DOI:10.19476/j.ysxb.1004.0609.2017.06.011

热处理对SPS烧结Ti-24Nb-4Zr-8Sn合金显微组织和力学性能的影响

刘万理1, 2,张玉勤1, 2,蒋业华1,周 荣1

(1. 昆明理工大学 材料科学与工程学院,昆明 650093;

2. 云南省钛材应用产品工程技术研究中心,楚雄 651209)

摘 要:利用放电等离子烧结技术制备生物医用Ti-24Nb-4Zr-8Sn合金,研究固溶时效处理对合金显微组织和力学性能(强度、塑韧性及弹性模量)的影响。结果表明:合金经850 ℃固溶处理后主要由β相、少量初生α相及淬火马氏体α″相组成;在450 ℃时效处理后,合金基体β相内析出大量细小无规则的针状次生α相,随着时效时间从4 h延长到48 h,次生α相趋于定向析出,含量和尺寸逐渐增大;与烧结态相比,固溶时效处理后合金抗压强度和弹性模量增大,而塑韧性呈先提高后降低趋势;经优化后固溶时效处理制度为(850 ℃,1.5 h,WQ)+(450 ℃,4 h,FC),此时合金抗压强度、屈强比和弹性模量分别为1701 MPa、0.69 GPa和42.8 GPa。

关键词:Ti-24Nb-4Zr-8Sn合金;放电等离子烧结;热处理;显微组织;力学性能

文章编号:1004-0609(2017)-06-1155-07 中图分类号:TG146.2 文献标志码:A

生物医用β型钛合金具有比强度高、弹性模量低、耐磨耐蚀性及生物相容性好等优异综合性能,成为人体硬组织植入与替代的理想选择材料之一[1-3]。Ti-24Nb-4Zr-8Sn合金(简称Ti2448)是中科院金属所研制开发的一种新型生物医用亚稳β型钛合金[4-7],其弹性模量最低可达40 GPa,与人骨非常接近,能明显减小“应力-屏蔽”效应;该合金同时还具有高强度、优异柔韧性、良好生物相容性(不含有毒元素)及抗腐蚀性等特点[8-9],因而在生物医用植入材料领域具有广阔的应用前景。

放电等离子烧结技术(Spark plasma sintering,简称SPS)具有升降温速度快(可达100 ℃/min以上)、烧结时间短(一般在30 min以内)、烧结温度低(比传统粉末烧结低大约200 ℃左右)、致密度高等优点[10],利用其制备生物医用Ti2448合金,可以有效改善传统真空熔炼法制备合金过程中由于Nb、Zr等高熔点元素加入导致的成分偏析和组织不均匀等问题,同时简化了合金制备工艺过程(为了避免在熔炼合金过程中可能产生的冶金缺陷,往往需要对材料进行多次重熔)[3]。前期采用SPS技术制备了Ti2448合金[11],研究了烧结温度对合金致密度、显微组织及力学性能的影响。结果表明,SPS烧结制备的Ti2448合金显微组织为由等轴β-Ti和少量残留针状α-Ti组成的均匀组织,具有较高致密度(98%以上)和良好力学性能(抗压强度在1500 MPa以上、弹性模量在40~48 GPa之间)。但是研究也发现,烧结态Ti2448合金的屈强比在0.8左右,塑韧性相对较差,影响了合金的冷成形能力以及发生屈服变形后抵抗破坏的能力。相关研究表明[12-13],利用亚稳β钛合金中高温β相的快速冷却会形成介稳β相或淬火马氏体等中间相,随后时效时又会分解形成二次析出相,通过固溶时效处理来调整合金的显微组织,可以进一步改善合金的塑韧性,获得优良的力学相容性。

因此,本文作者采用放电等离子烧结技术制备了Ti-24Nb-4Zr-8Sn合金,并对合金进行固溶时效处理,研究固溶时效处理对合金显微组织、力学性能的影响以及塑韧性的改善机理。

