文章编号:1004-0609(2010)10-2051-06

烧结法高浓度铝酸钠溶液中硅酸二钙的絮凝机理

刘桂华,黄亚军,彭志宏,周秋生,李小斌

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:通过测定硅酸二钙与高浓度铝酸钠溶液(ρ(Al2O3)≥180 g/L)反应后浆液的絮凝沉降性能,结合红外光谱、Zeta电位和接触角的测定结果,探讨絮凝剂与硅酸二钙的絮凝机理。沉降实验结果表明:添加含酰胺基、羧基的絮凝剂A和B时,浆液不絮凝沉降;而含酰胺基、羧基和羟肟酸的絮凝剂C的沉降效果好,沉降初始5 min的平均速度达到19.0 mm/min。红外光谱分析结果表明:添加絮凝剂A、B和C后,絮凝剂中的R—COO-基团均可与硅酸二钙中的Ca2+形成配位键。沉降后固相的有机碳含量分析结果表明:硅酸二钙可吸附约40%的絮凝剂A和B,或吸附91.04%的絮凝剂C,这直接导致吸附絮凝剂C的硅酸二钙的Zeta电位、接触角和固体表面能变化较絮凝剂A、B的大;在烧结法高浓度体系中,电中和脱稳不是主要原因,絮凝剂在颗粒表面的大量被吸附并通过疏水力增强或架桥作用的形成是改善浆液絮凝沉降的关键。

关键词:硅酸二钙;铝酸钠溶液;烧结法;絮凝机理

中图分类号:TF803.2 文献标志码:A

Flocculation mechanism of dicalcium silicate in concentrated sodium aluminate solutions by sintering process

LIU Gui-hua, HUANG Ya-jun, PENG Zhi-hong, ZHOU Qiu-sheng, LI Xiao-bin

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The settlement properties of dicalcium silicate in the concentrated solutions (ρ(Al2O3)≥180 g/L) were measured with addition of different flocculants by sintering process, and then the flocculation mechanism was discussed based on the analysis of infrared spectrum, Zeta potential and contact angle. The results of settlement experiment show that no flocculation occurs with adding either flocculant A or B containing amide groups and carboxyl groups, while flocculation appears much better and the average settlement rate of slurry reaches 19.0 mm/min in the first 5min after adding flocculant C containing amide groups, carboxyl groups and hydroxamic acid groups. And the IR results indicate that R—COO- in flocculant A, B or C easily forms coordination bond with Ca2+ in dicalcium silicate. Meanwhile dicalcium silicate absorbs 91.04% of flocculant C but about 40% of flocculant A or B during the settling process by the analysis of organic carbon content in solid, resulting in that the variations of Zeta potential, angle contact and solid surface energy of dicalcium silicate absorbing flocculant C are more than those absorbing flocculant A or B. These facts imply that more adsorption of flocculants onto dicalcium silicate favors the flocculant formation by hydrophobic interaction and bridge action instead of the charge neutralization.

Key words: dicalcium silicate; sodium aluminate solutions; sintering process; flocculation mechanism

目前我国烧结法粗液中氧化铝浓度为120 g/L左右,如果提高到180 g/L以上,将大大增加设备产能和生产效率。但熟料中约有30%的硅酸二钙,其在溶出浆液中随氧化铝浓度的升高、时间的延长,二次反应会越严重,造成氧化铝和碱的严重损失[1-2]。采用离心、过滤等方法能实现赤泥的快速分离,但由于成本高、设备结疤等原因未能工业化,因此,提高烧结法系统中氧化铝浓度的关键在于寻找合适的絮凝剂,采用沉降方式实现赤泥的快速分离。由于溶出浆液为浓碱体系,物相众多,因而其絮凝过程非常复杂。现有的研究大部分基于近中性溶液体系或低浓度粗液中,其作用机理在于絮凝剂中各种官能团通过氢键[3-4]、特性吸附[5]、电荷中和[6-7]、络合[8-9]与颗粒相互作用,然后,通过电中和脱稳、架桥等作用引起固相颗粒之间的有效凝聚,形成絮团。而对于烧结法高浓度铝酸钠(Al2O3含量180 g/L)体系絮凝机理还未见报道。鉴于此,本文作者以硅酸二钙纯物质为对象,分别加入3种具有不同官能团的絮凝剂测定硅酸二钙在高浓度铝酸钠溶液中的沉降性能,分析固相红外光谱,研究其与絮凝剂的作用形式,并测定了硅酸二钙颗粒的Zeta电位、接触角和固体表面自由能,结合颗粒表面絮凝剂吸附量的变化,从颗粒的界面性质对絮凝机理进行探讨。

