DOI: 10.11817/j.ysxb.1004.0609.2020-37633

含钠硅酸二钙烧结过程矿相转变行为

潘晓林1, 2,裴健男1,张 灿1,于海燕1, 2

(1. 东北大学 冶金学院,沈阳 110819;

2. 东北大学 多金属共生矿生态化冶金教育部重点实验室,沈阳 110819)

摘 要:为了阐明烧结法生产氧化铝过程中碱对硅酸二钙烧结行为的影响,采用热重-差热分析、X射线衍射、傅里叶红外光谱、扫描电子显微镜等方法研究Na2O存在下不同烧结制度对硅酸二钙(C2S)烧结过程中的物相转变、晶体结构和稳定性的影响,从而为低钠石灰烧结法提供理论依据。结果表明:在CaO-SiO2二元系中,烧结产物主要物相为γ-C2S;在CaO-SiO2-Na2O体系中,碱的存在使CaCO3分解温度降低,烧结产物主要物相为β-C2S,Na2O起到助熔剂和改变C2S晶型的作用。在Na2O存在的条件下,烧结产物中β-C2S和γ-C2S红外光谱特征峰分别为845 cm-1和930 cm-1。提高烧结温度和延长保温时间,促进了块状β-C2S向呈颗粒状γ-C2S转化,β-C2S含量逐渐减少,γ-C2S含量逐渐增多,使得烧结产物结晶度升高;同时使烧结产物在碱溶液中的稳定性提高,γ-C2S固溶体比β-C2S固溶体更稳定。

关键词:硅酸二钙;烧结过程;物相转变;晶体结构;稳定性

文章编号:1004-0609(2020)-09-2136-08 中图分类号:TF821 文献标志码:A

硅酸钙作为硅酸盐的主要成份之一,由于其在陶瓷[1-2]、水泥[3-5]、生物材料[6-7]等领域有广泛的应用,成为了国内外科研工作者的研究热点。而硅酸二钙(C2S)是烧结法生产氧化铝工艺中硅的主要存在物相,其包含α、α′L、α′H、β和γ五种晶型[8-10],使得在生产过程中对C2S的晶型控制较复杂。由于熟料中不同晶型的C2S对熟料中氧化铝的溶出率有一定的影响,为此,许多研究者对C2S稳定性的研究进行了大量工作,使得对C2S结构的研究取得了一定的进展[11-15]。在处理低品位铝土矿(n(Al2O3)/n(SiO2)<4)的过程中,采用石灰烧结法,会生成稳定的γ-C2S,但是能耗高、渣量大。采用碱石灰烧结法,虽然配钙量以及烧结温度较低,氧化铝回收率高,但是目前普遍采用湿料喷浆入窑,能耗高,而且由于引入了Na+,使得硅酸二钙晶型主要为自粉性差的β-C2S以及少量自粉性良好的γ-C2S,加重了磨碎过程的能量损耗,而β-C2S在熟料浸出过程中易与铝酸钠溶液发生二次反应[16],导致氧化铝溶出率低。

长期以来,氧化铝行业科学工作者进行了大量的探索性研究,试图实现干法配料、干法烧结,但都未成功。对此,作者提出了低钠石灰烧结法[17],无碱挥发问题,可以实现窑尾旋风预热、干法烧结;降低配钙,n(CaO)/n(Al2O3)≤1.4,熟料中氧化铝的溶出率可以达到90%[18],但是Na2O的存在会阻止β-C2S向γ-C2S转化,降低氧化铝溶出率。因此,本文通过模拟低钠石灰烧结法配料,借助TG-DSC、XRD、FT-IR、SEM等检测手段,研究了不同烧结制度对C2S烧结过程中的物相转变、晶体结构和稳定性能的影响,从而得到更稳定的C2S,为低钠石灰烧结法提供理论依据。

1 实验

首先采用分析纯试剂CaCO3、SiO2、Na2CO3为烧结配料,CaCO3和SiO2摩尔比为C/S,Na2O(以Na2CO3形式添加)和SiO2摩尔比为N/S。将C/S为2,不同N/S的试验原料按料球比为3:1装进混料罐放在混料机上混合2 h,使用压样器压制为d 20 mm×25 mm料柱,装进石墨坩埚放入箱式MoSi2电阻炉中以10 ℃/min的升温速率升到设定的烧结温度后并保温一定的时间,待烧结结束后,物料随炉冷却至室温取出,研究其反应机理。

