DOI:10.19476/j.ysxb.1004.0609.2018.11.02

新型热机械处理对7050铝合金微观组织与性能的影响

彭 景1,陈志国1, 2,任杰克1,马文静1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 湖南人文科技学院 材料工程系,娄底 417000)

摘 要:通过力学、抗腐蚀等性能测试,XRD、透射电镜等微观组织分析,研究了一种基于固溶热轧连续处理的新型热机械处理对7050铝合金微观组织与性能的影响规律。结果表明:通过新型热机械处理后的铝合金在保证良好塑性的同时,强度显著提高,最高屈服与抗拉强度分别达608.10 MPa 和651.24 MPa,较T6态的分别提高了82 MPa和51 MPa;其电导率介于T6与RRA状态的电导率之间,其抗晶间腐蚀性能优于T6态的而接近于RRA态的。铝合金综合性能的改善,是新型热机械处理过程所形成的位错组态及晶界析出相形态分布所致。

关键词:铝合金;热机械处理;晶间腐蚀;电导率

文章编号:1004-0609(2018)-11-2182-09 中图分类号:TG146.2 文献标志码:A

高速发展的航空航天工业对铝合金的综合性能提出了越来越高的要求[1-4]。热机械处理(TMT)作为一种提高铝合金综合性能的有效途径越来越受到广泛关注。HUO等[5]利用温轧与连续轧制处理相结合的热机械处理,成功地将7075铝合金晶粒细化到10 μm以下,从而提高了铝合金综合性能。LIN等[6]通过预时效-冷变形-再时效的方法,使Al-Mg-Si合金的屈服强度达到了301 MPa,电导率达到了58.9%IACS。LI等[7]通过83%的冷变形后再进行(100 ℃, 72 h)时效方法,使2024铝合金的屈服强度达到了711 MPa。ZUO等[8]研究发现,时效后的7055铝合金,在进行170 ℃下的变形后,可使强度提高的同时,还在晶界处形成了不连续分布的析出相,使抗腐蚀性能也得到提高。然而铝合金通过热机械处理后,其强塑性往往成倒置关系,且其工艺技术的复杂性严重制约着实际工业生产的应用。本课题组针对这一问题开展了大量卓有成效的研究[9-10],特别是近来基于固溶热轧连续处理提出了一种新的热机械处理工艺[11]。本文将新型热机械处理对7050铝合金力学性能、抗晶间腐蚀以及微观组织的影响规律进行了研究,并对其微观作用机理进行了较为深入的探讨。

1 实验

实验样品为12 mm厚的T73状态的7050合金,其化学成分如表1所示。

表1 7050铝合金的化学成分

Table 1 Chemical composition of 7050 alloy (mass fraction, %)

实验采用的热机械处理工艺如图1所示,可分步骤为:固溶热轧连续处理(Solidsolution-Hot roll,SSHR)、室温变形处理、时效处理。其中,固溶热轧连续处理是先将铝合金样品在475 ℃保温1 h,然后将样品冷却至455~465 ℃进行变形量为50%的热轧处理。室温轧制处理的变形量为60%,最后再进行不同的时效处理。

拉伸试验在型号为MTS-858的材料试验机上进行,拉伸的速率为2 mm/min,拉伸样品尺寸规格如图2。实验样品的光学金相观察采用型号为Leica DMILM的光学显微镜进行观察。晶间腐蚀试验按GB/T 7998—2005标准进行,腐蚀介质为NaCl57 g/L+10 mL/L H2O2溶液,腐蚀进行的温度为35 ℃,时间为6 h,试样表面积与试验溶液体积比小于20 mm2/mL。TEM试样经机械减薄至80~100 μm后采用硝酸和甲醇体积比为1:3的混合液在-25 ℃左右双喷穿孔,透射电镜分析在TecnaiG220电子显微镜上进行,加速电压200 kV。电导率是通过双臂电桥测导仪测得样品的电阻,再通过公式R=ρl/S(式中:ρ为电阻率,l为样品长度,S为样品界面积)求得电阻率ρ,最后通过电阻率与电导率互为倒数的关系求得电导率。实验样品XRD的测量在型号为Rigaku D/max 2500的X射线衍射仪上进行。

