不同还原度铁氧化物球团在微波场中的升温及还原行为

胡兵1,黄柱成1,姜涛1,彭虎2

(1. 中南大学 资源加工与生物工程学院,湖南 长沙,410083;

2. 长沙隆泰微波热工有限公司,湖南 长沙,410013)

摘要:为深入了解氧化球团在微波竖炉中的升温以及煤基直接还原行为,实验采用铁精矿氧化球团作为基础原料,在气体还原剂条件下进行预还原,通过控制还原时间得到不同还原度铁氧化物球团,并从不同还原度铁氧化物球团的结构以及性能出发,研究它们在微波场中的升温性能及其还原变化。电磁性能测试结果表明,球团中的铁及其氧化物在微波场中的升温速度从快到慢依次为:Fe3O4,Fe2O3,Fe,FeO。微波加热还原结果分析及矿相结构观察显示,Fe2O3的深还原时间较长,物相多重转变,造成过程温度和还原气氛跟不上氧化物的还原反应速度;Fe3O4阶段升温速度快,结构松散,有助于进一步的还原,但进入浮士体(FeO的固溶体)阶段后孔隙率降低,升温速度骤降,造成还原的困难;在还原度达到66.90%时,表层以金属铁相为主,孔洞发达,吸波性能强,在气化反应有效进行的条件下,球团将会实现快速还原。

关键词:氧化球团;预还原球团;微波场;煤基直接还原;微波竖炉

中图分类号:TF533 文献标志码:A 文章编号:1672-7207(2012)03-0789-08

Reduction behavior and temperature rising characteristics of iron oxide pellets at different reduction degree in microwave field

HU Bing1, HUANG Zhu-cheng1, JIANG Tao1, PENG Hu2

(1. School of Mineral Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Changsha SYNO-THERM Co. Ltd., Changsha 410013, China)

Abstract: To study the coal-based direct reduction behavior and temperature rising characteristics of oxidized pellets in microwave shaft furnace, this experiment first prepared several groups iron oxide pellets at different reduction degree by control roasting time in condition of gaseous reducing agent from iron concentrate pellets, then based on structure and properties of iron oxide pellets at different reduction degree, a serials of research about temperature rising characteristics and reduction behavior of them were done in microwave field. The electromagnetic properties results show that the rate of temperature rising of iron oxide powder in microwave field from higher to lower rate is: Fe3O4, Fe2O3, Fe, FeO. The reduction results and mineralogical structure of pellets after microwave heating show that Fe2O3 has longer reduction time and several changes of physical phase, and makes the rate of reduction reaction mismatching with temperature and reduction atmosphere; Fe3O4 has a rapid heating rate and loose structure which is helpful to reduction, but while ferrous oxide appears in the pellet, the rate of reduction decreases because the porosity reduced and temperature rising rate slowed. When reduction degree reaches 66.90%, the pellet surface metallization has a developed porosity and stronger electromagnetic wave absorbency which has a fast reduction when gasification reaction is carried out effectively.

Key words: oxidized pellets; pre-reduced pellets; microwave field; coal-based direct reduction; microwave shaft furnace

我国以低品位铁矿为主,天然气资源不足,煤炭资源丰富,适合发展铁精矿球团煤基直接还原[1]。传统工艺中的回转窑煤基直接还原法产量低,易结圈,能耗较高,在我国没有得到大规模的应用,鉴于我国对直接还原铁(DRI)的迫切需求,必须开发和研究新的方法生产DRI[2-4]。微波作为一种新兴能源,在冶金领域日益得到重视和发展,利用微波的选择加热、快速加热、体积加热以及高频振荡强化冶金过程等优点,研究工作者们对微波在球团矿的干燥、矿石的烧结点火、金属氧化物的还原、球团矿的氧化焙烧和矿石的磨碎等方面进行了大量的研究工作[5-13]。正是基于微波的自身特点、能量的有效利用以及生产的连续化等方面综合考虑,中南大学和长沙隆泰微波热工有限公司合作开发了铁精矿氧化球团微波竖炉煤基直接还原新方法。铁精矿氧化球团直接还原过程存在4种铁物相的转变,而且在物相转变过程中,球团的结构特点,基本电磁特性都有所改变,本文作者从不同还原度铁氧化物球团的矿物结构组成、电磁性能、孔隙率和在微波场中的升温情况等方面出发,研究了不同还原度铁氧化物球团在微波场中的升温性能以及煤基直接还原行为。期望可以更加深入地了解铁精矿氧化球团在微波场中的升温情况,结构变化和还原过程,深刻认识各个阶段微波与球团的匹配情况,为工业化更快更好的实现提供一些依据。

