DOI: 10.11817/j.ysxb.1004.0609.2020-37462

油气润滑对AZ80镁合金铸坯表面质量和组织的影响

李新涛,王顺成,周 楠,康跃华,甘春雷,刘明阳

(广东省材料与加工研究所,广州 510650)

摘 要:本文以自主设计的镁合金油气润滑铸造装置制备了直径154 mm的AZ80镁合金铸坯,系统研究油气润滑对AZ80镁合金铸坯表面质量和凝固组织的影响,并对其机理进行了探讨。采用结果表明:采用油气润滑铸造时,氩气和润滑油在石墨环内表面形成了一层油气混合膜,改变了熔体和结晶器的接触方式和热交换状态,从而制备出高品质的AZ80镁合金铸坯。随着气体压力的增加,铸坯表面粗大的偏析瘤和皮下偏析层得到抑制,凝固组织得到了明显细化。当气体压力增加到0.4 MPa时,铸坯皮下偏析层厚度从1252 μm降至628 μm,铸坯R/2、心部晶粒尺寸和二次枝晶间距显著减小。随着凝固组织的细化,Al、Zn和Mn元素的宏观偏析得到了改善。

关键词:AZ80镁合金;油气润滑;半连铸;表面质量;凝固组织

文章编号:1004-0609(2020)-03-0499-08 中图分类号:TG292 文献标志码:A

镁合金具有比强度和比刚度高、阻尼性和电磁屏蔽性能好等优点,是目前工程应用最轻的金属结构材料之一。近年来,镁合金挤压加工技术获得了较大的进展,挤压产品在交通运输、军工、3C等领域获得了越来越广泛的应用。铸坯是镁合金挤压加工的原材料,其质量对加工产品的性能有着重要影响。目前,垂直半连铸是制备镁合金铸坯最主要的方法之一[1-3]。然而,常规半连铸方法生产的铸坯中通常存在粗大的偏析瘤和较厚的皮下偏析层,在挤压加工前需要通过大量车削来消除这些缺陷,严重降低了材料的利用率,增加了生产成本。同时,受半连铸冷却方式影响,铸坯凝固组织粗大不均匀且存在成分偏析,增加了后续挤压加工的难度[4]。

为了提高半连续铸坯的质量,近年来不断探索和研究各种新型铸造装备和铸造技术[5-12]。其中,油气润滑铸造技术是在常规热顶铸造技术基础上发展起来的一种先进的铸造方法,其特点是在铸造过程中向结晶器内输入润滑油和压缩空气,在结晶器的冷却壁上形成一层具有润滑和缓冷作用的油气混合膜[13-19]。该膜的存在改变了熔体与结晶器之间的接触状态,从而显著改善铸坯的内部组织和表面质量。目前,油气润滑铸造技术在铝加工行业得到了广泛应用[20]。而镁合金的熔炼和铸造等技术要求均与铝合金的不同,目前尚未发现油气润滑铸造技术制备镁合金铸坯的报道。

为了探索镁合金油气润滑铸造技术,本文以AZ80镁合金为研究对象,自主设计了油气润滑结晶器,采用垂直半连铸的方法成功制备了规格为d 154 mm的镁合金铸坯,研究了油气润滑对AZ80镁合金铸坯表面质量、凝固组织和元素宏观分布的影响规律,并对其作用机理进行了探讨。