图1 铝合金新型热机械处理工艺流程

Fig. 1 Schematic presentation of novel thermo-mechanical treatments (TMT) of aluminum alloy

图2 铝合金拉伸试样尺寸规格

Fig. 2 Size of aluminum alloy tensile sample (Unit: mm)

2 实验结果

2.1 7050铝合金力学性能测试

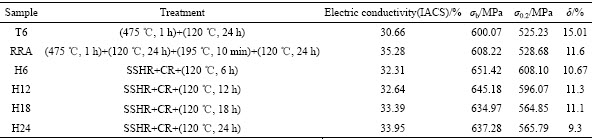

从表2的各样品力学性能可以看出,相较于T6、RRA这两种常规的铝合金处理工艺,通过热机械处理后的样品其抗拉强度、屈服强度都有显著的提高。其中样品H6的抗拉强度与屈服强度最高,分别达到了的651.42 MPa、608.10 MPa。但在本实验中,经热机械处理的样品其伸长率随时效时间的延长先升高后下降,其中样品H12的伸长率最高为11.3%,接近于RRA状态。此外,随着时效时间的延长,铝合金试样的强度逐渐下降,且样品H18与H24的强度接近。

2.2 7050铝合金电导率与腐蚀性能测试

比较表2中不同状态铝合金试样的电导率,可以明显看出,RRA状态的电导率最高为35.28%IACS,T6状态的电导率最低为30.66%IACS,而经过热机械处理后的铝合金试样的电导率介于T6状态与RRA状态之间,且随着时效时间的延长,其电导率逐渐升高。其中,样品H24的电导率最高,达到33.95%IACS;样品H6的电导率最低为32.31%IACS,但也明显高于T6状态。

图3所示为各实验样品在进行晶间腐蚀之后的腐蚀截面形貌。T6、RRA以及热机械处理的样品,在进行晶间腐蚀试验时,可在试验样品表面观察到大量白色的腐蚀产物。由于各样品进行的处理方式不同,各样品的晶间腐蚀形貌也有较大差异。经过热机械处理后的样品,其腐蚀截面形貌近似于纤维状,从图3中还可看出有些试样经过晶间腐蚀后有表面翘起的现象,而T6与RRA态样品的腐蚀形貌为明显的腐蚀沟。比较各实验样品的晶间腐蚀深度,T6状态的腐蚀深度80.34 μm,与样品H6的腐蚀深度83.64 μm相近,大于样品H12的腐蚀深度74.25 μm。随着时效时间的延长,铝合金试样的抗晶间腐蚀性能逐渐提高,经热机械处理后的样品H18与H24的晶间腐蚀深度均小于T6状态,其腐蚀深度分别为66.37 μm、60.26 μm。RRA状态的实验样品的晶间腐蚀深度最小为53.56 μm,其腐蚀性能为所有样品中最好,但与样品H24较为接近。

表2 不同处理条件下的样品拉伸力学性能及电导率

Table 2 Tensile mechanical and conductivities properties of 7050 alloy under different conditions

图3 不同处理状态7050铝合金试样晶间腐蚀截面形貌

Fig. 3 Intergranular corrosion morphologies of alloys after thermo-mechanical treatments

2.3 7050铝合金金相观察

图4(a)、(b)和(c)所示分别为热机械处理的铝合金试样金相显微组织TMT、T6和RRA的金相显微组织。观察金相组织可以发现, T6与RRA状态的铝合金试样由于在固溶温度下大部分晶粒发生再结晶长大,且二者晶粒形貌相似,都为等轴晶。而热机械处理试样的晶粒由于进行了轧制变形而拉长,成纤维状组织,这也解释了图2中热机械处理状态试样的晶间腐蚀截面形貌成纤维状的原因。