烧结产物稳定性试验步骤为将三口圆底烧瓶固定于恒温水浴锅中,安装搅拌装置及冷凝回流装置,按照试验所需的液固比将烧结产物和标准溶液缓慢倒入三口烧瓶中,打开搅拌装置。一定时间后结束反应,用布氏漏斗进行液固分离,采用滴定法分析液体中氧化铝、氧化钠及二氧化硅的浓度。

TG-DSC分析检测采用德国NETZSCH- STA449F1分析仪,测试范围升温阶段为30~1450 ℃,升温速度为10 ℃/min,降温阶段为1450~300 ℃,降温速度为20 ℃/min。XRD分析检测采用荷兰Philips X`Pert PW3040-60型X射线衍射分析仪,Cu Kα,管电压为40 kV,管电流为40 mA,扫描范围为5°~90°。在烧结产物中混入10%质量分数)MgO作为内标,通过半定量方法对烧结产物各物相含量、晶体结构参数、晶粒尺寸、结晶度进行拟合计算,拟合误差均小于10%。FT-IR光谱分析检测采用日本岛津SHIMADZU IRPrestige-21傅里叶变换红外光谱仪,样品采用KBr压片法进行制备,扫描范围为4000~400 cm-1。SEM微观形貌分析采用德国蔡司公司ULTRA PLUS-43-13型扫描电子显微镜,工作电压为15 kV。

2 结果与讨论

2.1 烧结物料TG-DSC热分析

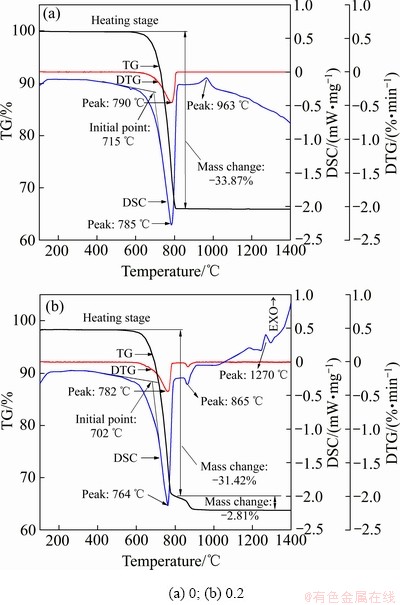

图1所示为N/S=0和N/S=0.2样品的TG-DSC热重曲线。由图1(a)可知,在N/S为0的条件下,升温过程中785 ℃处出现一个大吸热峰,结合质量曲线在该温度存在33.87%的质量损失,且在790 ℃时质量损失速率最大,表明该处吸热峰为CaCO3分解产生。同时由切线法得到该反应是在715 ℃开始发生,在785 ℃时反应速率最快,与DTG峰值基本吻合。963~1400 ℃呈下降趋势,963 ℃处出现一个小放热峰并且物料质量未发生变化,切点温度为952 ℃,表明CaO与SiO2在该温度下开始发生反应,生成C2S前驱体,该过程为吸热过程,在963 ℃时反应速率最快。由图1(b)可知,CaCO3分解反应发生在702 ℃,在764 ℃时反应速率最快,同时DTG峰值782 ℃为质量损失速率最大的点,与DSC峰值处有较好的吻合,并且N/S为0.2时CaCO3分解温度低于N/S为0时的分解温度,说明Na2O起到助熔剂的作用,降低了CaCO3的分解温度。在865 ℃处存在一个小吸热峰并伴随一个轻微质量损失,由切线法得到该反应是在856 ℃下开始发生,由于Na2CO3熔点为851 ℃,因此,认为此处变化为Na2CO3的熔融引起。865~1270 ℃呈上升趋势,较N/S为0时的热量曲线有明显区别,主要是由于Na+以部分置换或填隙形式进入C2S晶体结构的四面体或八面体空洞中改变了C2S晶型导致的,说明添加Na2O起到了改变C2S晶型的作用。