1 实验

1.1 实验原料

氢氧化铝(工业级),中国铝业中州分公司;氢氧化钠(工业级),重庆南州市宏原化工有限公司;二氧化硅(分析纯),国药集团化学试剂有限公司;氢氧化钙(分析纯),汕头市西陇化工有限公司。

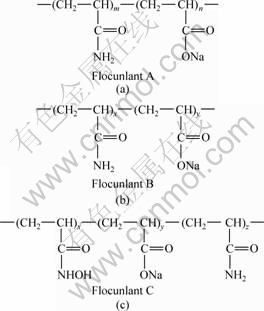

絮凝剂A:水解度为15%,相对分子量为2 300万的聚丙烯酰胺(中州铝厂);絮凝剂B:水解度为30%,相对分子质量为2 200万的聚丙烯酰胺(实验室自制);絮凝剂C:相对分子质量为2 000万的氧肟酸型聚丙烯酰胺(实验室自制)。各絮凝剂配制成质量浓度为0.1%的水溶液备用,其结构式如图1所示。

铝酸钠溶液:利用氢氧化铝和氢氧化钠配制苛性比αk(即氧化钠与氧化铝的摩尔比)1.45左右、氧化铝浓度180 g/L左右的溶液。

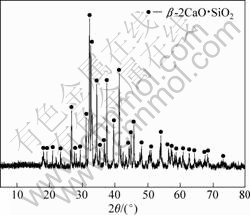

硅酸二钙:以氧化钙(分析纯氢氧化钙煅烧得到)和二氧化硅按摩尔比2?1配料,在多功能矿物混合机中混合4 h,于1 250 ℃下烧成,X射线衍射分析结果如图2所示。

1.2 实验设备

SX-8-16型马弗炉(控制精度±5 ℃),由长沙中华电炉厂生产;DY-8群釜低压装置(加热介质为甘油,

图1 3种絮凝剂的结构式

Fig.1 Structural formula of flocculants: Flocculant A, average relative molecular mass of 23 millions, degree of hydrolysis of 15%; Flocculant B, relative molecular mass of 22 millions, degree of hydrolysis of 30%; Flocculant C, average relative molecular mass of 20 millions

图2 硅酸二钙的XRD谱

Fig.2 XRD pattern of dicalcium silicate

自动控温,精度为±1 ℃);WMZK-01温控型水浴槽;JS94H微电泳仪,由上海中晨电子技术设备有限公司生产;SL200B接触角仪,由上海梭伦信息科技有限公司生产;美国生产的NICOLET 6700傅立叶红外光谱仪。

1.3 实验方法

沉降实验。取100 mL高浓度铝酸钠溶液、5 g硅酸二钙加入到150 mL钢弹中,并在钢弹中加入直径的20 mm和5 mm的钢球各2个以强化搅拌,在100 ℃的DY-8群釜低压装置中反应15 min后,将浆液倒入直径35 mm、高25 cm的玻璃沉降管内,在90 ℃水浴槽中分别加入6 mL质量分数为0.1%的絮凝剂A、B、C于沉降管中;其中:另一沉降管中不加任何絮凝剂,进行对比实验,30 min后将沉降底流硅酸二钙固相洗净后,于35 ℃左右风干,得到絮凝作用后的硅酸二钙颗粒,以用于有机碳、Zeta电位、红外光谱及接触角和表面自由能的测定。