2.4 7050铝合金位错密度计算

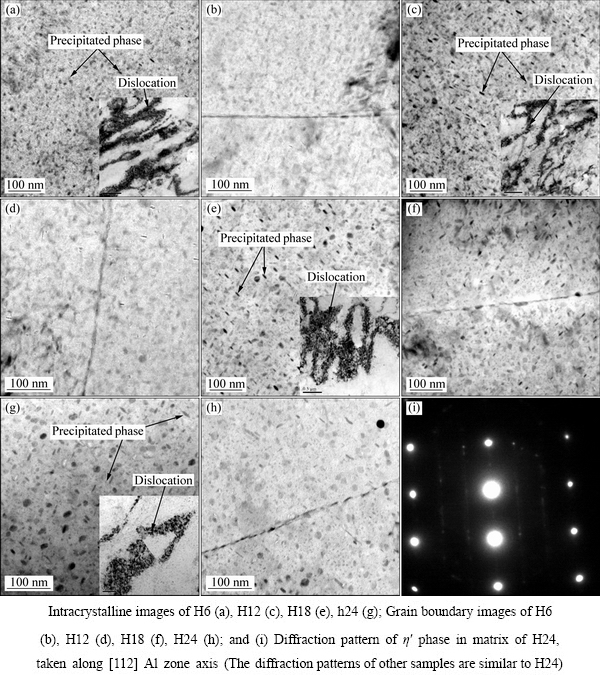

本实验的热机械处理工艺包括了固溶热轧连续处理、室温轧制处理,且没有在时效处理前进行固溶,因此在铝合金试样中有很多位错保留下来。由于时效的温度不足以将已形成的位错消除,因此可从图6的TEM照片上清晰地看到,在不同的时效时间处理后依然有大量的位错存在,且位错相互缠结。

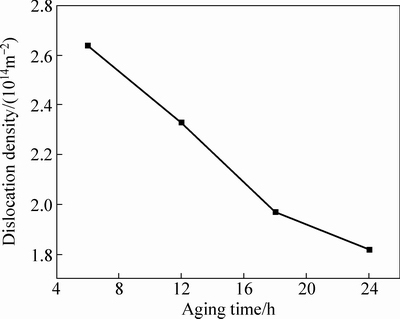

如图5所示为热机械处理的7050铝合金的位错密度。位错密度是采用方程 [12]进行计算得到,其中ρ表示位错密度,ε表示微应变,d表示微晶尺寸,b为铝的柏氏矢量。而微晶尺寸和微应力是通过XRD衍射峰的宽化,根据Williamson-Hall方法[13]得到,所用公式为:(Bcosθ/λ)n=(1/D)n+(4sinθ/λ)n,其中B为衍射峰半高宽,λ为X射线波长,D为微晶尺寸,ε为微应变,θ为半衍射角,n为反卷积参数。利用XRD所测量的半高宽数据,以(Bcosθ/λ)n 为纵坐标,以(4sinθ/λ)n为横坐标作图,并进行线性拟合,则可通过所作直线的斜率和纵坐标上的截距,分别得到微应变与微晶尺寸,再带入公式计算得到位错密度。

[12]进行计算得到,其中ρ表示位错密度,ε表示微应变,d表示微晶尺寸,b为铝的柏氏矢量。而微晶尺寸和微应力是通过XRD衍射峰的宽化,根据Williamson-Hall方法[13]得到,所用公式为:(Bcosθ/λ)n=(1/D)n+(4sinθ/λ)n,其中B为衍射峰半高宽,λ为X射线波长,D为微晶尺寸,ε为微应变,θ为半衍射角,n为反卷积参数。利用XRD所测量的半高宽数据,以(Bcosθ/λ)n 为纵坐标,以(4sinθ/λ)n为横坐标作图,并进行线性拟合,则可通过所作直线的斜率和纵坐标上的截距,分别得到微应变与微晶尺寸,再带入公式计算得到位错密度。

图4 不同处理状态7050铝合金试样金相显微组织

Fig. 4 Optical micrographs of 7050 under different conditions

随着时效时间的延长,从图5中可以看出,位错密度随时效时间增加逐渐减小。其中样品H6的位错密度最大为2.64×1014 m-2,而随着时效时间的延长,铝合金的位错密度逐渐下降,样品H12、H18、H24的位错密度分别为2.33×1014 m-2、1.97×1014 m-2、1.82×1014 m-2,分别较样品H6降低了12%、25%、30%。

