DOI: 10.11817/j.issn.1672-7207.2019.07.011

新一代高技术宽带钢冷轧机全机组一体化板形控制

曹建国1,2,3,江军1,2,3,邱澜1,2,3,李艳琳1,何安瑞2,4,张勇军2,4

(1. 北京科技大学 机械工程学院,北京,100083;

2. 北京科技大学 国家板带生产先进装备工程技术研究中心,北京,100083;

3. 北京科技大学 人工智能研究院,北京,100083;

4. 北京科技大学 高效轧制国家工程研究中心,北京,100083)

摘要:针对新一代高技术宽带钢冷轧机冷轧薄板高精度板形质量边降、凸度、同板差和平坦度等多指标日趋严苛难题,结合生产实践分析宽带钢冷轧机国际主流机型及其板形控制特点,提出宽带钢冷连轧“门户机架”“中间机架组”和“成品机架”全机组一体化板形控制策略。研究结果表明:从四辊和六辊冷轧机的凸度和边降构成特征可知,四、六辊轧机轧辊压扁的不均匀变形和“有害接触区”弯矩在带钢凸度和边降构成均占主要比例,四辊轧机板形控制能力随着宽度的增加而显著增强,且对四辊和六辊轧机高精度一体化板形控制应采取明显不同的实现途径。

关键词:冷轧;轧机机型;带钢;板形控制;边降控制

中图分类号:TG333.72 文献标志码:A 文章编号:1672-7207(2019)07-1584-08

High precision integrated profile and flatness control for new-generation high-tech wide strip cold rolling mills

CAO Jianguo1,2,3, JIANG Jun1,2,3, QIU Lan1,2,3, LI Yanlin1, HE Anrui2,4, ZHANG Yongjun2,4

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. National Engineering Research Center of Flat Rolling Equipment, University of Science and Technology Beijing, Beijing 100083, China;

3. Institute of Artificial Intelligence, University of Science and Technology Beijing, Beijing 100083, China;

4. National Engineering Research Center for Advanced Rolling Technology, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Aiming at the severe problem of the increasingly high precision cold rolled sheet profile and flatness quality requirement with multi-index edge drop, crown, transverse thickness deviation and flatness for the new generation of high-tech wide strip cold rolling mill, the leading mainstream mill types and its shape control characteristics were analyzed based on producing practice, the whole units and integration of “gate stand”, “intermediate stand group” and “final product stand” shape control strategy of wide strip tandem cold rolling was proposed. The results show that the composing characteristics of the edge drop and crown of 4-high and 6-high cold rolling mills show that the uneven deformation of rolls flattening and the deflection of work rolls caused by the pressure in undesired overhung contact areas between rolls are the main contributions to the strip crown and edge drop ratio. It is found that the profile and flatness controllability must be enhanced significantly with the increasement of the strip width in 4-high rolling mills, and the distinctly different approaches to high precision integrated profile and flatness control should be adopted in the 4-high and 6-high rolling mills.

Key words: cold rolling; mill type; strip; profile and flatness control; edge drop control

