DOI: 10.11817/j.issn.1672-7207.2017.01.005

烧结中使用钢渣磁选尾渣替代部分烧结熔剂的实验研究

孟飞,刘清才,朱广太,任山,朱博洪,兰苑培,刘国庆,牛德良

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:通过化学分析、X线衍射分析、光学显微分析等方法对钢渣磁选后剩余尾渣进行基础特性分析,并将其按照质量分数0,2.5%,5.0%和10.0%的比例分别配入烧结原料中,研究其代替部分烧结熔剂对烧结矿显微结构、质量及冶金性能的影响。研究结果表明:当烧结原料中尾渣配入量小于5.0%时,随着尾渣配入量的增加,烧结矿中铁酸钙含量增加,烧结矿的成品率、落下强度及转鼓强度均逐渐增大,之后均开始降低,而垂直烧结速度及烧结利用系数则一直逐渐降低。烧结矿的还原度及低温还原粉化性能随着尾渣配入量得到改善,但当尾渣配入量大于5.0%时开始下降。尾渣的配入会提高烧结矿的自由流动及完全熔化温度,扩大软熔区间,使得烧结矿软熔性能变差。

关键词:磁选尾渣;烧结;熔剂;冶金性能

中图分类号:X757 文献标志码:A 文章编号:1672-7207(2017)01-0031-08

Experimental study on application of steel slag magnetic tailings replacing part of sintering flux during sintering

MENG Fei, LIU Qingcai, ZHU Guangtai, REN Shan, ZHU Bohong, LAN Yuanpei,

LIU Guoqing, NIU Deliang

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: Fundamental characteristics of magnetic separation tail slags were studied by chemical analysis, X-ray diffraction analysis, optical microscope analysis and other analysis methods. The microstructure and metallurgical properties of the sinter were studied, while magnetic separation tail slags were added into sintering material with 0, 2.5%, 5.0% and 10.0%, respectively. The results show that when the mass fraction of tail slags in the sintering material is less than 5.0%, with the increase of tail slags content, calcium ferrite content in the sinter tends to increase, the sinter yield elevates, strength and drum strength both improve. Then all these metallurgical performances tend to decrease, while the mass fraction of tail slags continues to increase. However, the vertical sintering speed and productivity of sintering decrease if the content of tail slags in sintering increases. The reducibility index of sinter and the low temperature reduction degradation index can be improved with the increase of the slag content. And these performances decrease when the mass fraction of tail slags is more than 5.0%. With the increase of tail slags content, the high free flow temperature and soften-melting temperature of sinter make softening temperature intervals expand, and worsen the softening-melting properties of sinter.

Key words: magnetic separation tail slags; sintering; fluxes; metallurgical properties

钢渣是在钢铁生产过程中由造渣材料、冶炼反应物、侵蚀脱落的炉体和补炉材料、金属炉料带入的杂质和为调整钢渣性质而特意加入的造渣材料所组成的渣体,是钢铁生产过程的副产品。在生产中,每生产1 t钢,就有15%~20%的钢渣产生[1]。据统计,2014年我国粗钢产量达到8.26亿t,占世界粗钢总产量的50.21%,同时产生冶金渣达2亿t以上[2],国家“十一五”发展规划中指出,钢渣的综合利用率应达86%以上,基本实现“零排放”。然而,中国目前综合利用的现状与该规划相差甚远,尤其是素有“劣质水泥熟料”之称的转炉钢渣的利用率仅为10%~20%[3-4]。目前钢渣的利用主要是回收其中的铁,一般采用多段破碎多段干法磁选的方法得到渣钢或富铁钢渣作为炼钢或炼铁的原料,而尾渣中大部分被堆弃。大量堆弃的尾渣不仅占用大量耕地,而且其中大量细小颗粒飞扬污染空气,尾渣中的有害元素及重金属元素经雨水冲刷会污染周围生态环境。因此,加速深化钢渣磁选尾渣(下文简称尾渣)的综合利用是目前亟待解决的问题。许多学者已经对尾渣的综合利用进行研究,姜学东等[5]将磁选尾渣用于制作混泥土路面砖的研究,倪文等[6]研究了将磁选尾渣制备高强度人工鱼礁混凝土,孙继红等[7]开展了钢渣磁选尾渣制作建筑基础转的试验研究,方宏辉等[8]对尾渣制备胶结材料进行了研究,杨淇等[9]进行了尾渣制备耐火喷涂料的实验研究。由于尾渣中成分复杂波动较大,并且含有大量的f-CaO及f-MgO,用于制作路基材料及建筑材料时会造成材料性能不稳定,易开裂。使得处理尾渣技术难度大,成本较高,且不能大量综合回收利用尾渣。尾渣中氧化钙及氧化镁等碱性氧化物的含量较高,当用尾渣代替部分冶金烧结熔剂时,不仅可以减少生石灰、石灰石、白云石、萤石等烧结熔剂的添加量,降低烧结生产成本,而且可以回收尾渣中未磁选出的金属铁及FeO,MgO和MnO等有益成分[10-11]。既充分利用资源、又减轻了环境污染,还降低了烧结生产成本。因此,将尾渣用于烧结工序是尾渣综合利用的一条经济有效途径。为此,本文作者对尾渣的主要物化特性进行研究,并将尾渣配入烧结原料中代替部分烧结熔剂进行烧结杯实验,研究添加不同比例尾渣对烧结过程中主要参数及烧结矿强度、微观组织结构、冶金性能的影响,确定适宜的尾渣添加量,为烧结中充分利用尾渣提供理论依据。