Zeta电位的测定。取0.1 g硅酸二钙颗粒加入到20 mL蒸馏水中,分散后,在25 ℃、电压为10 V的条件下测定。

有机碳含量的测定。按GB17378.5—1998中重铬酸钾氧化-还原容量法测定吸附于颗粒表面的有机碳含量。

2 结果与讨论

2.1 絮凝剂对浆液沉降效果的影响

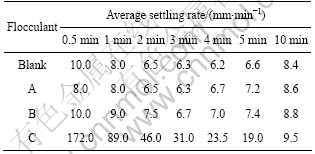

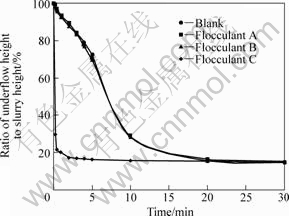

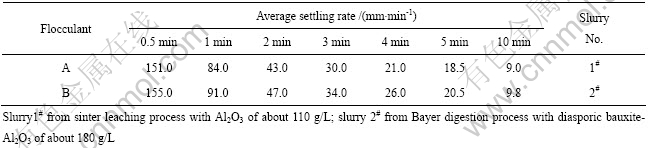

在絮凝沉降30 min内读取硅酸二钙浆液泥层高度的变化,以考察各絮凝剂对浆液沉降性能的影响。初始10 min浆液平均沉降速率列于表1中,絮凝剂对浆液底流高度比(底流高度与浆液总高度之比)的影响如图3所示。

在加入硅酸二钙的铝酸钠溶液中,絮凝剂A和B在沉降分离过程中无大絮团生成,其过程与不加絮凝剂时的自然沉降一样,絮凝剂C有明显的大絮团,并伴有强烈的絮团翻腾现象。由表1和图3可知,絮凝剂A和B的沉降底流高度和平均沉降速度都与自然沉降相近,而絮凝剂C沉降底流高度变化非常显著,平均沉降速率大,初始1 min内的平均速率达到89.0 mm/min。絮凝剂A、B在初始5 min内底流高度比仍然介于70%,平均沉降速率小,约为7 mm/min;絮凝剂C则在1 min后曲线趋于平缓,沉降过程进入压缩区;在5 min内完成大部分沉降,底流高度比为20%左右,平均沉降速率达到19.0 mm/min。同时,实验还可以观察到加入絮凝剂A和B沉降10 min后上清液浑浊,加入絮凝剂C的上清液清亮。工业生产中絮凝剂A和絮凝剂B能分别使氧化铝浓度为110 g/L左右的烧结法赤泥浆液和氧化铝浓度为180 g/L的拜耳法赤泥浆液絮凝沉降(见表2),而在氧化铝浓度180 g/L的体系中两者均失去了絮凝效果,说明在高浓度

表1 絮凝剂对浆液平均沉速的影响

Table 1 Influence of flocculants on average settling rate of slurry

图3 絮凝剂对浆液底流高度比的影响

Fig.3 Influence of flocculants on ratio of underflow height to slurry height (ρ(Al2O3)≈181.25 g/L, αk≈1.46)

表2 工业生产中絮凝剂A和B分别在不同浆液体系中的沉降性能

Table 2 Settlement of flocculation A and B in different slurries during industry production

烧结法赤泥体系中粒子的界面性质可能发生了变化,使得絮凝剂与粒子的相互作用改变。因此,需通过比较絮凝剂A、B、C与粒子的作用,阐述其絮凝机理。

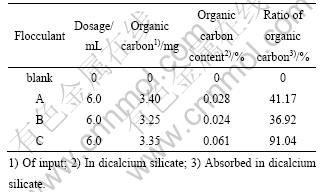

2.2 絮凝剂在固相表面吸附量的差异

絮凝剂在颗粒表面的吸附量可通过絮凝沉降后固相中的有机碳含量来进行表征。分别移取6 mL 0.1%絮凝剂加入至100 mL、固含量为50 g/L的浆液中,絮凝沉降剂后固相中有机碳含量及固相中有机碳与加入的总有机碳之比如表3所列。

由表3可以看出:3种絮凝剂在一定的加入量下,其在颗粒表面均有一定量的吸附。絮凝剂A、B在硅酸二钙固相中的有机碳含量分别为0.028%和0.024%,絮凝剂C为0.061%。同时,可以看出絮凝剂A、B吸附于固相中的有机碳与加入的总有机碳的百分比分别为41.17%和36.92%,而絮凝剂C达到91.04%,由此可知,絮凝剂C在颗粒表面的吸附量大,且远大于A和B。结合絮凝沉降实验可以看出:在一定的絮凝剂加入量下,絮凝剂在颗粒表面吸附量越大,其絮凝沉降效果越好。

