the structural parameters and assembly dimensions of spray header of multi-zone cooling on the coefficient of heat transfer and the temperature distribution of work rolls was studied. The 3-Dimensional unsteady VOF models were built up by ANSYS Fluent flow modeling software to simulate and analyze the multi-zone cooling performances according to the different parameters such as the characteristic ratio of nozzle outlet, the distance dimension between nozzle and work roll (WR) and the distance dimension between adjacent nozzles. The results show that the axis velocity of jet flow drops slowly with a smaller characteristic ratio of nozzle outlet. To determine the distance reasonably between nozzles and work rolls is an effective way to increase the multi-zone cooling efficiency by taking advantage of the cooling performance in characteristic decay region. The uniform cooling effect on the desired partial zones of WR temperature field can be obtained by a smaller distance between adjacent nozzles that is another effective way to increase the multi-zone cooling efficiency.

Key words: cold rolling; roll; flatness; multi-zone cooling; finite element analysis; mathematical model

随着汽车、家电等工业用户自身自动化水平和节能要求不断提高,冷轧薄板板形质量要求日趋严格,且随着宽幅冷轧薄板生产规模的增加,对大型冷轧机冷轧薄板的高次复杂浪形等板形控制能力要求日益提高。如某2180超宽冷连轧机轧制的宽幅冷轧薄板板形平坦度综合值控制效果好,但带钢的边中复合浪、高次复合浪、双侧小边浪和1/4浪等高次浪形缺陷难以有效消除。传统的板形调控手段如弯辊、窜辊和特殊辊形设计等手段虽然对控制对称浪形效果显著[1-7],但是,从理论和现有应用的情况来看,精细冷却是解决高次浪形的有效手段[8-10]。Azene等[11]研究了基于冷却特性的热轧轧辊冷却系统设计。赵永和[12]根据给定工作辊入口和出口各两排喷射梁等工艺条件,采用二维有限差分法计算温度场和分段冷却板形控制研究。华建新等[13-14]研究了精细冷却在线控制策略。王训宏等[15]研究了轧辊精细冷却的组成、特点和控制要求。Ginzburg[16]设计了距离可调的轧机上工作辊和带钢冷却系统。目前关于精细冷却喷射梁与工作辊相关的尺寸参数对冷却效果影响的研究很少。因此研究精细冷却喷射梁的结构参数及其安装尺寸对精细冷却效果的影响具有重要理论意义和实践价值。

1 工作辊精细冷却的影响因素

与冷却液和工作辊材料的物性参数和工作辊表面形貌相比,冷轧工作辊精细冷却(见图1)的喷射梁参数如喷嘴本身的出水口特征比e、喷嘴到工作辊的距离D、喷嘴之间的距离L、喷射压力以及喷射流量等来不易受其他条件制约,是最容易改变的参数,同时对精细冷却效果有直接影响。利用流体分析软件ANSYS Fluent建立两相流射流冷却工作辊的非稳态模型,求解表面换热系数和轧辊的表面温度场,以此作为判断冷却效果的依据,研究3个尺寸参数e,D和L对精细冷却的影响规律。

图1 宽带钢冷轧机工作辊精细冷却示意图

Fig.1 Schematic diagram of multi-zone cooling for work rolls of wide strip cold rolling mills

2 工作辊精细冷却模型的建立

2.1 非稳态模型建立与边界条件

利用Fluent 的前处理软件Gambit按喷嘴与工作辊距离D,工作辊直径Φ=600 mm,取辊身长度的一段Lroll=260 mm来建立模型。

因为读取的表面换热系数是某一瞬间值,只求换热系数时设定工作辊恒温;求冷却极短的时间内直接冷却区域轧辊表面处的温度,所以没有必要给工作辊增加轧制速度,提高了求解的稳定性。由于现场精细冷却的射流速度一般是通过压力表来调节,因此,以压力作为射流初始边界条件。1700宽带钢冷连轧机轧辊冷却液实测温度约为29 ℃[17],建模时取冷却液与空气温度为300 K;1700宽带钢冷连轧机工作辊实测温度为48~52 ℃[17],2030宽带钢冷连轧机工作辊实测温度为47~56 ℃,建模时取工作辊温度为50 ℃。模型的边界设定如表1和表2所示。