1 实验

1.1 实验原料物化特性

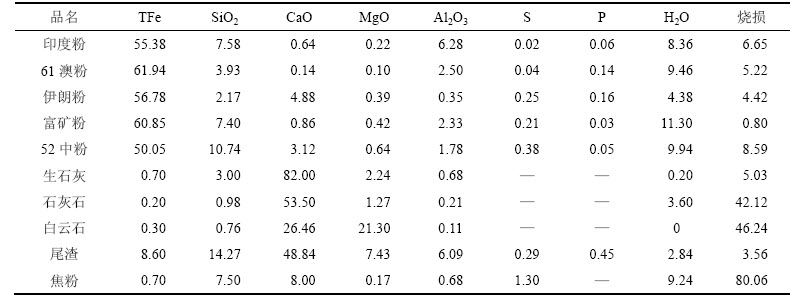

实验中所用尾渣取自于重庆钢铁股份有限公司,其他烧结原料来源于贵州六盘水水城钢铁股份有限公司,其化学成分如表1所示。

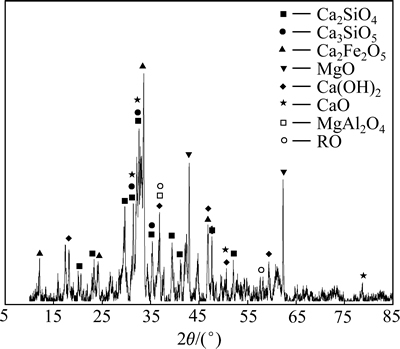

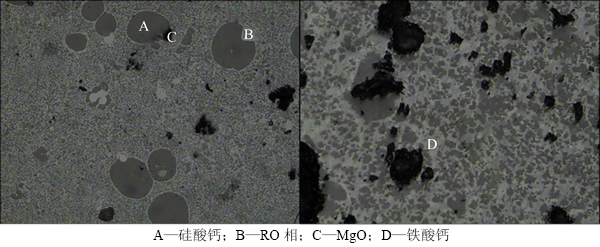

分别采用X线荧光衍射仪(XRD)、Zeiss Axioskop 40偏光显微镜及LEICA Q500图像分析仪对尾渣的物相组成及微观结构进行分析,结果如图1和图2所示。

由图1可以看出:尾渣主要物相为Ca2SiO4,Ca3SiO5,Ca2Fe2O5,MgO,Ca(OH)2,f-CaO,MgAl2O4和RO相,且Ca2SiO4,Ca3SiO5,Ca2Fe2O5和MgO的X线衍射峰较强,因此,这几种物质含量较高,为主要物相。由于尾渣为转炉渣、脱硫渣、精炼渣等磁选后剩余的尾渣,故含有这几种渣的物相。特别加入大量石灰石等造渣剂而形成的转炉渣,因此,尾渣中也含有一定量的Ca(OH)2与f-CaO。