1 实验

试验所用原料为Ti、Nb、Zr、Sn 粉末 (北京中诺新材科技有限公司提供),原料粉末的粒径匹配及纯度见表1。合金制备过程:按照质量分数Nb 24%、Zr 4%、Sn 8%、余量Ti称取粉末;将粉末放入行星式球磨机真空球磨罐中,按球料比3:1加入不锈钢球,同时加入无水乙醇并将其抽真空至10 Pa,在300 r/min 速度下球磨混粉10 h;将球磨干燥后的合金粉末装入石墨模具,在SPS-515S 型放电等离子烧结设备上进行烧结,烧结过程中持续外加40 MPa的轴向压力,升温速率为100 ℃/min,达到烧结温度1200 ℃,保温5 min后随炉冷却得到Ti2448合金试样。

表1 原料粉末的粒径匹配及纯度

Table 1 Particle size match and purity of raw powders

将制备的Ti2448合金试样进行固溶时效处理,经差示扫描量热法检测得到合金的(α+β)/β相转变温度在(770±5)℃。对于β型钛合金,固溶温度通常选择在相变点以上40~80 ℃,冷却方式一般为水淬(WQ),时效温度为400~500 ℃[14]。因此,本试验中合金固溶处理温度选择850℃,保温1.5 h,采用的冷却方式为水淬(WQ);时效处理温度选择为450 ℃,时效时间分别为4、8、24、48 h,然后对试样进行炉冷(FC)。热处理在真空气氛管式炉中进行,Ar气作为保护气体,采用的热处理工艺制度如表2所列。

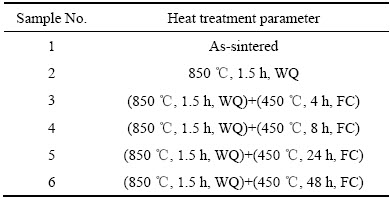

表2 SPS制备的Ti2448合金热处理工艺参数

Table 2 Heat treatment parameters of Ti2448 alloys by SPS

对烧结态、固溶及不同时效时间处理后的Ti2448合金取样,利用Bruker D8 Advance型X射线衍射仪检测分析合金的相结构,在Ziess大型金相显微镜及Philips XL30型扫描电镜下对合金显微组织进行观察;根据GB/T 7314-2005将样品制备成标准压缩试样,压缩强度试样尺寸为d 4 mm×10 mm、压缩弹性模量试样尺寸为d 2 mm×10 mm,在日本岛津AG-X万能材料试验机上进行力学性能检测,压缩速率1 mm/min。

2 结果与讨论

2.1 固溶时效处理对Ti-24Nb-4Zr-8Sn合金显微组织的影响

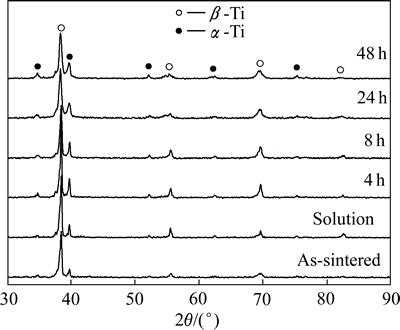

图1所示为烧结态、固溶及不同时效时间处理后Ti2448合金的XRD谱。从图1可以看出,合金在烧结态时主要由β相和少量残留α相组成;经850 ℃固溶处理后,由于超过相变点进行水淬后析出淬火马氏体α″,α″马氏体与α相的衍射峰几乎重合,因而α相含量与烧结态相比有所提高;经过450℃时效处理后,合金出现了β相向α相的转变过程,β基体内部形成了大量密集的次生α相,因而α相含量提高、β相含量呈降低趋势;随着时效时间的延长,α相含量略有增加,主要是由于亚稳β相进一步分解,析出的次生α相的数量逐渐增加导致的。

图1 烧结态、固溶及不同时效时间处理后Ti2448合金的X射线衍射图谱

Fig. 1 XRD patterns of Ti2448 alloys at as-sintered, solution and aging-treated at different aging time

