DOI: 10.11817/j.issn.1672-7207.2015.04.001

富硅软锰矿强磁选-碱浸脱硅工艺

冯雅丽1,李斌1,李浩然2

(1.北京科技大学 土木与环境工程学院,北京,100083

2.中国科学院 过程工程研究所生化工程国家重点实验室,北京,100190)

摘要:对硅锰质量比为3.5:1的富硅软锰矿采用强磁选-碱浸工艺脱硅,通过单因素和正交试验研究强磁选试验中磨矿细度和磁场强度,碱浸试验中反应温度、反应时间、NaOH浓度和液固比对硅脱除率的影响,利用“减缩核模型”研究碱浸过程中反应温度对硅脱除率影响的动力学,并得到相应的动力学方程。研究结果表明:在矿石入选粒度为小于74 μm占75%、磁场强度为1 273.2 kA/m、碱浸反应温度为120 ℃、反应时间为5.5 h、NaOH浓度为16 mol/L、液固比(mL/g)为5:1的条件下,得到碱浸渣中硅锰质量比为0.3:1,硅脱除率为81%。碱浸过程受化学反应控制,表观反应活化能为67.77 kJ/mol。

关键词:富硅软锰矿;磁选;碱浸;脱硅

中图分类号:TF792 文献标志码:A 文章编号:1672-7207(2015)04-1175-07

High-intensity magnetic separation-alkaline leaching process to desiliconize from silicon-rich pyrolusite

FENG Yali1, LI Bin1, LI Haoran2

(1. School of Civil and Environmental Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. National Key Laboratory of Biochemical Engineering, Institute of Process Engineering,

Chinese Academy of Science, Beijing 100190, China)

Abstract: By means of high-intensity magnetic separation-alkaline leaching to desiliconize from silicon-rich pyrolusite of silicon-manganese mass ratio of 3.5:1, using single factor and orthogonal experiments to study the grinding fineness and magnetic field strength in magnetic separation test, the effect of temperature and time of reaction, concentration of NaOH and the ratio of liquid-solid to the removal rate of silicon in alkaline leaching test, using the “Reduction of nuclear model” to study the dynamics of effect of reaction temperature to the removal rate of silicon in alkali leaching process, and get the corresponding dynamic equation. The results show that under the conditions of the selected ore particle size of 75% less than 74 μm, the magnetic field intensity of 1 273.2 kA/m, the alkaline leaching reaction temperature of 120 ℃, reaction time of 5.5 h, concentration of NaOH of 16 mol/L and the ratio of liquid-solid (mL/g) of 5:1, the alkali leaching residue is obtained with the silicon-manganese mass ratio of 0.3:1 and removal rate of silicon of 81%. The alkali leaching process is controlled by chemical reaction and the apparent activation energy is 67.77 kJ/mol.

Key words: silicon-rich pyrolusite; magnetic separation; alkaline leaching; desiliconize

目前,锰矿石的主要选矿方法有物理选矿法(洗矿、筛分、重选、磁选和浮选等)、化学选矿法和火法富集等方法。由于磁选方法操作简单,适应性强,易于控制,并且可用于各种锰矿石选别,近年来已在锰矿选矿中占主导地位[1-2]。软锰矿的浸出按其工艺流程的不同可分为两大类:预还原浸出和直接浸出[3-4]。前者存在流程复杂、能耗高、操作条件不易控制等缺点[5],后者则在简化流程的同时降低了能耗[6],改善了操作条件,逐渐成为软锰矿浸出工艺的发展方向[7]。此外,软锰矿中常含有大量脉石矿物石英,其在原矿中赋存状态较为稳定,为后续软锰矿的氧化还原反应综合利用带来诸多不便,目前国内外对于软锰矿除硅工艺研究较少,因此如何除去低品位软锰矿中大量赋存的石英也是亟待解决的问题。本文作者采用强磁选-碱浸联合工艺处理硅锰质量比为3.5:1的富硅低品位软锰矿,以解决软锰矿单一磁选过程中硅脱除率有限的问题,避免软锰矿预浸出时操作条件不易控制,能耗过高的问题,便于下一步的综合利用,具有较高的实用价值。