冷轧薄带钢产品在国民基础设施建设中具有重要作用,由于宽带钢后续加工方式主要为精密成形制造,对冷轧带钢不仅有日趋严苛的板形质量要求,而且有远超过其他轧制产品的质量均一性要求。带钢的板形主要包括平坦度和横截面外形,边降(也称边部减薄,edge drop)、凸度(crown)和同板差(transverse thickness deviation)是横截面外形的主要质量指标。严格控制轧制过程中带钢的边降、凸度和同板差,实现带钢横截面形状的“矩形化”,是冷轧薄带钢产品关键的板形质量要求,也是板形控制研究和实践的前沿领域及关键难点之一[1]。国际上,CVC,SmartCrown,T-WRS,T-WRS&C,ECC,HC/UC和VCMS等多种新型薄带冷轧机机型竞相出现,被称为“新一代高技术轧机”。上述各种新机型的名称,实际上就是所采用的新的板形技术的名称,国内外针对新一代冷轧机板形控制技术进行了板形调控模型建立、有限元分析、算法优化等方面的研究。ALJABRI等[2]分析了四辊PC轧机工作辊交叉角度和T-WRS&C轧机轴向窜动距离等轧制过程参数对薄带钢板凸度、边降的影响规律;王鹏飞等[3]应用理论分析建模结合生产实际的研究方法,制定了板形闭环控制的策略并应用于某1 450 mm五机架冷连轧机末机架的板形控制中;张清东等[4]通过建立辊件一体化仿真模型,研究了冷连轧过程带钢横向厚差的生成、遗传规律及凸度与边降的相互耦合影响;SHAN等[5]综合应用带钢平坦度和板廓效应矩阵建立平坦度和板廓的集成控制策略,实验研究表明能够有效提高冷连轧机的平坦度和板廓控制精度;郭忠峰等[6]对四辊CVC轧机和四辊SmartCrown轧机的辊形曲线、轧制过程中轴向力及辊缝凸度等方面进行比较研究;彭艳等[7]从轧件几何尺寸、辊廓自保持性、板形控制稳定性等方面对新一代轧机板形控制技术进行了归纳和阐述;周晓敏等[8]建立了六辊UCMW冷连轧机辊系与轧件一体化仿真模型,分析了板形调控手段对带钢中心凸度和边降的调控能力;何安瑞等[9]通过建立有限元模型详细分析了六辊UCM轧机的板形调控性能,指明UCM轧机在边降控制方面的不足,开发出具有高次曲线函数的边部变凸度工作辊,工业生产应用中无取向电工钢的边降合格率得到大幅度提高;LINGHU等[10]建立了六辊CVC冷轧机三维辊件一体化有限元模型,能够较为准确地模拟冷轧带钢轧制过程,为轧辊辊形优化和提高带钢板形平坦度质量提供了有效的途径。近年来,对电工钢、DI材、造币钢等高端板带材在平坦度的基础上提出了日趋严苛的边降、凸度和同板差等多指标、高精度的板形质量新要求。因此,开展新一代高技术宽带钢冷轧机机型与板形控制研究具有重要意义。

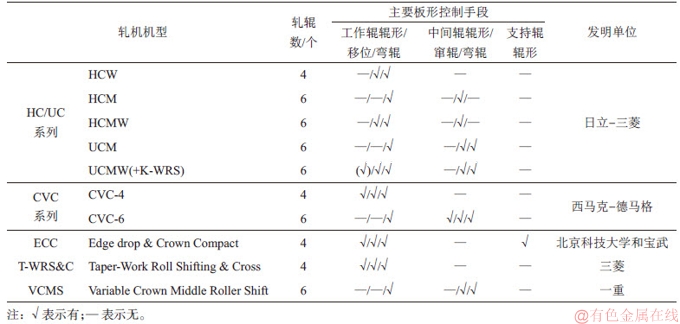

1 宽带钢冷轧机机型与板形控制特点

宽带钢冷轧机是冷轧板带生产的骨干设备,关于宽带钢冷轧机机型的研究和创新就是板形控制技术的研究与创新,国内外主要通过轧机机型设计实现和完善冷轧带钢板形质量控制[11]。目前已被广泛应用的冷轧机主流机型为日本日立开发的HC/UC(high crown/universal crown,万能凸度)系列机型、德国西马克开发的CVC(continuously variable crown,连续变凸度)机型(CVC-4和CVC-6)、北京科技大学与武钢合作开发的ECC(edge drop & crown compact,边降与凸度紧凑)机型、奥钢联在CVC技术基础上开发出的SmartCrown轧机机型、日本川崎制铁公司开发的T-WRS(taper-work roll shifting,锥形工作辊横移)与锥形工作辊横移和交叉T-WRS&C(taper-work roll shifting and cross,锥形工作辊横移和交叉)轧机机型以及中国一重在UCM基础上开发的VCMS(variable crown middle roll shift,变凸度中间辊横移)轧机机型等[12-13]。新一代宽带钢冷连轧机典型轧机机型与板形控制如表1所示。宽带钢冷连轧机通常由5机架四辊或六辊轧机组成,在实际生产中,常选用的四辊轧机机型包含常规四辊轧机、工作辊窜移型四辊轧机(如CVC-4,SmartCrown和ECC轧机)、成对交叉型四辊轧机(如PC轧机)和上、下辊交叉窜移型(如T-WRS&C和PC轧机),六辊轧机机型包括中间辊变凸度窜移型六辊轧机(如CVC-6轧机)、中间辊变接触窜移型六辊轧机(如HCM和UCM轧机)和中间辊/工作辊双窜移型六辊轧机(如UCMW和CVC-6+EDC轧机)。