1 实验

1.1 实验设备

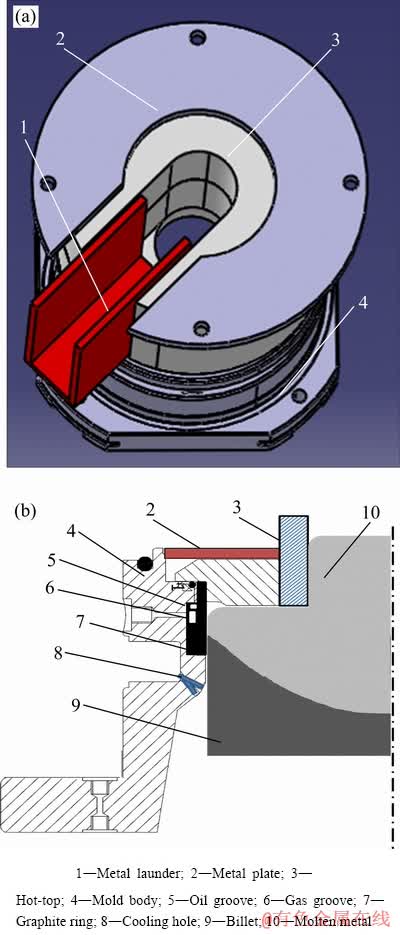

本文中的实验设备主要包括坩埚式电阻炉、不锈钢材质的熔体传输管、液位控制装置、油气润滑结晶器、铸造机和油气供给装置等。其中,油气润滑结晶器是关键设备,其结构如图1所示,主要由铝质结晶器本体、有透油透气功能的石墨环和热顶等组成。结晶器本体两侧对称有独立的油孔和气孔,孔的末端分别与石墨环外表面的油槽和气槽相对应。喷水结构采用双排喷水孔,喷水孔与垂直方向的夹角分别是30°和45°。这种喷水结构有利于消除冷却水的喷溅,提高二冷区的冷却强度[21]。石墨环采用冷等静压成型的多孔高纯石墨机加工而成,内径为154 mm,高度为22 mm。为保证结晶器的一次冷却效果,石墨环和结晶器本体之间采用过盈配合装配。

图1 油气润滑结晶器3D和剖面结构示意图

Fig. 1 Three-dimensional(a) and profile structural diagram(b) of oil-gas slip mold

1.2 实验方法

AZ80镁合金的化学成分如表1所示。

表1 AZ80镁合金的化学成分

Table 1 Chemical composition of AZ80 magnesium alloy (mass fraction, %)

实验选用纯度为(质量分数,下同)99.8%的工业纯铝、99.995%的0号锌锭、99.95%的1号镁锭和Al-10Mn中间合金作为原材料。原材料放入坩埚炉内熔炼,为了避免熔炼过程中增铁,铁质坩埚表面刷涂料。熔体表面用RJ-2号覆盖剂覆盖,并通入氩气进行保护。当熔体温度达到730 ℃时用C2Cl6进行精炼除渣,静置30 min。当熔体温度降到710 ℃时开始放流浇注,熔体通过预热过的传输管流到铸造平台上的蓄液池内,经流槽流入结晶器内,通过调节传输管流量来控制结晶器内的液位高度。蓄液池、流槽和结晶器内的液面均采用SF6+Ar混合气体进行保护,避免熔体与空气直接接触。实验采用的铸造速度为120 mm/min,冷却水流量为1.8 m3/h。

采用冷冻机油作为润滑介质,用供油装置以脉冲方式向结晶器供油。频率为2次/min,润滑油的供给量为2 mL/min,供油压力为4 MPa。

实验采用干燥的氩气(纯度≥99.99%)作为气体介质,由供气装置以连续供气的方式向结晶器供气。实验发现,在结晶器内熔体液位高度保持稳定不变的条件下,氩气的输出压力超过0.4 MPa时液面开始翻腾,出现了气泡从液面逸出的现象。由于气泡破坏了表面保护层,容易导致氧化烧损,严重时引起燃烧,因此将氩气的最大输出压力设置为0.4 MPa。

半连铸时,油气供给装置将润滑油和氩气分别经油孔和气孔注入石墨环的油槽和气槽内,油和气在压力作用下在石墨环内混合并通过微孔渗出,在石墨环内壁形成油气膜,如图2所示。

图2 石墨环内表面油气膜照片

Fig. 2 Picture of oil-gas film on inner surface of graphite ring

为了考察气体压力对铸坯表面和凝固组织的影响,选择氩气压力为0、0.2和0.4 MPa条件下进行对比试验。当氩气压力降低到0 MPa时,润滑油仅靠自身的压力不能渗透石墨环,无法在石墨环内表面形成润滑层。同时,由于油槽和气槽之间的石墨厚度小于油槽和石墨环内表面之间的壁厚,如果在不通气条件下持续注油,润滑油会渗透到气槽内,并倒流到气孔内将气孔堵死,影响结晶器的使用。因此,氩气压力降为0 MPa时停止供应润滑油。