1 试验

1.1 试验原料

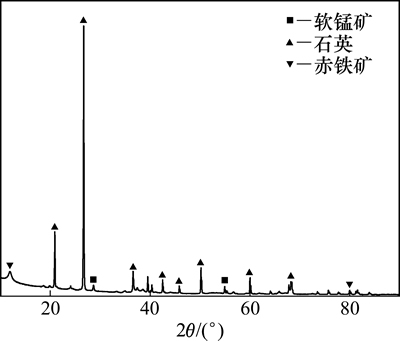

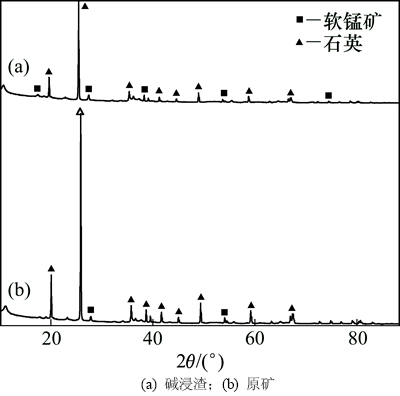

试验原料来自贵州省某地锰矿,其主要化学成分及X线衍射分析分别见表1和图1。

表1 原矿的主要化学成分分析结果(质量分数)

Table 1 Analysis results of mainly chemistry ingredient of raw ore %

图1 原矿的XRD谱

Fig. 1 XRD pattern of raw ore

从表1及图1可以看出:该矿石的主要成分为石英和软锰矿,杂质矿物主要为赤铁矿。

1.2 试验流程及设备

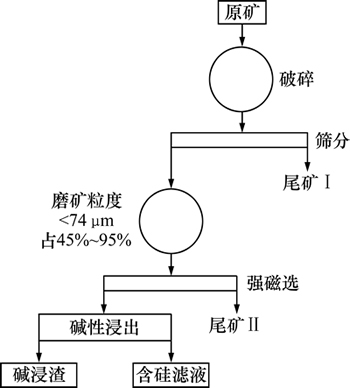

试验原则工艺流程如图2所示。

图2 试验工艺流程图

Fig. 2 Flow diagram of test process

主要试验设备有:RK/PEX 100×125(细碎型)颚式破碎机,XMB-70型三辊四筒棒磨机,RK/CSQ 50×70型湿式强磁选机。

碱浸法的反应装置如图3所示,反应器由聚四氟乙烯制成,上部装有可控性温度控制器及回流冷凝管,反应器接口处,采样口及顶部均采取密封措施,通过取样勺进行取样。加热装置为恒温式加热磁力搅拌器(油浴)。

图3 碱浸反应装置图

Fig. 3 Reaction device of alkali leaching

原矿及碱浸渣的物相组成通过X线衍射仪(日本理学公司D/max-γB型:Cu靶,波长λ为0.154 06 nm,管电压为40 kV,管电流为100 mA,衍射速度为4(°)/min,扫描范围2θ为10°~90°)测定。采用硅钼蓝光度法测定磁选精矿及碱浸渣中SiO2的质量分数,所用仪器为UV-1750型分光光度计。

1.3 试验方法

将原矿破碎至粒度小于0.3 mm脱泥,产品经一段磨矿后,筛至各粒级恒质量并按一定配比混合,在湿式强磁选机中进行选别,将磁选后精矿加入一定浓度的NaOH溶液,在聚四氟乙烯反应器中搅拌加热,并开通回流冷凝管中的冷却水,反应完毕后采用蒸馏水和砂滤漏斗进行多次洗涤过滤,浸出液和浸出渣收集并用于检测。

碱浸过程中硅的脱除率L的计算公式如下:

(1)

(1)

式中:w1为碱浸液中硅的质量分数;w2为磁选精矿中硅的质量分数。

2 结果与讨论

2.1 磁选试验

由于软锰矿为弱磁性矿物,脉石矿物石英为非磁性矿物,故可通过磁选将2种矿物分离,达到提锰降硅的效果。本试验分别从磨矿细度、磁场强度2个方面考察低品位软锰矿强磁选后的脱硅效果。

2.1.1 磁选磨矿细度试验

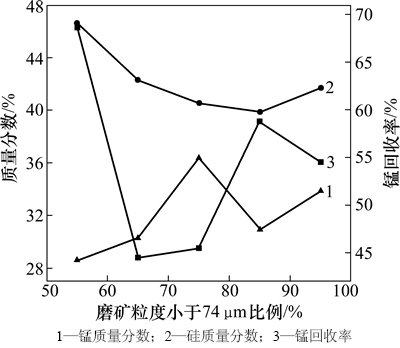

固定磨矿矿浆质量分数为60%,磁场强度为1 273.2 kA/m,矿浆分选质量分数为20%,分别选取不同粒级的原矿进行强磁选试验,将磁选精矿中锰和硅质量分数以及锰回收率进行对比,结果如图4所示。

