文章编号:1004-0609(2014)03-0643-08

新型热机械处理对2E12铝合金显微组织与性能的影响

任杰克1,陈志国1, 2,黄裕金1,张纪帅1,魏 祥1,方 亮1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 湖南人文科技学院 机电工程系,娄底 417000)

摘 要:采用拉伸与疲劳试验、扫描电子显微分析与透射电子显微分析,研究不同热机械处理条件下2E12铝合金的拉伸力学性能、疲劳性能以及显微组织结构。结果表明:采用本热机械处理可以使2E12合金同时获得高强度与高塑性,在屈服强度达到453.1 MPa、抗拉强度高达546.9 MPa的同时,伸长率仍然保持在16.5%。当应力比R=0.1,加载频率f=10 Hz,应力强度因子ΔK=10 MPa·m-1/2 时,热机械处理样品裂纹扩展速率约为6.74×10-5 mm/cycle,优于T3状态下的8.35×10-5 mm/cycle。显微组织观测结果表明:采取本新型热机械处理后,合金中位错密度较高且相互缠结,形成胞状组织。新型热机械处理大幅改善合金综合性能的机制是高密度位错胞状组织、溶质原子团簇及空位复合体、GPB区等复合组织结构的协同作用。

关键词:2E12铝合金;热机械处理;力学性能;显微组织

中图分类号:TG 146.2 文献标志码:A

Effect of new thermo-mechanical treatment on microstructure and properties of 2E12 aluminum alloy

REN Jie-ke1, CHEN Zhi-guo1, 2, HUANG Yu-jin1, ZHANG Ji-shuai1, WEI Xiang1, FANG Liang1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Mechanical and Electrical Engineering, Hunan University of Humanities,

Science and Technology, Loudi 417000, China)

Abstract: The tensile test and fatigue crack propagation test, as well as scanning electron microscope and transmission electron microscope, were used to study the tensile properties, fatigue property and microstructure of 2E12 alloy under different thermo-mechanical treatment (TMT) conditions. The results indicate that both high strength and high plasticity of 2E12 alloy can be achieved by the means of TMT, the yield strength reaches 453.1 MPa, and the ultimate tensile strength reaches to 546.9 MPa, while a high elongation rate of 16.5% is retained. Under the condition of stress ratio R=0.1, loading frequency f=10 Hz, stress intensity factor ΔK=10 MPa·m-1/2, the fatigue crack growth rate of the TMT sample is 6.74×10-5 mm/cycle, lower than that of T3 alloy (8.35×10-5 mm/cycle). As the result of microstructure observation indicates, the thermo-mechanical processed alloy contains a high density of tangled dislocation, which forms dislocation cell substructure. The mechanism of the new TMT that greatly increases the mechanical properties of the alloy is the synergistic effect of composite structures such as a high density of cell substructure of dislocations, the complex of Mg-Cu solute atoms clusters and vacancies, as well as GPB zones.

Key words: 2E12 aluminum alloy; thermo-mechanical treatment; mechanical properties; microstructure

随着现代航空航天等高新技术对材料综合性能要求的日益提高,先进铝合金的研发成为国内外的研究热点。2E12合金是我国在2A12铝合金基础上研制的新型Al-Cu-Mg系高性能航空铝合金,不仅保留了2A12合金强度高、耐热性好、成形性能优良及耐损伤的优点,同时还在2A12合金基础上通过进一步控制Fe和Si杂质含量、优化合金化元素配比、降低粗大析出相含量、获得更好的断裂韧性和耐疲劳性能[1-3]。

热机械处理结合变形强化与析出强化,可有效增加位错密度与降低析出相尺寸[4-7],使合金获得常规工艺无法同时获得的高强度及良好的塑性和韧性。尽管国内外有关热机械处理的研究成果,如高压扭转[8-9]、等道角挤压[10-11]、摩擦搅拌处理[12]等,能较显著地提高铝合金的强塑性配合,但由于2E12合金的工业应用多为T3态薄板[13],现有的如高压扭转等制度均难以得到实际应用,研究开发2E12先进铝合金的新型热机械处理具有十分重要的理论意义与实际应用价值。为此,本文作者对一种全新的热机械处理制度进行较为系统的探索,同时对该热机械处理的微观作用机理进行较为深入的研究。

