文章编号:1004-0609(2015)04-0910-08

新型热机械处理对Al-Zn-Mg-Cu合金显微组织与性能的影响

张纪帅1, 3,陈志国1, 2, 3,任杰克1, 3,陈继强1, 3,魏 祥1, 3,方 亮1, 3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 湖南人文科技学院 机电工程系,娄底 417000;

3. 中南大学 轻合金研究院,长沙 410083)

摘 要:通过拉伸实验、慢应变速率实验、剥落腐蚀实验、扫描电镜和透射电镜观察,研究新型热机械处理对Al-Zn-Mg-Cu合金显微组织及性能的影响。结果表明:冷变形最终热机械处理能够使合金在塑性不显著降低的情况下,提高合金的强度,温变形最终热机械处理能有效弥补常规最终热机械处理后伸长率较低的缺陷,同时能有效改善合金的抗剥落腐蚀性能;回归后冷变形可提高合金强度,但降低了合金的伸长率;回归后温变形处理能使合金获得良好的综合性能,如力学性能、抗应力腐蚀性和抗剥蚀性能。新型热机械处理改善合金性能的机理是合金晶粒形态、位错、初生相以及析出相等显微组织结构的协同作用。

关键词:高强铝合金;时效;热机械处理;应力腐蚀

中图分类号:TG146.2 文献标志码:A

Effect of new thermomechanical treatment on microstructure and properties of Al-Zn-Mg-Cu aluminum alloy

ZHANG Ji-shuai1, 3, CHEN Zhi-guo1, 2, 3, REN Jie-ke1, 3, CHEN Ji-qiang1, 3, WEI Xiang1, 3, FANG Liang1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Mechanical and Electrical Engineering,

Hunan University of Humanities Science and Technology, Loudi 417000, China;

3. Light Alloy Research Institute, Central South University, Changsha 410083, China)

Abstract: The effects of new thermomechanical treatment (TMT) on the microstructure and properties of Al-Zn-Mg-Cu alloy were studied by tensile test, slow strain rate tensile test (SSRT),exfoliation corrosion test (EXCO), scanning electron microscopy and transmission electron microscopy. The results indicate that the cold deformation final thermomechanical treatment (FTMTc) process can significantly increase the strength of the alloy without obvious plasticty loss,and warm deformation find thermomechanical treatment (FTMTw) at 200 ℃ can simultaneously improve the elongation and EXCO resistance. Cold rolling after regression (RRCA) can obtain high strength but low elongation, while warm rolling after regression (RRWA) can obtain good mechanical properties and a good combination of stress corrosion resistance (SCR) and exfoliation corrosion resistance. The mechanism of the new TMT process that improves the properties of the alloy is the synergistic effect of composite structures, such as grain structure, dislocations, as well as the size and distribution of primary phase and precipitate phase.

Key words: high strength aluminum alloy; ageing; thermomechanical treatment; stress corrosion

航空航天高技术的发展对铝合金的综合性能提出了越来越高的要求[1-3]。作为航空航天重要支撑的Al-Zn-Mg-Cu合金具有高的比强度、易加工成型以及较好的焊接性能,但其对应力腐蚀和剥落腐蚀比较敏感,能够提升该合金综合性能的回归再时效(Retrogression and reaging,RRA)、热机械处理(TMT)等工艺越来越受到关注[4-8]。CINA[6]提出的RRA工艺可保证该系合金同时拥有高强度和优异的耐腐蚀性能;OSTERMANN等[9]的研究结果表明,FTMT能够使Al-Zn-Mg-Cu合金疲劳性能提高25%;JAHN等[10]研究发现,合金经100 ℃的预时效热机械处理不仅提高强度,同时使疲劳寿命比T6态的提高19.5%。本课题组成员[11]的研究发现,新型最终热机械处理工艺(FTMT)能提高2E12铝合金的强塑性等综合性能。纵观7xxx铝合金热机械处理的研究,主要集中在时效前预变形的热机械处理[12-13],而对时效中添加形变的最终热机械处理与时效回归后添加形变的新型热机械处理工艺还缺乏研究[4],并且对热机械处理对提高合金的强度、抗应力腐蚀等性能的机理还不清楚。在此,本文作者对比研究了常规和新型热机械处理对高强铝合金的微观组织及性能的变化规律,并较系统地探索了新型热机械处理对合金显微组织的影响机理。

