文章编号:1004-0609(2015)02-0301-07

热处理对静液挤压AZ80镁合金管材腐蚀行为的影响

吴志林,吴多祥,袁人枢,赵 磊,赵言宝

(南京理工大学 机械工程学院,南京 210094)

摘 要:采用浸泡腐蚀、失重腐蚀以及电化学腐蚀中的动电位极化曲线、电化学阻抗谱等方法研究静液挤压AZ80镁合金经350 ℃退火热处理1、2和4 h后,在pH 6.1的0.1 mol/L Na2SO4溶液中的腐蚀行为。结果表明:退火热处理使得挤压后的AZ80镁合金晶粒发生再结晶,改变AZ80镁合金的组织和成分分布,可有效提高镁合金的腐蚀性能;但是热处理时间也会对合金的耐蚀性产生影响,其中经(350 ℃,1 h)退火热处理后,合金自腐蚀电位为-1.4501 V,腐蚀电流密度为0.02323 mA/cm2,耐腐蚀能力显著提高,表现出较好的综合性能。

关键词:AZ80镁合金;静液挤压;热处理;耐腐蚀性能

中图分类号:TG146.2 文献标志码:A

Effect of heat treatment on corrosion behavior of hydrostatic extruded AZ80 magnesium alloy tube

WU Zhi-lin, WU Duo-xiang, YUAN Ren-shu, ZHAO Lei, ZHAO Yan-bao

(College of Mechanical Engineering, Nanjing University of Science and Technology, Nanjing 210094, China)

Abstract: The effect of heat treatment (annealing at 350 ℃ for 1, 2 and 4 h, respectively) on the corrosion behavior of hydrostatic extruded AZ80 magnesium alloy tube was investigated by immersion tests, weightlessness corrosion, potentiodynamic polarization curves and electrochemical impedance spectroscopy (EIS) in the 0.1 mol/L Na2SO4 solution at pH of 6.1. The results indicate that the re-crystallization occurs in the hydrostatic extruded AZ80 magnesium alloy during annealing, which can effectively improve the corrosion performance of magnesium alloy for changing microstructure and composition distribution. However, the duration of heat treatment would affect the corrosion resistance of alloy, comparing to other samples heat treated for different times, the annealing one after 1h heat treatment time at 350 ℃ shows good comprehensive performance at the corrosion potential of -1.4501 V, corrosion current density of 0.02323 mA/cm2.

Key words: AZ80 magnesium alloy; hydrostatic extrusion; heat treatment; corrosion resistance

镁合金具有散热性好、比刚度高、密度小、生物相容性出色、阻尼减震性优良、电磁屏蔽效果佳、机械加工性能优秀、再生性好和回收容易等优点[1-3],在国防事业、机械汽车制造、航空航天、电子通讯、光学仪器、计算机以及医疗仪器等领域具有巨大的发展潜力和广阔的应用前景[4-5]。由于镁合金是密排六方晶体(HCP)结构,塑性差,传统挤压变形方式效率低,并且较高的挤压温度使得变形镁合金的实用性能 低[6]。对于脆性材料,静液挤压适合中低温条件下大塑性变形,不但能明显提高挤压产品的成品率和生产率,还能提高其抗拉强度、屈服强度及冲击韧性[7-8]。但是镁合金的耐腐蚀性能很差,在潮湿大气或酸性、中性、弱碱性溶液中都容易发生腐蚀[9],因此,镁合金的腐蚀性能差已经成为制约其进一步应用的瓶颈。