从图4可以看出:随着磨矿粒度逐渐变细,精矿中锰的产率逐渐降低,由磨矿粒度小于74 μm占55%时的59.91%降至20.04%,其原因可能是该过程导致软锰矿石部分泥化,少部分夹杂在非磁性矿物中随尾矿排除,造成产率过低。已知软锰矿所受的磁力作用与其比磁化系数、质量成正比[8],故随着磨矿粒度逐渐变小,精矿中锰品位应有所提高。当磨矿粒度为小于74 μm占55%~75%时,精矿中锰品位逐渐提高,由28.62%升至36.38%;精矿中锰回收率则呈下降趋势,由68.6%降至45.47%,这可能是由于锰矿物大颗粒连生体发生解离,解离出的软锰矿石颗粒不断增多,通过磁选进入精矿,导致锰品位逐渐升高。当磨矿粒度为小于74 μm占75%~95%时,虽然有更多的锰矿物连生体发生了解离,但磨矿粒度过细会造成矿物泥化,部分软锰矿颗粒与非磁性矿粒附着,无法通过磁选回收而流失,造成精矿中锰品位略有下降,回收率略有上升。

图4 磁选磨矿细度试验

Fig. 4 Magnetic grinding fineness test

从图4还可以看出:随着磨矿粒度逐渐变细,硅质量分数也逐渐降低,当磨矿粒度小于74 μm占85%时达到最低,为39.88%;锰质量分数则呈上升趋势,当磨矿粒度小于74 μm占75%时达到最高,为36.38%。考虑到强磁选的主要目的为降低软锰矿中的硅锰质量比,故选择磨矿粒度为小于74 μm占75%,此时硅锰质量比为1.2:1,硅质量分数降至40.56%,锰回收率为45.47%,锰品位为36.38%,提锰脱硅效果较好。

2.1.2 磁选磁场强度试验

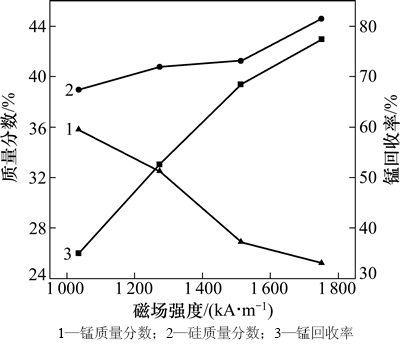

固定矿浆分选质量分数为20%,根据磨矿细度试验选择矿石入选粒度为小于74 μm占75%,在不同磁场强度条件下进行磁选试验,将磁选精矿中锰和硅质量分数以及锰回收率进行对比,结果如图5所示。

由图5可以看出:在磁场强度从1 034.5 kA/m提高到1 750.7 kA/m的过程中,精矿中锰产率逐渐升高,由23.33%升至52.65%;锰品位逐渐降低,且呈快速下降趋势;同时锰回收率快速上升。这可能是由于随着磁场强度的升高,包括赤铁矿在内的部分弱磁性杂质矿物夹带进入精矿的机会增加,恶化了磁选效果。

从图5还可以看出:在磁场强度从1 034.5 kA/m提高到1 750.7 kA/m的过程中,精矿中锰质量分数呈急剧下降趋势,同时硅质量分数呈缓慢上升趋势,硅锰质量比由1.1:1升至1.8:1。说明在此磁场强度范围内,场强的提高不利于软锰矿脱硅。

图5 磁选磁场强度试验

Fig. 5 Magnetic field strength test

考虑到目前工业实际生产软锰矿中湿式强磁选机的最高工作磁场强度一般为1 270~1 430 kA/m[9],试验应在保证精矿中硅锰质量比显著降低的同时提高锰的品位,故选择磁场强度为1 273.2 kA/m较好,此时硅锰质量比可由3.5:1降至1.1:1,硅质量分数降至40.77%,锰回收率为52.63%,锰品位为32.50%。

2.2 常压碱浸试验

磁选后的精矿在NaOH溶液中发生的主要反应为

SiO2+2NaOH=Na2SiO3+2H2O (2)

原矿中的其他杂质在碱性溶液中也可能发生如下反应:

Al2O3+2NaOH+3H2O=2NaAl(OH)4 (3)