在不同铸坯的表层、1/2半径处(R/2)和中心部位分别取样,试样经研磨、抛光、腐蚀后进行覆膜处理,使用偏光显微镜对皮下偏析层和显微组织进行分析。采用截线法,用Image Pro-plus软件测量统计铸坯的晶粒度和二次枝晶间距。

2 结果与讨论

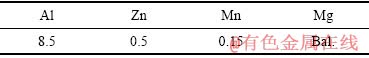

图3 不同油气润滑条件下制备铸坯的表面照片

Fig. 3 Surface pictures of billets prepared under different oil-gas slip conditions

图3所示为不同油气润滑条件下制备的铸坯的表面照片。由图3可知,在气体压力为0 MPa、未注油条件下制备的铸坯表面非常粗糙,有明显的偏析瘤,偏析瘤的平均高度约1 mm。在油气润滑条件下制备的铸坯随着气体压力的增加,铸坯表面质量明显改善。当气体压力为0.2 MPa时,表面偏析瘤显著缩小,高度降至约0.3 mm。当气体压力增加到0.4 MPa时,偏析瘤完全消失,铸锭表面光滑,近似镜面。

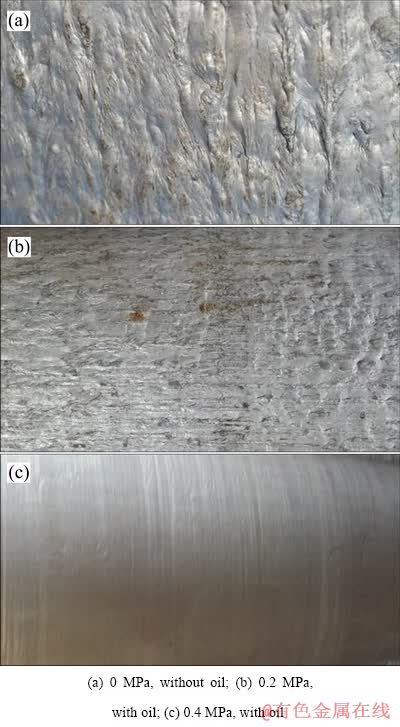

图4 不同油气润滑条件下制备铸坯的皮下微观组织

Fig. 4 Subsurface microstructures of billets prepared under different oil-gas slip conditions

采用半连铸方法制备的铸坯,凝固过程中受溶质分配系数的影响,表皮下会形成反偏析层,在后续变形加工过程中会引起开裂等缺陷。变形加工之前必须通过车削的方法将皮下偏析层去除,因此需要尽量减少皮下偏析层。图4所示为不同气体压力下铸坯的皮下偏析层的微观组织。为避免受表面偏析瘤的影响,从铸坯上取样时尽量避开表面偏析瘤,从相对平直光滑的位置取样。由图4可知,AZ80镁合金铸坯皮下组织主要由细晶组成,与内部组织之间有明显的分界线。未经油气润滑的铸坯皮下偏析层厚度约为1252 μm。油气润滑条件下制备的铸坯皮下偏析层厚度明显降低,而且随着气体压力的增加而减小。当气体压力为0.2 MPa时,偏析层厚度约为925 μm;当气体压力增大到0.4 MPa时,偏析层厚度减小到628 μm。

熔体和石墨环的接触方式以及热交换状态是影响镁合金铸坯表面质量的重要因素。在不通油气条件下进行半连铸时,熔体通过热顶进入结晶器,与石墨环直接接触受到一次冷却,熔体热量经石墨环和铝壁由冷却水带走。在一次冷却作用下,熔体开始凝固,形成初始凝固壳,并在铸造机的牵引下向下移动离开结晶器进入二冷区,并在冷却水的直接冷却作用下继续凝固形成铸坯。

本文所用结晶器本体的材质是锻造铝合金,它和石墨环的导热性能良好[22],因此铸坯初始凝固点位置靠近石墨环上端。凝固壳形成后开始收缩,与石墨环之间形成气隙,由于气隙导热能力差,导致结晶器对凝固壳的冷却能力迅速降低。在凝固壳内部尚未凝固的高温熔体及结晶潜热的共同作用下,低熔点物质重熔,并在熔体静压力和凝固壳收缩压力的共同作用下,沿着枝晶间隙渗透到铸坯表面,形成表面偏析瘤和皮下偏析层。