图1 不同N/S比的CaO-SiO2体系TG-DSC分析结果

Fig. 1 TG-DSC results of CaO-SiO2 system with different N/S ratios

2.2 烧结温度对C2S物相转变行为的影响

图2所示为C/S为2、N/S为0.1、保温时间为1 h时不同烧结温度下烧结产物的XRD谱,同时对烧结产物中各物相进行半定量分析,含量如表1所列。结合图2和表1可知,当烧结温度为1300 ℃时,烧结产物中主要物相为β-C2S,以及少量未反应的游离CaO。由于C2S的形成过程与铝酸钙的形成过程较接近,主要受扩散控制影响[19],当温度较低时不利于物料扩散,反应进行比较缓慢,反应不完全。当温度升高到1350 ℃时,CaO相消失,β-C2S含量降低,并出现γ-C2S。继续升高温度到1400 ℃,γ-C2S含量由12%升高到32%,β-C2S含量由51%下降到36%。同时,随着温度的升高,β-C2S特征峰的强度减弱,γ-C2S特征峰的强度增强,表明升高温度促进烧结产物中β-C2S向γ-C2S的转化。这是由于C2S的固溶体被认为是一种硅取代氧的缺陷固溶体,而纯净的C2S被认为是一种有某些缺陷的复杂物质,这些缺陷造成了化学不稳定状态,导致产生应变积聚的双晶现象,使β-C2S在冷却过程中生成γ-C2S。但是在有Na2O存在的条件下,Na+以部分置换Ca2+或填隙形式进入C2S晶体结构的四面体或八面体空洞中改变了C2S晶型,Na+固溶进C2S晶胞中,大大增加β-C2S的稳定性,β-C2S的晶面峰强度增强,使C2S始终成β-C2S存在。随着温度的升高,Na2CO3的熔融状态加剧,碱挥发量大,Na+固溶进C2S晶胞中的数量减少,导致晶胞体积变小,使得β-C2S的晶面峰强度降低,促进其向γ-C2S的晶面转变。

图2 不同烧结温度下烧结产物XRD谱

Fig. 2 XRD patterns of sintered products at different temperatures

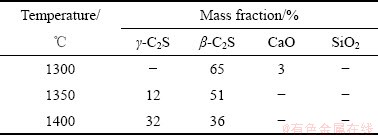

表1 不同烧结温度下烧结产物中的各物相含量

Table 1 Content of sintered products at different sintering temperatures

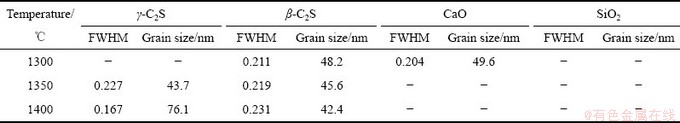

为了进一步验证上述结论,通过JADE对XRD谱进行分析,先进行平滑和Theta Calibration处理,然后采用Rietveld全谱拟合法分析各物相的衍射峰晶面指数、晶胞参数和结晶度。结晶度为相对结晶度,即认为非晶相和晶相强度之和为100%,晶相占总强度的比例为相对结晶度。由谢乐公式[20]计算晶粒尺寸,见式(1),γ-C2S、β-C2S、CaO和SiO2对应晶面依次为(130)、 、(200)和(200),计算结果如表2和表3所示。

、(200)和(200),计算结果如表2和表3所示。

(1)

(1)

式中:D是晶块尺寸,nm;K是谢乐常数,通常为0.89;λ是X射线衍射波长,nm;B是半高宽FWHM,rad;θ为衍射角,rad。

由表2可以看出,随烧结温度的升高,γ-C2S晶粒尺寸由1350 ℃的43.7 nm增加到1400 ℃的76.1 nm,半高宽呈降低趋势,β-C2S晶粒逐渐减小,半高宽呈增大趋势,半高宽与晶粒尺寸成反比。表明升高温度促进γ-C2S晶粒尺寸的长大,并降低了β-C2S晶粒尺寸。由表3可知,随烧结温度由1300 ℃升高到1400 ℃,β-C2S晶胞体积逐渐下降,总结晶度升高,这是由于Na2O添加导致烧结产物中C2S晶型变化,发生不同程度的晶格畸变以及出现非晶物质造成的,由于Na+的固溶作用使得总结晶度降低,随着温度的升高,晶胞中Na+固溶量减少,非晶物质数量减少,β-C2S向γ-C2S转化数量增加,总结晶度升高。