表1 新一代宽带钢冷连轧机典型轧机机型与板形控制

Table 1 Typical model and shape control of new-tech wide strip steel tandem cold rolling mills

2 宽带钢冷轧机板形控制策略发展

2.1 板形平坦度控制策略

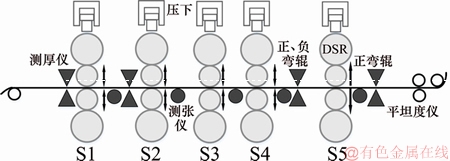

平坦度是板形控制主要指标之一,20世纪80年代开始的ASC板形自动控制(automatic shape control)主要是指AFC板形平坦度自动控制(automatic flatness control)。为此,宽带钢冷连轧机组带钢轧制过程是在轧件厚度最薄的第5机架集中进行板形平坦度控制。在实际生产中,第5机架通常选择板形控制能力和调控灵活性强的轧机,同时配备多种丰富的板形控制手段,在成品机架出口处配置板形仪完成平坦度测量,如某2 030 mm全四辊冷连轧机组第5机架工作辊采用CVC变凸度辊形、工作辊液压窜辊、液压弯辊系统和工作辊精细分段冷却板形控制技术,并在第5机架出口安装了ABB板形平坦度仪,用于第5机架的板形闭环控制。为进一步提高板形控制能力,在第5机架还增加了DSR支持辊等动态板形辊技术,如图1所示。

图1 2 030 mm冷连轧机组示意图

Fig. 1 2 030 mm wide strip steel tandem cold rolling mills

2.2 “抓两头带中间”板形控制策略

国内外研究者通过理论研究和生产实践逐步意识到门户机架也是进行板形控制的关键机架之一,既可实现对带钢来料凸度的适度控制,又可保证出口处带钢具有良好的平坦度。由于存在比例凸度死区,在冷轧门户机架适度偏离几何相似条件并不一定导致浪形的产生,陈先霖[14]提出了“抓两头带中间”板形控制策略,在高度重视成品机架板形控制的同时,在门户机架处强化板形控制能力适度消化热轧来料凸度对平坦度的影响,并通过大型工业轧机生产实践验证应用,如将变接触轧制技术应用于某1 700 mm冷连轧机门户机架,在工业试验中S1处平坦判据值达到1.303时实际带钢并没有出现浪形,取样带钢S1出口实际凸度相比于理论凸度都有大幅下降[13],如表2所示,同时推广应用于前述2 030 mm冷连轧机时取得板形质量提高的显著效果。某2 180 mm冷连轧机组S1采用六辊轧机并在S1出口处增设平坦度仪,如图2所示,同样体现了“抓两头带中间”板形控制策略。

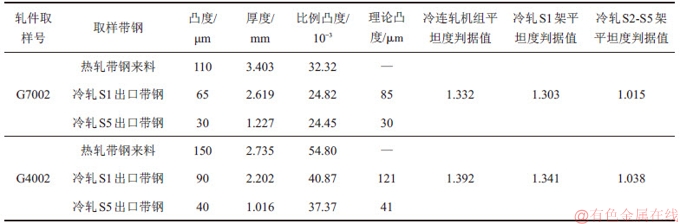

表2 带钢入口、出口横截面形状几何相似性分析

Table 2 Strip profile similarity analysis of entry and exit strip steel

2.3 全机组一体化板形控制策略

近年来,用户对电工钢、造币钢、DI材等高端板带材在平坦度基础上,提出了边降、凸度和同板差等多板形指标的质量要求,0.5 mm厚度的电工钢板边降要求从7 μm降到5 μm,带钢宽度方向同板差逐步提出要求到10 μm甚至7 μm以内,对冷轧带钢质量均一稳定性均提出了严格的要求,冷轧带钢板形控制难度有了很大提升。5机架连轧机组分“门户机架”(第1机架S1)、“成品机架”(第5机架S5)和3个“中间机架组”(第2到第4机架S2,S3和S4),轧制过程带钢的规格、性能等存在很大的差异,不同机架处会有不同的板形质量控制要求[1,7],要实现冷轧带钢高精度板形综合控制必须采取全机组边降、凸度、同板差和平坦度一体化板形控制策略,即第1机架要克服来料凸度和硬度波动对成品边降、凸度、平坦度等控制的影响,实现大压下量轧制;第5机架是对成品带钢板形平坦度进行最后控制的关键机架,应保持带钢的比例凸度不变,必须提供足够的板形控制能力;中间第2至第4机架处于冷连轧机机组的中央位置,主要任务是实现边降的控制,并保持比例凸度相等以实现良好的平坦度控制。