1 实验

试验样品为2 mm厚的冷轧态7075合金,其成分为(质量分数,%):Al-5.13Zn-2.58Mg-1.42Cu-0.21Cr- 0.27Si-0.12Fe。试样经470 ℃、1 h盐浴固溶后水淬,随后进行的热处理制度如表1所列。其中RRCA是试样在回归后冷轧,而RRWA是在合金回归过程后温轧,温轧温度均为200 ℃。拉伸试验在MTS-858型材料试验机上进行,拉伸速率为2 mm/min。慢应变速率实验在WDML-1型慢应变速率拉伸应力腐蚀试验机上进行,应变速率为2×10-6 s-1,腐蚀液为3.0%NaCl+0.5%H2O2(质量分数,%)水溶液,按HB 5254—1983标准制备样品。剥落腐蚀实验按ASTM- G34-01标准进行,腐蚀介质为4.0 mol/L NaCl+0.5 mol/L KNO3+0.1 mol/L HNO3溶液,溶液体积与试样实验面积之比为15 mL/cm2,试样浸泡不同时间后根据标准进行评级,评级代号:N—无明显腐蚀;P—点蚀或爆皮;PA—表面轻微点蚀;PB—表面点蚀较重;PC—表面呈严重点蚀,出现爆皮等;EA—初等剥蚀;EB—中等剥蚀;EC—严重剥蚀;+表示程度大,-表示程度小。扫描电镜观察是在Sirion 200场发射扫描电镜上进行,加速电压为25 kV。TEM试样经机械减薄后采用体积分数25%硝酸和75%甲醇混合液在-25 ℃左右双喷穿孔而成,透射电镜分析在TecnaiG220电子显微镜上进行,加速电压200 kV。

2 实验结果

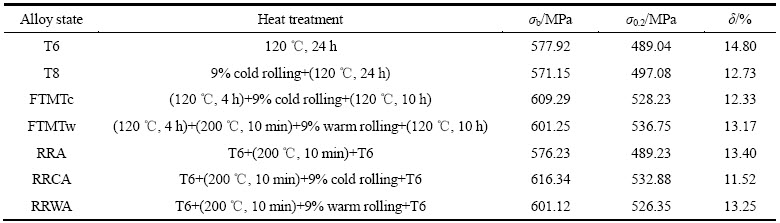

合金的拉伸力学性能如表1所列。由表1可知,T6态合金的强度较低,而伸长率较高。合金淬火后直接预变形的T8态合金的强度和伸长率都略有降低。而经过最终热机械处理的FTMTc态合金的强度提高而伸长率降低,FTMTw处理的合金的强度降低,伸长率略提高。RRA态合金的强度与T6态合金的力学性能接近。当合金在经回归处理后冷轧再时效的RRCA态的合金的强度提高约8%,而伸长率降低2.3%,合金在回归后直接温轧然后再时效的RRWA态合金的强度比RRA态合金的提高25 MPa,而伸长率与RRA合金态的接近。