表3 絮凝剂对沉降后硅酸二钙中有机碳含量的影响

Table 3 Influence of flocculants on organic carbon content of dicalcium silicate

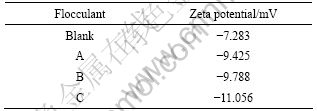

2.3 絮凝剂对固相Zeta电位的影响

Zeta电位是表征分散体系稳定性的重要指标。表4所列为硅酸二钙颗粒吸附絮凝剂后表面Zeta电位的变化情况。

由表4可知,在未加入絮凝剂时,硅酸二钙颗粒表面的Zeta电位为-7.283 mV,粒子带负电。加入絮凝剂A、B和C后,硅酸二钙颗粒表面负电荷均增加,Zeta电位绝对值增大。从絮凝剂与颗粒的相互作用来分析,加入的絮凝剂均为阴离子型絮凝剂,絮凝剂与颗粒存在排斥作用,理论上Zeta电位变化不明显,但实际上已发生显著变化,说明其中可能还有其它某种形式的吸附作用。从分散体系的稳定性来看,3种絮凝剂均使固相颗粒表面Zeta电位变得更负,且絮凝剂C的变化更大。同种粒子在较短距离时的静电排斥作用增强,浆液稳定性增加,浆液沉降性能变差[10]。但絮凝剂C能使颗粒絮凝沉降,表明在此过程中不能用传统的电中和脱稳解释絮凝机理。

表4 絮凝剂对硅酸二钙粒子Zeta电位的影响

Table 4 Influence of flocculants on surface potential (Zeta) of dicalcium silicate particles

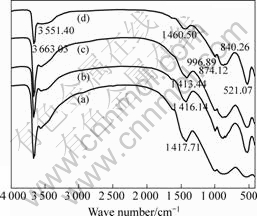

2.4 絮凝剂官能团与颗粒表面的作用形式

采用KBr压片法,用傅立叶红外光谱仪测定底流固相硅酸二钙的红外谱图,其结果如图4所示。

由图4可知,与絮凝剂作用后的硅酸二钙各振动峰除在1 460 cm-1处的峰发生40~50 cm-1的位移外,其余各峰的变化均在0.5 cm-1以内。其中,絮凝剂A的偏移至1 417.71 cm-1,絮凝剂B的偏移至1 416.14 cm-1,絮凝剂C的偏移至1 413.44 cm-1。在1 460 cm-1处由层状硅酸盐Si—O引起的振动峰,一般来说,层状硅酸盐中都含有平面六方Si—O环,由于阳离子或者羟基量的变化,会使振动频率发生位移[11]。絮凝剂是含有大量的—COO—基团的长链分子,其中的—COO—基团与硅酸二钙层状结构中的阳离子Ca2+发生化学吸附,形成R—COOCa 配位键[12],使得Ca2+

图4 絮凝剂与硅酸二钙作用后的红外光谱

Fig.4 Infrared spectra of flocculants on dicalcium silicate: (a) Flocculant A; (b) Flocculant B; (c) Flocculant C; (d) Blank

在层状中的数量和结构发生变化,导致该处振动峰位移。说明各絮凝剂在高浓度铝酸钠溶液中均能以化学键的作用形式吸附于硅酸二钙颗粒上。

2.5 絮凝剂对接触角和固体表面自由能的影响

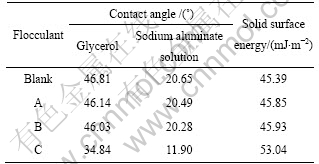

接触角是指液体在固体表面上达到热力学平衡时所形成的角。实验中分别以丙三醇(25 ℃时,表面张力为64.00 mN/m)和高浓度铝酸钠溶液(氧化铝浓度为181.25 g/L,αk为1.46)为测试液体,测定了硅酸二钙固体表面的接触角和固体表面自由能,结果如表5所列。

表5 凝剂对硅酸二钙接触角和固体表面能的影响

Table 5 Influence of flocculants on contact angle and solid surface energy of dicalcium silicate