1 实验

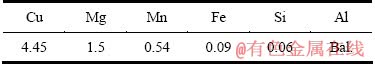

实验样品沿纵向取自2E12合金冷轧薄板,厚度为2 mm,由东北轻合金有限责任公司提供,其化学成分见表1。

表1 2E12合金的化学成分

Table 1 Chemical composition of 2E12 alloy (mass fraction, %)

样品经495 ℃、1 h固溶水淬后,分成不同组别在80和100 ℃下时效不同时间,每组包含至少3个平行样品。具体时效制度见表2。

表2 实验样品时效制度

Table 2 Aging conditions of samples

经时效处理后的样品以轧制方式进行冷变形,变形量为9%,然后自然时效15 d以上。拉伸试验在MTS-858型材料试验机上进行,拉伸速率为2 mm/min。疲劳裂纹扩展试验在MTS-858型材料试验机上进行,应力采用正弦波沿L-T向加载,加载频率为10 Hz,应力比R=0.1;裂纹扩展速率测定按照GBT6398-2000金属材料疲劳裂纹扩展速率试验方法进行。透射电镜薄膜样品经机械减薄至约0.1 mm后在MT-PI型双喷穿孔减薄仪进行双喷而成,电解液为HNO3与CH3OH混合液(体积比为l:3),温度约为-25 ℃。截取疲劳试验裂纹扩展试样的断口进行观察,断口观察在Qunta-2800 型扫描电镜上进行,加速电压为25 kV。显微组织观察在Tecnai G220电镜上进行,加速电压为200 kV。

2 结果与讨论

2.1 不同处理状态下2E12合金的拉伸性能

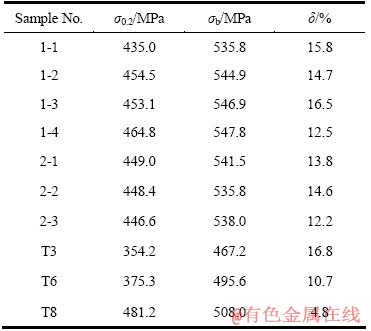

表3所列为在不同热机械处理状态及T3(固溶并冷变形6%后自然时效96 h以上)、T6峰时效(固溶处理后190 ℃时效12 h)和T8峰时效(固溶并冷变形6%后190 ℃时效12 h)状态下,2E12合金的拉伸力学性能。其中,屈服强度为样品发生0.2%塑性变形时的应力值,所有数据均为每组3个平行样品的平均值。为了便于与常规热处理条件下2E12合金的屈服强度及伸长率进行比较,将不同状态下的屈服强度及伸长率绘制于图1。

表3 不同状态下2E12合金的拉伸力学性能

Table 3 Tensile mechanical properties of 2E12 alloy under different conditions

图1 不同状态下2E12合金的屈服强度与伸长率的关系

Fig. 1 Relationship between yield strength and elongation of 2E12 alloy under different conditions

通过对比看出,经热机械处理后2E12合金的屈服强度和拉伸强度明显高于常规热处理中强度较低的T3和T6状态的合金,如1-2状态合金的屈服强度比T3状态下的高100 MPa,同时拉伸强度比T3态高约70 MPa。虽然经热机械处理后合金的屈服强度略低于常规热处理后强度最高的T8状态的,但拉伸强度则普遍高于T8状态的。这说明本组热机械处理可以明显提高2E12合金的强度。由于热机械处理工艺流程中包含了9%的冷轧变形,因而这一结果符合冷变形态金属强度提高的一般规律。

但是,通常在冷变形态金属强度提高的同时,往往会伴随着明显的塑性降低。而热机械处理的2E12合金的伸长率却没有明显下降,1-3状态合金伸长率高达16.5%,甚至接近T3态合金的伸长率(16.8%),热机械处理状态合金的伸长率普遍高于T6状态合金的伸长率(10.7%),更是远远高于T8状态合金的伸长率(4.8%)。

综合分析这些结果,可以得出以下结论:该热机械处理制度使2E12合金的综合力学性能得到显著提高,尤其是1-3状态合金在保持T3状态下良好塑性的同时,实现了强度的大幅提高。