2.5 7050铝合金微观透射观察

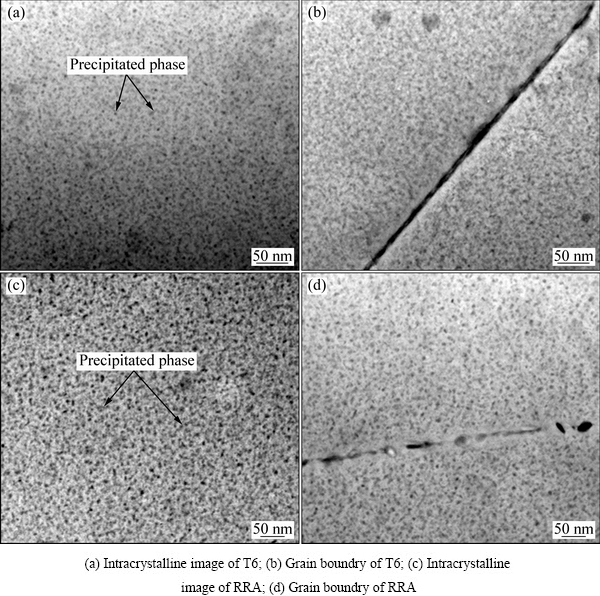

图6所示为T6与RRA状态的7050铝合金的TEM像。从图6中可以看出,T6与RRA状态的铝合金试样的晶内析出相尺寸及其分布相似,细小的析出相η′均匀地分布于基体中。但比较晶内析出相与晶界析出相可以发现,两种状态的晶界析出相都明显较晶内的大,且T6状态的晶界析出相呈连续分布而RRA的晶界析出相为不连续分布。此外,观察两种状态的晶界析出相,还可以发现明显的无析出带(Precipitate free zone, PFZ)。

图7所示为经过热机械处理后的铝合金透射照片。其中比较不同时效时间的铝合金晶内析出相均可发现,大量析出相η′分布于铝基体中。而随着时效时间的延长,可以通过TEM像发现析出相有长大的趋势。在样品H18与样品H24的TEM像中还可清晰地发现粗大的析出相,且析出相的密度有所降低。观察晶界析出相可以看到,样品H6与样品H12的晶界析出相为连续的,而样品H18与样品H24的晶界析出相为不连续分布,但其尺寸较RRA状态小。

图5 热机械处理后的7050铝合金位错密度

Fig. 5 Dislocation density of 7050 alloy after TMT

3 分析与讨论

3.1 7050铝合金力学性能分析

图6 T6与RRA状态7050铝合金TEM像

Fig. 6 TEM images of alloy after different treatments

Al-Zn-Mg-Cu铝合金作为典型的时效强化合金,时效处理时所形成的析出相是铝合金强度的主要决定因素。但在热机械处理中,变形引入的位错也将会对铝合金力学性能产生影响。由此可知,通过不同的处理工艺得到的铝合金,其力学性能有着较大差别。对于时效强化的铝合金,其屈服强度可通过式(1)[14]进行描述:

(1)

(1)

式中:σy为铝合金屈服强度;τ0为摩擦应力约为7 MPa;Δσgb为晶界强化所引起的强度变化;Δτc为固溶强化所引起的强度变化;Δτd为位错引起的强度变化;Δτp为析出相引起的强度变化。本文中的试样,均已经过时效处理,可视为其固溶原子都已析出,因此固溶强化对铝合金强度的影响可忽略不计。Δσgb可通过Hall-Petch公式Δσgb=kD-1/2进行衡量,其中k为一常数,D为平均晶粒尺寸。由于进行的热机械处理相同,因此不同时效时间的铝合金的晶粒尺寸相近。Δτp主要决定于析出相的尺寸与析出相的分布情况。

从图6可知,铝合金的晶内析出相大小相近,均匀地分布于铝基体,又因为该两种状态都是经过固溶之后直接时效,其位错等缺陷可以认为在固溶时基本消除。因此,对于T6与RRA状态的铝合金,位错对于强度的影响可忽略,且其晶粒尺寸相近,所以两者的强度较为接近。