国内外镁合金表面防腐主要集中在如下几种方法,如化学转化膜[10]、阳极氧化[11]、金属镀层处理[12]和微弧阳极氧化[13]等。关于镁合金电化学腐蚀机理方面研究较多的是铸造镁合金,电解液也是以3.5%NaCl (质量分数)为主,而在无活性阴离子的溶液中以及大气腐蚀条件下,热处理工艺对变形镁合金电化学性能影响的报道较少。在Mg-Al系合金中主要有两种相:基体α相和晶界处的β相,研究表明,镁合金的耐蚀性一方面与α固溶体的显微组织及其铝含量有关;另一方面合金中形成的β相可作为耐蚀相阻碍镁合金腐蚀,也可作为阴极与α相构成腐蚀电池加速镁合金腐蚀[14-15]。宋丹等[16]对等径角挤压制备镁合金块材腐蚀性研究得出,造成其腐蚀性下降的因素如下:1) 大角度晶界、高密度位错等高能晶体缺陷使得α固溶体化学活性变高以及额外β相的析出导致α相中Al含量降低;2) 细化的β相丧失了阻滞腐蚀介质向α固溶体扩散的屏障作用。

由于热处理可使静液挤压后的镁合金管材组织发生再结晶,使过剩相充分溶解到固溶体中,从而获得晶粒细小、性能更好的管材。通过对比300、350和400 ℃温度下分别保持1、2和4 h的结果发现,350 ℃条件下的镁合金管材的抗拉强度和屈服强度最优,晶粒尺寸较小。因此,本文作者选用腐蚀介质为pH 6.1的0.1 mol/L Na2SO4溶液(模拟大气腐蚀),对静液挤压后的AZ80镁合金进行350 ℃时退火热处理1、 2和4 h。利用浸泡腐蚀、失重腐蚀以及电化学腐蚀等方法研究不同的热处理工艺对变形镁合金腐蚀行为及耐蚀性能的影响,旨在进一步探讨镁合金的腐蚀机理,优化出热处理工艺。

1 实验

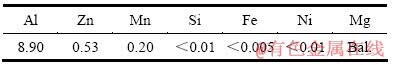

所用材料是直径d 60 mm 的商用AZ80镁合金连铸锭,其成分如表1所列。

表1 AZ80镁合金的化学成分

Table 1 Chemical composition of AZ80 magnesium alloy (mass fraction, %)

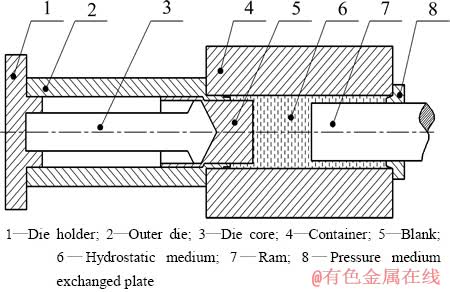

AZ80镁合金管材静液挤压成形工艺流程依次为均匀化热处理、静液挤压成形和热处理。其中,均匀化热处理工艺参数如下:镁合金连铸锭加热到415 ℃,保温16 h,空冷。静液挤压工艺参数如下:坯料、外模和模芯的预热温度为200 ℃,挤压筒的预热温度为150 ℃,挤压变形比为2.77,即挤压成内径为di 60 mm,外径为d0 70 mm的镁合金管材。热处理工艺参数如下:在350 ℃温度下分别保持1、2和4 h的热处理,冷却方式为水冷。静液挤压加工示意图如图1所示。

图1 静液挤压加工示意图

Fig. 1 Schematic illustration of hydrostatic extrusion

金相试样从镁合金管材上切取后,经机械打磨抛光,用腐蚀剂(4.2 g苦味酸、10 mL醋酸、20 mL蒸馏水和70 mL乙醇)侵蚀后在蔡司Axiovert200型金相显微镜对腐蚀后的试样进行金相组织观察。

浸泡腐蚀试样从镁合金管材切取后,经机械打磨抛光,用丙酮超声清洗及干燥后分别浸入pH 6.1的 0.1 mol/L Na2SO4溶液中腐蚀48 h,试验温度为(20±1) ℃。样品腐蚀后取出放入干燥箱内干燥,采用数码相机对试样进行宏观腐蚀形貌观察,并在FEI Quanta250 F场发射环境扫描电镜下进行微观腐蚀形貌观察。腐蚀产物成分用Bruker D8 X射线衍射仪对腐蚀表面进行扫描,扫描角度2θ,扫描范围30.0°~90.0°,扫描速度为4 (°)/min。