2.2 合金疲劳性能

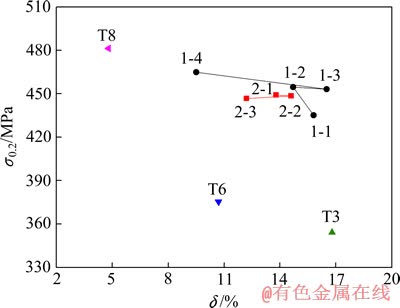

图2 不同状态下2E12合金疲劳裂纹扩展速率曲线

Fig. 2 Fatigue crack growth rate curves of 2E12 alloy under different conditions

图2所示为T3、T6及热机械处理制度1-3状态下在裂纹扩展速率(dA/dn)与应力强度因子(ΔK)双对数坐标中的2E12合金疲劳裂纹扩展速率曲线,加载频率f=10 HZ,应力比R=0.1。

图2中3条曲线均明显呈现出典型的3阶段特征[14-15]。以1-3状态对应曲线为例,当ΔK小于6 MPa·m-1/2、dA/dN小于10-5 mm/cycle时,为微观裂纹稳态扩展阶段。当ΔK为6~20 MPa·m-1/2之间时,处于宏观裂纹稳态扩展阶段,裂纹扩展速率与应力强度因子间的关系接近线性。当ΔK大于20 MPa·m-1/2时,为高速扩展阶段,对应的疲劳裂纹扩展速率急剧增大,随后样品发生断裂。在宏观裂纹稳态扩展阶段,裂纹扩展速率与应力强度因子近似满足Paris公 式[16-17]。为便于比较,在近似计算出Paris公式中的两个常数后,列出这3种不同处理制度下疲劳裂纹扩展速率与应力强度因子的关系式[18]:

在热机械处理制度1-3状态下,

dA/dN=5.87×10-8(Δ K)3.06 (1)

T3状态下,

dA/dN=4.09×10-8(ΔK)3.31 (2)

T6状态下,

dA/dN=7.94×10-8(ΔK)3.29 (3)

式(1)中ΔK的指数幂及系数均小于式(3)中的,可见,在宏观裂纹稳态扩展阶段,1-3状态样品疲劳裂纹扩展速率小于T6态样品。为比较式(1)与式(2)大小关系,将ΔK=10 MPa·m-1/2分别代入上述两式,此时1-3状态和T3状态下合金的扩展速率分别为6.74×10-5和8.35×10-5 mm/cycle,1-3状态样品裂纹扩展速率小于T3态的。