表2 不同温度下烧结产物中各物相半高宽和晶粒大小

Table 2 FWHM and grain size of phases in sintered products at different temperatures

表3 不同温度下烧结产物物相晶胞参数

Table 3 Lattice parameters of sintered products at different sintering temperatures

图3 不同烧结温度下烧结产物FT-IR分析图谱

Fig. 3 FT-IR spectra of sintered products at different sintering temperatures

图3所示为不同烧结温度下烧结产物的红外光谱。在红外光谱中γ-C2S特征峰位为931 cm-1、820 cm-1、555 cm-1、440 cm-1,β-C2S特征峰位在890 cm-1、845 cm-1、520 cm-1。由图4可以看出,随着温度由1300 ℃升高至1400 ℃,997 cm-1处Si—O键的反对称弯曲振动逐渐减弱;845 cm-1处为β-C2S的特征辨识谱带,其吸收峰强度减弱,说明温度升高β-C2S含量降低;930 cm-1为γ-C2S特征辨识谱带,随着温度的升高,峰强度明显增强,说明温度升高γ-C2S含量增加。845~877 cm-1波段为Si—O键反对称伸缩吸收峰,845 cm-1波段峰位向高频偏移,516 cm-1和490 cm-1为O—Si—O键对称弯曲振动,但随着温度升高,谱峰范围变窄,红外光谱吸收峰数目增多。这是由于极化能力比Ca2+小的离子对β-C2S都有稳定作用[21],Na+极化能力低于Ca2+的,Na+固溶进β-C2S晶格后,使得Na+在β-C2S的缺陷上富集,使缺陷的自由能降低,Na+在新相晶核的晶界上将大大降低晶界迁移率,于是新相难以长大,对γ-C2S成核起阻碍作用。而随着温度的升高,碱挥发增大,晶胞中Na+固溶量减少,C2S晶体缺陷自由能升高,β-C2S向γ-C2S转化的抑制作用减弱,这与XRD分析结果一致。

图4所示为不同烧结温度下烧结产物的微观形貌。由图4可知,在温度为1300 ℃时,烧结产物主要呈块状,晶体表面呈现很多不规则的微小裂隙。继续升高温度,块状表面出现分散的颗粒状,并且随着温度的升高数量越来越多。这是由于在1300 ℃时,烧结产物主要是自粉性差的块状β-C2S,而随着温度升高,碱挥发增大,晶胞中Na+固溶量减少,自粉性差的β-C2S逐渐向自粉性良好的颗粒状γ-C2S转化。进一步证明升高温度有利于γ-C2S的生成。

图4 不同烧结温度下烧结产物微观形貌

Fig. 4 Micromorphologies of sintered products at different sintering temperatures

2.3 保温时间对C2S物相转变行为的影响

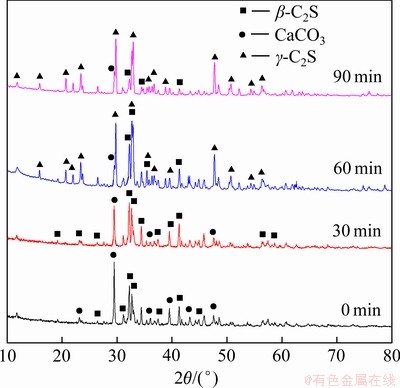

图5所示为C/S为2、N/S为0.1、烧结温度为1350 ℃时不同保温时间下烧结产物的XRD谱。由图5可以看出,烧结产物物相成分主要为γ-C2S、β-C2S和CaO。随着保温时间由0 min增加到90 min,XRD谱β-C2S特征峰强度先增强后减弱。保温时间在30 min以内,烧结产物的主要物相为β-C2S,并且检测到一定量的游离CaO,说明保温时间较短,物料扩散缓慢,烧结原料未反应完全,同时Na2O固溶在β-C2S中,抑制β-C2S向γ-C2S转化。随着反应时间的进一步延长,烧结物相中的CaO消失,β-C2S增多,并且出现了新物相γ-C2S,这是由于随着时间的延长,β-C2S的含量增多,同时碱挥发增大,晶胞中Na+固溶量减少,使得Na2O的稳定作用减弱,降温过程中部分β-C2S转化成γ-C2S。当保温时间为90 min时,β-C2S特征峰强度减弱,原因为晶胞中Na+固溶量进一步减少,β-C2S转化成γ-C2S较多。说明延长保温时间有助于Ca2+的扩散,加快烧结反应进程,促进固相反应的发生,同时也促进γ-C2S的生成。