失重腐蚀实验参照JB/T 7901—1999[17]标准进行。试验温度为(20±1) ℃;腐蚀介质为pH 6.1的0.1 mol/L Na2SO4溶液;失重腐蚀的时间分别为6、12、24、48和144 h。腐蚀后的试样在铬酸中清洗10 min以去除表面的腐蚀产物,蒸馏水清洗、丙酮擦拭及吹风机吹干后用分析天平称量。

电化学腐蚀试样用铜导线捆绑,铜线及试样非工作面用亚克力树脂封装,试样的工作面积为1 cm2。阳极极化曲线及电化学阻抗谱(EIS)均在CHI604E电化学工作站,采用三电极体系进行测量,工作电极为不同状态的AZ80镁合金试样,参比电极为饱和甘汞电极(SCE),辅助电极为铂电极,实验温度为25 ℃,腐蚀介质为pH 6.1的0.1 mol/L Na2SO4溶液。阳极极化曲线测量时,试样为获得稳定的开路电位(φOPC)先在Na2SO4溶液中浸泡25 min,再从起始电压为 -2.5 V以10 mV/s的速度进行正向动态阳极极化扫描。电化学阻抗谱测量时,试样为获得稳定的开路电位在Na2SO4溶液中浸泡30 min,测试的频率范围为10 mHz~100 kHz,初始电压定为1.5 V,正弦波交流激励信号幅值为±5 mV,应用ZsimpWin软件进行电化学阻抗谱分析。实验所用药品均为分析纯,溶液采用去离子水配制。

2 结果与分析

2.1 AZ80镁合金试样的显微组织

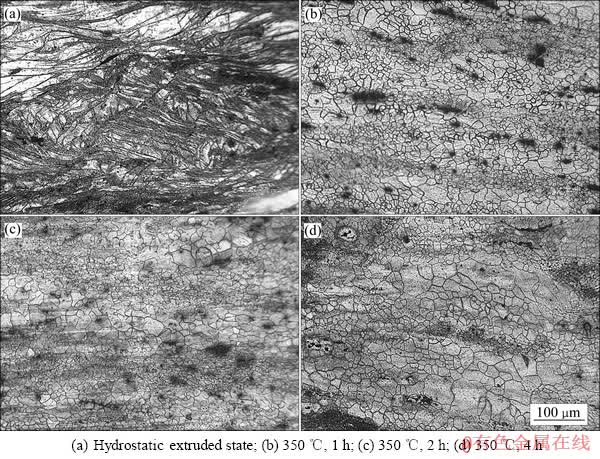

由于在静液挤压成形中因挤压温度较低及管材成形直径较小,AZ80镁合金管材未能发生动态再结晶。再结晶退火热处理可使静液挤压后的镁合金管材组织内部能量再分配,使储能差消失实现再结晶,获得晶粒细小、综合性能良好的AZ80镁合金管材。

静液挤压后的AZ80镁合金经过不同热处理后的组织形貌如图2所示,可以看出,挤压后的镁合金晶粒沿轴向被拉长,出现纤维状组织,亚晶粒及孪晶增多,晶粒尺寸难分辨。在加热350 ℃温度条件下,保温1 h后的镁合金晶粒再结晶充分,较大和较小的晶粒同时存在。保温2 h后的镁合金晶粒尺寸有所增大,同时,大的晶粒吞噬小的晶粒,变成更大的晶粒,呈现不均匀的分布。保温4h的镁合金有异常长大的晶粒出现,一些晶界消失,晶粒长大更明显。通过平均截直线法得到在350 ℃下经过1、2和4 h热处理后的平均晶粒尺寸分别为9.5、12和14.3 μm,可知,随着热处理时间的延长,晶粒长大。