2.3 扫描电镜观察及分析

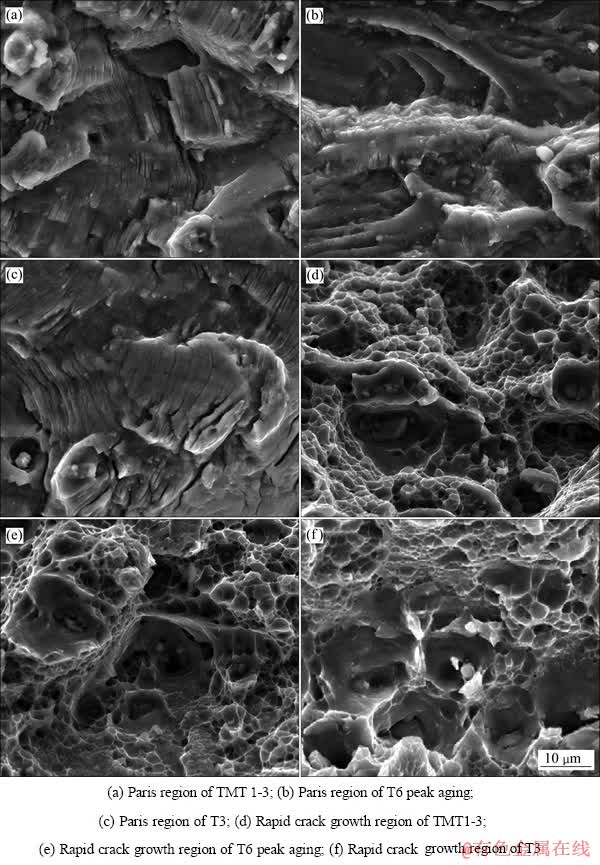

图3 疲劳裂纹扩展试样的断口形貌

Fig. 3 Fracture morphologies of fatigue crack propagation samples

图3所示为2E12合金在热机械处理制度1-3、T6峰时效及T3状态的疲劳裂纹扩展试样的稳态扩展区(Paris区)及瞬时断裂区断口形貌。观察图3(a)~(c)可以看出,1-3态合金的断口上布满了由裂纹组成的条带,扩展路径与疲劳裂纹扩展方向垂直,且比较崎岖;T6峰时效态合金沿裂纹扩展方向解理开裂,断口具有许多高低不平的台阶;T3态合金断口也布满了垂直于主裂纹扩展方向由二次裂纹形成的条带,与1-3状态相比,其条带间距与宽度略大,说明在裂纹扩展的稳态扩展区,1-3状态合金的疲劳裂纹扩展速率略慢于T3状态下的合金。1-3状态及T3态合金断口具有大量条带,在裂纹扩展时将会大量地消耗能量,增大疲劳裂纹扩展的阻力。当△K相等时,1-3状态合金的裂纹扩展驱动力比较小,其裂纹扩展速率较T6峰时效的慢。图3(d)~(f)呈现韧性断裂的典型特征,样品断口均布满了两种不同尺寸的韧窝,大量的小韧窝分布在大韧窝之间,且图3(d)中的大韧窝比图3(e)中更深且数目更多。此外,图3(d)~(f)中大韧窝中均包含破碎第二相粒子,而图3(f)中的第二相粒子最为粗大。

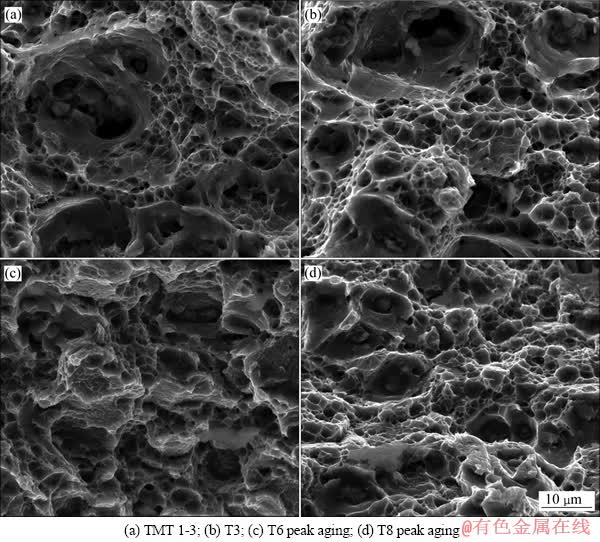

图4所示为热机械处理制度1-3、T3、T6峰时效以及T8峰时效状态下2E12合金的拉伸试样断口形貌。图4(a)和(b)中均包含两种不同尺寸的韧窝,大量尺寸均匀的小韧窝分布在大韧窝之间,且韧窝深度较大,呈现出明显的韧性断裂的特征。图4(c)中韧窝数量及深度均有明显降低,还出现了剪切平台。图4(d)中也有多处出现了剪切平台,呈现出部分剪切断裂特征。图4(c)及(d)中韧窝中心均出现了破碎的第二相粒子,这说明裂纹的形成与粗大的第二相粒子有关,粗大的第二相粒子往往成为断口的薄弱部分,使材料的韧性降低。电子探针分析表明,这些第二相粒子的成分接近S相(Al2CuMg)。因此,避免时效过程中粗大第二相析出,减少时效时间和降低时效温度对保持2E12合金的韧性具有重要作用。