由于在热机械处理过程(固溶热轧连续处理—室温轧制处理—时效处理)引入了位错,所以经热机械处理后的铝合金力学性能将受到位错的影响。Δτd可通过如下公式进行描述:Δτd=αGbρ1/2[15],其中ρ为位错密度,α、G、b都为常数。因此,位错密度增大会阻碍位错运动使铝合金强度提高。通过图5可以知道,经热机械处理的铝合金,随着时效时间的延长位错密度逐渐下降。此外,通过图7可以发现,随着时效时间的延长,析出相长大且析出相密度减小。因此随着时效时间的延长,铝合金的强度逐渐降低。而相较于T6与RRA状态,经热机械处理后的铝合金由于其强化方式不仅有时效析出强化,还由于位错的存在使其强度得到进一步提高,因此经热机械处理后的铝合金强度明显高于T6与RRA状态。

铝合金的塑性受其在进行拉伸实验时,形变所产生位错的影响。热机械处理后的铝合金,由于变形引入了位错,但在进行时效处理时回复而消除了部分位错。部分位错的消除将会为在进行拉伸试验时的位错累积提供空间,而使合金塑性提高。随着时效时间的延长,铝合金的伸长率从样品H6的10.67%提高到H12的11.3%。然而从时效18 h开始,铝合金的伸长率又呈现下降趋势,这是由于随着时效时间的延长,在铝合金中开始出现粗大的析出相,使其不能被位错切过,位错在粗大的析出相周围堆积,造成在铝合金进行拉伸时应力在粗大析出相集中,从而导致拉伸试样较为快速地断裂,降低了铝合金伸长率,相应的样品H18与H24的伸长率分别下降到11.1%、9.3%。

图7 经热机械处理后不同时效时间的7050铝合金TEM像

Fig. 7 TEM images of alloy after TMT

3.2 7050铝合金电导率与腐蚀性能分析

比较表2中不同处理制度下的铝合金的电导率,其大小关系为:T6<H6<H12<H18<H24<RRA。铝合金的电导率受多个因素的影响,根据Mathiessen理论[16],可用式(2)进行描述,

(2)

(2)

式中:ρ0为纯铝的电导率,Δρs是合金元素的固溶对电导率的影响,Δρp是铝合金的析出对电导率的影响,Δρv是空位对铝合金电导率的影响,Δρd是位错对电导率的影响,Δρg是晶界对电导率的影响。空位与位错等缺陷的存在会导致铝合金电导率的降低。而铝合金的析出对其电导率有着两方面的影响:一方面,由于溶质原子的析出,减小了铝基体晶格畸变,有利于电导率的提高;另一方面,析出相可阻碍电子的运动,对电子有散射作用,不利于电导率。

在所有的铝合金试样中RRA的电导率最高,因为RRA状态的铝合金在时效时,经过了过时效的处理,因此其溶质原子的析出较T6更为完全,更有利于减小晶格畸变对电导率的不利影响,且RRA晶界析出相较为粗大也对电导率有利。而经过热机械处理的铝合金,由于位错的引入,一方面促进了铝合金的析出,提高其电导率;另一方面又会加强晶格畸变,对电导率产生不利影响。而通过比较不同处理制度下铝合金的电导率,可以发现位错对铝合金析出的促进从而减小晶格畸变对电导的影响更大[8],因此经热机械处理后的铝合金电导率都大于T6状态的。随着时效时间进一步延长,铝合金在析出更加完全的同时,位错密度也逐渐降低,因此电导率也逐渐升高。而电导率的升高,也有利于铝合金的抗腐蚀性能。

铝合金的抗腐蚀性能主要受晶界析出相、以及晶界无析出带(PFZ)影响。铝合金晶间腐蚀主要为电化学腐蚀[17],晶界处的析出相在进行腐蚀时将作为腐蚀阳极优先消耗掉,而晶界析出相的尺寸与分布情况是关键因素:当晶界析出相较小且分布连续时,其很容易成为腐蚀连续进行的通道,不利于抗腐蚀性能;而如果晶界析出相较为粗大且断续分布,则有利于抗腐蚀性能。由于RRA状态的铝合金在进行(120 ℃, 24 h)的预时效后在晶内形成了细小而分布均匀的析出相,随后在195 ℃进行保温时,晶内析出相将重新溶于铝基体而晶界析出相将继续长大并形成断续分布,最后再进行(120 ℃, 24 h)保温后,晶内细小而分布均匀的析出相重新析出并且晶界处粗大而断续分布的析出相保留了下来,形成了如图6(d)所示的晶界形貌,而由于T6晶界析出相为连续分布,因此RRA状态的铝合金的晶间腐蚀深度53.56 μm远小于T6的80.34 μm。