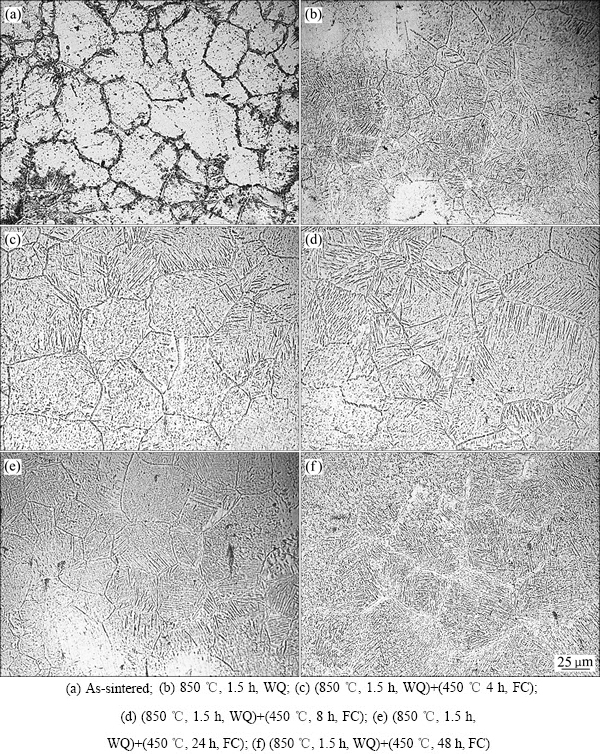

图2所示为烧结态、固溶及不同时效时间处理的Ti2448合金的光学显微照片。从图2(a)中可以看出,烧结态合金组织主要由等轴β相和少量针状α相组成,基体连续而均匀;850 ℃固溶水淬处理后(见图2(b)),亚稳β相以过饱和固溶体形式固定到室温,原始β晶粒内部包含着交错分布长直针状马氏体和分布其间尺寸较小的细针状马氏体;在随后450 ℃时效处理过程中,β相晶粒内部析出针状次生α相,在光镜下均匀细小难以观察;随着时效时间的延长(见图2(c)~(f)),原子扩散更加充分,从而为析出相的粗化提供了足够的驱动力,促进了α相的聚集和长大,次生α相由细小的针状变为粗大的长条状,且晶粒内α相含量明显增大。

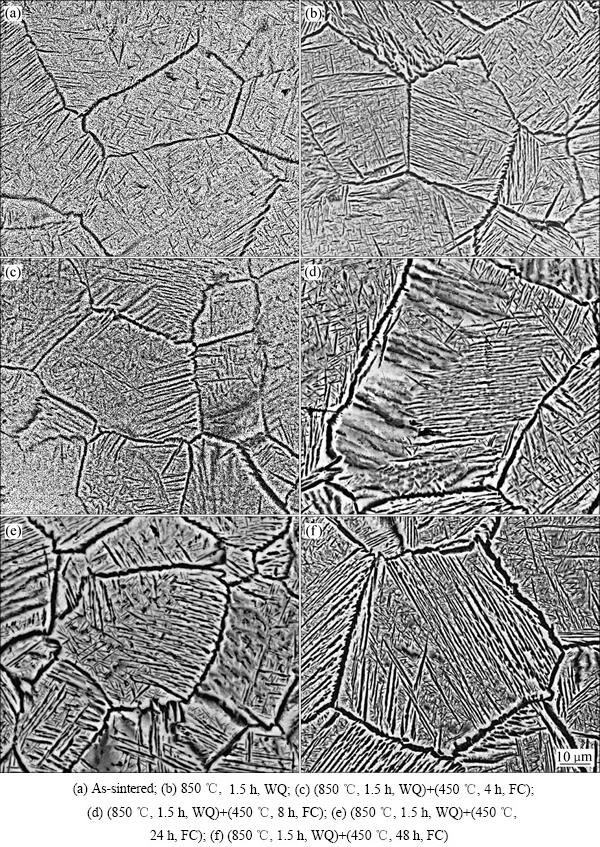

利用SEM对烧结态、固溶及不同时效时间处理后Ti2448合金的显微组织进一步进行了观察,如图3所示。与烧结态相比(见图3(a)),固溶后合金中基体β相内出现了以无扩散的切变方式产成的短针状淬火马氏体α”(见图3(b) )。在450 ℃时效处理后,因固溶体过饱和度大,β晶粒内析出大量细密而且位向无规的针状次生α相。从图3(c)~(f)可以看到,随着时效时间的延长,晶界α相由薄变厚,针状α相向晶内生长,逐渐由晶界析出向晶内析出转变,次生α相由短变长,由窄变宽,粗化成层片状,并沿着一定的惯析面定向析出,呈现出互相平行的组织形态。