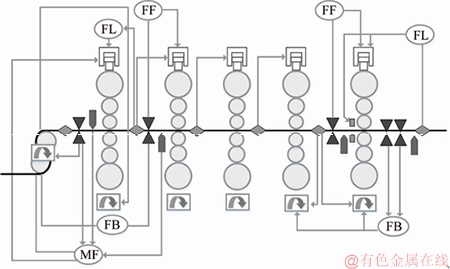

图2 2 180 mm冷连轧机组示意图

Fig. 2 2 180 mm wide strip steel tandem cold rolling mills

3 宽带钢冷轧机凸度和边降构成与特征分析

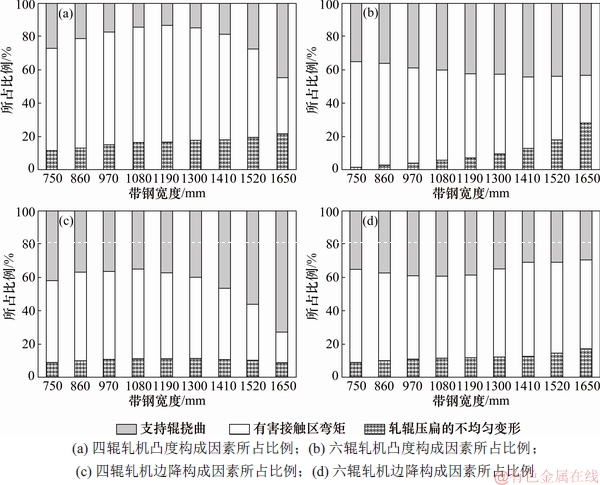

支持辊的挠曲变形、“有害接触区”弯矩和轧辊压扁的不均匀变形是带钢产生凸度和边降的重要原因[1, 12, 15-17]。图3(a)所示为四、六辊轧机的自然凸度构成,对于四辊轧机来说,支持辊挠曲变形占11.6%~21.7%;不均匀压扁占13.9%~45.5%;悬臂段弯矩占32.9%~69.6%;六辊轧机中,支持辊弯曲占1.41%~28.07%;不均匀压扁占35.6%~44.3%;悬臂段弯矩占28.1%~63.0%。四辊轧机和六辊轧机“有害接触区”弯矩所造成的自然凸度所占比例都最大,其次为轧辊压扁的不均匀变形所造成的自然凸度,支持辊挠曲变形所造成的自然凸度所占比例最小。四、六辊轧机的边降构成如图3(b)所示。四辊轧机中,支持辊挠曲变形占9.1%~11.4%,轧辊压扁的不均匀变形占35.3~72.9%,“有害接触区”弯矩占18.0%~53.3%,对于六辊轧机,支持辊挠曲变形占9.0%~16.8%,轧辊压扁的不均匀变形占30.4%~39.5%,“有害接触区”弯矩占49.4%~55.2%。

图3 四、六辊轧机凸度和边降构成

Fig. 3 Proportion of crown and edge drop of 4-high and 6-high rolling mills

通过对图3中四辊轧机凸度和边降构成进行分析发现:在带钢常规宽度(1 050,1 180和1 230 mm等)范围内,“有害接触区”弯矩在带钢边降、凸度构成中所占比例要高于轧辊压扁的不均匀变形,但在进行超宽带钢轧制时,四辊轧机轧辊压扁不均匀变形的影响会随着带钢宽度的增加明显提高,并高于“有害接触区”弯矩所占比例。因此,针对不同宽度的带钢需要采用不同的板形控制路径实现边降、凸度的有效控制,轧机的板形控制能力应随着带钢宽度的变化而不断增强。而对于六辊轧机来说,在整个带钢轧制宽度范围内“有害接触区”弯矩对带钢边降的影响都高于轧辊压扁的不均匀变形。四、六辊轧机中的“有害接触区”弯矩和轧辊压扁的不均匀变形在轧制力造成的自然凸度和带钢边降构成中所占比例都最大[1]。