从图7可以看到,经过热机械处理的铝合金样品H6与样品H12由于晶界析出相为连续分布,因此其晶间腐蚀深度与T6状态相近,分别为83.65 μm、74.25 μm。而随着时效时间的延长,晶界析出相长大,长大过程中消耗了周围的溶质原子,由此晶界析出相开始出现断续分布,使其抗晶间腐蚀性能提高,晶间腐蚀深度减小,样品H18与样品H24的晶间腐蚀深度分别为66.37 μm、60.26 μm。此外,通过比较,经热机械处理的铝合金的晶间腐蚀深度都大于RRA状态的。这是由于RRA态的铝合金晶界析出相更为粗大,且粗大析出相的间距更大,还具有较宽的PFZ,因此更有利于提高铝合金的抗腐蚀性能。

4 结论

1) 新型热机械处理能使7050合金在保持良好塑性的同时,其强度较T6态与RRA态的显著提高。经新型热机械处理后,铝合金的屈服强度与抗拉强度较T6态的分别提高了82 MPa和51 MPa、伸长率可达 11.3%。新型热机械处理中,时效12 h的样品塑性与强度达到最好配合,其屈服强度与抗拉强度分别为645.18 MPa、596.07 MPa,伸长率为11.3%。

2) 与常规热处理相比,新型热机械处理的铝合金电导率低于RRA态的而高于T6态的。随时效时间的延长,热机械处理后的铝合金的晶间腐蚀深度逐渐变小。新型热机械处理过程中,时效24 h的铝合金抗晶间腐蚀性能最好,其晶间腐蚀深度较T6态的小20 μm,接近于RRA态的。

3) 新型热机械处理过程中形成的位错组态,与析出相协同提高铝合金的强度;同时,由于新型热机械处理合金的位错密度较常规热处理显著增加,使溶质原子引起的晶格畸变对电导率的影响大大减小,且随着时效时间的延长,晶界析出相长大成不连续分布,使抗晶间腐蚀性能得到提高。

REFERENCES

[1] RIOJA R J, LIU J. The evolution of Al-Li base products for aerospace and space applications[J]. Metallurgical and Materials Transactions A, 2012, 43(9): 3325-3337.

[2] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials & Design, 2014, 56: 862-871.

[3] 张新明, 邓运来, 张 勇. 高强铝合金的发展及其材料的制备加工技术[J]. 金属学报, 2015, 51(3): 257-271.

ZHANG Xin-ming, DENG Yun-lai, ZHANG Yong. Development of high strength aluminum alloys and Processing techniques for the materials[J]. Acta Metallurgica Sinica, 2015, 51(3): 257-271.

[4] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVREC W. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2010, 58(14): 4814-4826.

[5] HUO W, HOU L, CUI H, ZHUANG L, ZHANG J. Fine-grained AA 7075 processed by different thermo-mechanical processings[J]. Materials Science & Engineering A, 2014, 618: 244-253.

[6] LIN G, ZHANG Z, WANG H, ZHOU K, WANG H. Enhanced strength and electrical conductivity of Al–Mg–Si alloy by thermo-mechanical treatment[J]. Materials Science & Engineering A, 2016, 650: 210-217.

[7] LI H, XU W, WANG Z, FANG B, SONG R, ZHENG Z. Effects of re-ageing treatment on microstructure and tensile properties of solution treated and cold-rolled Al-Cu-Mg alloys[J]. Materials Science & Engineering A, 2016, 650: 254-263.

[8] ZUO J, HOU L, SHI J, CUI H, ZHUANG L, ZHANG J. Effect of deformation induced precipitation on dynamic aging process and improvement of mechanical/corrosion properties AA7055 aluminum alloy[J]. Journal of Alloys and Compounds, 2017, 708: 1131-1140.

[9] CHEN Zhi-guo, REN Jie-ke, ZHANG Ji-shuai, CHEN Ji-qiang, FANG Liang. Regulation mechanism of novel thermomechanical treatment on microstructure and properties in Al-Zn-Mg-Cu alloy[J]. Journal of Materials Engineering and Performance, 2016, 25(2): 359-364.