由表5可知:在吸附絮凝剂的硅酸二钙对丙三醇的接触角中,絮凝剂C对接触角影响大;对比丙三醇,吸附絮凝剂的硅酸二钙对铝酸钠溶液的接触角变化较小,但两者的接触角变化趋势是一致的,说明高浓度铝酸钠溶液测试底流固相硅酸二钙接触角和固体表面能的结果是可信的;加絮凝剂A和B与未加絮凝剂相比,其接触角略有变小,分别从20.65?减小至20.49?和20.28?;而添加絮凝剂C时,接触角变化明显,从20.65?变小为11.90?。接触角大颗粒表面亲水性强,接触角小则颗粒表面疏水性强。接触角的变化表明,絮凝剂吸附于颗粒表面后,固相表面疏水性增强[13-14]。

添加絮凝剂A和B时,硅酸二钙颗粒固体表面能略有增大,分别从45.39 mJ/m2增大到45.85 mJ/m2和45.93 mJ/m2。加入絮凝剂C时,其固体表面能从45.39 mJ/m2增加到53.04 mJ/m2,增加的幅度大。各絮凝剂中均含有—COO—极性基团,固体表面能与固相颗粒表面含氧官能团有关,颗粒表面—COO—浓度增加,固体表面能增大[15]。由此可知,絮凝剂A和B作用时,硅酸二钙固相表面的—COO—基团浓度低,表明颗粒表面絮凝剂含量低;与絮凝剂C作用时,颗粒表面的—COO—基团浓度高,颗粒表面絮凝剂含量高,这与有机碳含量测定结果是一致的。

在相同的药剂投料量时,絮凝剂C中的—COO—活性基团能更多地吸附在颗粒的表面,同时,絮凝剂是含有许多—COO—基团的长链状聚合物分子,有利于通过疏水力强化絮凝或可通过“架桥”方式同时结合多个颗粒[16],形成大絮团,提高絮凝性能。而絮凝剂A和B在颗粒表面吸附量低,不能同时将多个颗粒束缚在絮凝剂分子中形成絮团,无絮凝现象。这表明在烧结法高浓度铝酸钠溶液中,絮凝剂在颗粒表面的吸附使颗粒通过架桥作用形成絮团,是浆液絮凝沉降的关键。

3 结论

1) 絮凝剂在高浓度溶出浆液中的絮凝沉降效果不同,添加絮凝剂A和B时,浆液无絮凝效果;而絮凝剂C的沉降效果好,初始5 min的平均速度达到19.0 mm/min。

2) 相比絮凝剂A和B,絮凝剂C在固相颗粒表面吸附量大,Zeta电位、接触角和固体表面能的变化大;添加絮凝剂A、B和C后,絮凝剂中的—COO—基团与硅酸二钙层状结构中的阳离子Ca2+存在较强的化学吸附作用,形成了R—COOCa配位键。这表明在烧结法铝酸钠浓碱体系中,电中和脱稳不是主要原因,而絮凝剂在颗粒表面的大量吸附使颗粒形成絮团,是浆液絮凝沉降的关键。

REFERENCES

[1] 李小斌, 徐华军, 刘桂华, 彭志宏, 周秋生, 刘云峰. 氧化铝熟料溶出过程中SiO2的行为[J]. 过程工程学报, 2006, 6(3): 431-434.

LI Xiao-bin, XU Hua-jun, LIU Gui-hua, PENG Zhi-hong, ZHOU Qiu-sheng, LIU Yun-feng. Behavior of SiO2 during leaching process of alumina sinter[J]. The Chinese Journal of Process Engineering, 2006, 6(3): 431-434.

[2] 李小斌, 张 建, 刘桂华, 陈 滨, 齐天贵. 原硅酸钙在铝酸钠溶液中的反应行为[J]. 中南大学学报: 自然科学版, 2009, 40(2): 275-281.

LI Xiao-bin, ZHANG Jian, LIU Gui-hua, CHEN Bin, QI Tian-gui. Reactive behaviors of calcium silicate in sodium aluminate solutions[J]. Journal of Central South University: Science and Technology, 2009, 40(2): 275-281.

[3] HUANG Chuan-bing, WANG Yu-hua. Removal of aluminosilicates from diasporic-bauxite by selective flocculation using sodium polyacrylate[J]. Separation and Puri?cation Technology, 2008, 59(3): 299-303.

[4] 张玉敏, 刘桂华. 赤泥分离中的絮凝剂[J]. 轻金属, 2002(4): 10-11.

ZHANG Yu-min, LIU Gui-hua. Flocculants for red mud[J]. Light Metals, 2002(4): 10-11.