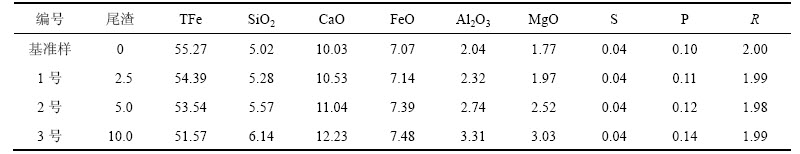

表1 尾渣及烧结原料化学成分(质量分数)

Table 1 Chemical compositions of materials and steelmaking slag tailings %

图1 尾渣的X线衍射图

Fig. 1 XRD pattern of steelmaking slag tailings

由图2可知:尾渣中主要由3种不同颜色的物相,分别为黑色、灰色和白色。其中呈圆形或不规则椭圆形的深灰色A相为硅酸钙相。呈现不规则形状,分布在A相周围的白色B相为二价金属Fe,Mn和Mg等氧化物连续固溶体,即RO相。黑色不规则形状的C相为MgO。以无限延伸状态的分布于深灰色A相之间的浅灰D相为铁酸钙相。根据各物相的分布情况可知:尾渣中主要物相为硅酸钙相和铁酸钙相,这与XRD的分析结果一致。

1.2 实验方法

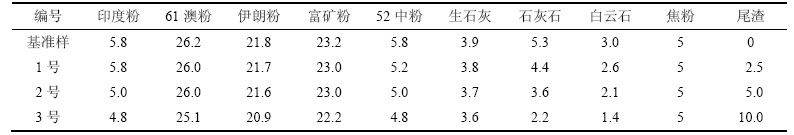

由于尾渣为钢厂多段破碎多段磁选后的钢尾渣,其粒径在0~40 mm之间,为了保证在烧结过程中能充分分解及矿化,将尾渣粒度破碎至5 mm以下,并按照质量分数为2.5%,5.0%和10.0%的比例与烧结原料混合,分别编号为1号、2号和3号,并以未添加尾渣作为基准样,其配比方案如表2所示。

各原料按照表2配比方案配齐后,先由人工在铁板上混匀,再装入直径×长度为700 mm×1 000 mm的圆筒混料机中混合,混合制粒时间为5 min,混合过程中喷洒适量的水使混合料润湿,控制混合料最终水分的质量分数为7.5%±5.0%。然后将混合好的原料加入直径×长度为250 mm×700 mm的烧结杯中,控制料层厚度为600 mm左右,加入之前在烧结杯底部铺入1 kg左右的烧结矿为垫底料。装料完毕后,控制抽风机,使点火负压为6 kPa,调节空气阀与天然气阀,控制空气流量与天然气流量分别为16 m3/h和1.6 m3/h。点火1 min,点火温度为1 100 ℃,点火完成后控制烧结负压为12 kPa。烧结完成后,分别测定烧结矿的技术指标、机械性能及冶金性能。

添加尾渣后烧结矿性能分析包括烧结矿的机械强度、900 ℃还原性、低温还原粉化性以及熔滴性能。检测方法简要介绍如下。

1) 落下强度检测方法。由于我国并未制定相关的测定标准,大都采用日本标准JIS-M8711-7进行烧结矿的落下强度测定。落下试验区10~40 mm的烧结矿(3±0.05) kg,放入1个方型料箱中,提升至2 m处,让其自由落在20 mm的钢板上往复4次。然后用10 mm的方孔筛分级,以大于10 mm的粒级质量分数表示落下强度指标。

图2 尾渣矿相图

Fig. 2 Mineral phase images of steelmaking slag tailings

表2 尾渣与烧结原料配比方案(质量分数)

Table 2 Proportioning scheme of tailing and sintering raw material %

2) 转鼓强度检测方法。采用GB 8209—87进行烧结矿机械强度测定。根据提供的烧结矿试样,按实际的粒度组成,分40~25,25~16和16~10 mm 3个粒级配制转鼓试样。取矿石试样(7.50±0.05) kg放入转鼓内,以25 r/min的转速转动200转,然后将试料用机械摇筛分级,机械摇筛筛孔为6.3 mm×6.3 mm,反复次数为20次/min,筛分时间为1.5 min共往复30次。

