文章编号:1004-0609(2013)S1-s0433-04

热处理工艺对TB8钛合金显微组织和力学性能的影响

商国强,王新南,费 跃,李 军,朱知寿

(北京航空材料研究院,北京 100095)

摘 要:研究不同热处理制度对TB8钛合金的显微组织特征和力学性能的影响。结果表明:当固溶温度高于β相变点并随后进行时效处理后,形成了明显的晶界,获得了长大的再结晶β晶粒组织。随着时效温度的升高,TB8合金的拉伸强度逐渐降低,而伸长率和断面收缩率均略有升高,其变化不是很明显。当固溶温度低于β相变点并随后进行时效处理后,再结晶后的β晶粒较小,晶界不连续且晶内组织非常细小,拉伸强度和拉伸塑性均获得明显提高,获得了更优的强塑性匹配效果。TB8钛合金经不同固溶时效处理后,均具有较高的剪切强度。

关键词:TB8合金;热处理;显微组织;力学性能

中图分类号:TG146.4 文献标志码:A

Effects of heat treatment processing on microstructure and mechanical properties of TB8 alloy

SHANG Guo-qiang, WANG Xin-nan, FEI Yue, LI Jun, ZHU Zhi-shou

(Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: Effects of different heat treatments on microstructure and mechanical properties of TB8 alloy were analyzed. The results show that, when the solution temperature is above the β transus followed by aging treatment, the obvious grain boundary forms, and the grown recrystal β grains are obtained. With the aging temperature increasing, the tensile strength of TB8 alloy decreases gradually, while the tensile plasticity does not change obviously. When the solution temperature is below the β transus followed by aging treatment, the recrystal β grains are smaller, the grain boundary is discontinuation and the intragranular microstructures are very finer. At the same time, the tensile strength and tensile plasticity obtains increase obviously, the best combination of strength and ductility are obtained. After different heat treatments, all TB8 alloys have higher shear strength.

Key words: TB8 alloy; heat treatment; microstructures; mechanical properties

TB8钛合金[1-2](名义成分为Ti-15Mo-3Al-2.7Nb- 0.2Si)为我国在“九五”期间研制的一种新型亚稳β型钛合金,具有优良的高温强度和抗蠕变性能、优异的成型性、较好的焊接性能、较高的抗氧化性和良好的抗腐蚀能力,是一种较为理想的航空结构材料,可用于板材、箔材、带材、丝材、管材、棒材以及锻件等[3-5]。

TB8钛合金最明显的特点就是可以通过固溶时效热处理进行热处理强化,强度-塑性匹配性能好,通过调整热处理工艺,其抗拉强度可达1 400 MPa以上[6]。本文作者对比研究热处理工艺对TB8钛合金小规格棒材组织和性能的影响,以期为TB8钛合金在航空领域的扩大应用提供理论和试验依据。

1 实验

本研究所用TB8原材料为经过3次真空自耗电弧熔炼制备出的合金锭,后经开坯、锻造、精锻、轧制等工序加工成d15 mm的棒材,合金化学成分见表1。通过金相法测定该合金的相变点温度在815 ℃附近。

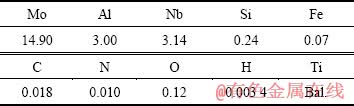

表1 TB8合金的化学成分

Table 1 Chemical composition of TB8 (mass fraction,%)

通过线切割的方法从d15 mm棒材上截取尺寸为d15 mm×71 mm的圆柱状试样,随后进行热处理,热处理制度分别如下:(830 ℃,0.5 h,AC)+(510 ℃,8.5 h,AC),简记ST1;(830 ℃,0.5 h,AC)+(530 ℃,8.5 h,AC),简记ST2;(800 ℃,0.5 h,AC)+(520 ℃,8.5 h,AC),简记ST3。室温拉伸试验采用标准的d5 mm标准试样,每3根圆棒为1组,在拉伸试样头部截取金相试样,研究热处理后的组织变化。金相试样采用化学成分配比为1HF-2HNO3-50H2O(体积分数,%)的Kroll试剂腐蚀;利用JSM-5600LV型扫描电镜试样进行显微组织和断口分析;利用电子万能试验机测定合金经不同热处理处理后的力学性能。