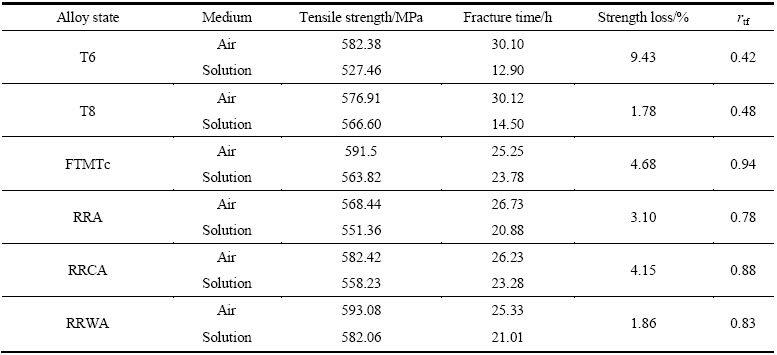

表2所列为高强铝合金在不同热处理状态下的慢应变速率实验拉伸(SSRT)结果,应力腐蚀开裂(Stress corrosion crack, SCC)的敏感性[14]可用在腐蚀液中的断裂时间与空气中的断裂的时间之比rtf来表征。合金经过不同制度的热处理后抗应力腐蚀性有明显的变化。T6态合金的强度损失最大,为9.43%,同时断裂时间比为0.42,可知T6态合金的应力腐蚀断裂(SCC)敏感性很大。时效前预变形的T8态合金在空气中的抗拉强度为576.91MPa,虽然的强度损失很小,但是其断裂时间rtf比较小,该状态合金在腐烛介质中的拉伸时间较短,具有较大的SCC敏感性。RRA态合金的强度损失比为3.1%,同时,具有较高的rtf,表明该处理态能使合金抗应力腐蚀性提高。FTMTc态合金有一定的强度损失,但在腐蚀溶液中断裂时间较长,具有很高的rtf值,RRCA态合金的强度损失与FTMT态合金接近,同时也具有较高的断裂时间比(rtf=0.83),FTMT态、RRWA与RRCA热机械处理态的合金具有较低的强度损失比和较高的rtf值,可见新型热机械处理态合金具有较佳的抗应力腐蚀性,而RRWA态合金表现出更优异的抗应力腐蚀性。

表1 7075 合金在不同热处理的拉伸力学性能

Table 1 Tensile property results of 7075 alloy under different heat treatments

表2 7075铝合金慢应变速率实验拉伸结果

Table 2 Slow strain tensile test results of 7075 alloy

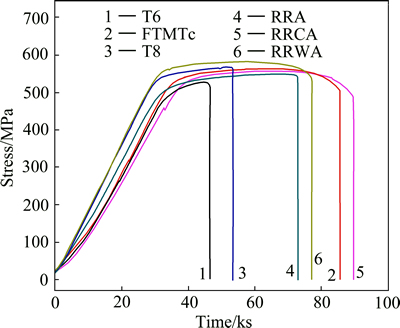

图1所示为不同的热处理条件下合金在3%NaCl+ 0.5%H2O2(质量分数)腐蚀介质中的慢应变速率拉伸曲线。从图1可以看出,T6态的合金对腐蚀液具有较强的敏感性,RRA、RRWA、FTMT、RRCA态合金在腐蚀溶液中应力-寿命曲线的塑性平台明显地比T6态合金的长,RRWA态合金的抗拉强度很高,T8态合金的次之,T6态合金的抗拉强度最小。