图5 不同保温时间下烧结产物XRD谱

Fig. 5 XRD patterns of sintered products for different durations

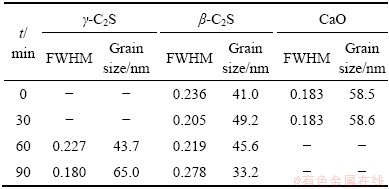

根据XRD数据处理软件JADE中的晶胞精修板块计算保温时间范围为0~90 min烧结产物各物相的晶体参数,其中γ-C2S选取晶面指数为(130),2θ为29.78°,β-C2S选取的晶面指数为 ,2θ为32.17°,计算结果如表4和图6所示。根据表4和图6可知,在1350 ℃,随着时间的延长,β-C2S晶粒尺寸呈先升高再降低趋势,这是由于在保温时间短的条件下,烧结产物晶体结构不完善,非晶物质多,延长到30 min,β-C2S晶型趋于完善,同时由于Na+的固溶作用,β-C2S晶胞体积变大,非晶物质逐渐增多,晶粒尺寸逐渐变大。随着保温时间的再度延长,碱挥发量增大,晶胞中Na+固溶量减少,β-C2S晶胞体积和非晶物质逐渐减小,β-C2S开始向新相γ-C2S转化,β-C2S晶粒尺寸开始变小。说明延长保温时间,有利于Ca2+扩散到SiO2界面和晶格中,加快烧结反应进程,使烧结产物总体结晶度升高。

,2θ为32.17°,计算结果如表4和图6所示。根据表4和图6可知,在1350 ℃,随着时间的延长,β-C2S晶粒尺寸呈先升高再降低趋势,这是由于在保温时间短的条件下,烧结产物晶体结构不完善,非晶物质多,延长到30 min,β-C2S晶型趋于完善,同时由于Na+的固溶作用,β-C2S晶胞体积变大,非晶物质逐渐增多,晶粒尺寸逐渐变大。随着保温时间的再度延长,碱挥发量增大,晶胞中Na+固溶量减少,β-C2S晶胞体积和非晶物质逐渐减小,β-C2S开始向新相γ-C2S转化,β-C2S晶粒尺寸开始变小。说明延长保温时间,有利于Ca2+扩散到SiO2界面和晶格中,加快烧结反应进程,使烧结产物总体结晶度升高。

表4 不同保温时间下烧结产物中各物相半高宽和晶粒大小

Table 4 FWHM and grain size of phases in sintered products for different durations

图6 不同保温时间下烧结产物中C2S晶胞体积及总结晶度

Fig. 6 Unit cell volume and total crystallinity of C2S in sintered products for different durations

对保温时间范围为0~90 min烧结产物进行FT-IR分析,进一步探究保温时间对C2S含量以及晶体结构的影响,结果如图7所示。由图7可知,随着保温时间由0 min延长到90 min,吸收峰强度明显升高,表明延长保温时间有助于C2S晶粒长大,结晶度增加,含量增加;在930 cm-1以及815 cm-1波段出现了γ-C2S特征辨识谱带;847 cm-1波段由844 cm-1发生一定程度的峰位偏移,与γ-C2S在该波段处的标准谱峰848 cm-1 Si—O反对称伸缩振动几乎一致;499 cm-1波段O—Si—O键对称弯曲振动偏移到495 cm-1处,谱峰范围变窄,说明延长时间有助于完善β-C2S晶型,同时降低固溶在β-C2S中Na2O的含量,在降温过程中更有利于转化成γ-C2S。996 cm-1为β-C2S的特征谱带,吸收峰强度变化与β-C2S的含量变化一致;499 cm-1处谱带为O—Si—O键对称弯曲振动,振动吸收峰的强度呈先降低后升高趋势,随保温时间由0 min增加到90 min,峰位向高频波段移动,至495 cm-1处,逐渐趋向γ-C2S标准图谱峰位。以上结果与XRD分析结果一致。