2 结果与分析

2.1 TB8钛合金的显微组织

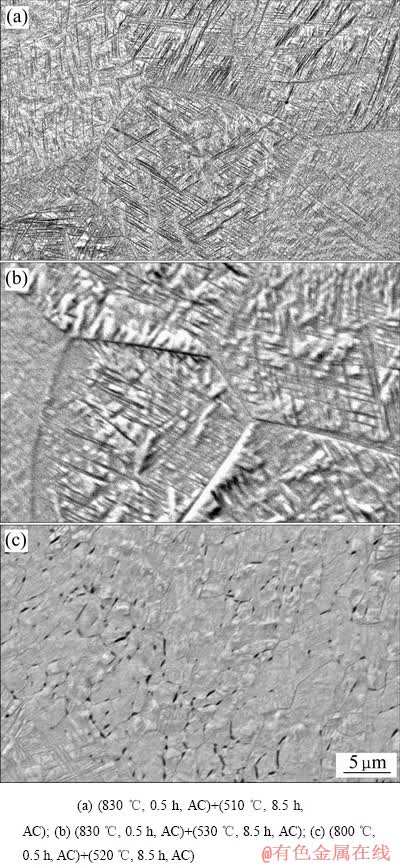

TB8钛合金经不同固溶时效处理后的显微组织如图1所示。由图1可以看出,当固溶温度高于β相变点之上固溶处理并随后进行时效时(如ST1和ST2),合金形成明显的晶界,获得了长大的再结晶β晶粒组织,如图1(a)和(b)所示。通过扫描照片进一步观察可以得出,从亚稳β基体中析出的片层状次生α相在晶内和晶界处同时析出,均匀地分布在β基体中,且片层状α相与β基体保持伯格斯位相关系[7]。这是由于在时效过程中,α相与β相的原子排列相近并能较好地匹配,当α相形核后,厚度方向的长大速度较慢而垂直方向的长大速度较快,因而形成了片层状α相。同时,当时效温度由510 ℃(ST1)升高到530 ℃(ST2)时,次生α相发生了比较明显的粗化现象。当固溶温度低于β相变点时(如ST3),由于固溶温度处于两相区,再结晶后的β晶粒较小,晶界不连续且晶内组织非常细小,合金显微组织主要由等轴初生α相和β转变组织组成,在时效过程中沿原始晶界和晶内析出的初生α相尺寸较细小,如图1(c)所示。

图1 TB8合金经不同固溶时效处理后的显微组织

Fig. 1 Microstructures of TB8 alloy after different solution and aging treatments

2.2 TB8钛合金的拉伸性能

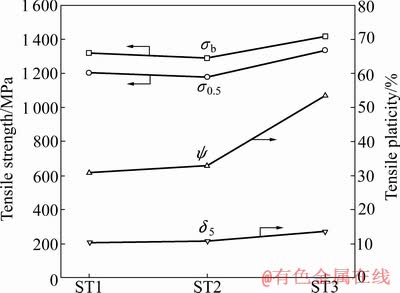

TB8钛合金经不同固溶时效处理后的力学性能如图2所示。由图2可以看出,当固溶温度高于β相变点时(如ST1和ST2),随着时效温度由510 ℃升高到530 ℃,TB8合金的抗拉强度和屈服强度均逐渐降低,而伸长率和断面收缩率均略有升高,变化不是很明显。当固溶温度低于β相变点时(如ST3),TB8合金的强度和塑性均获得明显提高,抗拉强度由ST2热处理制度的1 286 MPa提高到ST3热处理制度的1 415 MPa,尤其是断面收缩率,由ST2热处理制度的32.8%提高到ST3热处理制度的53.6%,提高了63.5%。亚稳β钛合金经等温时效后显微组织中次生α相的体积分数和形态决定材料的强度水平,β晶粒的大小和初生α相的体积分数决定材料的塑性[8-10],当固溶温度高于β相变点时,随着时效温度的提高,在时效过程中由亚稳β相析出的次生α相体积分数逐渐减少,最终使得合金抗拉强度和屈服强度不断下降。当合金中存在初生α相时,一方面由于初生α相呈较大的等轴状,其可开动的滑移系较多,当试样进行塑性变形时,滑移首先在个别位向因子最大的α晶粒内开动,α颗粒越多,变形能很快分散到许多晶粒中去,不至于在个别晶粒中引起应力集中而开裂;另一方面,颗粒状初生α相能够限制合金在固溶过程中β晶粒的长大,两者的共同作用使得合金具有较好的拉伸塑性。从测试结果来看,对于亚稳β型TB8合金,固溶温度在β相变点以下时可以获得更优的强塑性匹配。