2.2 AZ80镁合金腐蚀形貌分析

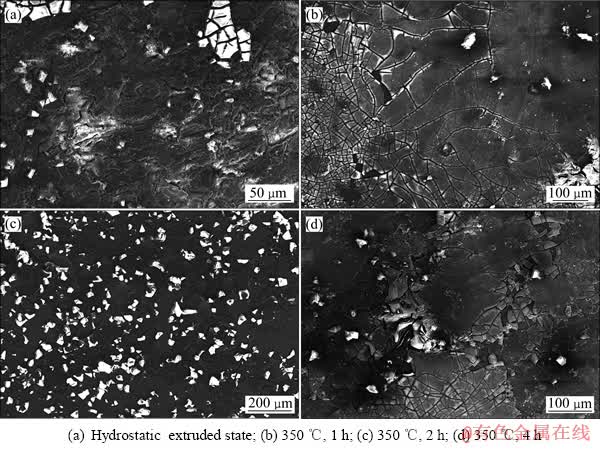

2.2.1 镁合金表面腐蚀形貌分析

图3所示为挤压态及不同热处理态AZ80镁合金管材在pH 6.1的0.1 mol/L Na2SO4溶液中浸泡48 h后腐蚀表面的SEM像。可以看出,静液挤压态和(350 ℃,4 h)试样腐蚀较严重,腐蚀产物膜呈龟裂状已脱落,表面出现了严重的腐蚀坑;(350 ℃,1 h)的试样表面呈现龟裂状,(350 ℃,2 h)的试样表面腐蚀膜突出,均未脱落。静液挤压后腐蚀产物疏松,不能阻挡进一步的腐蚀,(350 ℃,1 h)和(350 ℃,2 h)热处理后腐蚀产物层致密,能有效地保护内部镁合金不受腐蚀;(350 ℃,4 h)热处理后,镁合金内部有大量方块相生成,割裂基体,易发生腐蚀。

图2 静液挤压态和不同热处理后AZ80镁合金管材金相组织

Fig. 2 Metallographs of AZ80 magnesium alloy at hydrostatic extruded state and after different heat treatments

图3 静液挤压态及不同热处理态AZ80镁合金腐蚀表面的SEM像

Fig. 3 SEM images of AZ80 magnesium alloy at hydrostatic extruded state and after different heat treatments

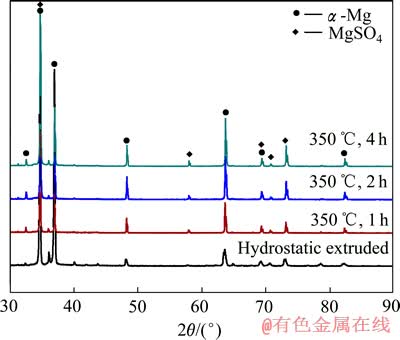

2.2.2 腐蚀产物分析

图4所示为挤压态及不同热处理态AZ80镁合金管材在pH 6.1的0.1 mol/L Na2SO4溶液中腐蚀产物的XRD谱。可见,AZ80镁合金表面腐蚀产物膜主要是MgSO4,是阳极反应产物Mg2+和SO42-硫酸根形成的。由于膜较薄,可在图谱中明显观察到基体相α-Mg。随着热处理时间的延长,73.17°处,MgSO4的峰值强度增加,说明腐蚀逐步严重。

图4 静液挤压态及不同热处理AZ80镁合金XRD谱

Fig. 4 XRD patterns of AZ80 magnesium alloy at hydrostatic extruded state and after different heat treatments