图7 不同保温时间下烧结产物FT-IR分析图谱

Fig. 7 FT-IR spectra of sintered products for different durations

将烧结产物与碱溶液(NaOH浓度为60 g/L(以Na2O计),Na2CO3浓度为50 g/L(以Na2O计),Al2O3浓度为58 g/L,反应温度80 ℃,反应时间1 h,液固比为10)进行反应,并计算出C2S反应率,C2S的反应方程式及反应率(η)分别见式(2)~(5),计算结果如图8所示。由图8可看出,随着保温时间的延长,C2S反应率由12.57%下降至7.77%。当保温时间低于30 min时,C2S反应率下降缓慢,这是由于烧结产物中的主要物相为β-C2S以及非晶物质,β-C2S与溶液中的碱反应造成的。但是随着保温时间增加到90 min,烧结产物的结晶度升高,并生成较稳定的γ-C2S,因此,C2S反应率急剧降低,说明γ-C2S固溶体比β-C2S固溶体稳定。

2CaO·SiO2(s)+2NaOH(l)=Na2SiO3(l)+2Ca(OH)2(s) (2)

3Ca(OH)2(s)+2NaAl(OH)4(l)=3CaO·Al2O3·6H2O(s)+2NaOH(l) (3)

3CaO·Al2O3·6H2O(s)+nNa2SiO3(l)=3CaO·Al2O3·nSiO2·(6-2n)H2O(s)+2nNaOH(l)+nH2O (4)

(5)

(5)

式中:η为硅酸二钙的反应率,%; 为溶液中二氧化硅浓度,g/L;V为溶液总体积,mL;m为原料质量,g;

为溶液中二氧化硅浓度,g/L;V为溶液总体积,mL;m为原料质量,g; 为原料中硅酸二钙的含量,%;

为原料中硅酸二钙的含量,%; 为硅酸二钙相对分子质量;

为硅酸二钙相对分子质量; 为二氧化硅相对分子质量。

为二氧化硅相对分子质量。

图9所示为不同保温时间烧结产物反应渣的XRD谱。由图9可以看出,当保温时间低于30 min时,由于此时β-C2S含量较多与溶液中的碱发生反应,使得反应渣主要物相为CaCO3。随着保温时间的延长,烧结产物中出现了较稳定的γ-C2S,因此,反应渣中CaCO3含量随之降低,γ-C2S含量升高。

图8 不同保温时间下烧结产物中C2S反应率

Fig. 8 Reaction rate of C2S of sintered products for different durations

图9 不同保温时间烧结产物反应渣XRD谱

Fig. 9 XRD patterns of residues of sintered products for different durations

3 结论

1) 在CaO-SiO2二元系中,CaCO3开始分解温度为715 ℃,烧结产物主要物相为γ-C2S;在CaO-SiO2-Na2O体系中,CaCO3开始分解温度降低到702 ℃,烧结产物主要物相为β-C2S,Na2O起到助熔剂和改变C2S晶型的作用。

2) 烧结产物中β-C2S和γ-C2S红外光谱特征峰分别为845 cm-1和930 cm-1。提高烧结温度,促进β-C2S向γ-C2S转化,并使块状β-C2S含量逐渐减少,呈分散性的颗粒状γ-C2S含量逐渐增多,结晶度升高。

3) 延长保温时间促进β-C2S向γ-C2S转化,使烧结产物在碱溶液中的稳定性提高,γ-C2S固溶体比β-C2S固溶体更稳定。

REFERENCES

[1] LI H, CHANG J. Stimulation of proangiogenesis by calcium silicate bioactive ceramic[J]. Acta Biomaterialia, 2013, 9(2): 5379-5389.

[2] LIN K L, CHANG J, ZENG Y, QIAN W J. Preparation of macroporous calcium silicate ceramics[J]. Materials Letters, 2004, 58(15): 2109-2113.