图2 烧结态、固溶及不同时效时间处理后Ti2448合金的光学显微组织照片

Fig. 2 Optical micrographs of Ti2448 alloys at as-sintered, solution treatment and aging-treated at different time

2.2 固溶时效处理对Ti-24Nb-4Zr-8Sn合金力学性能的影响

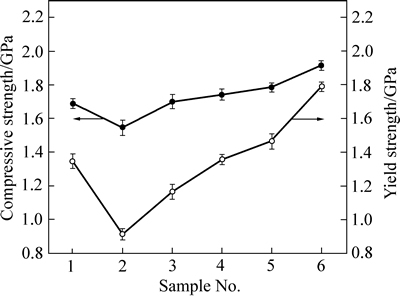

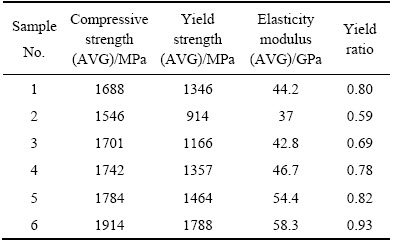

图4所示为烧结态、固溶及不同时效时间处理后Ti2448合金抗压强度和屈服强度的变化趋势,表3所列为烧结态、固溶及不同时效时间处理后Ti2448合金的力学性能值。从图4和表3中可以看出,合金经过固溶处理后,抗压强度和屈服强度明显降低,屈强比降低,塑韧性提高,但强度尤其是屈服强度下降了32%,下降过多,不能满足生物医用材料对力学稳定性的要求。经450 ℃时效处理后,合金强度与固溶态相比明显提高,且随着时效时间的延长,抗压强度呈缓慢增加趋势,而屈服强度明显提高,屈强比也随之提高,塑韧性降低。图5所示为烧结态、固溶及不同时效时间处理后Ti2448合金的应力-应变曲线。可以看出,在850 ℃固溶处理时,合金的塑韧性与烧结态相比得到提高;经450 ℃时效处理后,随着时效时间的延长,合金室温下的屈服应力逐渐增大,应力-应变曲线面积逐渐减小,塑韧性不断降低,与热处理对合金强度的影响规律相符。

图3 烧结态、固溶及不同时效时间处理后Ti2448合金的SEM像

Fig. 3 SEM images of Ti2448 alloys at as-sintered, solution treatment and aging-treated at different time

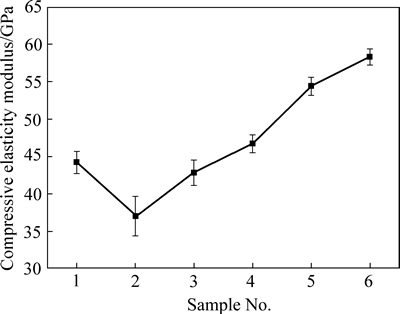

图6所示为烧结态、固溶及不同时效时间处理后Ti2448合金的弹性模量。从图6和表3中可以看出,合金经过固溶处理后弹性模量最低(37GPa),随着时效时间的增加(4~48 h),合金的弹性模量逐渐增大,由42.8 GPa增大到58 GPa。综上可知,在(850 ℃, 1.5 h, WQ)+(450 ℃, 4 h, FC)固溶时效处理条件下,Ti2448合金获得了与烧结态(抗压强度1688 MPa、弹性模量44.2 GPa)相近的抗压强度(1701 MPa)和弹性模量(42.8 GPa),而应变量和应力应变曲线面积均大于烧结态,合金的塑韧性提高,实现了强度和塑韧性的较好匹配。