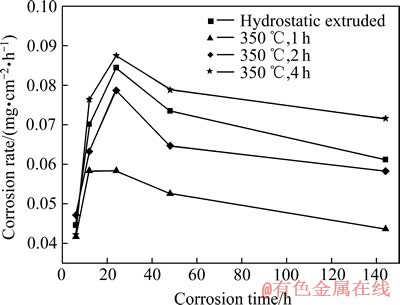

2.3 AZ80镁合金失重腐蚀分析

图5所示为用失重法测得的挤压态及不同热处理态AZ80镁合金管材在pH 6.1的0.1 mol/L Na2SO4溶液中的腐蚀速率的曲线。可见,浸泡48 h挤压态的腐蚀速度稍低于经(350 ℃,4 h)处理后合金的,但是明显高于经(350 ℃,1 h)和经(350 ℃,2 h)处理的,其中,经(350 ℃,1 h)热处理后合金的腐蚀速度最小,而且晶粒尺寸也最小,可以发现,晶粒大小与腐蚀速度有关,晶粒尺寸越小,耐腐蚀性能越高。可见,热处理可以改善合金的微观组织,从而对其腐蚀性能产生影响,但是热处理时间过长,粗大的组织及析出相的生成又会降低合金的耐蚀性能。可以看出,合金的腐蚀速率趋势也是呈现先增后减,主要是由于刚开始因腐蚀溶液中硫酸根离子的存在形成点蚀,使得腐蚀速率上升,而后合金表面形成的腐蚀产物膜阻碍了合金的腐蚀,使得腐蚀速率下降。

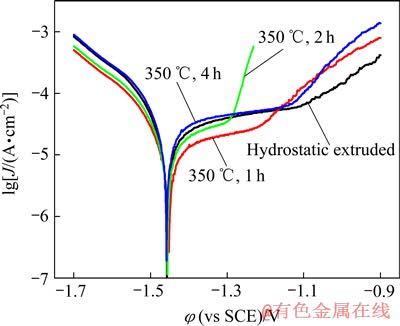

2.4 热处理对AZ80镁合金电化学性能的影响

2.4.1 极化曲线的测定

图6所示为挤压态及不同热处理态AZ80镁合金管材在pH 6.1的0.1 mol/L Na2SO4溶液中的阳极极化曲线。从图6中可以看出,极化曲线都呈现类似于自钝化的现象。在平台区域,随着电位的上升,电流密度缓慢升高,这是由于MgSO4腐蚀产物膜阻止了镁合金的继续溶解,形成的欧姆电压抑制了反应离子的扩散和迁移。之后出现的明显拐点是点蚀点,该点后电流密度随着电位上升急剧升高,说明该点后试样表面的腐蚀明显加剧。

图5 静液挤压态及不同热处理态AZ80镁合金失重腐蚀速率

Fig. 5 Corrosion rate of AZ80 magnesium alloy at hydrostatic extruded state and after different heat treatments

图6 静液挤压态及不同热处理态AZ80镁合金的极化曲线

Fig. 6 Polarization curves of AZ80 magnesium alloy at hydrostatic extruded state and after different heat treatments

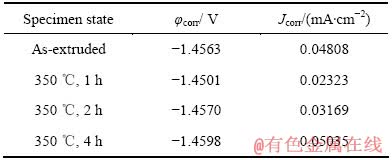

由表2中的阳极电化学数据可以看出:挤压态与经(350 ℃,1 h)、(350 ℃,2 h)、(350 ℃,4 h)热处理后AZ80镁合金的自腐蚀电位都相差不大,腐蚀电流密度由大到小的顺序为挤压态、(350 ℃,4 h)、(350 ℃,2 h)、(350 ℃,1 h)。腐蚀电流密度除(350 ℃,4 h)较挤压态的略微增大外,均有所减小,说明合适的热处理可以降低AZ80镁合金的腐蚀速率,从而提高其耐蚀性。

表2 静液挤压态及不同热处理态AZ80镁合金的阳极电化学数据

Table 2 Data of electrochemical measurement of AZ80 magnesium alloy at hydrostatic extruded state and after different heat treatments