4 宽带钢冷轧机全机组一体化板形控制实现路径

4.1 宽带钢UCMW冷轧机板形控制

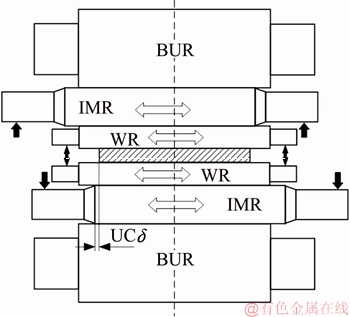

近年来,生产实践中为满足用户日趋严苛的高精度板形多指标质量要求,国内外新建冷连轧机大多采用全六辊轧机机型,如宝武集团宝钢三冷轧、武钢二硅钢、日本新日铁Nippon Steel的八幡、韩国浦项POSCO光阳和韩国现代钢管HDP的全五机架六辊冷连轧机UCMW机型。UCMW冷轧机具有丰富的板形控制手段,可以实现冷轧带钢边降、凸度和同板差等多指标高精度的板形控制效果,是国际上先进的冷轧机型之一。UCMW轧机的中间辊和工作辊通常为平辊,可通过调整中间辊和工作辊弯辊力补偿轧辊在轧制过程中发生的弹性弯曲。根据带钢的宽度,UCMW轧机通过移动中间辊的轴向位置来调整轧辊之间的接触长度,进而改变辊间接触压力的分布,消除有害接触区。通过工作辊横移来改变轧制力分布,进而改善带钢边部的受力状态和工作辊端部弹性压扁,两方面作用结合可有效减小带钢边降[18-19]。配备K-WRS技术的六辊UCMW轧机机型在冷轧带钢横截面板形控制中发挥了重要作用,具有单锥度辊形结构的工作辊和中间辊的组合窜动可以有效降低轧辊压扁的不均匀变形,进行带钢的边部板形控制,通过工作辊的轴向移动控制带钢进入轧辊边部锥形段的位置,有效补偿工作辊不均匀弹性压扁产生的带钢边部金属变形,减小带钢边降,其工作原理如图4所示。

图4 六辊UCMW轧机工作原理

Fig. 4 6-high UCMW mill working principle

4.2 宽带钢冷轧机ECC机型与板形控制

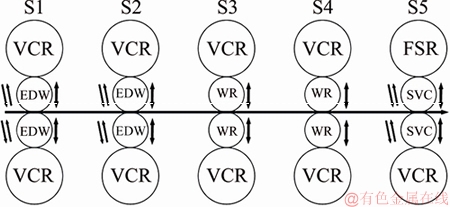

国内外新建的宽带钢冷连轧机绝大多数均采用5机架六辊冷连轧机组,而四辊冷轧机是宽带钢冷连轧机的主力机型之一,具有易实现高速、大扭矩稳定轧制,辊系简单,可靠性好和节能降耗的特点,但是板形控制质量并没有根本解决,尤其是边降、凸度、同板差等多指标高精度板形控制问题解决难度极大。通过不懈探索和潜心研究,北京科技大学和宝武课题组自主研制的新机型ECC四辊冷连轧机具有实现边降、凸度和平坦度稳定高精度板形控制、工艺紧凑、装备潜能得到充分发挥的特点[1],如图5所示。图5中,第1和第2机架(S1和S2)采用EDW边降控制工作辊和配套VCR变接触支持辊技术,有效降低“有害接触区”弯矩,均匀化辊间接触压力,提高轧机的板形调控能力;第3、第4机架(S3和S4)采用常规工作辊WR和配套的VCR变接触支持辊技术,有效减小“有害接触区”的影响,提高弯辊板形调控能力[20]。第5机架(S5)采用空载辊缝凸度调节能力与板宽的关系比线性化更好且调节能力具有连续可变凸度的SVC(super variable crown)智能变凸度工作辊技术和具有非对称辊形曲线的FSR(flexible shape backup roll)柔韧板形支持辊技术以及配套的板形控制策略,增强轧机的板形控制综合能力,第1,2和5机架配备有工作辊液压窜辊系统,实现对成品板形特别是平坦度的良好控制。与日本T-WRS轧机和西门子奥钢联SmartCrown轧机相比,ECC冷连轧机带钢实际凸度控制能力平均增强14.29%,带钢原料比例凸度与成品比例凸度的比值由83.33%提高到95.24%;边降平均值≤10 μm的比例由引进日本T-WRS轧机的62.5%提高到100%,且边降平均值≤7 μm的比例达到98.22%;同板差≤10 μm的比例达97.25%,达到国际上板形控制效果先进的日本六辊UCMW冷连轧机96.31%的同期高精度控制水平。