图2 TB8合金经不同固溶时效处理后的拉伸性能

Fig. 2 Tensile properties of TB8 alloy after different solution and aging treatments

2.3 TB8钛合金的剪切性能

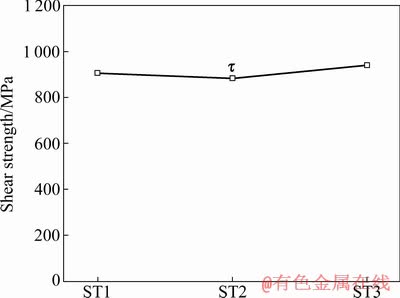

TB8钛合金经不同固溶时效处理后的剪切性能如图3所示。由图3可以看出,随着TB8合金热处理制度从ST1到ST3,其剪切强度先降低后升高,与抗拉强度和屈服强度的变化规律一致,均具有较高的剪切强度,变化不是很明显。

2.4 TB8钛合金的拉伸断口形貌

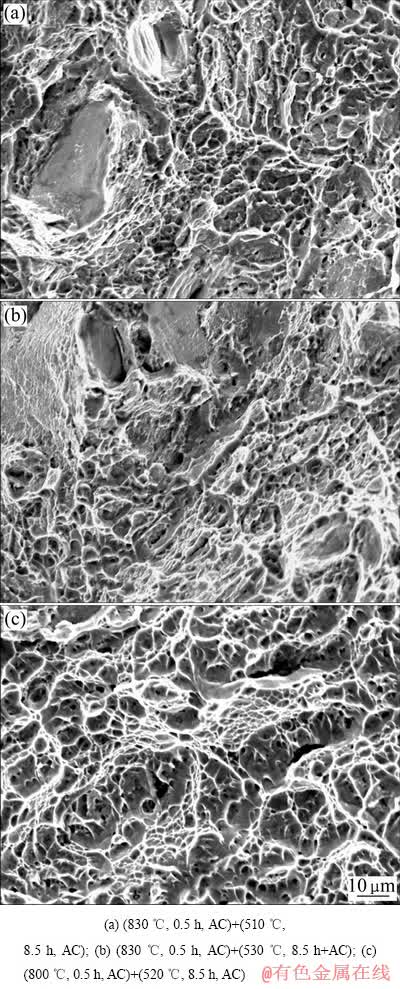

TB8钛合金经不同固溶时效处理后拉伸试样断口的形貌如图4所示。由图4可以看出,当TB8钛合金棒材采用ST1热处理制度时,断口可见大晶粒原始轮廓(见图4(a)),晶粒之间为撕裂产生的二次裂纹,晶粒轮廓上可见较浅的撕裂韧窝。当采用ST2热处理制度时,拉伸断口形貌和热处理制度为ST1时没有本质的区别,均可见大晶粒原始轮廓和等轴韧窝的存在(见图4(b)),因此两者拉伸性能相当。当采用ST3热处理制度时,拉伸断口显示大晶粒原始轮廓完全消失,均为尺寸较大的韧窝形貌(见图4(c)),这是由于当固溶处理处于两相区时,其大晶粒未完全形成,且存在一定含量的初生α相,大大增加了裂纹扩展的位错,使得断面整体均为穿晶韧窝,具有更高的拉伸强度和拉伸塑性。