在油气润滑条件下进行半连铸时,镁合金熔体与石墨环之间有一层均匀的油气膜,且输入的氩气压力越大,油气膜对熔体的压力也越大。镁合金熔体在径向上受力如下:

(1)

(1)

式中:Fm为石墨环对熔体的支撑力;Ff为油气膜对熔体施加的压力;ρgh为熔体静压力,其中ρ为熔体密度,g为重力加速度,h为熔体高度。

在未施加油气润滑条件下进行铸造时,Ff=0,熔体压力完全作用到石墨环内表面上,此时石墨环对熔体的支撑力等于熔体静压力。

当油气润滑铸造时,油气膜对熔体的压力抵消了部分熔体静压力。初始凝固壳在向下移动时(滑动摩擦因数为μ),受到的摩擦力f为

(2)

(2)

润滑油和气体均是良好的润滑介质,有良好的润滑效果,可以降低凝固壳和石墨环之间的摩擦因数。本文中润滑油的压力恒定不变,因此油气膜的压力随着氩气压力的增大而增大。从式(2)可以看出,随着气体压力的增加,凝固壳与结晶器之间的摩擦力逐渐减小。当油气膜压力与熔体静压力相当时,坯壳与结晶器之间的摩擦力为零,铸坯的表面质量得到改善。继续增大气体压力,油气膜压力超过熔体静压力,熔体受力平衡受到破坏,气泡开始从结晶器表面逸出。

油气膜是以氩气为主要成分的油气混合物,其导热系数远低于铝合金本体和石墨环[22]。在油气膜的作用下,结晶器的一次冷却强度被显著减弱,熔体在结晶器内的初始凝固点位置下移,缩短了初始凝固壳与二冷区之间的距离。在铸造速度不变的情况下,凝固壳形成后以更短的时间进入二冷区,受到二冷水的直接冷却,有利于减轻或避免低熔点物质的重熔,有效地抑制了表面偏析瘤和皮下偏析层的形成,进一步提高了铸坯的表面质量。