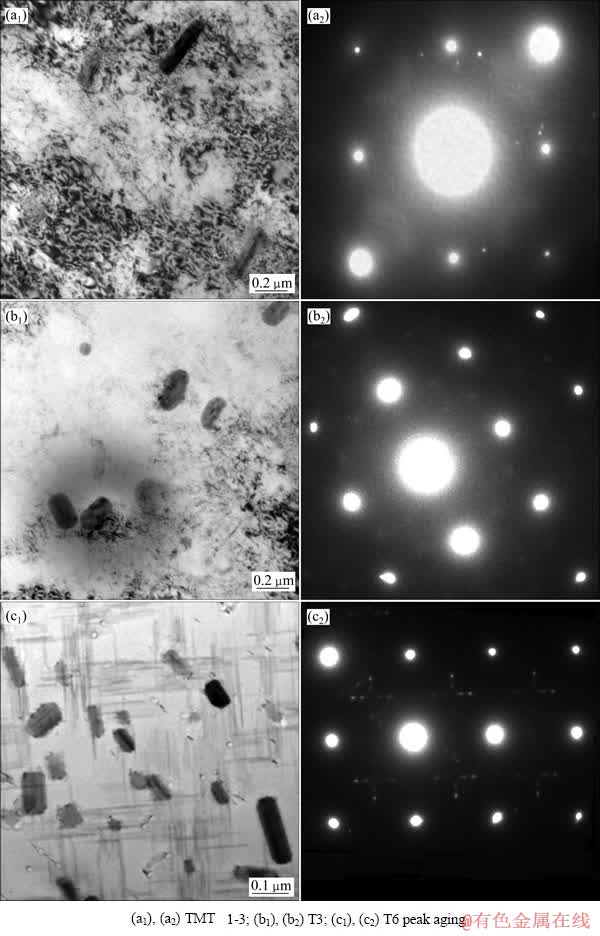

2.4 透射电镜显微组织观察

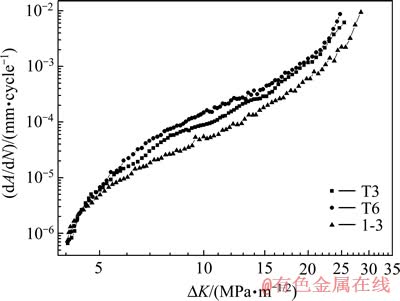

采用的铝合金中n(Cu)/n(Mg)=2.97,根据Al-Cu-Mg合金相图可知,该合金位于相图的α+S(Al2CuMg)相区,其沉淀析出顺序为SSS→GPB1→GPB2/S″→ S′→S。图5所示为T3、T6峰时效和热机械处理制度1-3状态2E12合金的显微组织及对应的衍射斑。

观察图5(a)及(b)可以看出,图5(a)中的位错密度较高,大部分位错相互缠结形成胞状组织,粗大的含Mn相周围位错密度却并没有显著提高。图5(b)中的位错密度较高,粗大析出相附近有位错缠结,但其位错密度明显低于图5(a)中的位错密度。除了粗大棒状相外,图5(a)及(b)均无法明显观察到析出相的存在,且图5(a)及(b)对应的衍射斑也进一步证明其中基本没有其他类型的析出相。

2E12合金T6及T8态的主要强化相均为针状的S′相,其微观形貌及对应衍射斑点如图5(c)所示。S′相是与基体半共格且不可被位错切割的析出相,在变形过程中位错必须以奥罗万机制绕过S′相,从而使合金得到强化。T6状态2E12合金晶粒内位错密度较低,导致S′相发生束集,这是因为S′在晶内主要发生非均匀形核,因而新的S′相将在已有S′相位置形核。通常T8状态2E12合金中S′相分布较T6状态的更为均匀,同时尺寸更加细小,并且不会发生束集。S′相的分布状态及冷变形的强化效应使得T8态具有较高的强度,但同时在变形过程中位错会大量缠结在S′相周围,引起应力集中,使合金塑性降低。峰时效会在晶界形成粗大的晶界析出相及晶界无析出带,裂纹也容易在此形核,发生剪切断裂。

图4 2E12合金拉伸试样断口形貌

Fig. 4 Fracture morphologies of 2E12 alloy for tensile test

图5 不同热处理制度下2E12合金的显微组织及对应的衍射斑

Fig. 5 TEM images of 2E12 alloy with corresponding diffraction patterns under different heat treatment conditions