[3] RICARDO S,FRANCO Z. Recycling of hydrated cement pastes by synthesis of α′H-C2S[J]. Cement and Concrete Research, 2017, 100: 398-412.

[4] ZHOU X, MU Y D, LIU Z C, WANG F Z. Fabrication and characterization of a novel carbonated 0-3 piezoelectric γ-C2S composite[J]. Ceramics International, 2018, 44(11): 13426-13429.

[5] WANG D G, ZHANG Y, HONG Z R. Novel fast-setting chitosan/β-dicalcium silicate bone cements with high compressive strength and bioactivity[J]. Ceramics International, 2014, 40(7): 9799-9808.

[6] AHMAD O, SOODEH A. Reconstruction of radial bone defect in rat by calcium silicate biomaterials[J]. Life Sciences, 2018, 201: 45-53.

[7] LEE Y L, WANG W H, LIN F H, LIN C P. Hydration behaviors of calcium silicate-based biomaterials[J]. Journal of the Formosan Medical Association, 2017, 116(6): 424-431.

[8] LINK T, BELLMANN F, LUDWING H M, BEN H M. Reactivity and phase composition of Ca2SiO4 binders made by annealing of alpha-dicalcium silicate hydrate[J]. Cement and Concrete Research, 2015, 67(1): 131-137.

[9] EYSEL W, HAHN T. Polymorphism and solid solution of Ca2GeO4 and Ca2SiO4[J]. Crystalline Materials, 1970, 131: 322-341.

[10] SMITH D K, MAJUMDAR A, ORDWAY F. The crystal structure of γ-dicalciumsilicate[J]. Acta Crystallographica, 1965, 18(4): 787-795.

[11] 张巨松, 张添华, 郑万荣, 王文军, 金建伟, 白洪彬, 隋智通. 氧化钛对硅酸二钙形成的影响[J]. 沈阳建筑大学学报(自然科学版), 2006, 22(3): 424-427.

ZHANG Ju-song, ZHANG Tian-hua, ZHENG Wan-rong, WANG Wen-jun, JIN Jian-wei, BAI Hong-bin, SUI Zhi-tong. The Influence of titania on bicalcium silicate formation[J]. Journal of Shenyang Jianzhu University (Natural Science),2006, 22(3): 424-427.

[12] 钟 侚, 蹇守卫, 柯 凯. V5+及Cr3+掺杂对C2S多晶型的影响机制[J]. 济南大学学报(自然科学版), 2011, 25(4): 350-353.

ZHONG Xun, JIAN Shou-wei, KE Kai. Influence of V5+ and Cr3+ doping on polymorphic forms of C2S[J]. Journal of Jinan University (Natural Science), 2011, 25(4): 350-353.

[13] MAITI S C, GHOROI C. Influence of catalytic nano-additive for stabilization of β-dicalcium silicateand its hydration rate with different electrolytes[J]. Cement and Concrete Research, 2017, 98: 111-121.

[14] 邹 千, 马 妍, 王玺堂, 王周福, 刘 浩, 刘 奇. Ba2+离子掺杂对C2S结构稳定性的影响[J]. 耐火材料, 2016, 50(4): 265-268.

ZOU Qian, MA Yan, YU Xi-tang, WANG Zhou-fu, LIU Hao, LIU Qi. Effect of Ba2+ doping on stability of C2S structure[J]. Naihuo Cailiao, 2016, 50(4): 265-268.

[15] 潘晓林, 董凯伟, 侯宪林, 于海燕, 涂赣峰, 毕诗文. 含硼铝酸钙熟料的高温成矿机理及其浸出性能[J]. 中国有色金属学报, 2014, 24(6): 1664-1670.

PAN Xiao-lin, DONG Kai-wei, HOU Xian-lin, YU Hai-yan, TU Gan-feng, BI Shi-wen. High-temperature metallogenic mechanism and leaching property of calcium aluminate clinker with B2O3[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1664-1670.

[16] 郭 琴, 王 军. 二次反应对熟料中氧化铝溶出率的影响[J]. 轻金属, 2003(10): 10-12.

GUO Qin, WANG Jun. Effect of secondary reaction on dissolution rate of alumina in clinker[J]. Light Metals, 2003(10): 10-12.