大量研究表明,合金力学性能与热处理后析出相体积分数、取向、尺寸以及基体晶粒大小等组织存在密切的关系。SPS烧结的Ti2448合金经固溶处理后,主要由过饱和亚稳β相和淬火马氏体α″相组成,相对于β相,α″马氏体具有高塑性、低强度、低硬度的特点[15],因此强度明显降低,塑性增强;在450 ℃温度下进行时效处理,针状α相集中在晶界处,晶内次生α相短、细而无规则且没有固定的位向关系,产生弥散强化和细晶强化效应,强度与固溶态相比明显提高,细小均匀的组织使的试样变形时应力分布均匀,与烧结态相比表现出较高的塑性;但是随着时效时间的延长,次生α相进一步充分析出和长大,晶界α相增厚,晶内α相平直、粗大且有一定方向性的形貌使合金具有较高的变形抗力,造成变形不均匀,导致试样过早断裂[16],因而塑性降低,强度进一步提高。

时效过程中,合金的弹性模量随时效时间的变化取决于时效过程中析出的α相含量,对钛合金弹性模量E值影响程度按相结构依次大体为ω>α′>α>β≈α″[17];固溶态合金主要由亚稳β相和淬火马氏体α″组成,α″弹性模量与β相近,固弹性模量出现了大幅的下降。在钛合金中α相为硬化相,与β相相比有较高的弹性模量,随着时效时间的延长,α相体积分数增加,固合金的弹性模量随着时效时间的延长而显著增大。

综上所述,SPS烧结的Ti2448合金经过固溶时效处理后,与烧结态相比,抗压强度和弹性模量增大,而塑韧性呈先提高后降低趋势。经优化后固溶时效处理制度为(850 ℃,1.5 h,WQ)+(450 ℃,4 h,FC),此时合金抗压强度、屈强比和弹性模量分别为1701 MPa、0.69 GPa和42.8 GPa。通过固溶时效处理来调整的显微组织,可以调节强度、弹性模量和塑性之间的匹配关系,提高合金的塑韧性。

图4 烧结态、固溶及不同时效时间处理后Ti2448合金的抗压强度和屈服强度

Fig. 4 Compressive strength and yield strength of Ti2448 alloys at as-sintered, solution treatment and aging-treated at different time

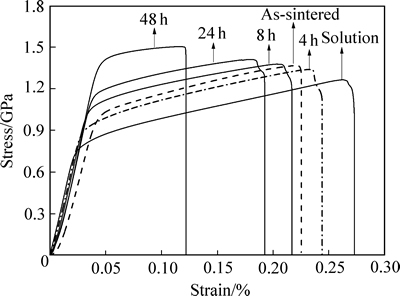

表3 烧结态、固溶及不同时效时间处理后Ti2448合金的力学性能

Table 3 Mechanical properties of Ti2448 alloys at as-sintered, solution treatment and aging-treated at different time

图5 烧结态、固溶态和不同时效时间处理后Ti2448合金的应力-应变曲线

Fig. 5 Compression stress-strain curves of Ti2448 alloys at as-sintered, solution treatment and aging-treated at different time

图6 烧结态、固溶态和不同时效时间处理后Ti2448合金的弹性模量

Fig. 6 Elasticity modulus of Ti2448 alloys at as-sintered, solution treatment and aging-treated at different time

3 结论

1) SPS烧结的Ti2448合金经固溶处理后主要由亚稳β相、少量初生α相及淬火马氏体α″组成;时效处理后,合金基体β相内析出大量细小无规则的针状次生α相,随着时效时间的延长,次生α相趋于定向析出,含量和尺寸逐渐增大。

2) SPS烧结的Ti2448合金经固溶时效处理后,与烧结态相比,抗压强度和弹性模量增大,而塑韧性呈先提高后降低趋势。通过固溶时效处理来调整的显微组织,可以调节强度、弹性模量和塑性之间的匹配关系,提高合金的塑韧性。

3) 经(850 ℃, 1.5 h, WQ)+(450 ℃, 4 h, FC)热处理后,SPS烧结的Ti2448合金抗压强度、弹性模量及塑韧性达到最佳配合,此时合金抗压强度、屈强比和弹性模量分别为1701 MPa、0.69和42.8 GPa,塑韧性得到改善。

REFERENCES

[1] CHEN Q Z, THOUAS G A. Metallic implant biomaterials[J]. Materials Science and Engineering R, 2015, 87: 1-57.