3) 还原性检测方法。按照GB/T 13241—91进行还原实验。称取10~12.5 mm矿石试样(500±1) g,在900 ℃条件下还原,还原时间为180 min,在整个实验期间还原炉温度保持在(900±10) ℃之间。还原性气体的标准流量保持在(15±1) L/min,还原气体成分是CO体积分数为30%±0.5%,N2体积分数为70%±0.5%。利用减重法测定铁矿石还原度RI,取双试样的平均值,极差的绝对值不超过5%。

4) 低温还原粉化性检测方法。按照GB/T 13242—91方法测定添加垃圾飞灰后烧结矿低温还原粉化性。称取10.0~12.5 mm烧结矿试样(500±1) g,实验在(500±10) ℃下还原,还原时间为60 min,还原气体的标准流量为(15±1) L/min,还原气体的成分保持CO体积分数为20%±0.5%,N2体积分数为60%±0.5%。把还原后的试样全部装入转鼓(直径×长度为130 mm×200 mm)内进行检验,该转鼓内有2个高20 mm的挡板,以30 r/min的速度旋转10 min,将转后的试样进行筛分,以粒径大于6.3 mm,大于3.15 mm和小于0.5 mm级质量与还原后入转鼓试样总质量之比作为评价标准。

5) 熔滴性能检测方法。试样粒度为10.0~12.5 mm,质量约为200 g,上焦炭质量为15 g,下焦炭质量为20 g,荷重为1.0 kg/cm2;气体流量为15 L/min,还原气体成分中CO与N2的体积分数比φ(CO)/φ(N2) =30/70;升温步骤为:小于900 ℃时,升温速度为10 ℃/min,900 ℃时恒温60 min,大于900 ℃时,升温速度为5 ℃/min;在400 ℃以下,通N2保护试样,400 ℃时通还原气体。

2 结果与讨论

2.1 添加尾渣烧结矿化学成分分析

各方案烧结矿成分检测结果如表3所示。由表3可以看出:在烧结矿碱度R约为2时,随着尾渣配入量的增加,烧结矿中SiO2和CaO质量分数分别由5.02%和10.03%增加到6.14%和12.23%,P质量分数从0.10%增加到0.14%。尾料中铁含量低,硅含量高,随着尾渣的配入量增加,使得烧结原料中铁含量降低,从而使烧结矿TFe大幅降低。