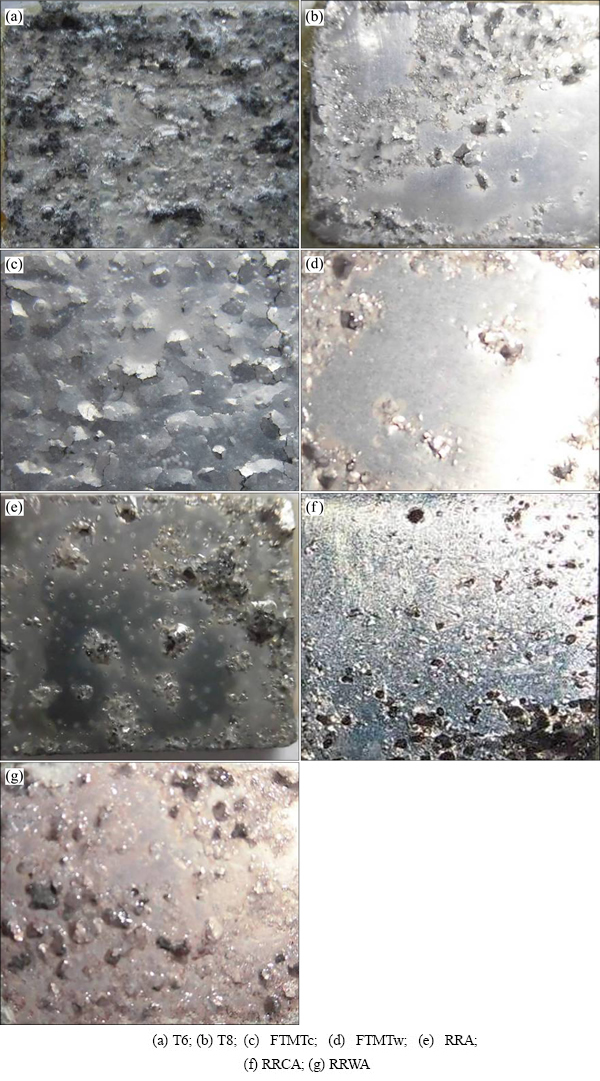

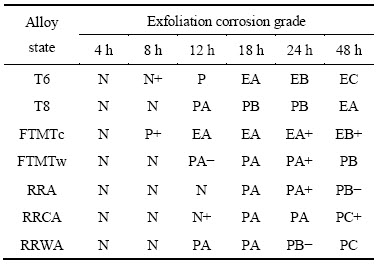

图2所示为合金在EXCO溶液中浸泡48 h的剥蚀形貌。由图2可知,T6峰时效态的合金表现出了严重的起皮和剥落腐蚀产物脱落,腐蚀深入金属;T8态合金表面的剥蚀较重,出现了爆皮和向金属合金内部腐蚀的现象;FTMTc态的合金表面出现了鼓泡现象,腐蚀产物使合金的表面鼓起并发生开裂,同时腐蚀向金属厚度方向发展,但FTMTw态合金表现为轻微的点蚀;RRA、RRCA及RRWA态合金具有较好的耐腐蚀性,表面呈暗灰色,出现轻微的点蚀,可观察到疱疤。合金的剥蚀性能主要受晶界处的析出相和轧制使晶粒拉长的综合影响,对不同热处理状态合金的剥落腐蚀发展评级如表3所列。

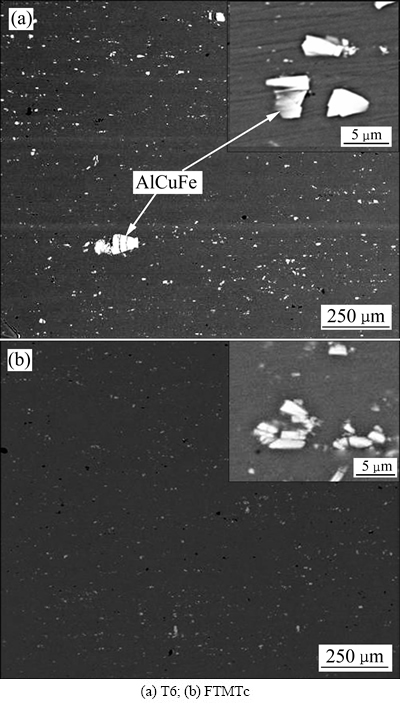

图3所示为T6态和FTMT态合金的SEM像。从图3可观察到白色的初生相随机分布在基体中,这些粗大的初生相的主要成分为AlCuFe,而合金基体中的成分为Al(Zn,Mg)。由于初生相中的Fe、Cu元素不活泼,而合金基体中的Zn、Mg元素活泼,两者能产生电位差,将会形成微电池。初生相(Al,Cu)6(Fe,Cu)、Al7Cu2Fe相对于基体将作为阴极相,在一定的环境中将会优先在初生相附近发生腐蚀[15]。T6态合金没有发生形变,在组织中能观察到个别的粗大相。而最终热机械处理态的合金(见图3(b))经轧制后,合金中的初生相被粉碎,使合金较大的初生相形成的微电池减弱,降低了点蚀敏感性,有利于合金提高耐腐蚀性。

图1 不同热处理条件下合金在3%NaCl +0.5%H2O2腐蚀介质中的SSRT曲线

Fig. 1 SSRT curves of aluminum alloy under different heat treatments in 3%NaCl +0.5%H2O2 corrosion medium

图2 不同热处理态合金浸泡48h的剥落腐蚀形貌

Fig. 2 Surface exfoliation corrosion morphologies of aluminum alloy under different heat treatments