一般来说,镁合金阳极材料中电偶腐蚀为主要的腐蚀形式[18],合金元素Al及含Al的第二相可以起到去极化作用,充当阴极使得镁基体表面的腐蚀产物剥落,使电化学腐蚀反应维持下去,从而加速腐蚀过程。静液挤压使得AZ80镁合金晶粒变形不均匀,大量的位错及空穴使得位错密度增加,耐腐蚀性能降低。从图2(b)可以看出,经(350 ℃,1 h)热处理后,AZ80镁合金的晶粒细小均匀,晶粒内大部分β-Mg17Al12相已经溶于α-Mg基体中,改善了其耐腐蚀性能。但随着热处理时间的延长,使得晶粒出现长大且分布极不均匀现象,粗大的晶粒使得析出的β-Mg17Al12相和非平衡相的电位差变大,基体与第二相间的电位差增大导致电偶腐蚀的驱动力增大,腐蚀抗力减小,从而构成电偶使得局部腐蚀速率过快,晶粒大小的不均匀也导致腐蚀不均匀。

2.4.2 电化学阻抗谱的测定

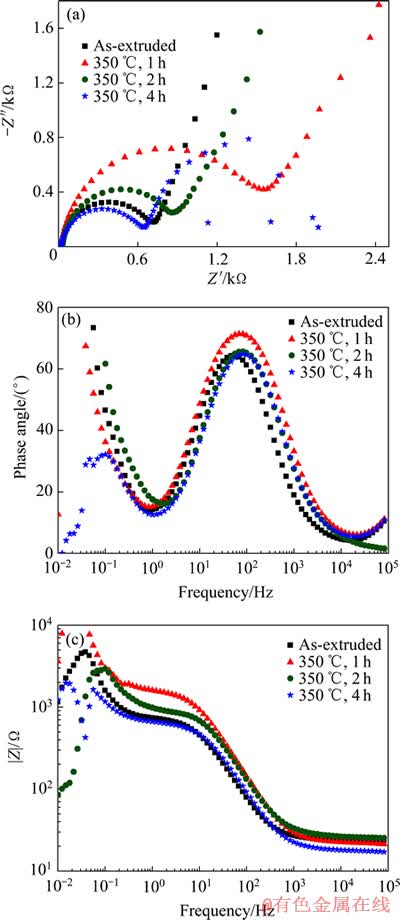

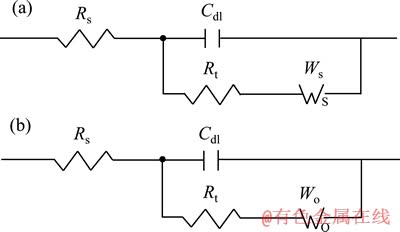

图7所示为挤压态及不同热处理态AZ80镁合金管材在pH 6.1的0.1 mol/L Na2SO4溶液中的Nyquist图和Bode图,从图7(a)可以看出,挤压态及(350 ℃,1 h)、(350 ℃,2 h)状态的EIS谱在高频部分为双电层的容抗弧,在低频部分出现Warburg半无限扩散阻抗。高频容抗弧意味着存在一个时间常数,对应图7(b)中高频段(100Hz)的“峰”,表示电极表面与薄液膜间的双电层弛豫现象。

低频扩散阻抗的出现意味着电极反应过程存在扩散受阻的情况,扩散步骤由电荷传递和物质扩散混合控制,并且扩散控制超过电化学控制,其等效电路如图8(a)所示。而(350 ℃,4 h)状态的EIS谱在低频部分则表现为有限层扩散阻抗,其等效电路如图8(b)所示。

图7 静液挤压态及不同热处理态AZ80镁合金的Nyquist图和Bode图

Fig. 7 Nyquist(a) and Bode plots((b), (c)) of AZ80 magnesium alloy at hydrostatic extruded state and after different heat treatments

高频区的容抗弧的半径越大,说明合金表面的转移电阻越大,耐腐蚀性能越好。从图7(a)中可以看出,高频区容抗弧由大到小依次为(350 ℃,1 h)、(350 ℃,2 h)、挤压态、(350 ℃,4 h),说明静液挤压AZ80镁合金经(350 ℃,1 h)热处理后的耐腐蚀性增强,且随着热处理时间的延长耐腐蚀能力随之降低。从图7(b)可以看出,经(350 ℃,1 h)热处理后的相位角比(350 ℃,2 h)、(350 ℃,4 h)和挤压态的相位角平台更宽,相位角也更高。由图7(c)可以看出,模值由大到小的顺序依次为(350 ℃,1 h)、(350 ℃,2 h)、挤压态、(350 ℃,4 h)。