1 实验

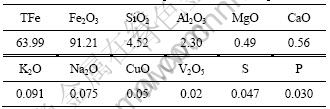

本实验所采用的氧化球团粒级范围在12.5~15 mm,球团强度3 036 N/个,主要的化学成分如表1所示。煤粉的工业分析结果如表2所示,粒度组成如表3所示。

从表1可以看出:氧化球团中Fe2O3占91.21%,脉石主要有SiO2和Al2O3,其他杂质含量少。实验采用无烟煤作为还原剂,主要从无烟煤的吸波能力强以及固定碳含量高两方面考虑,从表2和表3可以看出: 实验用无烟煤固定碳含量高,粒度较细,有利于实验室条件下煤气化反应的进行。

表1 氧化球团的主要化学成分分析(质量分数)

Table 1 Main chemical composition of oxidized pellet %

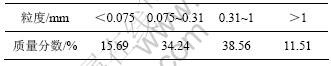

表2 无烟煤粉的主要化学成分(质量分数)

Table 2 Chemical composition of anthracite powder

表3 无烟煤粉的粒级组成

Table 3 Grain size composition of anthracite powder

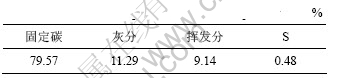

为了得到不同还原度的铁氧化物球团,采用上述氧化球团在电阻炉中加热,并且通入40% CO和60% N2进行还原,气体流速为15 L/min,温度控制在850 ℃,不同还原度条件下球团的真孔隙率变化情况如图1所示。

图1 不同还原度铁氧化物球团对应的真孔隙率的变化

Fig.1 Change of true porosity for iron oxide pellets under different reduction degrees

从图1可以看出:氧化球团在还原过程中孔隙率发生了明显的变化,这种结构的变化是与物质的改变成对应关系的。首先,球团孔隙明显增多,体积膨胀,根据文献介绍[14]:在Fe2O3还原到Fe3O4的过程中,体积膨胀达到25%;其次,当浮士体相生成初始金属铁时,球团体积出现收缩,孔隙率降低;而随着铁晶粒的聚集长大,周围晶粒或颗粒产生松动或位移,另外在浮士体相过渡到金属铁相的过程中,产生大量的气体,在内部气压的作用下,再次造成体积的膨胀,孔隙率也随之增大;随着铁晶粒的进一步长大和球团内部气压的降低,球团出现明显的收缩,结构致密化,孔隙减少。

根据氧化球团的还原程度以及结构变化情况,选取还原度为0,21.56%,33.88%和66.90% 4种球团放入微波炉中在外配煤粉的条件下进行直接还原。采用多模腔微波炉作为反应器,微波频率2.45 GHz,微波功率0~1.5 kW可调。热电偶在金属外套管保护下插入物料中实时测量温度的变化。实验均在氮气保护下进行,根据铁氧化物中氧的含量配加适当的无烟煤粉,以实现铁氧化物在微波场中的还原。研究主要考查了不同还原度铁氧化物球团在微波场中的升温以及还原行为。采用矢量网络分析仪研究不同还原度铁氧化物的电磁性能变化情况,化学分析方法研究球团还原前后的金属化程度变化,以及采用矿相显微镜研究球团微波加热还原前后的微观结构和矿相组成。