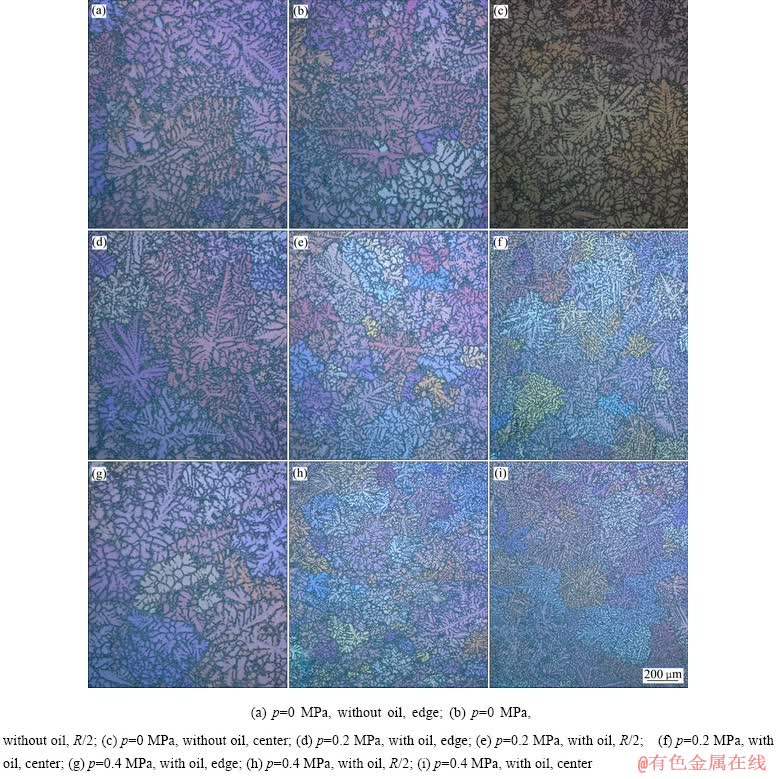

图5所示为不同铸坯边部、R/2处和心部的铸态显微组织。由图5(a)可知,未进行油气膜润滑的铸坯边部是典型的枝晶结构,一次枝晶和二次枝晶粗大。在R/2处枝晶有所细化,一次枝晶和二次枝晶都明显变小,部分二次枝晶形成缩颈并从一次枝晶上脱落(见图5(b));心部枝晶较R/2处枝晶粗化(见图5(c)),但晶粒尺寸均匀性有所提高。油气润滑条件下制备的铸坯,边部也是粗大的枝晶组织,但一次枝晶和二次枝晶较未进行油气润滑的铸坯枝晶组织变短、变细(见图5(d)和(g))。随着氩气压力的增大,铸坯R/2处和心部枝晶逐步得到细化,一次枝晶和二次枝晶显著变细、变短,且晶粒尺寸更加均匀(见图5(e)、(f)、(h)和(i))。

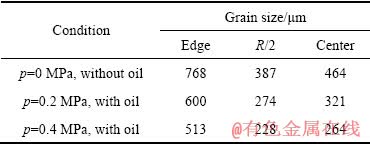

测量不同铸坯边部、R/2处和中心部位的晶粒度,取其平均值进行比较,结果如表2所示。由表2可知,未进行油气润滑的铸坯边部、R/2处和心部的晶粒度分别为768、387和464 μm。而在油气润滑条件下制备的铸坯,随着气体压力的增加,凝固组织逐渐得到了细化,且R/2处和心部的晶粒度更加接近。当气体压力为0.4 MPa时,铸坯边部、R/2处和心部晶粒度分别降到513、 228和264 μm。

在油气润滑条件下半连铸时,油气膜使熔体和结晶器之间不直接接触,减弱了结晶器的一次冷却强度。本文所用的结晶器采用了双排水的冷却结构,增大了冷却水的喷射角,有利于消除冷却水的喷溅,提高二冷区的冷却强度和铸坯轴向传热能力[21]。在弱一冷、强二冷的凝固条件下,铸坯液穴变浅,液穴内部温度梯度减小,提高了结晶前沿边部和中部熔体的温度和成分均匀性,从而抑制了晶粒长大,减小了不同部位晶粒度的差异。

图5 不同油气润滑条件下制备铸坯的金相组织

Fig. 5 Metallographs of billets prepared under different oil-gas slip conditions

表2 不同条件下制备铸坯的晶粒度

Table 2 Grain size of billets prepared under different conditions

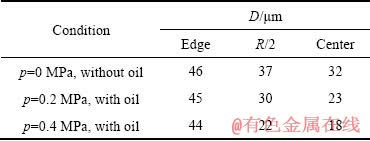

表3 不同条件下制备铸坯的二次枝晶间距

Table 3 Secondary dendrite arm spacing(D) of billets prepared under different conditions

二次枝晶间距是评价铸坯凝固组织的一个重要参数[23]。本文采用截线法对金相试样的二次枝晶间距

行测量,取其平均值进行比较,结果如表3所示。由表3可以看出,在不同油气润滑条件下制备的铸坯,表面部位二次枝晶间距大小接近,但在沿着径向方向上变化趋势不同。未施加油气润滑条件下铸造的铸 坯,R/2处的二次枝晶间距为37 μm,心部减小到32 μm。在油气润滑条件下铸造的铸坯,二次枝晶间距从表面到中心位置明显减小,且氩气的压力越大,二次枝晶间距越小,当氩气压力增加到0.4 MPa时,铸坯R/2处的二次枝晶间距减小到22 μm,心部的二次枝晶间距减小到16 μm。

二次枝晶间距是由冷却速率和合金性质决定的,在合金成分一定时,影响二次枝晶间距的主要因素是冷却速率。根据传热传质理论,合金的冷却速率与二次枝晶间距的关系如下[24-25]:

(3)

(3)

式中:D是二次枝晶间距;β是与合金成分、冷却条件相关的常数;v是合金凝固时的冷却速率。由式(3)可以看出,二次枝晶间距D随着冷却速率v的增大而呈指数减小。油气润滑条件下进行半连铸时,初始凝固点下移,且气体压力越大,初始凝固点位置与二冷水见水点位置越近。在冷却水的直接强冷作用下,熔体凝固时间短,冷却速率增大。在大的冷却速率作用下,二次枝晶的生长速度受到抑制,二次枝晶间距变小。由于心部二次枝晶显著变细,因此心部的二次之间间距较R/2处的更小。在不通油气条件下进行半连铸时,由于气隙的影响,初始凝固点位置距离二冷水见水点远,熔体得不到快速冷却,因此二次枝晶间距变大。