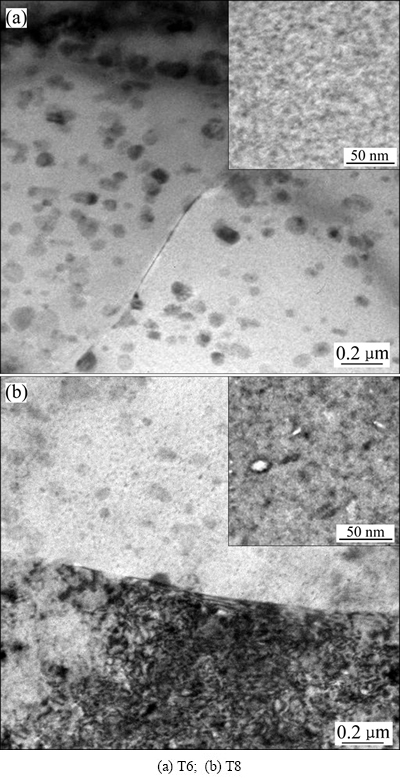

图4所示为T6和T8峰时效态下合金的TEM像。由图4可知,合金晶内析出的强化相为细小弥散的GP区与η′相,晶界处存在连续的析出相,同时也可观察到较宽的无沉淀带析出(Precipitation free zone, PFZ)。T8态合金的透射电镜像与T6态的微观组织有较大的不同,显微组织中出现了高密度的位错缠结区,晶内析出相除了η′相外,还产生了粗大的平衡相η相,在晶界处形成了非连续的析出相,仔细观察在位错中有粗大的析出相形成,轧制变形产生的位错促进了析出相η相的形成。

表3 不同热处理状态下合金的剥落腐蚀级别

Table 3 Exfoliation corrosion grade of alloy under different heat treatments for different corrosion exposure times

图3 合金经不同热处理后的SEM像

Fig. 3 SEM images of alloys after different heat treatments

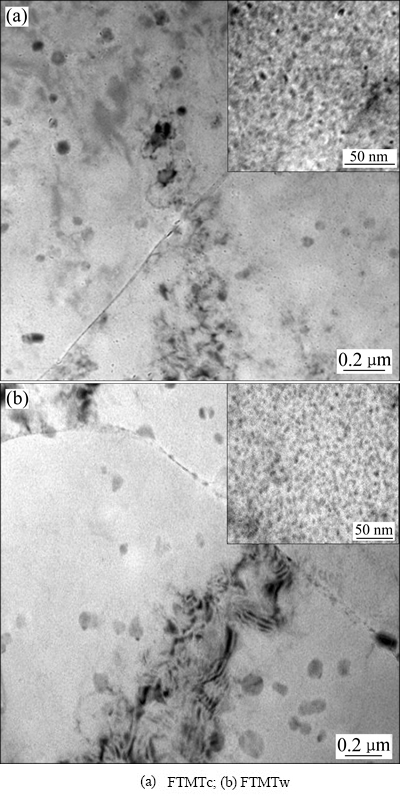

在冷变形的FTMTc((120 ℃, 4 h)+9%+(120 ℃, 10h))态合金显微组织中(见图5(a))也可以观察到合金中有位错缠结区,同时在位错上有沉淀物析出,值得指出的是,晶内析出相比T8态合金的析出相细小,同时晶界处的无沉淀析出带(PFZ)消失,这可能是由于位错为基体内的溶质原子向晶界处析出相扩散提供有效的通道,为晶界析出相的长大提供充足的溶质原子,使晶界处的PFZ形成减弱。图5(b)所示为温变形FTMTw态合金的TEM像,在相同的变形程度下,温变形合金中的位错密度比冷变形的低。在晶界处的析出相比冷变形态的更粗大且不连续 ,并且出现了一定宽度的PFZ,晶内为弥散分布的细小析出相η′相。