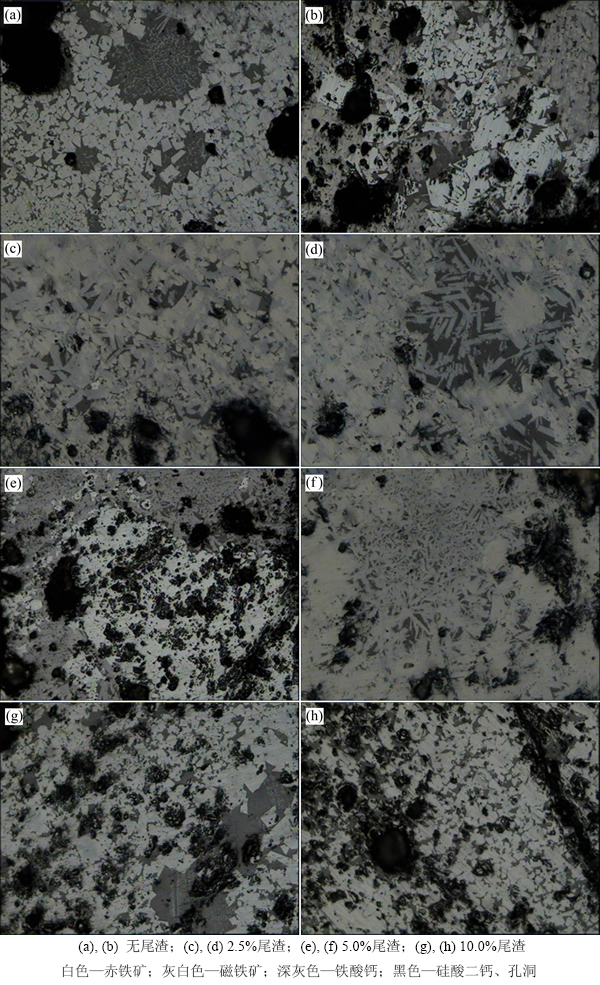

图3所示为配入不同比例尾渣后成品烧结矿矿相图。由图3可知:未添加尾渣的烧结矿(见图3(a)和3(b))主要为斑状结构,主要物相为赤铁矿、磁铁矿、硅酸二钙,铁酸钙含量较少,主要以斑状形式存在。磁铁矿主要以自形晶、半自形晶形态存在,主要与硅酸二钙形成斑状结构。当烧结矿中配入2.5%的尾渣时(见图3(c)和3(d)),主要物相为磁铁矿、硅酸二钙和铁酸钙,且铁酸钙含量较图3(a)和3(b)中的有所增加,且主要以板条状形式存在。当尾渣配入比例进一步增加到5.0%时(见图3(e)和3(f)),铁酸钙含量进一步增加,以强度及还原性较好的针状形式存在,并与磁铁矿形成交织的熔蚀结构,具有较大的强度。当尾渣配入比例为10.0%时(见图3(g)和3(h)),烧结矿中铁酸钙含量减少,几乎没有发现针状铁酸钙,而磁铁矿含量增加,形成致密的显微结构,使得烧结矿强度及还原性降低。当尾渣配入比例为10.0%时,烧结矿中MgO质量分数高达3.03%,由于 Mg2+和 Fe2+的离子半径比较接近,Mg2+容易进入磁铁矿晶格,赋存在磁铁矿中形成镁尖晶石[(Fe, Mg)O·Fe2O3],可稳定磁铁矿晶格,使得磁铁矿氧化为赤铁矿的反应受阻,因而烧结矿中磁铁矿含量增大;同时,由于赤铁矿生成受阻抑制铁酸钙的生成[12],使得铁酸钙含量减少,烧结强度降低。

表3 添加尾渣烧结矿化学成分分析(质量分数)

Table 3 Chemical composition analysis of sinter adding with tailings %

图3 烧结矿矿相图

Fig. 3 Mineral phase images of sintering

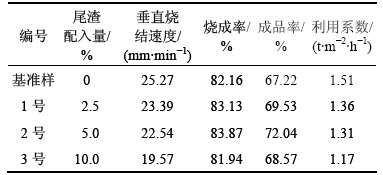

2.2 烧结过程技术经济指标及机械性能

表4和图4所示分别为不同尾渣配比下烧结过程中主要经济指标及烧结矿机械强度。由表4可以看出:随着尾渣配入量逐渐增加,垂直烧结速度与烧结利用系数逐渐减小,而烧成率及成品率在尾渣配入量为2.5%和5.0%时逐渐上升,之后开始下降。这是由于尾渣的软化温度较低,生成的液相多,高温燃烧带变宽, 料层透气性下降,抽风阻力加大,使垂直烧结速度降低,垂直烧结速度下降,最终导致利用系数下降。而且随着尾渣配入量的增加,烧结矿中Al2O3和MgO质量分数增加,Al2O3和MgO都是高熔点物质,降低了料层过热度,提高了液相黏度,影响黏结效果[13-14],在烧结过程中使透气性变差,从而降低烧结速度与利用系数。由图3可知:烧结原料中尾渣配入比例过高,则会导致烧结矿中铁酸钙质量分数减少,烧结矿强度降低,从而导致烧结成品率下降。