2 结果与分析

2.1 微波场中不同还原度球团的升温性能

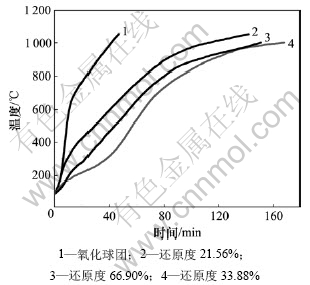

氧化球团120 g,其他预还原球团以还原前的120 g计算,微波输入功率1.3 kW,炉内采用氮气保护,其他条件一致。不同还原度铁氧化物球团在微波场中的升温情况如图2所示。

图2 不同还原度铁氧化物球团在微波场中的升温曲线

Fig.2 Heating curves of iron oxide pellets under different reduction degrees in microwave field

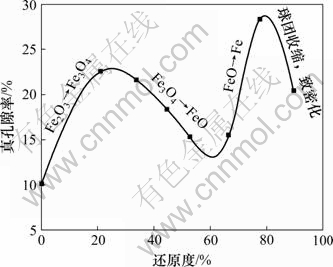

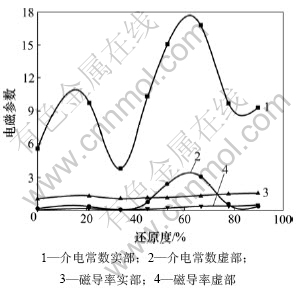

从图2可以看出:氧化球团在微波场中较其他预还原球团具有更快的升温速度,平均升温速度可以达到20.32 ℃/min;还原度达到33.88%的铁氧化物球团在微波场中升温速度最慢,平均升温速度只有5.41 ℃/min。出现上述现象的主要原因是不同还原度铁氧化物球团的电磁性能发生了变化(图3,频率为2.45 GHz)。

图3 不同还原度铁氧化物球团矿的电磁性能测试结果

Fig.3 Change of electromagnetic properties of iron oxide pellets under different reduction degree

从图1和图3可以看出:不同还原度铁氧化物球团的电磁性能变化是与孔隙率的变化和物质的转变一致的。根据吸波材料的基本物理原理,材料需要同时具备合适的波阻抗匹配特性和衰减特性,这样既能有效透过微波,也可以把电磁能最大限度的转化为热能。图3显示,不同还原度铁氧化物球团的介电特性发生了显著的变化,结合球团从外往内分层还原的实际情况,导致了图2所示升温速度的不一致。微波的阻抗匹配特性要求物料对微波的反射率小,尽可能的让微波进入到物料中,即式(1)中的R不能过大[15]。

(1)

(1)

其中:z0=377 ?, 为介质波阻抗,

为介质波阻抗, ,

, ;

; 和

和 分别为磁导率的实部和虚部;

分别为磁导率的实部和虚部; 和

和 分别为介电常数的实部和虚部;

分别为介电常数的实部和虚部; 和

和 分别为真空介电常数和磁导率。

分别为真空介电常数和磁导率。

根据图3的电磁性能数据变化情况可以得出,铁及其氧化物在微波场中的升温速度从快到慢依次为:Fe3O4,Fe2O3,Fe,FeO。对于还原度21.56%的球团,表层主要为浮士体,而球团大部分依然是Fe3O4,所以在微波场中表现为升温速度较其他还原度球团慢,而其经破碎、混合再成型后的电磁性能显示具有较强的吸波能力,并且反射较小。而还原度66.90%时,球团电磁损耗大,但同时在球团表面反射的能量大,使得相同输入功率下球团的升温速度较慢。

2.2 还原物料在微波场中加热和还原

2.2.1 物料在微波场中的升温

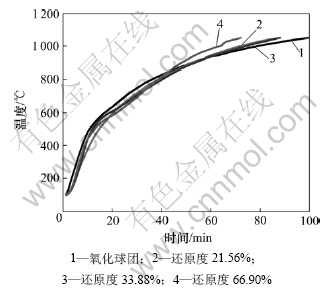

分别采用氧化球团120 g,其他预还原球团以还原前的120 g计算,根据球团中铁氧化物的含氧量,以碳氧比为1.05∶1(质量比)外配煤粉,微波输出功率 1.3 kW,炉内采用氮气保护,其他条件一致。微波场中不同还原度铁氧化物球团在外配煤粉条件下的升温如图4所示。