图4 T6态与T8态合金的TEM像

Fig. 4 TEM images of alloy after different treatments

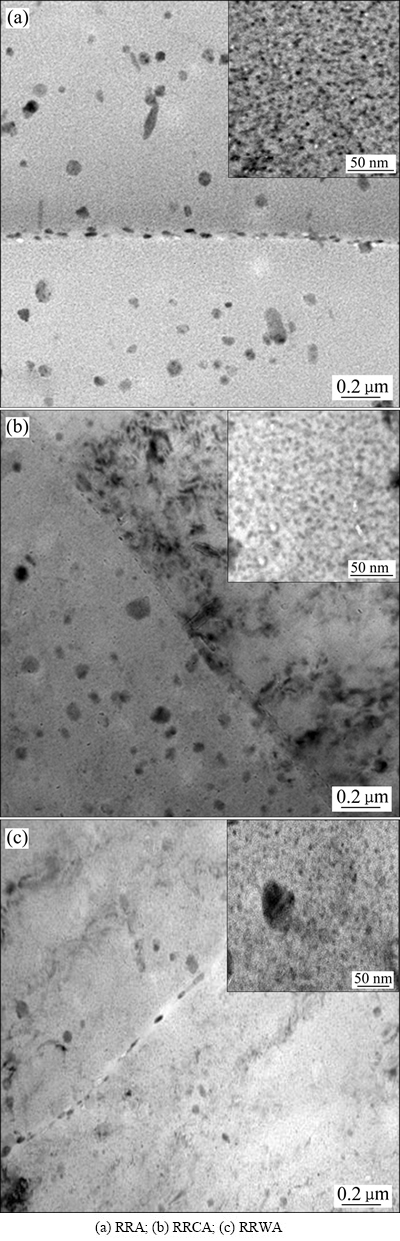

图6所示为合金在RRA、RRCA和RRWA热处理态的TEM像。RRCA和RRWA是基于RRA与FTMT两种工艺的改进工艺,其特点为在合金回归后进行直接轧制和冷却后轧制。由图6可以看出,合金在RRA处理后晶内的析出相呈细小弥散分布,尺寸比T6态的析出相略大,晶界为粗大不连续的平衡相η相。而在RRCA态的合金组织中的晶内分布着缠结位错,同时观察到位错也在晶界处发生塞积,晶内析出相与RRA态合金的相似,主要为细小弥散的η′相,晶界处未发现PFZ,晶界密布着相对细小且呈断续状的析出相。在RRWA态合金中,由于进行了温变形,合金中的位错密度相对较低,合金晶界处的析出相粗大且不连续,间距较大,晶内的析出相分布和RRA态及RRCA态合金的相似,但尺寸稍微增大。

图5 不同形变热处理状态合金的TEM像

Fig. 5 TEM images of alloy after different treatments

3 分析与讨论

Al-Zn-Mg-Cu合金是典型的时效硬化合金,晶内的析出相对合金的强度起主要作用,晶界处的析出相对合金的抗腐蚀性起主要作用。当进行热机械处理时,合金引入形变,在合金的内部会产生大量的位错。位错与析出相产生相互作用,进而影响合金的组织与性能。

图6 不同回归时效后热处理的TEM像

Fig. 6 TEM images of alloy after different regression heat treatments

在Al-Zn-Mg-Cu合金中,GP区和η′相的形核析出和位错关系不大,主要依靠过饱和溶质原子与空位扩散形成,而粗大的η相容易在位错等晶格缺陷处优先非均匀形核长大[16]。T6态合金晶内析出相细小,强度较高;晶界处的析出相呈连续状,在腐蚀介质中容

易成为阳极腐蚀通道,加速晶间腐蚀,进而造成应力腐蚀开裂与剥落腐蚀,因而T6态合金具有较高的剥落腐蚀和应力腐蚀敏感性。T8态的合金(见图4(b))晶内出现了相对粗大的η相,而且η′相数量减少。根据WATERLOO等[17]的研究,细小的析出相η′或GP区在预变形后时效数量会减少,主要原因如下:1) 粗大的析出η相在位错网络上的非均匀形核会使合金中周围的溶质元素浓度降低;2) 位错对空位的吸收会导致过饱和空位(VRC)的溶解,而过饱和空位是η′相或GP区的有效形核位置。T8态合金时效前进行变形引入的位错不利于GP区和η′相析出而促进η相的析出,粗大的η相析出会使T8态合金的强度降低,同时变形引入的缠结位错会导致塑性降低,但粗大的析出相一定程度上减弱了合金的腐蚀敏感性。FTMTc工艺过程中的预时效使GP区和η′相在基体中均匀弥散的预析出,这些析出物在变形时与位错相互作用,导致较均匀的形变。其次,同时预析出的细小GP区或η′相可为终时效过程中析出相形核提供位置,减少了在位错上的粗大相的析出,晶内为细小弥散的析出相,这使合金的强度提高。此外,热机械处理可粉碎合金组织中的粗大初生相,使其分布均匀弥散,同时轧制变形后的纤维状的晶粒结构阻碍了应力腐蚀裂纹扩展,这些因素都可使合金的抗应力腐蚀性提高[18]。