另一方面,溶液中生成的Na2SiO3也可与NaAl(OH)4反应生成水合铝硅酸钠,并沉淀析出[10](反应式(4)):

nNa2SiO3+2NaAl(OH)4=Na2O·Al2O3·nSiO2+2nNaOH+(4-n)H2O (4)

当溶液中有足够浓度的Al2O3时,便可能发生反应(4),考虑到原矿中Al2O3的质量分数只有2.80%,故反应(4)对提锰脱硅效果影响很小,可忽略不计。

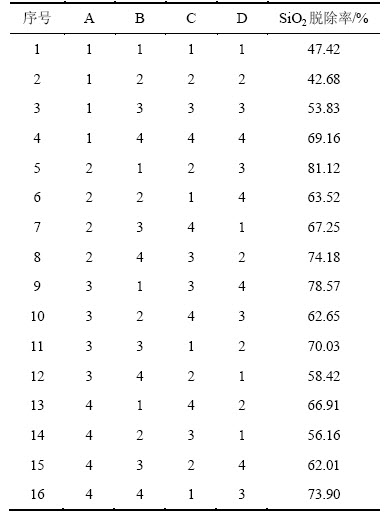

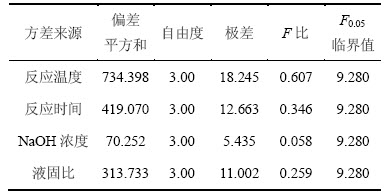

将强磁选后的软锰矿精矿进行碱浸试验,为了得到碱浸法脱硅的优化工艺条件,试验拟定对反应温度、反应时间、NaOH浓度和液固比4个主要影响因素进行研究,通过四因素四水平正交试验L16(44)来研究各因素对脱硅效果的影响,得到各因素对硅脱除率的影响程度及与最佳工艺条件。常压碱浸试验正交表如表2所示,不同条件下SiO2脱除率见表3;采用方差分析法处理试验数据,其结果见表4。

表2 因素水平确定表

Table 2 Determination of factors and levels

表3 SiO2脱除率正交分析表

Table 3 Orthogonal analysis of emergence rate of silicon

表4 SiO2脱除率方差分析结果

Table 4 Variance analysis of emergence rate of silica

由表4可知:反应温度的偏差平方和最大,反应时间次之,液固比较小,NaOH浓度最小,因此各因素影响SiO2脱除率由大到小顺序依次为反应温度,反应时间,液固比,NaOH浓度。考虑到降低能耗、节约成本、提高效率等目的,选择优化工艺条件为A2B1C1D3,即反应温度为120 ℃、反应时间为5.5 h、NaOH浓度为16 mol/L和液固比为5:1,在此条件下碱浸渣中硅锰质量比为0.3:1,SiO2质量分数为11.79%,硅脱除率为81%。碱浸渣中锰回收率为59.82%,锰品位为43.36%。对该碱浸渣进行化学成分分析,结果如表5所示。

表5 碱浸渣主要化学成分分析结果(质量分数)

Table 5 Analysis results of mainly chemistry ingredient of alkali leaching residue %

将表5与表1对比可以看出:经碱浸后锰质量分数显著增加,硅质量分数明显减少,同时Al2O3质量分数有所减少,这可能是反应(3)所致。将软锰矿原矿和碱浸渣进行XRD分析,结果如图6所示。

图6 原矿和碱浸渣的XRD谱

Fig. 6 XRD patterns of raw ore and alkali leaching residue

从图6可以看出:碱浸渣中石英衍射峰强度较原矿显著降低,尤其是2θ在19°~21°,25°~27°和47°~49°时最为明显;另一方面,在2θ为16°~18°和37°~38°时出现了新的软锰矿衍射峰。这说明经强磁选-碱浸联合工艺得到的碱浸渣中硅质量分数较原矿明显减少,同时锰质量分数较原矿有所增加,这进一步证明该工艺对富硅低品位软锰矿进行预处理脱硅效果较好。

3 碱浸过程动力学研究

对于碱浸过程中发生的主要化学反应:

SiO2(s)+2NaOH(aq)=Na2SiO3(aq)+2H2O(l) (5)

假定反应物NaOH(aq)的浓度恒定且不随反应时间改变,因为生成物Na2SiO3可溶于水,固相的外形尺寸随反应的进行而减小直至完全消失,故可采用液固反应的“减缩核模型”[11]来研究碱浸过程中反应温度对硅脱除率的影响,具体方程式如下:

(6)

(6)

式中:αt为t时刻时SiO2的脱除率,%;M为:SiO2的相对分子质量,g;c为溶液中NaOH的浓度,mol/L;b为反应物NaOH的化学计量系数;d0为球形颗粒的初始直径,cm;ρ为SiO2的密度,g/cm3;F为几何形状的函数;k为反应速率常数。

对于球形颗粒有F=3,令式(6)中

(7)

(7)

其中:k′可视为表观速率常数,则式(6)可变为

(8)

(8)

将式(8)左边用f表示,有

(9)

(9)

Arrhenius公式[11]表达了恒定浓度反应体系中反应温度与反应速率的关系:

(10)

(10)

式中:k为反应速率常数;A为频率因子;R为摩尔气体常数;E为反应的活化能,kJ/mol;T为热力学温度,K。

对式(10)两边取对数,得:

(11)

(11)

由式(7)得

(12)

(12)

在试验条件下,令

(13)

(13)

Q为常数,则

k=Qk′ (14)

(15)

(15)

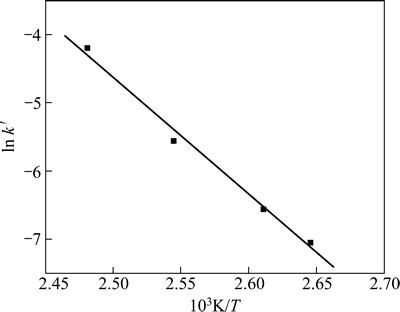

以lnk′对1/T作图得一直线,由直线斜率为-E/R可求出反应的活化能E。

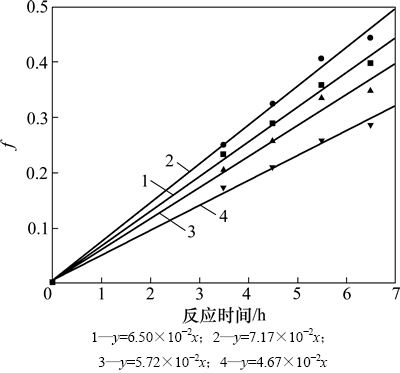

固定NaOH浓度为16 mol/L和液固比为5:1,不同反应温度下硅脱除率随反应时间的变化如图7所示。

将图7结果用式(9)处理,结果如图8所示。

由图7和图8可知:在反应温度为105~120 ℃范围内升高温度可显著提高硅脱除率,当温度大于120 ℃时硅脱除率有所下降。以不同温度下ln k′对1/T作图,结果如图9所示。

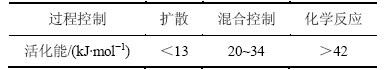

由图9中直线斜率可求得反应(4)表观活化能E=67.77 kJ/mol。对于产物为水溶物种的液固反应,决定其反应速率的判断依据如表6所示[11-12]。

图7 反应温度对硅脱除率的影响

Fig. 7 Effect of reaction temperature on silicon reduction

图8 f与反应温度变化关系曲线图

Fig. 8 Relationship between f and reaction temperature

图9 ln k′与1/T关系图

Fig. 9 Relationship between ln k′ and 1/T

表6 过程控制条件与活化能的关系

Table 6 Relationship between the process control conditions and activation energy

由表6可知反应(5)过程由化学反应控制,同时可求出常压碱浸脱硅过程中反应温度对硅脱除率影响的动力学方程:

(16)

(16)

4 结论

1) 对硅锰质量比为3.5:1的富硅软锰矿进行强磁选磨矿细度和磁选强度试验,在入选粒度为小于74 μm占75%、磁场强度为1 273.2 kA/m的条件下,精矿中硅锰质量比可由3.5:1降至1.1:1,硅质量分数为40.77%。

2) 对磁选精矿进行碱浸试验,在反应温度为120 ℃、反应时间为5.5 h、NaOH浓度为16 mol/L和液固比为5:1的条件下,碱浸渣中硅锰质量比降至0.3:1,硅质量分数为11.79%,硅脱除率为81%,其中锰回收率为59.82%,锰品位为43.36%。

3) 利用“减缩核模型”研究碱浸过程中反应温度对硅脱除率的影响,结果表明该过程受化学反应控制,表观活化能E=67.77 kJ/mol,相应的动力学方程为

参考文献:

[1] 张志华, 薛生晖, 黎红兵, 等. 广西某低品位软锰矿还原焙烧—酸浸工艺研究[J]. 中国锰业, 2012, 30(2): 19-22.