图4 微波场中不同还原度铁氧化物球团在外配煤粉条件下的升温曲线

Fig.4 Heating curves of iron oxide pellets under different reduction degrees with coal blending in microwave field

从图4可以看出:在外配煤粉条件下,微波场中不同还原度铁氧化物球团在800 ℃前具有相同的升温速度,之后升温速度出现显著的变化,其中球团还原度66.90%条件下的物料具有最快的升温速度,而氧化球团外配煤粉在微波场中升温速度最慢。出现上述现象的原因可能是:一是铁氧化物向金属铁转化过程中需要消耗热量,特别是煤的气化反应是一个强吸热过程。对于氧化球团含氧量最多,随着还原程度的提高,球团中含氧量减少,需要消耗的能量低,从而在800 ℃后出现升温速度的不一致。二是煤粉吸波能力强,在800 ℃前掩盖了球团的吸波能力,而随着气化反应的进行,煤粉得到了相应的消耗,球团的吸波能力开始决定物料的升温状况,氧化球团处在浮士体阶段长,升温速度慢,还原程度越高,相应浮士体阶段短,升温速度越快。

2.2.2 还原效果

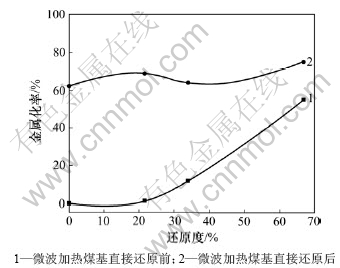

采用不同还原度铁氧化物球团在微波场中进行煤基直接还原,在物料升至1 050 ℃所得到的金属化球团的变化如图5所示。

图5 微波场中不同还原度铁氧化物球团煤基直接还原前后的金属化率

Fig.5 Change of metallization rate of iron oxide pellets by coal-based reduction in microwave field

从图5可以看出:不同还原度铁氧化物球团经微波加热煤基直接还原后,球团的金属化程度相应有所提高,在实验室条件下,还原气氛成为限制球团还原的最主要因素。还原的两大条件是温度和还原气氛,从图3和图4可知,煤粉和浮士体以外的其他铁相皆具有强的吸收微波的能力,并且煤粉和铁氧化物球团在微波场中内外可以同时加热,避免了由于球团中心温度低而造成还原速度慢的问题;还原气氛在实验室条件下成为了微波场中铁氧化物球团还原的限制性环节,一方面反应物料太少,还原气体在物料中不能保证一定的微正压,使得球团内部产生的热气压大于外部气压,造成气体交换的困难。从图1可知:氧化球团预还原后孔隙率增加,这将有助于还原气体的扩散,加速球团的还原。值得一提的是,在实验室氮气外保护的条件下,预还原球团首先与煤粉进行反应生成CO2,接着1 mol CO2和1 mol煤粉中的C反应生成2 mol的CO,对于预还原铁氧化物球团来说,外表面氧量减少是不利于煤的气化反应的,所以实验室条件下还原气氛是影响预还原球团微波加热煤基直接还原反应的最主要因素。