表4 不同尾渣配比下烧结杯实验结果

Table 4 Results of sinter pot test with different tailing contents

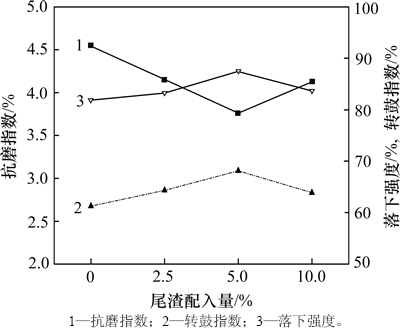

由图4可知:烧结矿的落下强度及转鼓强度在尾渣的配入量为5.0%以内,分别从81.82%和61.27%上升至87.46%和68.13%,但当尾渣配入比例增加到10%时,落下强度、转鼓强度均下降较为明显。因此,烧结原料中尾渣配入比例大于5.0%时,烧结矿产量、质量指标大幅度下降,不利于烧结矿的生产。其原因是尾渣软化温度低且含有一定量的FeO,配加尾渣有利于液相的提前形成,并且形成的液相增多,使得烧结高温区加厚,有利于液相扩散和再结晶,从而提高烧结矿强度。而且液相的增多,会提高铁相和胶结相结晶程度,减少玻璃质的产生,改变矿相结构,烧结矿中强度较好的针状铁酸钙质量分数增加,使得烧结矿强度得到改善。但尾渣配入10.0%后,烧结矿中MgO质量分数增加到3.03%,使得磁铁矿氧化为赤铁矿的反应受阻,因而烧结矿中强度较低磁铁矿质量分数增大;同时,由于赤铁矿生成受阻抑制铁酸钙的生成,使得铁酸钙含量减少,烧结强度降低。这与配加不同比例尾渣后,烧结矿显微结构分析结果一致。

2.3 添加尾渣烧结矿的冶金性能分析

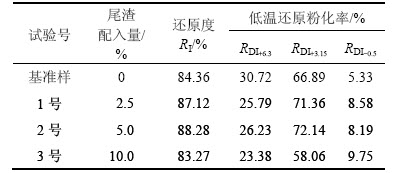

表5所示为不同尾渣配比下烧结矿的还原度及低温还原粉化性检测结果。由表5可知:当尾渣配入少于5.0%时,烧结矿还原度RI随着尾渣配入量增加逐渐升高,从84.36%上升至88.28%。但当尾渣配入量为10.0%时,还原度下降至83.27%。

图4 烧结矿机械强度测试结果

Fig. 4 Mechanical strength test of sintering ore

随着尾渣的加入量增加,烧结矿低温粉化率RDI+3.15呈现先增大后减小的趋势。当配入比例小于5.0%时,RDI+3.15上升至72.14%。但当尾渣配入量进一步增加至10.0%时,RDI+3.15则大幅下降至58.06%。这是由于在加入尾渣过程中,烧结矿的FeO和MgO质量分数增加,可抑制Fe3O4在冷却过程中在氧化成Fe2O3,减少Fe2O3质量分数,抑制了还原过程中赤铁矿晶形转变造成的粉化,从而使烧结矿RDI+3.15增大。当尾渣添加比例为10.0%,烧结矿中Al2O3质量分数为3.31%,Al2O3质量分数高将会生成大量的铝酸钙和铁酸钙的固溶体。许多学者认为赤铁矿中的Al2O3固熔体是造成还原粉化的主要因素[15-16],Al2O3可成倍地集中于玻璃质黏结相内,造成玻璃韧性大大降低,从而导致烧结矿的低温还性能恶化。

表5 烧结矿还原性测定结果

Table 5 Reducibility test of sintering ore

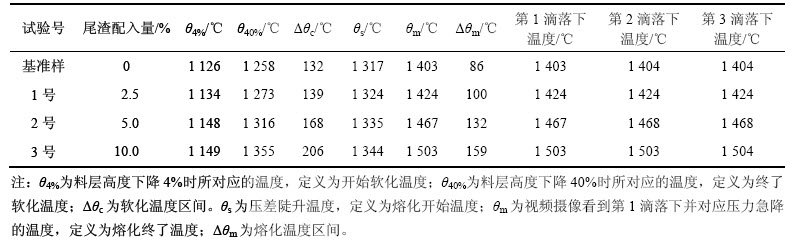

表6所示为添加尾渣烧结矿熔滴性能测定结果。由表6可知:烧结矿中配加尾渣量后,烧结矿的开始软化温度及熔化温度均变化不大,为1 126~1 149 ℃。

表6 添加尾渣烧结矿熔滴性能测定结果

Table 6 Melt-dropping property test of sintering ore

但烧结矿完全熔化及液相自由流动温度升高较为明显,导致软熔区间扩大,软化区间从132 ℃上升至 206 ℃。其原因是随着尾渣配入量增加,烧结矿中Al2O3和MgO质量分数增加,烧结矿中Al2O3和MgO含量提高会形成一些高熔点物质,同时烧结矿中Al2O3增高会增加液相表面张力,增大液相黏度,使得烧结矿完全熔化温度升高,增大烧结矿的软熔区间,恶化烧结矿的软熔性能。