图5 四辊ECC冷连轧机机型

Fig. 5 4-high ECC tandem cold rolling mill

4.3 全六辊UCM宽带钢冷连轧机板形综合控制方案

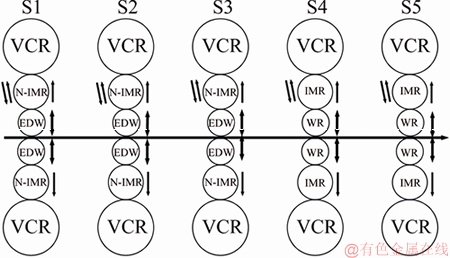

图6 六辊UCM冷连轧机机型

Fig. 6 6-high UCM tandem cold rolling mill

在国内热连轧机纷纷引进四辊CVC轧机机型的同时,国内冷连轧机纷纷引进六辊UCM/UCMW轧机机型,由于六辊轧机工作辊液压窜辊系统设计、制造和应用相对复杂,除了少数采用具有国际先进水平的5机架全六辊UCMW轧机机型外,其余更多地采用5机架全六辊UCM轧机机型。值得指出的是,六辊UCMW轧机机型技术配置虽然成本较高,但可以很好地满足技术需求和产品质量要求。而国内新建的一批高速宽带钢冷连轧机均采用5机架六辊UCM轧机机型,工作辊都不具备液压窜辊系统这一重要的板形控制手段,在边降、凸度和同板差的高精度控制方面存在着瓶颈难题。

依据前述带钢冷轧全机组一体化板形控制策略和图3所示轧机凸度、边降构成特征的分析,结合六辊UCMW轧机机型与板形控制分析和自主研发四辊ECC轧机机型与板形控制实践,提出如下全六辊UCM宽带钢冷连轧机板形综合控制方案:UCM轧机通过中间辊窜辊可以使轧机辊缝具有很大的辊缝横向刚度[21],克服热轧来料引起的轧制力波动;同时,还可在S1~S3开发边降控制中间辊新辊形N-IMR,充分利用中间辊液压窜辊系统增强轧机的板形控制能力。门户机架S1在采用边降控制中间辊辊形的基础上还可采用变凸度复合中间辊辊形,以增大轧机辊缝凸度调节域,从而增强轧机对热轧来料凸度变化的消化控制能力。由于UCM轧机不具备工作辊窜辊系统而缺乏边降控制能力,因此,S1~S3等3个机架可根据来料规格配置具有不同特殊辊形的工作辊(如结合生产实际自主研发的EDW边降控制工作辊)作用于带钢边部,减小轧辊压扁的不均匀变形,以增强机组的边降控制能力和满足图3所示随着带钢宽度的变化而不断增强的板形控制能力要求。S4和S5机架采用常规中间辊IMR和工作辊WR,在此基础上,对轧机全机组进行一体化辊形优化设计,可采用VCR变接触支持辊有效消除“有害接触区”和增强中间辊弯辊的板形调控能力,在保证较大横向刚度的同时提高轧机的辊缝凸度调节柔性,建立低凸度、高刚度的辊缝,如图6所示。结合UCM生产实践开展5个机架的工作辊、中间辊和支持辊均采用一体化辊形设计以及配套的弯辊和窜辊模型的研究,可望提高并满足用户日趋严苛的高精度板形多指标质量要求。

5 结论

1) 结合生产实践对国际上广泛应用的宽带钢冷轧机机型及其板形控制特点进行分析,提出宽带钢冷连轧机全机组一体化的板形控制策略,对四辊和六辊冷轧机凸度和边降的构成及其特征进行研究。四、六辊轧机“有害接触区”弯矩和轧辊压扁不均匀变形在轧制力造成的自然凸度和带钢边降构成中均占主要比例,四辊轧机的板形控制能力应随着带钢宽度增加而不断增强,超宽带钢轧制时,四辊轧机轧辊压扁的不均匀变形的影响会随着带钢宽度的增加明显提高,并高于“有害接触区”弯矩所占比例。六辊轧机在整个带钢轧制宽度范围内“有害接触区”弯矩对带钢边降的影响都高于轧辊压扁的不均匀变形。四辊和六辊轧机高精度板形控制应采取明显不同的实现途径,并用于分析讨论冷轧机全机组一体化板形控制方案。