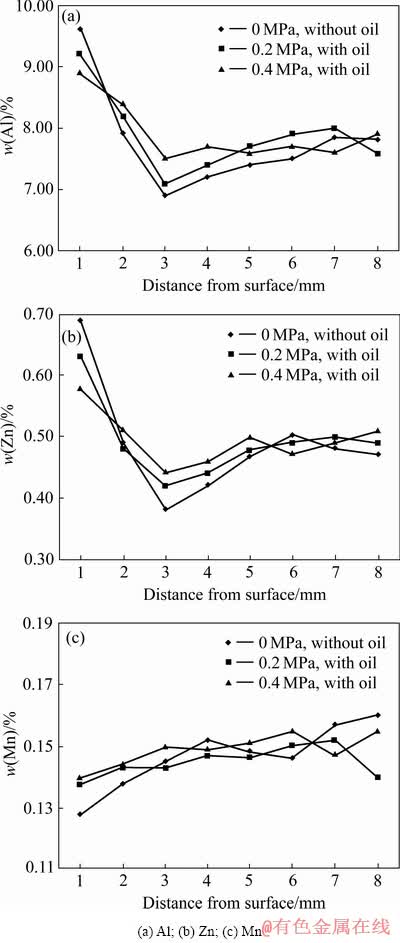

采用半连铸方法制备的镁合金铸坯,溶质元素在铸坯截面尺度范围内分布不均匀,形成宏观偏析,偏析严重时会降低合金的成材率和力学性能。在铸坯横截面上,沿径向方向从边部至心部每隔11 mm钻取金属屑,采用化学分析法测定Al、Zn和Mn元素的含量,分析油气润滑对铸态组织中溶质元素宏观分布的影响。为减小误差,同一长度距离从三个不同位置钻取屑,金属屑充分混合后从中取一部分进行分析,结果如图6所示。Al和Zn元素从边部向心部呈负偏析,Mn元素含量从铸锭边部向心部逐渐升高,呈正偏析。同时,在油气润滑条件下制备的铸坯,Al、Zn和Mn三种合金元素的偏析程度比未施加油气润滑的铸坯偏析程度低。

AZ80合金在半连铸过程中形成了发达的枝晶,枝晶间聚集着含有大量溶质元素的金属液,由于Al元素和Zn元素扩散系数K<1,在金属液静压力和收缩压力的作用下,沿着枝晶间的间隙向外部扩散,从而形成了负偏析。Mn元素在镁合金中属于难熔组元,容易形成金属中间化合物,汇聚在液穴底部,因此在凝固结束时形成正偏析现象。

在油气润滑条件下进行铸造时,由于初始凝固点位置下移,加快了熔体的凝固速率,缩短了凝固时间。

随着凝固速率的增加,晶粒组织细化,二次枝晶间距减小,减轻了溶质沿枝晶的富集,富溶质熔体的长距离流动受到抑制,从而减轻了溶质元素的宏观偏析。

图6 溶质元素沿径向的分布

Fig. 6 Distribution of solute elements along radius direction

3 结论

1) 采用油气润滑铸造方法能够制备出高品质的AZ80镁合金铸坯,随着氩气压力的增加,铸坯表面质量明显改善。当气体压力增加到0.4 MPa时,铸坯偏析瘤消失,表面偏析层厚度减小至628 μm。

2) 油气润滑细化铸坯晶粒组织,提高晶粒尺寸均匀性,减小二次枝晶间距。随着凝固组织的细化,Al、Zn和Mn元素的宏观偏析得到了改善。

3) 半连铸时施加润滑油和氩气形成的油气膜改善了熔体和结晶器的接触方式和热交换状态,提高了铸坯的表面质量和凝固组织。

REFERENCES

[1] 赵 辉, 彭晓东, 王艳光, 赵凯阳, 魏群义. 半连铸工艺对AZ31镁合金铸锭组织的影响[J]. 兵器材料科学与工程, 2011, 34(6): 22-26.