图3 TB8合金经不同固溶时效处理后的剪切性能

Fig. 3 Shear property of TB8 alloy after different solution and aging treatments

图4 TB8合金不同固溶时效处理后的断口形貌

Fig. 4 Fracture micrographs of TB8 alloy after different solution and aging treatments

3 结论

1) TB8钛合金在β相变点以上温度固溶并随后进行时效处理时形成了明显的晶界,获得了长大的再结晶β晶粒组织。从亚稳β基体中析出的片层状次生α相在晶内和晶界处同时析出,均匀地分布在β基体中。当在β相变点以下温度固溶并随后进行时效处理时,再结晶后的β晶粒较小,晶界不连续且晶内组织非常细小。

2) 当固溶温度高于β相变点时,随着时效温度的升高,TB8合金的拉伸强度逐渐降低,而伸长率和断面收缩率均略有升高,变化不是很明显。而当固溶温度低于β相变点时,TB8合金的强度和塑性均明显提高,获得了更优的强塑性匹配效果。

3) TB8钛合金经不同固溶时效处理后均具有较高的剪切强度。

REFERENCES

[1] 《中国航空材料手册》编辑委员会. 中国航空材料手册[M]. 2版. 北京: 中国标准出版社, 2001.

Editorial Board of China Aeronautical Materials Handbook. China aeronautical materials handbook[M]. 2nd ed. Beijing: China Standard Press, 2001.

[2] 黄伯云, 李成功, 石力开, 邱冠周, 左铁镛. 中国材料工程大典(第4卷)[M]. 北京: 化学工业出版社, 2005.

HUANG Bai-yun, LI Cheng-gong, SHI Li-kai, QIU Guan-zhou, ZUO Tie-yong. China materials engineering manual (Volume 4) [M]. Beijing: Chemical Industry Press, 2005.

[3] 于冬梅. 新型钛合金TB8的应用研究[J]. 飞机设计, 2002(2): 57-65.

YU Dong-mei. The application study of the new type titanium TB8 [J]. Aircraft Design, 2002(2): 57-65.

[4] 沙爱学, 王庆如, 李兴无. 航空用高强度结构钛合金的研究及应用[J]. 稀有金属, 2004, 28 (1): 239-242.

SHA Ai-xue, WANG Qing-ru, LI Xing-wu. Research and application of high-strength titanium alloys used in airplane structure [J]. Chinese Journal of Rare Metals, 2004, 28(1): 239-242.

[5] 朱知寿, 王庆如. TB8钛合金板材冷成形工艺及其应用研究[J]. 金属学报, 2002, 38(z1): 414-416.

ZHU Zhi-shou, WANG Qing-ru. Cold forming processes and application of TB8 titanium sheet [J]. Acta Metallurgica Sinica, 2002, 38(z1): 414-416.

[6] 周晓虎, 马文革, 俞汉清, 朱知寿. TB8超高强度钛合金热工艺参数研究[J]. 材料工程, 2003(8): 37-39.

ZHOU Xiao-hu, MA Wen-ge, YU Han-qing, ZHU Zhi-shou. Thermo-mechanical processing parameters of TB8 super-high strength titanium alloy [J]. Journal of Materials Engineering, 2003(8): 37-39.

[7] KAR S K. Modeling of mechanical properties in alpha/beta-titanium alloys [D]. Ohio: The Ohio State University, 2005: 14.

[8] IVASISHIN O M, MARKOVSKY P E, SEMIATIN S L, WARD C H. Aging response of coarse-and fine-grained β titanium alloys [J]. Mater Sci Eng A, 2005, 354: 296-305.

[9] DUERIG T W, WILLIAMS J C. Beta titanium alloys in the 80s [M]. Warrendale, PA: TMS, 1984: 19-67.

[10] BOYER R R, WELSCH G, COLLINGS E W. Materials properties handbook: Titanium alloys [M]. ASM International, The Materials Information Society, 1994: 485-632, 685-865.

(编辑 何学锋)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:商国强,工程师,硕士; 电话:010-62496635; E-mail: shanggq1984@126.com