表1 仿真工况参数

Table 1 Parameters of working conditions for simulation

表2 工作辊和冷却液物理参数

Table 2 Physical parameters of working roll and coolant

2.2 非稳态模型的控制方程

研究的流体介质是乳化液,其在流动过程中与工作辊进行强迫对流换热。乳化液在流动过程中,雷诺数Re>12 000,属于湍流流动状态。分析时忽略它的可压缩性,即认为其密度是常数,因此,流体的流动可视为非定常不可压缩黏性流体的湍流流动,流体的流动应满足如下控制方程[18]。

不可压缩定常流体的质量守恒方程(连续方程):

(1)

(1)

动量守恒方程(Navier-Stokes运动方程):

(2)

(2)

能量守恒方程:

(3)

(3)

可实现k-ε模型中k和ε的输运方程:

(4)

(4)

(5)

(5)

(6)

(6)

式中: ;

; ;u,v,w分别为速度在x,y和z方向的分量;p为流体微元体上的压力;τxx,τxy和τxz为因分子黏性作用而产生的作用在微元体表面上的黏性应力的分量;Fx,Fy和Fz为微元体上的体力,若体力只有重力,且z 轴竖直向上,则Fx=0,Fy=0,Fz=-ρg;cp为比热容;T 为热力学温度;ST为流体的内热源及由于黏性作用流体机械能转换为热能的部分;σk=1.0;σε=1.2;C2=1.9;

;u,v,w分别为速度在x,y和z方向的分量;p为流体微元体上的压力;τxx,τxy和τxz为因分子黏性作用而产生的作用在微元体表面上的黏性应力的分量;Fx,Fy和Fz为微元体上的体力,若体力只有重力,且z 轴竖直向上,则Fx=0,Fy=0,Fz=-ρg;cp为比热容;T 为热力学温度;ST为流体的内热源及由于黏性作用流体机械能转换为热能的部分;σk=1.0;σε=1.2;C2=1.9; ;k为湍动能;ε为湍动耗散率;μt为湍动黏度;Gk为平均速度梯度引起的湍动能k的产生项;Eij为时均应变率;i=1,2,3,j=1,2,3。

;k为湍动能;ε为湍动耗散率;μt为湍动黏度;Gk为平均速度梯度引起的湍动能k的产生项;Eij为时均应变率;i=1,2,3,j=1,2,3。

3 精细冷却仿真分析

3.1 出水口特征比对冷却效果的影响

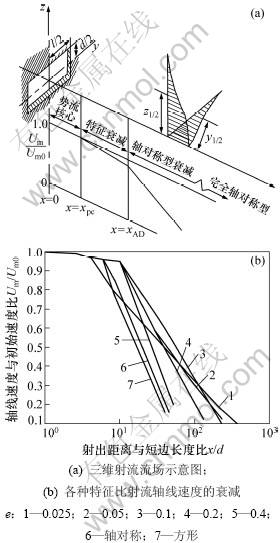

精细冷却喷嘴近似长矩形,可简化成矩形讨论。图2所示为三维射流流场变化规律。定义孔口特征比e=d/l(图2(a)),以反映孔口形状的特征,l和d分别表示孔口断面的长轴和短轴。为提供可比性,设计特征比分别为e=2/15,3/10,5.48/5.48的孔口,即出口(outlet)面积都为30 mm2,再设置相同喷射压力(即初速度v基本相等),以相同的初始动量(m×v)进行单股射流仿真。