[2] Geetha M, Singh A K, Asokamani R, Gogia A K. Ti based biomaterials, the ultimate choice for orthopaedic implants: A review[J]. Progress in Materials Science, 2009, 54: 397-425.

[3] Nouri A, Hodgson P D, Wen C E. Effect of process control agent on the porous structure and mechanical properties of a biomedical Ti-Sn-Nb alloy produced by powder metallurgy[J]. Acta Biomaterialia, 2009, 6(4): 1630-1639.

[4] Hao Y L, Li S J, Sun S Y, YANG R. Effect of Zr and Sn on Young's modulus and superelasticity of Ti-Nb-based alloys[J]. Materials Science and Engineering A, 2006, 441(1): 112-118.

[5] 张 强, 李述军, 张思倩, 郝玉琳, 杨 锐. 固溶处理对Ti2448合金低周疲劳性能的影响[J]. 中国有色金属学报, 2013, 23(S1): s441-s444.

ZHANG Qiang, LI Shu-jun, ZHANG Si-qian, HAO Yu-lin, YANG Rui. Effects of solid solution treatment on low cycle fatigue performance of Ti2448[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(S1): s441-s444.

[6] Zhang Y W, Li S J, Obbard E G, WANG H, WANG S C, Hao Y L, YANG R. Elastic properties of Ti-24Nb-4Zr-8Sn single crystals with bcc crystal structure[J]. Acta Materialia, 2011, 59(8): 3081-3090.

[7] 田宇兴, 李述军, 郝玉琳, 杨 锐. Ti2448合金在不同应变速率下的高温变形机制[J]. 中国有色金属学报, 2010, 20(S1): s83-s86.

TIAN Yu-xing, LI Shu-jun, HAO Yu-lin, YANG Rui. Elevated temperature deformation mechanism of Ti2448 alloy at different strain rates[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s83-s86.

[8] Li S J, Cui T C, Hao Y L, YANG R. Fatigue properties of a metastable β-type titanium alloy with reversible phase transformation[J]. Acta Biomaterialia, 2008, 4(2): 305-317.

[9] 白 芸, 李述军, 郝玉琳, 杨 锐, 郭正晓. 磷酸盐缓冲溶液中Ti-24Nb-4Zr-8Sn合金的电化学腐蚀行为[J]. 中国有色金属学报, 2010, 20(S1): s1031-s1033.

BAI Yun, LI Shu-jun, HAO Yu-lin, YANG Rui, GUO Zheng-xiao. Electrochemical corrosion behavior of Ti-24Nb-4Zr-8Sn in phosphate buffer saline solutions[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s1031-s1033.

[10] 路 新, 何新波, 李世琼, 曲选辉. 放电等离子烧结TiAl基合金的显微组织及力学性能[J]. 北京科技大学学报, 2008, 30(3): 254-257.

LU Xin, HE Xin-bo, LI Shi-qiong, QU Xuan-hui. Microstructures and mechanical properties of TiAl-based alloys by spark plasma sintering[J]. Journal of University of Science and Technology Beijing, 2008, 30(3): 254-257.

[11] 谷 一, 张玉勤, 蒋业华, 周 荣. 烧结温度对SPS制备Ti-24Nb-4Zr-8Sn合金组织和力学性能的影响[J]. 稀有金属材料与工程, 2014, 43(5): 1238-1241.

Gu Yi, Zhang Yu-qin, Jiang Ye-hua, ZHOU Rong. Effect of sintering temperature on microstructure and mechanical properties of Ti-24Nb-4Zr-8Sn alloy prepared by SPS[J]. Rare Metal Materials and Engineering, 2014, 43(5): 1238-1241.

[12] Grosdidier T, Philippe M J. Deformation induced martensite and superelasticity in a β-metastable titanium alloy[J]. Materials Science and Engineering A, 2000, 291(1/2): 218-223.

[13] Karasevskaya O P, Ivasishin O M, Semiatin S L, Matviychuk Y V. Deformation behavior of beta-titanium alloys[J]. Materials Science and Engineering A, 2003, 354(1/2): 121-132.