2.2.3 矿相结构的变化

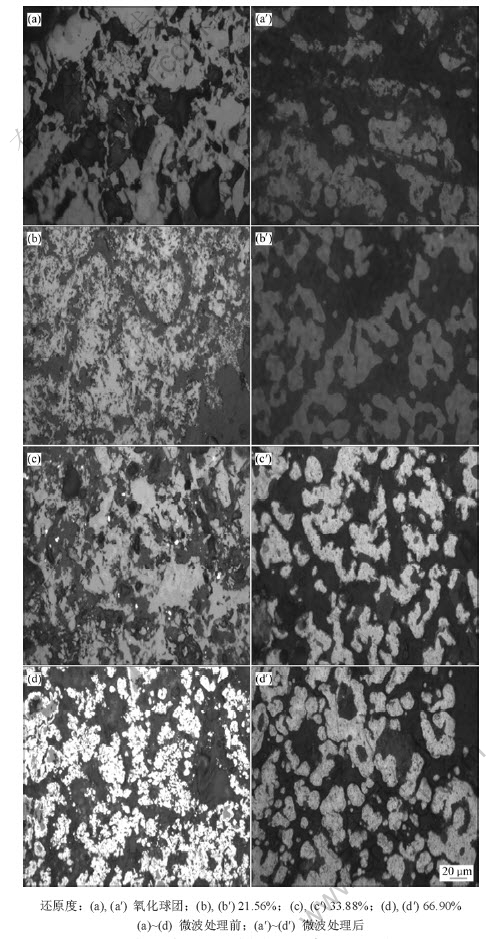

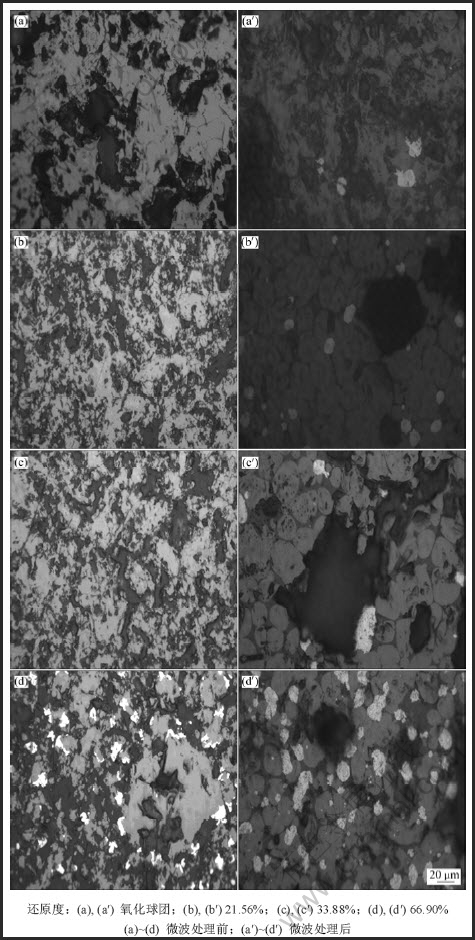

不同还原度铁氧化物球团在微波加热煤基直接还原前后的显微矿相结构变化情况如图6(球团边缘)和图7(球团中心)所示。

图6 不同还原度球团在微波加热煤基直接还原前后的显微矿相结构(边缘)

Fig.6 Mineralogical structure changes of iron oxide pellets by coal-based reduction in microwave field(edge)

图7 不同还原度球团在微波加热煤基直接还原前后的显微矿相结构(中心)

Fig.7 Mineralogical structure changes of iron oxide pellets by coal-based reduction in microwave field(center)

从图6可以看出:氧化球团边缘铁物相皆为Fe2O3,且晶粒粗大,连接紧密,呈大孔厚壁状;当还原度达到21.56%时,仍然未有金属铁的生成,主要的铁物相为Fe2O3和Fe3O4,有部分浮士体,此时颗粒细小,孔洞发达;在还原度达到33.88%后,边缘出现少量金属铁相,主要成分为Fe3O4和浮士体,颗粒有聚集成块的趋势,孔洞较少;球团还原度为66.90%时,边缘除少数大颗粒中心未金属化以外,铁氧化物皆被还原成金属铁,并且铁晶粒细小,孔隙率高。从图6(a′)~(d′)可以看出:不同还原度铁氧化物球团通过微波加热煤基直接还原后,球团边缘的矿相结构差异不大,铁晶粒粗大,孔洞分布广泛,仍然拥有较多的气体扩散通道。