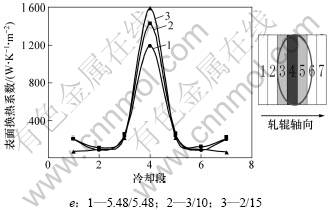

把射流喷射的轧辊曲面分成7小段,每段轴向宽度为10 mm,周向弧面长度为150 mm,第4段为喷嘴正射位置,取每一小曲面的面平均换热系数。图3所示为不同孔口特征比的换热系数对比。由图3可见:不同孔口特征比的轧辊都是轴线处的换热系数最大,往两侧减少,两者相差可达8倍多。根据射流理论(如图2(b)所示),特征比越小的孔口,轴线速度衰减越慢,越接近圆形孔口,其轴线速度在特征衰减区内衰减急剧。所以特征比比较小的孔口可获得一个较大冲击的轴线速度,强迫换热能力增强,此时轴线处的换热系数最大,即冷却效果最好。实际应用中,还得兼顾喷嘴的结构尺寸和喷射流量限制,适当选择孔口特征比。

图2 三维射流流场变化规律

Fig.2 Flow performance of three-dimension jet flow

图3 不同孔口特征比的换热系数对比

Fig.3 Coefficient of heat transfer of different characteristic ratio of nozzle outlet

3.2 喷嘴到轧辊距离对冷却效果的影响

当喷嘴到工作辊距离D分别为110,120,140,160,180,200 mm时进行仿真计算,仿真结果见图4。由图4可见:当D为110~160 mm时,表面换热系数变化不大,即这段距离内的换热效果基本一致,当距离增大到180 mm时,换热系数减少明显。

图4 不同的喷射距离对换热的影响

Fig.4 Effect of dimension on cooling performance

根据射流理论分析(图2(a)),三维射流可分为3个区域:势流核心区(Potential core region),特征衰减区(Characteristic decay region)和轴对称衰减区(Axisymmetric type decay region)。当D不大于160 mm时,射流还处于特征衰减区内,此阶段射流形状还保持一定的孔口特征、轴线速度衰减慢,所以换热系数变化不大。当D继续增大,射流进入轴对称衰减区域后,冷却液与空气摩擦往外扩散,喷射到轧辊的速度明显减少,强迫对流换热效果变差。所以,从仿真结果看,喷嘴与工作辊距离D<160 mm,即射流控制在特征衰减区内换热效果最好。

3.3 喷嘴之间的距离对冷却效果的影响

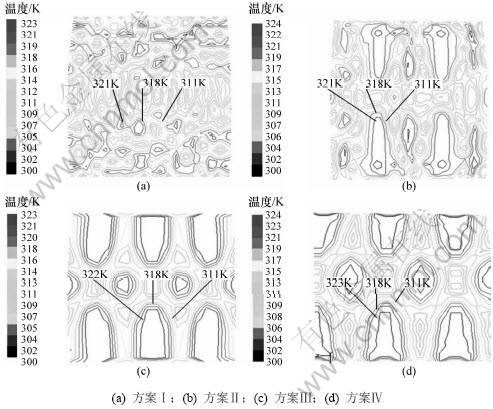

由于喷嘴之间的距离L较大时喷嘴数量减少,当其他条件一样时,冷却液流量减少,理论上冷却效果差。宝钢2030 冷轧板形控制系统设计的喷嘴间距为52 mm[14],LECHLER公司提供的喷射梁安装尺寸一般为78 mm以上。为进一步研究喷嘴之间的间距L对冷却效果与冷却均匀性的影响,以相同的孔口特征(等比例放大)、相同的初始动量(喷射孔口总面积和喷射初始速度相等) 设计实验方案,方案如表3所示。