2.4 烧结熔剂使用量及尾渣适宜配比分析

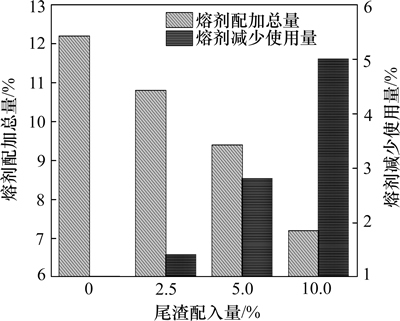

图5所示为不同尾渣配比时,石灰石、生石灰、白云石等烧结熔剂需要配入总量及熔剂减少使用量图。

图5 配加尾渣后烧结熔剂使用情况

Fig. 5 Usage of sintered flux added tailings

由图5可知:烧结矿中配入一定量尾渣后,可以减少生石灰、石灰石、白云石等烧结熔剂的使用量。并且随着尾渣配入量的增加,烧结熔剂使用量逐渐减少。当配入5.0%和10.0%的尾渣时,与未添加尾渣相比,烧结熔剂配加总量分别减少了2.8%和5.0%。因此,烧结中使用尾渣代替部分烧结熔剂有利于减少烧结熔剂的使用量,降低烧结成本。

但尾渣比例配加过高,使得烧结矿中Al2O3和MgO等质量分数偏高,虽然可以强化烧结矿强度,但会恶化烧结矿还原粉化性,增大软熔区间,不利于高炉的顺行。且尾渣比例配加过高,会增加烧结矿中P含量,烧结及炼铁工序中无法脱除P,P基本上全部进入铁水中,将会增加炼钢工序中脱P负担。同时,尾渣比例配加过高,会降低烧结矿品位,反而增加焦比与高炉生产成本。因此,尾渣在烧结过程中需配入合理的比例,才能保证改善烧结矿冶金性能的同时,提高资源利用率。

3 结论

1) 烧结中配入尾渣使得铁酸钙含量的增多,有利于强度与还原性较好的针状铁酸钙生成。但尾渣添加量过高时,铁酸钙质量分数则逐渐降低,磁铁矿质量分数增加,使得烧结矿强度及还原性变低。

2) 随着烧结矿中尾渣配入量的增加,烧结矿的落下强度、转鼓强度、烧结矿的烧成率、成品率、还原度RI、烧结矿低温粉化率RDI+3.15均呈现先增大后减小的趋势,当尾渣配入量为5.0%时达到最大。而垂直烧结速度与烧结利用系数则一直降低。

3) 随着尾渣配入量的增加,烧结矿的开始软熔温度变化不大,但烧结矿完全熔化及液相自由流动温度升高较为明显,导致软熔区间扩大,使得烧结矿软熔性能变差。

4) 使用尾渣代替部分烧结熔剂,有利于减少熔剂使用量,降低烧结成本。但尾渣比例配加过高,使得烧结矿中Al2O3,MgO和P等质量分数偏高,恶化烧结矿还原粉化性,增大软熔区间,不利于高炉的顺行。因此,烧结矿中尾渣配入量应不大于5.0%。

参考文献:

[1] 程绪想, 杨全兵. 钢渣的综合利用[J]. 粉煤灰综合利用, 2010(5): 45-49.

CHEN Xuxiang, YANG Quanbing. The comprehensive utilization of steel slag[J]. Fly Ash Comprehensive Utilization, 2010(5): 45-49.

[2] 于先坤, 杨洪, 华绍广. 冶金固废资源化利用现状及发展[J]. 金属矿山, 2015(2): 117-180.

YU Xiankun, YANG Hong, HUA Shaoguang. The utilization and development status of metallurgical solid waste resource[J]. Metal Mine, 2015(2): 117-180.

[3] 张朝晖, 廖杰龙, 巨建涛, 等. 钢渣处理工艺与国内外钢渣利用技术[J]. 钢铁研究学报, 2013, 25(7): 1-4.

ZHANG Zhaohui, LIAO Jielong, JU Jiantao, et al. Treatment process and utilization technology of steel slag in China and abroad[J]. Journal of Iron and Steel Research, 2013, 25(7): 1-4.