从图7可以看出:氧化球团中心Fe2O3结晶较完整,只有少部分Fe3O4夹杂在大颗粒中,还原度21.56%和33.88%的预还原球团中心的矿相结构相差不大,都未有金属铁相的出现,且颗粒松散,孔洞发达,当还原度达到66.90%时,大部分小颗粒和大颗粒的边缘出现金属铁相,孔隙率增加,有助于气体在球团内部的扩散。从图7(a′)~(d′)可以看出:不同还原度铁氧化物球团通过微波加热煤基直接还原后,球团中心的矿相结构差异很大,其中经氧化球团还原后的初晶发育尚不完整,晶体轮廓不清晰,只有极少量的金属铁相出现;还原度21.56%和33.88%的球团经微波加热还原后,晶体粗大,轮廓分明,但金属铁相较少,而且孔隙率降低,将不利于进一步的还原;还原度66.90%的球团经微波加热还原后,中心晶形完整,颗粒较小,孔隙发达,有助于气体的扩散,较易实现深度还原。球团中心还原程度较边缘差的主要原因是还原气氛不足,使得中心的矿物晶粒只能再结晶长大而得不到充分的还原。

对于不同还原度铁氧化物球团在微波场中的还原反应,物料升温速度的快慢是决定微波能的利用率和直接还原生产率的重要因素,而铁氧化物的还原速率则主要受还原气氛的影响,球团内外层孔隙的多少决定气体扩散的难易程度,在过量煤粉的条件下,气化反应产生CO,只有当气化反应顺利进行,产生足够的CO时,微波场中铁氧化物的还原反应才能快速有效的发生。而且铁氧化物以及煤粉在微波场中皆有较快的升温速度,可以在短时间内达到煤的气化和铁氧化物还原所需要的温度,并且这种加热是对整个物料内外同时进行的,宏观上不存在温度差异。浮士体阶段球团的孔隙率降低,而且在微波场中的升温速度下降,通过测试不同还原度球团的抗压强度可知,在还原度40%左右球团的抗压强度最低,此时物相组成以浮士体相为主,对于微波竖炉生产DRI,进入微波段的预还原球团尽可能使得还原度超过60%,这样不仅可以提高球团的升温速度,避免了球团因膨胀而造成下料的不畅,还可以实现快速还原,提高直接还原生产率。

3 结论

(1) 不同还原度铁氧化物球团以及无烟煤粉在微波场中皆具有较强吸收微波的能力,物料可以在短时间内达到煤的气化和铁氧化物还原所需的温度。电磁性能测试结果显示,球团中铁及其氧化物在微波场中的升温速度从快到慢为:Fe3O4,Fe2O3,Fe,FeO。所以进入微波场中的氧化物球团不应处在浮士体阶段,以提高微波能的利用率和缩短物料升温的时间。

(2) 氧化球团经气基预还原后,孔隙率增加,强度下降明显,但没有出现煤基还原时的“爆裂式膨胀”。所以采用预还原球团进行微波加热煤基直接还原,不仅解决了球团还原时的气体扩散问题,还避免了由于球团膨胀造成下料不畅的问题。

(3) 对于不同还原度铁氧化物球团微波加热煤基直接还原,温度和还原气氛仍然是主导还原的两大因素。浮士体阶段球团在微波场中的升温和还原条件都是最恶劣的,对于还原度66.90%的预还原球团,边缘以金属铁物相为主,孔隙率高,吸波性能强,中心颗粒较小,孔洞发达,只要煤的气化反应有效进行,球团在微波场中将实现快速还原。

参考文献:

[1] 张群, 赵刚, 戴淑芬. 论自然资源与钢铁生产发展的关系[J]. 钢铁, 2002, 37(3): 72-74.

ZHANG Qun, ZHAO Gang, DAI Shu-fen. Natural resources and development of steel industry[J]. Iron & steel, 2002, 37(3): 72-74.

[2] 阴继翔. 煤基直接还原技术的发展[J]. 太原理工大学学报, 2000, 31(3): 314-316.