[17] 于海燕, 潘晓林, 王 波, 毕诗文, 顾松青. 采用低铝硅比含铝资源干法或半干法生产氧化铝的方法: 中国, 201210069963.8[P]. 2014-07-16.

YU Hai-yan, PAN Xiao-lin, WANG Bo, BI Shi-wen, GU Song-qing. Method for producing alumina by using dry or semi-dry method of aluminum resources that low-aluminum silicon ratio: China, 201210069963.8[P]. 2014-07-16.

[18] TIAN Y P, PAN X L, YU H Y, TU G F. Formation mechanism and crystal simulation of Na2O-doped calcium aluminate compounds[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(3): 848-858.

[19] OHAMED B M, SHARP J H. Kinetics and mechanism of formation of tricalcium aluminate, Ca3Al2O6[J]. Thermochimica Acta, 2002, 388: 105-114.

[20] 魏立帅, 陈诺夫, 张 航, 王从杰, 贺 凯, 白一鸣, 陈吉堃. 石墨衬底上铝诱导法制备多晶硅薄膜[J]. 人工晶体学报, 2017, 46(9): 1709-1713.

WEI Li-shuai, CHEN Nuo-fu, ZHANG Hang, WANG Cong-jie, HE Kai, BAI Yi-ming, CHEN Ji-kun. Preparation of polycrystalline silicon thin film by AIC on graphite substrate[J]. Journal of Synthetic Crystals, 2017, 46(9): 1709-1713.

[21] 冯修吉, 龙世宗. 微量离子对β-C2S稳定性的影响及其机理研究[J]. 硅酸盐学报, 1985, 13(4): 425-432.

FENG Xiu-ji, LONG Shi-zong. Effect of minor ions on the stability of β-C2S and its mechanism[J]. Journal of Silicate, 1985, 13(4): 425-432.

Mineral transition behavior of dicalcium silicate doped with Na2O during sintering

PAN Xiao-lin1, 2, PEI Jian-nan1, ZHANG Can1, YU Hai-yan1, 2

(1. School of Metallurgy, Northeastern University, Shenyang 110819, China;

2. Key Laboratory for Ecological Metallurgy of Multimetallic Mineral, Ministry of Education, Northeastern University, Shenyang 110819, China)

Abstract: In order to clarify the influence of alkali on the sintering behavior of dicalcium silicate in the production of alumina by the sinter process, the phase transformation, crystal structure and stability of dicalcium silicate (C2S) in the presence of Na2O during the high-temperature sintering process under different sintering conditions were investigated by TG-DSC, XRD, FT-IR and SEM methods, providing theoretical basis for the low-sodium lime sinter process. In the CaO-SiO2 binary system, the main phase of the sintered product is γ-C2S. In the CaO-SiO2-Na2O system, the decomposition temperature of CaCO3 is reduced by Na2O, and the main phase is β-C2S. Na2O acts as the role of flux and can alter the C2S crystal forms. In the presence of Na2O, the characteristic peak of infrared spectroscopy of β-C2S and γ-C2S in the sintered product are 845 cm-1 and 930 cm-1, respectively. The increase of sintering temperature and the extension of holding time promote the phase transformation of blocky β-C2S to granular γ-C2S, decrease the content of β-C2S, increase the content of γ-C2S, and increase the crystallinity of the sintered product. The stability of the sintered product in the alkali solution is improved, and the γ-C2S solid solution is more stable than the β-C2S solid solution.

Key words: dicalcium silicate; sintering process; mineral transition; crystal structure; stability

Foundation item: Project(2018YFC1901903) supported by the National Key Research and Development Program of China; Project(51674075) supported by the National Natural Science Foundation of China

Received date: 2019-11-07; Accepted date: 2020-06-23

Corresponding author: PAN Xiao-lin; Tel: +86-24-83686460; E-mail: panxl@smm.neu.edu.cn

(编辑 王 超)

基金项目:国家重点研发计划资助项目(2018YFC1901903);国家自然科学基金资助项目(51674075)

收稿日期:2019-11-07;修订日期:2020-06-23

通信作者:潘晓林,副教授,博士;电话:024-83686460;E-mail:panxl@smm.neu.edu.cn