表3 以相同的孔口特征设计不同的仿真方案

Table 3 Different models designed with the same outlet characteristic ratio

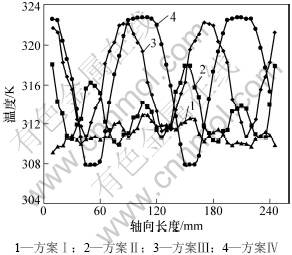

图5所示为冷却1.2 s时轧辊表面的温度场;图6所示为冷却1.2 s,喷射梁正对的工作辊表面轴向温度变化情况。

射流以相同的初始动量冷却轧辊,当L较大,如方案Ⅲ和Ⅳ,射流冲击区冷却很快,往两侧的壁面射流区和上喷形成区的温度几乎没有减少,温度差约14 ℃;当L较小,如方案Ⅰ和Ⅱ,射流之间有干涉,两股射流之间的壁面射流区和上喷形成区被压缩,射流直接冲击区增大,轧辊的目标控制区段内冷却更均匀,温度差约4 ℃。而且方案Ⅰ比方案Ⅳ的表面平均温度低约5 ℃,总体冷却前者要比后者快。降低整体热凸度稳定部分对板形的影响可通过弯辊、窜辊等措施快速实现,而精细冷却通过冷却液有计量地冷却工作辊的局部以提高冷却效率,改变工作辊的局部热凸度,从而达到减少或消除宽薄带钢的高次浪形缺陷的目的。很显然,当工作辊局部温度需要快速地降低以减少局部热凸度时,喷嘴间距L较小的喷射梁方案对工作辊局部凸度控制响应迅速,在如今高速轧制的情况下,更能提高高次浪形的板形控制能力。

图5 不同喷嘴间距下喷射区的轧辊温度分布情况

Fig.5 Temperature field of work roll surface cooled by jet with different dimensions

图6 轧辊表面冷却温度分布

Fig.6 Temperature distribution of surface of work roll

4 结论

(1) 建立FLUENT两相流的非稳态模型,得到影响因素复杂的表面换热系数和轧辊的温度场的数值求解方法。

(2) 喷嘴孔口特征比较小时,射流轴线速度衰减慢,精细冷却效果好;喷嘴到工作辊距离设定在射流的特征衰减区内有利于提高工作辊的精细冷却能力;在相同的射流初始动量的情况下,喷嘴之间的距离适当减少,工作辊的冷却速度更快,冷却更均匀。结合实际情况,综合考虑这3个参数e,D,L设计安装喷射梁,通过精细冷却而提高工作辊局部凸度控制能力从而有效减少板带的高次浪形缺陷。

参考文献:

[1] Arif A F M, Khan O, Sheikh A K. Roll deformation and stress distribution under thermo-mechanical loading in cold rolling[J]. Journal of Materials Processing Technology, 2004, 147: 255-267.

[2] 杨光辉, 曹建国, 张杰, 等. SmartCrown四辊冷连轧机工作辊辊形[J]. 北京科技大学学报, 2006, 28(7): 669-671.

YANG Guang-hui, CAO Jian-guo, ZHANG Jie, et al. SmartCrown work roll contour of a 4-hi tandem cold rolling mil[J]. Journal of University of Science and Technology Beijing, 2006, 28(7): 669-671.

[3] Seilinger A, Mayrhofer A, Kainz A. SmartCrown—a new system for improved profile & flatness control in strip mills[J]. Aluminium International Today, 2003, 15(2): 26-28.

[4] WANG Xiao-dong, YANG Quan, HE An-rui, et al. Comprehensive contour prediction model of work rolls in hot wide strip mill[J]. Journal of University of Science and Technology Beijing: Mineral, Metallurgy, Material, 2007, 14(3): 130-146.

[5] CAO Jian-guo, ZHANG Jie, YANG Guang-hui, et al. Comprehensive edge drop control technology of non-oriented electrical steel strip in 4-high ECC tandem cold rolling mills[C]//WENG Yu-qing. Proceedings of the 10th International Conference on Steel Rolling. Beijing: Metallurgical Industry Press, 2010: 1065-1073.

[6] 王澜, 曹建国, 贾生晖, 等. 冷轧带钢板形屈曲变形失稳限的有限元分析[J]. 中南大学学报: 自然科学版, 2007, 38(6): 1157-1161.

WANG Lan, CAO Jian-guo, JIA Sheng-hui, et al. Finite element analysis of shape buckling load for cold rolled strips[J]. Central South University: Science and Technology, 2007, 38(6): 1157-1161.