根据对淬火态Al-Cu-Mg合金时效早期硬化规律的研究[19-20],Al-Cu-Mg合金的硬化过程分为两个阶段,硬化第一阶段十分迅速,而随后几小时内合金硬度几乎不变,直到硬化第二阶段开始。而不论是TEM还是HRTEM观察,都只有在硬化接近第二阶段时才能观察到GPB区的存在。因此,RINGER等[19-20]提 出,引起第一阶段硬化的是Cu、Mg原子共同形成的原子团簇。由于热机械处理工艺中进行的是低温欠时效,所以并未引起明显的第二相析出。在图5(a)所示的明场相照片及选区衍射图样中并不能明显观察到S′相,因而其强化机理并不是S′相析出引起的第二相强化,Cu-Mg原子团簇形成很可能对2E12合金综合性能的提高起到了重要作用。Cu-Mg原子团簇的形状、大小、组成、取向和有序程度均与GPB区有区别,其结构与GPB区相比更不固定,其强化机理类似于更进一步的固溶强化。Cu-Mg原子团簇中往往含有大量的空位,这是因为Cu-Mg原子团簇与空位间具有强烈的相互吸引作用。随后的冷变形过程将会在金属中引入大量的位错,由于铝合金具有较高的层错能,故变形过程中产生的位错往往会通过交互作用形成位错缠结,也就是图5(a)中所示的状态。热机械处理状态合金比T3态合金具有更高的晶内位错密度,这是因为当2E12合金在进行变形时,晶内含有弥散而均匀分布的GPB区或Cu-Mg原子团簇,所以变形时所产生的大量相互缠结的位错,在受到外力作用发生运动时将受到这些粒子的阻碍,避免位错继续运动至晶界处形成塞积,并减小了位错继续运动过程中相互合并或抵消的可能。在最终时效阶段,由于在室温下存放时间较长,部分Cu-Mg原子团簇将进一步偏聚形成GPB区,还有大量Cu-Mg原子团簇通过原子扩散,对位错产生类似柯垂尔气团的钉扎作用。同时由于没有S′相的存在,故位错分布不像T8态组织中那样,大量缠结在粗大的S′相周围,在局部产生明显的应力集中,引起不均匀变形,导致塑性降低。同时,由于T8工艺进行峰时效处理时时效温度较高,合金在脱溶的同时会发生较明显的回复,使位错密度降低,位错胞状组织胞壁变薄,形变强化效果降低。因此,通过高密度的位错胞状组织、溶质原子团簇及空位复合体和GPB区的协同作用,新型热机械处理使合金的综合性能得到显著提高。

3 结论

1) 采取本新型热机械处理制度可以显著提高2E12合金的力学性能,同时获得高强度与良好塑性。尤其是制度1-3可以在伸长率高达16.5%的同时,将抗拉强度提高至546.9 MPa。

2) 采取本新型热机械处理制度可以提高合金的疲劳性能,在裂纹稳态扩展阶段,制度1-3样品疲劳裂纹扩展速率小于T3及T6峰时效态的裂纹扩展速率。

3) 本新型热机械处理大幅提升合金综合性能的机制是高密度的位错胞状组织、溶质原子团簇及空位复合体和GPB区等复合组织结构的协同作用。

REFERENCES

[1] WARNER T. Recently-developed aluminum solutions for aerospace applications[J]. Materials Science Forum, 2006, 519/521(2): 1271-1278.

[2] SRIVATSAN T S, KOLAR D, MAGUUSCN P. The cyclic fatigue and final fracture behavior of aluminum alloy 2E12[J]. Materials & Design, 2002, 23: 129-139.

[3] MANABU N, TAKEHIKO E. New aspects of development of high strength aluminum alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 285: 62-68.

[4] HUANG Yu-jin, CHEN Zhi-guo, ZHENG Zi-qiao. A conventional thermo-mechanical process of Al-Cu-Mg alloy for increasing ductility while maintaining high strength[J]. Scripta Materialia, 2011, 64: 382-385.

[5] 黄裕金, 陈志国, 周 娴, 杨文玲. 铝合金热机械处理的研究发展[J]. 材料导报, 2010, 24: 93-98.

HUANG Yu-jin, CHEN Zhi-guo, ZHOU Xian, YANG Wen-ling. Development of thermo-mechanical treatment in aluminum alloys[J]. Materials Review, 2010, 24: 93-98.

[6] WANG Jian-hua, YI Dan-qing, SU Xu-ping, YIN Fu-cheng. Influence of deformation ageing treatment on microstructure and properties of aluminum alloy 2618[J]. Materials Characterization, 2008, 59: 965-968.

[7] SINGH S, GOEL D B. Influence of thermomechanical aging on tensile properties of 2014 aluminum alloy[J]. J Mater Sci, 1990, 25: 3894-3900.