2) 讨论六辊 UCMW轧机和自主研发的全四辊 ECC 冷连轧机等机型的板形控制技术特点,采用全机组一体化板形控制的四辊ECC边降与凸度紧凑冷连轧机长期稳定工业生产实践取得边降、凸度和同板差等重要板形控制指标达到国际上板形控制效果先进的日本全六辊UCMW冷连轧机同期高精度控制水平,显著高于日本四辊T-WRS 轧机和西门子奥钢联 四辊SmartCrown 轧机,并针对冷轧带钢边降、凸度、同板差和平坦度等板形控制要求,提出一种提升国内外广泛采用的全六辊 UCM宽带钢冷连轧机板形质量的板形综合控制方案,可望提高并满足用户日趋严苛的高精度板形多指标要求。

参考文献:

[1] CAO Jianguo, CHAI Xueting, LI Yanlin, et al. Intergrated design of roll contours for strip edge drop and crown control in tandem cold rolling mills[J]. Journal of Materials Processing Technology, 2018, 252: 432-439.

[2] ALJABRI A, JIANG Zhengyi, WEI Dongbin, et al. Thin strip profile control capability of roll crossing and shifting in cold rolling mill[J]. Materials Science Forum, 2013, 773/774: 70-78.

[3] 王鹏飞, 刘宏民, 彭艳, 等. 1 450 mm冷连轧机多变量最优板形闭环控制策略研究与应用[J]. 燕山大学学报, 2014, 38(2): 122-126.

WANG Pengfei, LIU Hongmin, PENG Yan, et al. Strategy and application of flatness control system based on multi-variable optimal control of 1 450 mm cold strip mill[J]. Journal of Yanshan University, 2014, 38(2): 122-126.

[4] 张清东, 张晓峰, 文杰. 薄带钢冷连轧横向厚差控制理论及DI材横向厚差控制技术研究[J]. 机械工程学报, 2013, 49(24): 30-38.

ZHANG Qingdong, ZHANG Xiaofeng, WEN Jie. Theory and technology of transverse thickness deviation control for DI thinplate during tandem cold rolling[J]. Journal of Mechanical Engineering, 2013, 49(24): 30-38.

[5] SHAN Xiuying, LIU Hongmin, JIA Chunyu, et al. Flatness and profile integration control model for tandem cold mills[J]. Journal of Iron and Steel Research, International, 2012, 19(3): 31-37.

[6] 郭忠峰, 徐建忠, 李长生, 等. 几类典型轧辊横移变凸度辊型的比较与分析[J]. 东北大学学报(自然科学版), 2008, 29(6): 830-833.

GUO Zhongfeng, XU Jianzhong, LI Changsheng, et al. Comparative analysis of some typical roll shapes with roll gap variable through roll shifting[J]. Journal of Northeastern University (Natural Science), 2008, 29(6): 830-833.

[7] 彭艳, 牛山. 板带轧机板形控制性能评价方法综述[J]. 机械工程学报, 2017, 53(6): 26-44.

PENG Yan, NIU Shan. Review on assessment methods for shape control performance of strip rolling mills[J]. Journal of Mechanical Engineering, 2017, 53(6): 26-44.

[8] 周晓敏, 张清东, 王长松, 等. UCMW轧机的边缘降控制性能和影响因素分析[J]. 北京科技大学学报, 2007, 29(4): 417-420.

ZHOU Xiaomin, ZHANG Qingdong, WANG Changsong, et al. Edge drop control performance and influence factor analysis of a UCMW cold mill[J]. Journal of University of Science and Technology Beijing, 2007, 29(4): 417-420.

[9] 何安瑞, 邵健, 孙文权, 等. 冷轧无取向硅钢横向厚差控制[J]. 机械工程学报, 2011, 47(10): 25-30.

HE Anrui, SHAO Jian, SUN Wenquan, et al. Transverse thickness deviation control of non-oriented silicon steel during cold rolling[J]. Journal of Mechanical Engineering, 2011, 47(10): 25-30.

[10] LINGHU Kezhi, JIANG Zhengyi, ZHAO Jingwei, et al. 3D FEM analysis of strip shape during multi-pass rolling in a 6-high CVC cold rolling mill[J]. The International Journal of Advanced Manufacturing Technology, 2014, 74(9/10/11/12): 1733-1745.