图8 静液挤压态及不同热处理态AZ80镁合金的电化学等效电路图

Fig. 8 Electrochemical equivalent circuit of EIS plots of AZ80 magnesium alloy at hydrostatic extruded state and after different heat treatments

这均表明热处理可以提高静液挤压AZ80镁合金的耐蚀性能,但是热处理时间的长短也会对合金的耐蚀性能产生影响。其中,经350 ℃热处理1 h的双电层电容小于热处理2 h和4 h后的,即热处理1 h的转移电阻大于2 h和4 h后的,由于转移电阻越小,金属的腐蚀速率越大,所以静液挤压后的AZ80镁合金经350 ℃热处理1 h的耐腐蚀性能优于热处理2 h和4 h后的。

合金中的主要组成相成分中,α-Mg为基体,β-Mg17Al12相以连续或半连续的形态分布于晶界和基体中,静液挤压后的AZ80镁合金经过退火热处理,晶粒发生再结晶,第二相从半连续析出转变为连续析出,晶粒的细化及成分的均匀降低了镁合金的腐蚀速率。但是随着热处理时间的延长,晶粒的长大和不均匀分布使得析出的β-Mg17Al12相和非平衡相的电位差变大,基体与第二相间的电位差增大导致电偶腐蚀的驱动力增大,导致合金的腐蚀速率增加。

3 结论

1) 失重实验中,平均腐蚀速率以及极化曲线中腐蚀电流密度由大到小的顺序依次为(350 ℃,4 h)、挤压态、(350 ℃,2 h)、(350 ℃,1 h)。从腐蚀形貌来看(350 ℃,1 h)和(350 ℃,2 h)的腐蚀较挤压态轻,说明合适的热处理工艺可以提高静液挤压后AZ80镁合金的耐腐蚀性能。

2) 退火热处理使得静液挤压镁合金晶粒发生再结晶,晶粒细化提高了镁合金的腐蚀性能,但是随着热处理时间的延长,使得晶粒长大且分布不均匀,导致电偶腐蚀的驱动力增大,降低了镁合金的耐腐蚀性能。

3) 静液挤压后AZ80镁合金在(350 ℃,1 h)退火热处理条件下可获得较理想的再结晶组织,耐腐蚀性能显著提高,综合性能最佳。

REFERENCES

[1] 巫瑞智, 张景怀, 尹东松. 先进镁合金制备与加工技术[M]. 北京: 科学出版社, 2012.

WU Rui-zhi, ZHANG Jing-huai, YI Dong-song. Advanced magnesium alloy preparation and processing technology[M]. Beijing: Science Press, 2012.

[2] CLOW B B. Magnesium industry overview[J]. Advanced Materials Process, 1996, 150(4): 33-34.

[3] 余 琨, 黎文献, 王日出. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu. The research, development and application of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[4] 张 津, 张宗和. 镁合金及其应用[M]. 北京: 化学工业出版社, 2004.

ZHANG Jin, ZHANG Zong-he. Magnesium alloy and its application[M]. Beijing: Chemical Industry Press, 2004.

[5] 丁文江, 吴玉娟, 彭立明. 高性能镁合金研究及应用的新发展[J]. 中国材料发展, 2010, 29(8): 37-45.

DING Wen-jiang, WU Yu-juan, PENG Li-ming. The new development of research and application of high performance magnesium alloys[J]. Development of China Materials, 2010, 29(8): 37-45.

[6] 张世军, 黎文献, 余 琨, 谭敦强. 镁合金的晶粒细化工艺[J]. 铸造, 2001, 50(7): 373-375.