YIN Ji-xiang. Development of coal-based direct reduction technologies[J]. Journal of Taiyuan University of Technology, 2000, 31(3): 314-316.

[3] 储满生, 赵庆杰. 中国发展非高炉炼铁的现状及展望[J]. 中国冶金, 2008, 18(9): 1-9.

CHU Man-sheng, ZHAO Qing-jie. Present status and development perspective of direct reduction and smelting reduction in China[J]. China Metallurgy, 2008, 18(9): 1-9.

[4] ZHANG Shou-rong, YIN Han. The trends of ironmaking industry and challenges to Chinese blast furnace ironmaking in the 21st century[C]//Proceedings of the 5th International Congress on the Science and Technology of Ironmaking. Shanghai, 2009: 2-15.

[5] 武文华, 唐惠庆, 黄务涤. 微波干燥和焙烧球团矿[J]. 北京科技大学学报, 1994, 16(2): 118-121.

WU Wen-hua, TANG Hui-qing, HUANG Wu-di. Microwave drying and roasting pellets[J]. Journal of University of Science and Technology Beijing, 1994, 16(2): 118-121.

[6] Kingman S W, Vorster W, Rowson N A. The influence of mineralogy on microwave assisted grinding[J]. Minerals Engineering, 2000, 13(3): 313-327.

[7] Ku S H, Siores E, Taube A, etc. Productivity improvement through the use of industrial microwave technologies[J]. Computer & Industrial Engineering, 2002, 42: 281-290.

[8] WANG Yong-qing. Direct steelmaking through microwave and electric arc heating[D]. Michigan Technological University. Department of Materials Science and Engineering, 2005: 131-135.

[9] Ishizaki K, Nagata K. Selectivity of microwave energy consumption in the reduction of Fe3O4 with carbon black in mixed powder[J]. ISIJ International, 2007, 47(6): 811-816.

[10] Ishizaki K, Nagata K, Hayashi T. Localized heating and reduction of magnetite ore with coal in composite pellets using microwave irradiation[J]. ISIJ International, 2007, 47(6): 817-822.

[11] BAI Cheng-guang, REN Wei, QIU Gui-bao, et al. The review of microwave applications in metallurgical process in China[J]. ISIJ International, 2007, 47(4): 528-532.

[12] 黄亚雷, 黄柱成, 毛晓明, 等. 铁矿石微波热风烧结点火研究[J]. 矿冶工程, 2008, 28(5): 64-67.

HUANG Ya-lei, HUANG Zhu-cheng, MAO Xiao-ming, et al. Study on ignition of iron ore sintering by microwave heat airflow[J]. Mining and Metallurgical Engineering, 2008, 28(5): 64-67.

[13] CHEN Jin, WANG She-bin, ZHANG Meng, et al. Kinetics of voluminal reduction of chromium ore fines containing coal by microwave heating[J]. Journal of Iron and Steel Research, International, 2008, 15(6): 10-15.

[14] 傅菊英, 姜涛, 朱德庆. 烧结球团学[M]. 长沙: 中南工业大学出版社, 1996: 355-357.

FU Ju-ying, JIANG Tao, ZHU De-qing. Sintering and pelletizing[M]. Changsha: Central South University of Technology Press, 1996: 355-357.

[15] 周克省. 镧锰氧化物与铁氧体改性体系的微波吸收特性研究[D]. 长沙: 中南大学化学化工学院, 2008: 4-5.

ZHOU Ke-sheng. Study on microwave absorption properties of modified systems of la-manganities and ferrite[D]. Changsha: Central South University. School of Chemistry and Chemical Engineering, 2008: 4-5.

(编辑 陈爱华)

收稿日期:2011-04-11;修回日期:2011-06-29

基金项目:教育部新世纪优秀人才支持计划资助项目(NCET-04-0748)

通信作者:胡兵(1983-),男,湖南邵阳人,博士研究生;从事钢铁冶金和微波直接还原等研究;电话:0731-88830542;E-mail: csu0206@163.com