[11] 陈先霖. 新一代高技术薄带冷轧机的发展趋向[J]. 上海金属, 1995, 17(4): 1-8.

CHEN Xianlin. Development trend of the new generation of high-tech thin strip cold rolling mills[J]. Shanghai Metals, 1995, 17(4): 1-8.

[12] CAO J G, ZHANG J, YANG G H, et al. Comprehensive edge drop control technology of non-oriented electrical steel strip in 4-high ECC tandem cold rolling mills[C]// Proceedings of the 10th ICSR. Beijing, 2010: 1065-1073.

[13] 曹建国, 顾云舟, 张杰, 等. 1 700 mm冷轧带钢轧机板形控制能力研究[J]. 钢铁研究, 2002, 30(3): 16-19.

CAO Jianguo, GU Yunzhou, ZHANG Jie, et al. Study on controllability of profile and flatness at 1 700 mm tandem cold rolling mill[J]. Research on Iron and Steel, 2002, 30(3): 16-19.

[14] 陈先霖. 新一代高技术宽带钢轧机的板形控制[J]. 北京科技大学学报, 1997, 19(S1): 1-5.

CHEN Xianlin. Flatness control in new generation high-tech mills for wide strip rolling[J]. Journal of University of Science and Technology Beijing, 1997, 19(S1): 1-5.

[15] 孙文权, 杨荃, 邵健, 等. UCM冷连轧机硅钢边降控制技术[J]. 北京科技大学学报, 2010, 32(10): 1340-1345.

SUN Wenquan, YANG Quan, SHAO Jian, et al. Edge drop control technique of silicon steel for UCM tandem cold rolling mills[J]. Journal of University of Science and Technology Beijing, 2010, 32(10): 1340-1345.

[16] ZHOU Xiaomin, CHENG Xiaoxu. The analysis of influence on the edge drop of tandem cold rolling mill[J]. Applied Mechanics and Materials, 2014, 548/549: 363-366.

[17] 陈云鹏. UCMW轧机带钢边缘降的成因分析与控制[J]. 轧钢, 2010, 27(5): 21-25.

CHEN Yunpeng. Research on strip edge drop control performance of UCMW mill[J]. Steel Rolling, 2010, 27(5): 21-25.

[18] WANG Lubing, YAN Linjing, HE Anrui, et al. Research on broken edge wave control strategy caused by edge drop control in UCMW cold tandem rolling[J]. Advanced Materials Research, 2013, 655/656/657: 1525-1529.

[19] ZHOU Xiaomin, YUE Xiaoxue. The research on optimization of edge drop control for cold tandem rolling mill[C]// Advanced Material Science and Engineering (AMSE2016). Shenzhen, China, 2016: 207-212.

[20] 曹建国, 齐杰斌, 张杰, 等. 宽带钢冷连轧机边降控制支持辊辊形研究[J]. 中南大学学报(自然科学版), 2008, 39(5): 1011-1016.

CAO Jianguo, QI Jiebin, ZHANG Jie, et al. Backup roll contour for edge drop control technology in tandem cold rolling mill[J]. Journal of Central South University (Science and Technology), 2008, 39(5): 1011-1016.

[21] 曹建国, 张勇, 杨光辉, 等. UCM六辊冷轧机中间辊辊形研究[J]. 中南大学学报(自然科学版), 2011, 42(4): 966-971.

CAO Jianguo, ZHANG Yong, YANG Guanghui, et al. Intermediate roll contour of 6-hi UCM cold rolling mill[J]. Journal of Central South University (Science and Technology), 2011, 42(4): 966-971.

(编辑 杨幼平)

收稿日期: 2018 -09 -28; 修回日期: 2018 -11 -26

基金项目(Foundation item):科技部创新方法工作专项(2016IM010300);“绿扬金凤计划”创新领军人才项目(yzlyjfjh2015CX055); 中央高校基本科研业务费专项(FRF-GF-17-A5)(Project(2016IM010300) supported by Innovation Method Fund of China; Project(yzlyjfjh2015CX055) supported by Lüyang Jinfeng Program for the Innovation Leading Talents; Project(FRF-GF-17-A5) supported by the Fundamental Research Funds for the Central Universities)

通信作者:曹建国,博士,教授,从事板形控制及轧制自动化、智能制造建模与质量控制、机器人仿生电子皮肤等研究;E-mail:geocao@ustb.edu.cn