[7] ZHAO Ning-tao, CAO Jian-guo, ZHANG Jie, et al. Work roll thermal contour prediction model of non-oriented electrical steel sheets in hot strip mills[J]. Journal of University of Science and Technology Beijing: Mineral, Metallurgy, Materials, 2008, 15(6): 352-356.

[8] Atack P A, Robinson I S. An investigation into the control of thermal camber by spray cooling when hot rolling aluminium[J]. Journal of Material Processing Technology, 1994, 45(1/2/3/4): 125-130.

[9] Hartung H G, Holz R, Pawelski H. Increased yield of cold strip through the EDC system[J]. Metal, 2000, 54(10): 581-585.

[10] 刘宏民, 贾春玉, 单修迎. 智能方法在板形控制中的应用[J].燕山大学学报, 2010, 34(1): 1-5.

LIU Hong-min, JIA Chun-yu, SHAN Xiu-ying. Application of intelligent methods in flatness control[J]. Journal of Yanshan University, 2010, 34(1): 1-5.

[11] Azene Y T, Roy R, Farrugia D, et al. Work roll cooling system design optimization in presence of uncertainty and constrains[J]. CIRP Journal of Manufacturing Science and Technology, 2010(2): 290-298.

[12] 赵永和. 分段冷却控制板形的理论研究[D]. 秦皇岛: 燕山大学机械工程学院, 2000: 18-26.

ZHAO Yong-he. Theoretical study on the shape control by coolant spray distribution[D]. Qinhuangdao: Yanshan University. School of Mechanical Engineering, 2000: 18-26.

[13] 华建新, 金以慧, 吴文斌. 冷轧板形控制中的精细冷却控制[J]. 冶金自动化, 2002, 26(1): 41-44.

HUA Jian-xin, JIN Yi-hui, WU Wen-bin. Spray cooling control in flatness control on cold rolling mill[J]. Metallurgical Industry Automation, 2002, 26(1): 41-44.

[14] 王骏飞. 冷连轧机乳化液分段冷却控制方法. 中国: CN101683660[P]. 2010-03-31.

WANG Jun-fei. A control method of multi-zone cooling for cold tandem rolling mill. China: CN101683660 [P]. 2010-03-31.

[15] 王训宏, 李有元, 王勇, 等. 冷轧机组不对称高次浪形的控制[J]. 轧钢, 2008, 25(3): 25-27.

WANG Xun-hong, LI You-yuan, WANG Yong, et al. Control of asymmetric higher order flatness in cold rolling mill[J]. Steel Rolling, 2008, 25(3): 25-27.

[16] Ginzburg V B. Roll and strip cooling system for rolling mills. United States: US5517842[P]. 1996-05-21.

[17] 贾生晖. 变凸度冷连轧机辊形及板形的研究[D]. 北京: 北京科技大学机械工程学院, 2005: 68-76.

JIA Sheng-hui. Study on roll contour and strip flatness of variable crown tandem cold rolling mills[D]. Beijing: University of Science and Technology Beijing. School of Mechanical Engineering, 2005: 68-76.

[18] 张少军, 胡树山, 刘国勇, 等. 基于Fluent的无缝钢管控制冷却喷嘴布置参数[J]. 北京科技大学学报, 2010, 32(1): 123-127.

ZHANG Shao-jun, HU Shu-shan, LIU Guo-yong, et al. Layout parameters of controlled cooling nozzles for seam less pipes based on Fluent software[J]. Journal of University of Science and Technology Beijing, 2010, 32(1): 123-127.

(编辑 赵俊)

收稿日期:2010-11-11;修回日期:2011-03-29

基金项目:国家自然科学基金资助项目(59835170);北京科技大学科技发展专项基金资助项目(20050311890)

通信作者:曹建国(1971-),男,湖南衡山人,教授,博士生导师,从事板带轧机板形控制、轧制技术及自动化研究;E-mail:geocao@ustb.edu.cn