ZHANG Shi-jun, LI Wen-xian, YU Kun, TAN Dun-qiang. The grain refinement process of magnesium alloy[J]. Foundary, 2001, 50(7): 373-375.

[7] 王富耻, 张朝晖. 静液挤压技术[M]. 北京: 国防工业出版社, 2008.

WANG Fu-zhi, ZHANG Zhao-hui. The technology of hydrostatic extrusion[M]. Beijing: National Defense Industry Press, 2008.

[8] 胡丽平. 静液挤压技术的研究现状[J]. 金属成形工艺, 1995, 6: 40-43.

HU Li-ping. Research status of hydrostatic extrusion technology[J]. Metal Forming Technology, 1995, 6: 40-43.

[9] 宋光铃. 镁合金腐蚀与防护[M]. 北京: 化学工业出版社, 2006.

SONG Guang-ling. Corrosion and protection of magnesium alloys[M]. Beijing: Chemical Industry Press, 2006.

[10] ZENG Rong-chang, SUN Xin-xin, SONG Ying-wei, ZHANG Fen, LI Shuo-qi, CUI Hong-zhi, HAN En-hou. Influence of solution temperature on corrosion resistance of Zn-Ca phosphate conversion coating on biomedical Mg-Li-Ca alloys[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3293-3299.

[11] 张荣发, 单大勇, 韩恩厚, 曾志良. 镁合金阳极氧化的研究进展与展望[J]. 中国有色金属学报, 2006, 16(7): 1136-1148.

ZHANG Rong-fa, SHAN Da-yong, HAN En-hou, ZENG Zhi-liang. Status and prospect of anodization on magnesium and its alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1136-1148.

[12] SHARMA A K. Electroless nickel plating on magnesium alloys[J]. Metal Finishing, 1998, 3: 10-18.

[13] GUO Hui-xia, MA Ying, WANG Jin-song, WANG YU-shun, DONG Hai-rong, HAO Yuan. Corrosion behavior of micro-arc oxidation coating on AZ91D magnesium alloy in NaCl solutions with different concentrations[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1786-1793.

[14] ZHANG Tao, LI Ying, WANG Fu-hui. Role of β phase in the corrosion process of AZ91D magnesium alloy[J]. Corrosion Science, 2006, 48(5): 1249-1264.

[15] SONG G, AMANDA L B, DAVID H S. Corrosion resistance of aged die cast magnesium alloy AZ91D[J]. Materials Science and Engineering A, 2004, 336(1): 74-86.

[16] 宋 丹, 马爱斌, 江静华, 林萍华, 范俊峰, 杨东辉. 等径角挤压制备的超细晶AZ91D镁合金块材的腐蚀行为[J]. 中国有色金属学报, 2010, 20(3): 397-406.

SONG Dan, MA Ai-bin, JIANG Jing-hua, LIN Ping-hua, FAN Jun-feng, YANG Dong-hui. Corrosion behavior of ultra-fine grained bulk AZ91D Mg alloy fabricated by equal-channel angular pressing[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 397-406.

[17] JB/T 7901—1999. 金属材料实验室均匀腐蚀全浸试验方法[S].

JB/T 7901—1999. Metal materials laboratory corrosion immersion test method[S].

[18] 王乃光, 王日初, 余 琨, 冯 艳, 彭超群. 合金化和热处理对镁合金阳极材料组织及性能的影响[J]. 中国有色金属学报, 2009, 19(1): 38-43.

WANG Nai-guang, WANG Ri-chu, YU Kun, FENG Yan, PENG Chao-qun. Influence of alloying and heat treatment on the microstructure and mechanical properties of magnesium alloy anode materials[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 38-43.

(编辑 龙怀中)

基金项目:国家重大科技专项资助项目(2012ZX04010101)

收稿日期:2014-06-20;修订日期:2014-11-14

通信作者:吴志林,教授,博士;电话:13913882392;E-mail: wuruinan-1994@njust.edu.cn