ZHANG Zhihua, XUE Shenghui, LI Hongbing, et al. Study on reduction roasting-acid leaching with Guangxi pyrolusite ore[J]. China’s Manganese Industry, 2012, 30(2): 19-22.

[2] 杨志超. 低品位菱锰矿制备四氧化三锰的研究[D]. 北京: 北京科技大学土木与环境工程学院, 2013: 5-13.

YANG Zhichao. Study on preparation of manganese tetraoxide from low grade rhodochrosite ore[D]. Beijing: University of Science and Technology Beijing. School of Civil and Environmental Engineering, 2013: 5-13.

[3] YANG Zhichao, FENG Yali, LI Haoran, et al. Effect of Mn(Ⅱ) on quartz flotation using dodecylamine as collector[J]. Journal of Central South University, 2014, 21(9): 3603-3609.

[4] CAI Zhenlei, FENG Yali, LI Haoran, et al. Selective separation and extraction of vanadium (IV) and manganese (II) from co-leaching solution of roasted stone coal and pyrolusite via solvent extraction[J]. Industrial & Engineering Chemistry Research, 2013, 52(38): 13768-13776.

[5] YANG Zhichao, FENG Yali, LI Haoran, et al. Effect of biological pretreatment on the flotation recovery of pyrolusite[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5): 1571-1577.

[6] CAI Zhenlei, FENG Yali, LI Haoran, et al. Co-recovery of manganese from low-grade pyrolusite and vanadium from stone coal using fluidized roasting coupling technology[J]. Hydrometallurgy, 2013, 41/42/43/44/45: 131-132.

[7] 冯雅丽, 张旭, 李浩然, 等. FeS2-MnO2-H2SO4浸出软锰矿反应[J]. 东北大学学报(自然科学版), 2014, 35(2): 241-244.

FENG Yali, ZHANG Xu, LI Haoran, et al. Pyrolusite leaching reactions in FeS2-MnO2-H2SO4 system[J]. Journal of Northeastern University (Natural Science), 2014, 35(2): 241-244.

[8] Hancock, H A, Fray, D J. Use of coal and lignite to dissolve manganese from low-grade manganese dioxide in acidic solutions[J]. Transaction of Institution of Mining and Metallurgy: Section C, 1986, 95: 27-31.

[9] 秦勤. 湖南湘西某低品位碳酸锰矿磁浮分选技术研究[D]. 武汉: 武汉科技大学资源与环境工程学院, 2012: 4-16.

QIN Qin. Research on flotation and magnetic separation technology for the low-grade manganese carbonate ore in west Hunan province[D]. Wuhan: Wuhan University of Science and Technology. School of Resource and Environmental Engineering, 2012: 4-16.

[10] 陈超, 韦萍, 栗海锋, 等. 常压碱溶法提取软锰矿酸浸渣中的硅[J]. 无机盐工业, 2012, 44(9): 36-38.

CHEN Chao, WEI Ping, LI Haifeng, et al. Leaching silicon from acid leaching residue of pyrolusite by alkaline leaching method at atmospheric pressure[J]. Inorganic Chemicals Industry, 2012, 44(9): 36-38

[11] 杨显万, 邱定蕃. 湿法冶金[M]. 北京: 冶金工业出版社, 1998: 164-211.

YANG Xianwan, QIU Dingfan. Hydrometallurgy[M]. Beijing: Metallurgical Industry Press, 1998: 164-211.

[12] Bafghi M S, Zakeri A, Ghasemi Z, et al. Reduction dissolution of manganese ore in sulfuric acid in the presence of iron metal[J]. Hydrometallurgy, 2008, 90: 207-212.

(编辑 杨幼平)

收稿日期:2014-04-23;修回日期:2014-06-29

基金项目(Foundation item):国家自然科学基金资助项目(21176026,21176242);中国大洋矿产资源研究开发计划项目(DY125-15-T-08);国家高技术研究发展计划(863计划)项目(2012AA062401)(Projects (21176026, 21176242) supported by the National Natural Science Foundation of China; Project (DY125-15-T-08) supported by the China Ocean Mineral Resources Research & Development Program; Project (2012AA062401) supported by the National High-Tech Research & Development Program (863 Program))

通信作者:李浩然,副研究员,从事矿物加工工程研究;E-mail:hrli@home.ipe.ac.cn