[10] 任杰克, 陈志国, 黄裕金, 张纪帅, 魏 祥, 方 亮. 新型热机械处理对2E12铝合金显微组织与性能的影响[J]. 中国有色金属报, 2014, 24(3): 643-650.

REN Jie-ke, CHEN Zhi-guo, HUANG Yu-jin, ZHANG Ji-shuai, WEI Xiang, FANG Liang. Effect of new thermomechanical treatment on microstructure and properties of 2E12 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 643-650.

[11] 陈志国, 彭 景, 任杰克. 一种显著提高铝锌镁合金综合性能的热机械处理工艺: 中国, ZL201710059182.3[P]. 2017-06-13.

CHEN Zhi-guo, PENG Jing, REN Jie-ke. A thermo-mechanical treatment that can promote comprehensive property of Al-Zn-Mg: China, ZL201710059182.3[P]. 2017-06-13.

[12] ZHAO Y H, LIAO X Z, JIN Z, VALIEV R Z, ZHU Y T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing[J]. Acta Materialia, 2004, 52(15): 4589-4599.

[13] UNGAR T S, OTT S, SANDERS P G. Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis[J]. Acta Materialia, 1998, 46(10): 3693-3699.

[14] STARINK M J, WANG S C. A model for the yield strength of overaged Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2003, 51(17): 5131-5150.

[15] LUO P, MCDONALD D T, XU W, PALANISAMY S, DARGUSCH M S, XIA K. A modified Hall-Petch relationship in ultrafine-grained titanium recycled from chips by equal channel angular pressing[J]. Scripta Materialia, 2012, 66(10): 785-788.

[16] DUGDALE J S, BASINSKI Z S. Mathiessen’s rule and anisotropic relaxation times[J]. Physical Review, 1967, 157(3): 552-560.

[17] 罗 勇, 许晓静, 吴桂潮, 张允康, 宋 涛, 王 斌. 强化固溶处理对7085铝合金晶间腐蚀和剥落腐蚀性能的影响[J]. 稀有金属材料与工程, 2012, 41(s2): 262-265.

LUO Yong, XU Xiao-jing, WU Gui-chao, ZHANG Yun-kang, SONG Tao, WANG Bin. Effect of enhanced-solid-solution on intergranular corrosion and exfoliation corrosion properties of 7085 aluminum alloy[J]. Rare Metal Materials And Engineering A, 2012, 41(s2): 262-265.

Effect of novel thermo-mechanical treatment on microstructure and properties of 7050 aluminum alloy

PENG Jing1, CHEN Zhi-guo1, 2, REN Jie-ke1, MA Wen-jing1

(1.School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Materials Engineering, Hunan University of Humanities, Science and Technology, Loudi 417000, China)

Abstract: A novel thermo-mechanical treatment (TMT) based on solid solution-hot roll treatment(SSHR) and its influence on properties of 7050 alloy were studied by tensile and corrosion resistance testing. The influence on microstructure was studied by methods such as XRD and transmission electron microscope observation. The results indicate that the strength of 7050 alloy is enhanced by the novel TMT, meanwhile, a good plasticity remains. The highest yield strength and ultimate tensile strength reach 608.10 MPa and 651.24 MPa, respectively. They are increased by 82 MPa and 51 MPa, comparing with the yield strength and ultimate tensile strength of T6. The conductivities of TMT sample are between T6 and RRA, and the intergranular corrosion resistance is better than that of T6, and close to that of RRA. The results of microstructure analysis indicate that the comprehensive properties of 7050 alloy is promoted by the configuration of dislocations formed during TMT and the shape and distribution of grain boundary precipitates.

Key words: aluminum alloy; thermo-mechanical treatment; intergranular corrosion; conductivities

Foundation item: Project(50871123) supported by the National Natural Science Foundation of China; Project (51011120052) supported by DEST-China Grant

Received date: 2017-08-24; Accepted date: 2018-01-02

Corresponding author: CHEN Zhi-guo; Tel: +86-738-8325517;E-mail: hngary@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(50871123);中澳科技合作特别基金资助项目(51011120052)

收稿日期:2017-08-24;修订日期:2018-01-02

通信作者:陈志国,教授,博士;电话:0738-8325517;E-mail:hngary@163.com