[5] QUADIR M, PHILLIPS E C, BRAMMER L E, MAHONEY R P, KILDEA J D, RAMESH M, MALITO J T. High molecular weight polymers containing pendant salicylic acid process liquors: US, 0024156[P]. 2004.

[6] 曹文仲, 钟 宏, 田伟威, 占昌朝. 赤泥矿物表面电性与高分子官能团选择絮凝[J]. 有色金属, 2006(2): 72-74.

CAO Wen-zhong, ZHONG Hong, TIAN Wei-wei, ZHAN Chang-chao. Surface electro-chemical performance of mud-mineral from alumina production and selective flocculation with polymer functional group[J]. Nonferrous Metals, 2006(2): 72-74.

[7] CONNELLY L J, SELVARAJAN R. Flocculants for bauxite (red mud): US 4545902[P]. 1985.

[8] JONES F, van BRONSWIJK W, FARROW J B. Flocculation of haematite in synthetic Bayer liquors[J]. Colloids and Surfaces A, 1998, 135: 183-192.

[9] CHEN H T, RAVISHANKAR S A, FARINATO R S. Rational polymer design for solid-liquid separations in mineral processing applications[J]. International Journal of Mineral Process, 2003, 72: 75-86.

[10] 张跃军, 黄娟凤, 周 莉, 李潇潇, 张鲁琰, 贾进洲, 仇 金. 不同离子性质絮凝剂在淤泥脱水中的脱水作用特征[J]. 精细化工, 2007, 24(9): 903-909.

ZHANG Yue-jun, HUANG Juan-feng, ZHOU Li, LI Xiao-xiao, ZHANG Lu-yan, JIA Jin-zhou, QIU Jin. Dehydration characteristics of flocculants with different ionic properties and molecular weights in the processes of sludge dehydration[J]. Fine Chemicals, 2007, 24(9): 903-909.

[11] 杨南如. 无机非金属材料测试方法[M]. 武汉: 武汉理工大学出版社, 1990: 268-272.

YANG Nan-ru. Test methods of inorganic non-metallic materials [M]. Wuhan: Wuhan University of Technology Press, 1990: 268-272.

[12] RUIREN J, HU Wei-bai, HOU Xian-jun. Mechanism of selective flocculation of hematite from quartz with hydrolyzed polyacrylamide[J]. Colloids Surfaces, 1987, 26: 317-331.

[13] 马晓星, 王秀芬, 张立群. NH3等离子体处理的PET表面接枝氨基酸的研究[J]. 北京化工大学学报, 2007, 34(3): 290-292.

MA Xiao-xing, WANG Xiu-fen, ZHANG Li-qun. Grafting glutamic acid to a polyethylene terephthalate(PET) film treated with NH3 plasma[J]. Journal of Beijing University of Chemical Technology, 2007, 34(3): 290-292.

[14] 刘丹丹, 王 宜, 胡 健, 周雪松, 宁 平, 张英东. PBO纤维表面等离子改性及界面性能[J]. 华南理工大学学报: 自然科学版, 2006, 34(3): 10-14.

LIU Dan-dan, WANG Yi, HU Jian, ZHOU Xue-song, NING Ping, ZHANG Ying-dong. Plasma modification on PBO fiber surface and interfacial properties of PBO fiber[J]. Journal of South China University of Technology: Natural Science Edition, 2006, 34(3): 10-14.

[15] 林志勇, 叶 葳, 杜慷慨, 曾汉民. 碳纤维表面官能团均一化及其表面能[J]. 华侨大学学报: 自然科学版, 2001, 22(3): 261-263.

LIN Zhi-yong, YE Wei, DU Kang-kai, ZENG Han-min. Homogenization of functional groups on surface of carbon fiber and its surface energy[J]. Journal of Huaqiao University: Natural Science, 2001, 22(3): 261-263.

[16] 郭玲香. 聚合物絮凝与助滤作用机理[M]. 南京: 东南大学出版社, 2007: 126-142.

GUO Ling-xiang. Flocculation and filtration mechanism of polymer[M]. Nanjing: Southeast University Press, 2007: 126-142.

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2005CB623702)

收稿日期:2009-12-22;修订日期:2010-05-13

通信作者:周秋生,副教授,博士;电话:0731-88830453;E-mail:qszhou@mail.csu.edu.cn