[8] TOTH L S, ARZAGHI M, FUNDENBERGER J J, BEAUSIR B, BOUAZIZ O, ARRUFFAT-MASSION R. Severe plastic deformation of metals by high-pressure tube twisting[J]. Scripta Materialia, 2009, 60: 175-177.

[9] LIU Man-ping, ROVEN H J, MURASHKIN M, VALIEV R Z. Structural characterization by high-resolution electron microscopy of an Al-Mg alloy processed by high-pressure torsion[J]. Materials Science and Engineering A, 2009, 503: 122-125.

[10] VIDAL V, ZHANG Z R, VERLINDEN B. Precipitation hardening and grain refinement in an Al-4.2wt%Mg-1.2wt%Cu processed by ECAP[J]. J Mater Sci, 2008, 43: 7418-7425.

[11] PRADOS E, SORDI V, FERRANTE M. Tensile behavior of an Al-4wt%Cu alloy deformed by equal-channel angular pressing[J]. Materials Science and Engineering A, 2009, 503: 68-70.

[12] KWON Y J, SHIGEMATSU I, SAITO N. Mechanical properties of fine-grained aluminum alloy produced by friction stir process[J]. Scripta Materialia, 2003, 49: 785-789.

[13] SRIVATSAN T S, KOLAR D, MAGNUSEN P. The cyclic fatigue and final fracture behavior of aluminum alloy 2E12[J]. Materials & Design, 2002, 23(2): 129-139.

[14] 杨 胜, 易丹青, 杨守杰, 钟 利. 腐蚀环境下2E12航空铝合金疲劳裂纹扩展行为研究[J]. 材料工程, 2007, 12: 26-29.

YANG Sheng, YI Dan-qing, YANG Shou-jie, ZHONG Li. Effect of corrosive environment on fatigue crack propagation of 2E12 aerospace aluminum alloy[J]. Journal of Material Engineering, 2007, 12: 26-29.

[15] 刘 岗, 郑子樵, 杨守杰, 戴圣龙, 李世晨. 2E12铝合金的疲劳性能与裂纹扩展行为[J]. 机械工程材料, 2007, 31: 65-68.

LIU Gang, ZHENG Zi-qiao, YANG Shou-jie, DAI Sheng-long, LI Shi-chen. The fatigue performance and fatigue crack propagation behavior of 2E12 Al alloy[J]. Materials for Mechanical Engineering, 2007, 31: 65-68.

[16] 刘立名, 段梦兰, 柳春图, 赵慧娟. 对裂纹扩展规律Paris公式物理本质的探讨[J]. 力学学报, 2003, 35(2): 171-175.

LIU Li-ming, DUAN Meng-lan, LIU Chun-tu, ZHAO Hui-juan. A discussion on the physical essence of Paris formula, the law of crack propagation[J]. Acta Mechanica Sinica, 2003, 35(2): 171-175.

[17] ZHAO Tian-wen, ZHANG Ji-xi, JIANG Yan-yao. A study of fatigue crack growth of 7075-T651 aluminum alloy[J]. International Journal of Fatigue, 2008, 30: 1169-1180.

[18] 杨海生, 常新龙. LD10铝合金疲劳裂纹扩展速率的研究[J]. 理化检验: 物理分册, 2005, 41: 333-335.

YANG Hai-sheng, CHANG Xin-long. A research on fatigue crack growth rate of LD10 aluminum alloy[J]. Physical Testing and Chemical Analysis: Phys Test, 2005, 41: 333-335.

[19] RINGER S P, HONO K, SAKURAI T, POLMEAR I J. Cluster hardening in Al-Cu-Mg alloys[J]. Scripta Materialia, 1997, 36: 517-521.

[20] RINGER S P, SAKURAI T, POLMEAR I J. Origins of hardening in Al-Cu-Mg-(Ag) alloys[J]. Acta Mater, 1997, 45: 3731-3744.

(编辑 陈卫萍)

基金项目:中澳科技合作特别基金资助项目(51011120052);国家自然科学基金资助项目(50871123)

收稿日期:2013-01-20;修订日期:2013-04-25

通信作者:陈志国,教授,博士;电话:0738-8325517;E-mail: zgchen@mail.csu.edu.cn