ZHAO Hui, PENG Xiao-dong, WANG Yan-guang, ZHAO Kai-yang, WEI Qun-yi. Effect of semi-continuous casting processing on ingot microstructure of AZ31 magnesium alloy[J]. Ordnance Material Science and Engineering, 2011, 34(6): 22-26.

[2] JI H M, LUO T J, WANG C, CUI J, YANG Y S. Direct chill casting of magnesium alloy under pulsed magnetic field[J]. Materials Science & Technology, 2016, 33(1): 33-39

[3] CARON E, WELLS M A. Secondary cooling in the direct- chill casting of magnesium alloy AZ31[J]. Metallurgical & Materials Transactions B, 2009, 40(4): 585-595.

[4] 冀焕明, 罗天娇, 杨院生. AZ80镁合金低压脉冲磁场半连续铸造过程的数值模拟和实验研究[J]. 中国有色金属学报, 2017, 27(3): 468-476.

JI Huan-ming, LUO Tian-jiao, YANG Yuan-sheng. Numerical simulation and experimental research of low voltage pulsed magnetic field DC casting of AZ80 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(3): 1692-1698.

[5] BOLOURI A, BAE J W, KANG C G. Tensile properties and microstructural characteristics of indirect rheoformed A356aluminum alloy[J]. Materials Science and Engineering A, 2013, 562(1): 1-8.

[6] ZHANG L, LI W, YAO J P, QIU H. Effects of pulsed magnetic field on microstructures and morphology of the primary phase in semisolid A356 Al slurry[J]. Materials Letters, 2012, 66(1): 190-192.

[7] XING Bo, HAO Yuan, LI Yuan-dong, MA Ying, CHEN Ti-jun. Microstructure control of AZ31 alloy by self- inoculation method for semisolid rheocasting[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 567-575.

[8] ZHANG Liang, WU Guo-hua, WANG Shao-hua, DING Wen-jing. Effect of cooling condition on microstructure of semi-solid AZ91slurry produced via ultrasonic vibration process[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2357-2363.

[9] LIN C, WU S S, LV S L, AN P, WAN L. Microstructure and mechanical properties of rheo-diecast hypereutectic Al-Si alloy with 2% Fe assisted with ultrasonic vibration process[J]. Journal of Alloys and Compounds, 2013, 568: 42-48.

[10] ZHANG Yang, WU Guo-hua, LIU Wen-cai, ZHANG Liang, PANG Song, DING Wen-jiang. Effects of processing parameters on microstructure of semi-solid slurry ofAZ91D magnesium alloy prepared by gas bubbling[J]. Transactions of Nonferrous Metals and Society of China, 2015, 25(7): 2181-2187

[11] GUO S J, CUI J Z, LE Q C, ZHAO Z H. The effect of alternating magnetic field on the process of semi-continuous casting for AZ91 billets[J]. Materials Letters, 2005, 59(14/15): 1841-1844.

[12] MAPELI C, GRUTTADAURIA A, PERONI M. Application of electromagnetic stirring for the homogenization of aluminum billet cast in a semi-continuous machine[J]. Journal of Materials Processing Technology, 2010, 210(2): 306-314.

[13] BISSCHOPS T, VIJFVINKEL J. Large ultra-precision motion feed through designs[J]. Vacuum, 2001, 60(1/2): 161-165.

[14] AOYAMA T, KAKINUMA Y, KOBAYASHI Y. Numerical and experimental analysis for the small vibration of aerostatic guide ways[J]. Annals of the CIRP, 2006, 55(1): 419-422.

[15] BELFORTE G, RAPARELLI T, VIKTOROV V. Modeling and identification of gas journal bearings: Self-acting gas bearing results[J]. Journal of Tribology, 2002, 124(4): 716-724.

[16] SAVOULIDES N, BREUER K S, JACOBSON S, EHRICH F F. Low-order models for very short hybrid gas bearings[J]. Journal of Tribology, 2001, 123(2): 368-375.

[17] FARIA M T C, SAN ANDRES L A. On the numerical modeling of high-speed hydrodynamic gas bearings[J]. Journal of Tribology, 2000, 122(1): 124-130.

[18] EHRICH F F, JACOBSON S A. Development of high-speed gas bearings for high-power density microdevices[J]. Journal of Engineering for Gas Turbines and Power, 2003, 125(1): 141-148.