由于合金晶粒的长宽比和晶界组织对合金的剥落腐蚀有显著的影响,冷轧使合金的晶粒长宽比增加,故合金具有一定的剥蚀敏感性,而通过温变形热机械处理可降低合金的剥蚀敏感性。这得益于温变形除了使合金中的位错分布均匀及密度减少外,同时会对合金中的析出相有重要的影响。当预时效的合金在200 ℃保温一定时间时,合金中GP区和细小的η′相会发生溶解固溶到基体中,而晶界处相对粗大的析出相则继续长大,当再进行终时效时,合金晶内的GP区与细小的沉淀相则会再析出,这保证了合金的强度;晶界处粗大断续的析出相则使合金具有良好的耐腐蚀性。RRA态合金晶界处粗大不连续的相,抑制了阳极腐蚀通道的形成,使其具有很高的耐腐蚀性,RRCA态合金晶界析出相虽然没有RRA态合金的粗大,但晶界处无PFZ,且晶界处呈断续弥散状析出相与晶内组织相似,这可能会降低晶界析出相与晶内析出相的电位差,发生均匀腐蚀,进而提高腐蚀性。RRWA态合金晶内组织为GP区和细小的η′相,比T6态合金的稍微粗大,晶界析出相呈粗大、断续分布(见图6(c)),能够有效地抑制阳极溶解腐蚀,进而使RRWA态合金具有较高的抗应力腐蚀性和抗剥蚀性能。

4 结论

1) 常规冷变形FTMTc处理能够使Al-Zn-Mg-Cu合金在塑性不显著降低的情况下,提升合金的强度。200 ℃温变形FTMTw处理能有效改善该合金常规FTMT处理后伸长率较低的不足。

2) RRCA(回归后冷变形)处理虽然可提高Al-Zn-Mg-Cu合金强度,但降低了合金的伸长率;RRWA(回归后温变形)处理能使合金获得良好的综合力学性能。

3) 200 ℃温变形的FTMT((120 ℃, 4 h)+(200 ℃, 10 min)+9%+(120 ℃, 10 h))工艺处理能有效改善Al-Zn-Mg-Cu合金的抗剥落腐蚀性能,新型RRWA处理的Al-Zn-Mg-Cu合金具有良好的抗应力腐蚀性和抗剥蚀性能。

4) 新型热机械处理改善Al-Zn-Mg-Cu合金综合性能的微观机理是晶粒形态、位错组态、初生相以及析出相分布形态等微观组织结构的协同作用。

REFERENCES

[1] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVREC W, BAROUX B. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2010, 58(1): 248-260.

[2] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVREC W. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2010, 58(14): 4814-4826.

[3] 张 珏. 铝合金在航空航天中的应用[J]. 铝加工, 2009(3): 50-53.

ZHANG Jue. Application of aluminum alloy to aerospace industry[J]. Aluminium Fabrication, 2009(3): 50-53.

[4] 宁爱林, 刘志义, 曾苏民, 莫亚武. 铝合金形变热处理工艺研究进展[J]. 材料导报, 2007, 21(3): 74-76.

NING Ai-lin, LIU Zhi-yi, ZENG Su-min, MO Ya-wu. Research and progress of thermomechanical treatment of aluminium alloy[J]. Materials Review, 2007, 21(3): 74-76.