[14] 张 翥, 王群骄, 莫 畏. 钛的金属学和热处理[M]. 北京: 冶金工业出版社, 2009.

ZHANG Zhu, WANG Qun-jiao, MO Wei. Metallurgy and heat-treatment of titanium[M]. Beijing: Metallurgical Industry Press, 2009.

[15] 郝玉琳, 杨 锐, 李述军, 崔玉友, 李 东, Niimomi M. 时效处理对Ti-29Nb-13Ta-4.6Zr医用钛合金Young’s模量和力学性能的影响[J]. 金属学报, 2002, 38(z1): 126-129.

HAO Yu-lin, YANG Rui, LI Shu-jun, CUI Yu-you, LI Dong, Niimomi M. Ageing response of Young’s modulus and mechanical properties of Ti-29Nb-13Ta-4.6Zr for biomedical applications[J]. Acta Metallurgica Sinica, 2002, 38(z1): 126-129.

[16] 周义刚, 曾卫东, 李晓芹, 俞汉清, 曹春晓. 钛合金高温形变强韧化机理[J]. 金属学报, 1999, 35(1): 45-48.

ZHOU Yi-gang, ZENG Wei-dong, LI Xiao-qin, YU Han-qing, CAO Chun-xiao. An investigation of high-temperature deformation strengthening and toughening mechanism of titanium alloy[J]. Acta Metallurgica Sinica, 1999, 35(1): 45-48.

[17] 郝玉琳, 杨 锐, 李述军, 崔玉友, 李 东, Niimomi M. α″马氏体相对Ti-29Nb-13Ta-4.6Zr医用钛合金杨氏模量和力学性能的影响[J]. 金属学报, 2004, 38(z1): 236-239.

HAO Yu-lin, YANG Rui, LI Shu-jun, CUI Yu-you, LI Dong, Niimomi M. Yong’s modulus and mechanical properties of Ti-29Nb-13Ta-4.6Zr in relation to α″ martensite [J]. Acta Metallurgica Sinica, 2004, 38(z1): 236-239.

Effects of heat treatment on microstructure and mechanical properties of Ti-24Nb-4Zr-8Sn alloy by spark plasma sintering

LIU Wan-li1,2, ZHANG Yu-qin1,2, JIANG Ye-hua1, ZHOU Rong1

(1. School of Materials Science and Engineering, Kunming University of Science and Technology, Kunming 650093, China;

2. Engineering Technology Research Center of Titanium Products and Application of Yunnan Province, Chuxiong 651209, China)

Abstract: Biomedical Ti-24Nb-4Zr-8Sn alloys were prepared by spark plasma sintering. The effects of solution-aging heat treatments on the microstructure and mechanical properties (strength, ductility and elastic modulus) of the alloys were investigated. The results show that the alloys are composed of metastable β phase, little primary α phase and α″ martensite after solution treatment at 850 ℃. After aging at 450 ℃,much short , fine and disordered needle α phases precipitated within primary β grains. With the aging time increases from 4 h to 48 h, the content and grain size of secondary α phase grows up which precipitates directionally from β matrix. Compared with the as-sintered, the compressive strength and elasticity modulus of the alloys increase after solution and aging heat treatment, while the ductility of the alloys increases at first and then decreases. After the suitable heat treatment of (850 ℃, 1.5 h, WQ)+(450 ℃, 4 h, FC), the compressive strength, yield ratio, elasticity modulus are 1701 MPa, 0.69 GPa and 42.8 GPa, respectively.

Key words: Ti-24Nb-4Zr-8Sn alloy; spark plasma sintering; heat treatment; microstructure; mechanical property

Foundation item: Project(31660262) supported by the National Natural Science Foundation of China; Project (2013IB006) supported by the Special Cooperation in Science and Technology of Yunnan Province, China

Received date: 2016-01-25; Accepted date: 2016-11-11

Corresponding author: ZHANG Yu-qin; Tel: +86-13708861766; E-mail: zyqkust@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(31660262);云南省省院省校科技合作专项资助项目(2013IB006)

收稿日期:2016-01-25;修订日期:2016-11-11

通信作者:张玉勤,教授,博士;电话:13708861766;E-mail: zyqkust@163.com