[19] YU T H, SADEGHI F. Thermal effects in thrust washer lubrication[J]. Journal of Tribology, 2002, 124(1): 166-177.

[20] YU Yun, MA Nai-heng, XU Zhen-ming, LI Jian-guo. Theoretical analysis of the solidification of aluminum alloy billet in air-slip mold[J]. Journal of Shanghai Jiao Tong University (Science), 2004, 9(4): 47-51.

[21] ALLEN J W, WAGSTAFF R B, BOWLES K D. 扩大圆锭结晶器冷却水出口区[J]. 轻合金加工技术, 1999, 27(1): 15-18.

ALLEN J W, WAGSTAFF R B, BOWLES K D. Augmented water exit geometry for billet molds[J]. Light Alloy Fabrication Technology, 1999, 27(1): 15-18.

[22] 于 赟, 李小平, 李建国. 气膜结晶器结构与传热分析[J]. 特种铸造及有色合金, 2010, 30(5): 400-402.

YU Yun, LI Xiao-ping, LI Jian-guo. Analysis of heat-transfer and structure of air slip mold[J]. Special Casting and Nonferrous Alloys, 2010, 30(5): 400-402.

[23] MUKAI T, YAMANOI M, WATANABE H, HIGASHI K. Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure[J]. Scripta Materialia, 2001, 45(1): 89-94.

[24] WON Y M, THOMAS B G. Simple model of micro- segregation during solidification of steel[J]. Metallurgical and Materials Transactions A, 2001, 32(7): 1755-1767.

[25] 张丁非, 兰 伟, 丁培道, 张保平. AZ91镁合金的凝固冷却速度与二次枝晶间距的定量关系研究[J]. 材料工程, 2007(4): 23-26.

ZHANG Ding-fei, LAN Wei, DING Pei-dao, ZHANG Bao-ping. Quantitative research on relationship between secondary dendrite arm spacing and solidification cooling rate of AZ91 magnesium alloy[J]. Journal of Materials Engineering, 2007(4): 23-26.

Effect of oil-gas slip on surface quality and solidification structure of AZ80 magnesium alloy billets

LI Xin-tao, WANG Shun-cheng, ZHOU Nan, KANG Yue-hua, GAN Chun-lei, LIU Ming-yang

(Guangdong Institute of Materials and Processing, Guangzhou 510650, China)

Abstract: AZ80magnesium alloy billets with diameter of 154 mm were prepared using oil-gas slip casting device designed in dependently. The effects of oil-gas slip on surface quality and solidification structure of AZ80 magnesium alloy billets were systematically studied and theoretically discussed. The results indicate that high quality AZ80 magnesium alloy billets can be prepared by oil-gas casting process. Argon and lubricating oil form an oil-gas film on the inner surface of the graphite ring, which changes the contact mode and thermo exchanging state between melt and graphite ring. With the increase of gas pressure, the coarse segregation tumors and the subsurface segregation layer on the billets surface are inhibited, and the solidification structure is refined obviously. When the gas pressure increases to 0.4 MPa, the thickness of subsurface segregation layer decreases from 1252 μm to 628 μm, and the grain size and secondary dendrite spacing at R/2 and center of the billets decrease significantly. Meanwhile, macrosegregation of Al, Zn and Mn elements is improved with the refinement of solidification structures.

Key words: AZ80 magnesium alloy; oil-gas slip; semi-continuous casting; surface quality; solidification structure

Foundation item: Project(2017GDASCX-0117) supported by the Science and Technology Development of GDAS, China; Project(2017A070701029) supported by the Public Welfare Research and Capacity Building of Guangdong Province, China

Received date: 2018-12-07; Accepted date: 2019-11-04

Corresponding author: LI Xin-tao; Tel: +86-20-61086616; E-mail: lxt_hq@163.com

(编辑 何学锋)

基金项目:广东省科学院院属骨干科研机构创新能力建设专项资助项目(2017GDASCX-0117);广东省公益研究与能力建设项目(2017A070701029)

收稿日期:2018-12-07;修订日期:2019-11-04

通信作者:李新涛,高级工程师,博士;电话:020-61086616;E-mail:lxt_hq@163.com