[5] PARK J K, ARDELL A J. Effect of retrogression and reaging treatments on the microstructure of Al 7075-T65[J]. Metallurgical Transactions A, 1984, 15(8): 1531-1539.

[6] CINA B. Reducing the susceptibility of alloys, particularly aluminium alloys, to stress corrosion cracking: US Patent, 3856584[P]. 1974-12-24.

[7] XIAO Y P, PAN Q L, LI W B, LIU X Y, HE Y B. Influence of retrogression and reaging treatment on corrosion behaviour of an Al-Zn-Mg-Cu alloy[J]. Materials and Design, 2011, 32(4): 2149-2156.

[8] 张云崖, 邓运来, 万 里, 张新明. 形变热处理对Al-Zn-Mg-Cu合金板材组织与硬度的影响[J]. 金属学报, 2011, 47(10): 1270-1276.

ZHANG Yun-ya, DENG Yun-lai, WAN Li, ZHANG Xin-ming. Effects of thermalmechanical treatment on the microstructures and hardness of an Al-Zn-Mg-Cu alloy plate[J]. Acta Metall Sin, 2011,47(10): 1270-1276.

[9] OSTERMANN F. Improved fatigue resistance of Al-Zn-Mg alloys through thermomechanical processing[J]. Metallurgical Transactions, 1971, 2(10): 2897-2902.

[10] JAHN M T, LUO J. Tensile and fatigue properties of a thermomechanically treated 7475 aluminium alloy[J]. Journal of Materials Science, 1988, 23: 4115-4120.

[11] 任杰克, 陈志国, 黄裕金, 张纪帅. 新型热机械处理对2E12铝合金显微组织与性能的影响[J]. 中国有色金属学报, 2014, 24(3): 643-650.

REN Jie-ke, CHEN Zhi-guo, HUANG Yu-jin, ZHANG Ji-shuai. Effect of new thermomechanical treatment on microstructure and properties of 2E12 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 643-650.

[12] WANG D, MA Z Y. Effect of prestrain on microstructure and stress corrosion cracking of overaged 7050 aluminum alloy[J]. Journal of Alloys and Compounds, 2009, 469(1/2): 445-450.

[13] HAN N M, ZHANG X M, LIU S D, KE B. Effects of prestretching and ageing on the strength and fracture toughness of aluminum alloy 7050[J]. Materials Science and Engineering A, 2011, 528(10/11): 3714-3721.

[14] LI X Z, HANSEN V, GI N J. HRTEM study and structure modeling of the η′ phase, the hardening precipitates in commercial Al-Zn-Mg alloys[J]. Acta Materialia, 1999, 47(9): 2651-2659.

[15] ANDREATTA F, TERRYN H, de WIT J H W. Effect of solution heat treatment on galvanic coupling between intermetallics and matrix in AA7075-T6[J]. Corrosion Science, 2003, 45: 1733-1746.

[16] 韩念梅, 张新明, 刘胜胆, 宋丰轩. 预拉伸对7050铝合金断裂韧性的影响[J]. 中国有色金属学报, 2010, 20(11): 2088-2093.

HAN Nian-mei, ZHANG Xin-ming, LIU Sheng-dan, SONG Feng-xuan. Effect of prestretching on fracture toughness of 7050 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2088-2093.

[17] WATERLOO G, HANSEN V,  , SKJERVOLD S R. Effect of predeformation and preaging at room temperature in Al-Zn-Mg-(Cu,Zr) alloys[J]. Materials Science and Engineering A, 2001, 303(1/2): 226-233.

, SKJERVOLD S R. Effect of predeformation and preaging at room temperature in Al-Zn-Mg-(Cu,Zr) alloys[J]. Materials Science and Engineering A, 2001, 303(1/2): 226-233.

[18] ENUNG N, SUNARA P. Improvement of stress corrosion resistance in aluminum alloy 7075 through retrogression and re-aging modification[J]. Advanced Materials Research, 2013, 789: 467-475.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50871123);中澳科技合作特别基金资助项目(51011120052)

收稿日期:2014-07-23;修订日期:2014-11-20

通信作者:陈志国,教授,博士;电话:0738-8325517;E-mail: hngary@163.com