[4] 郭家林, 赵俊学, 黄敏. 钢渣综合利用技术综述及建议[J]. 中国冶金, 2009, 19(2): 35-38.

GUO Jialin, ZHAO Junxue, HUANG Min. Technical summary and suggestions of comprehensive utilization of steel slag[J]. China Metallurgy, 2009, 19(2): 35-38.

[5] 姜学东, 魏积义. 磁选尾渣混凝土路面砖的试验研究[J]. 沈阳建筑工程学院学报, 1994, 10(2): 175-178.

JIANG Xuedong, WEI Jiyi. Experimental study on magnetic separation tailings concrete road brick[J]. Journal of Shenyang Architectural and Civil Engineering Institute, 1994, 10(2): 175-178.

[6] 倪文, 李颖, 胡文, 等. 钢尾渣综合利用的两种新途径[J]. 矿物学报, 2012(S1): 13-15.

NI Wen, LI Yi, HU Wen, et al. Two new ways of comprehensive utilization of steel tailing slag[J]. Acta Mineralogica Sinica, 2012(S1): 13-15.

[7] 孙继红, 徐明君. 磁选尾渣基础砖的试验研究[J]. 辽宁建材, 2000(2): 36-37.

SUN Jihong, XU Mingjun. Experimental study on the slag base brick of magnetic separation tailings[J].Liaoning Building Materials, 2000(2): 36-37.

[8] 方宏辉, 朱书景. 钢渣尾泥配制胶结材的试验研究[J]. 河南建材, 2009(5): 54-56.

FANG Honghui, ZHU Shujing. Experimental study on the preparation of cemented material from slag tailings sludge[J]. Henan Building Materials, 2009(5): 54-56.

[9] 杨淇, 连芳, 文天阳, 等. 利用钢渣尾渣制备耐火喷涂料的试验研究[J]. 矿物学报, 2012(S1): 194-195.

YANG Qi, LIAN Fang, WEN Tianyang, et al. Experimental study on the preparation of fire resistance spray paint by tailing slag[J]. Acta Mineralogica Sinica, 2012(S1): 194-195.

[10] BOLUKBASI O S, TUFAN B. Steelmaking slag beneficiation by magnetic separator and impacts on sinter quality[J]. Science of Sintering, 2014, 46(3): 331-334.

[11] MUMCU A, ARISOY C, SESEN M K. The effects of basic oxygen furnace (BOF) slag at utilization in sinter production[C]// 1st National Iron and Steel Symposium and Exhibition. Zonguldak, 2001: 3-5.

[12] 范晓慧, 李文琦, 甘敏, 等. MgO 对高碱度烧结矿强度的影响及机理[J]. 中南大学学报(自然科学版), 2012, 43(9): 3325-3330.

FAN Xiaohui, LI Wenqi, GAN Min, et al. Influence and mechanism of MgO on strength of high basicity sinter[J]. Journal of Central South University (Science and Technology), 2012, 43(9): 3325-3330.

[13] WU S L, KASSI E, OMORI Y. Influence of property of adhering layers on bonding strength of granules after sintering[J]. ISIJ International, 1989(2): 961-967.

[14] 吴胜利, 韩宏亮, 姜伟忠, 等. 烧结矿中MgO作用机理[J]. 北京科技大学学报, 2009, 31(4): 428-432.

WU Shengli, HAN Hongliang, JIANG Weizhong, et al. MgO interaction mechanism in sinter[J]. Journal of University of Science and Technology Beijing, 2009, 31(4): 428-432.

[15] 于文涛, 左海滨, 张建良, 等. 高Al2O3烧结矿冶金性能研究[C]// 第九届中国钢铁年会论文集. 北京: 冶金工业出版社, 2013: 1-5.

YU Wentao, ZUO Haibin, ZHANG Jianliang, et al. Study on metallurgical properties of high Al2O3 sinter[C]// The 9th China Steel conference Proceedings. Beijing: Metallurgy Industry Press, 2013: 1-5.

[16] LU L, HOMES R J, MANUEL J R. Effects of alumina on sintering performance of hematite iron ores[J]. ISIJ International, 2007, 47(3): 349-358.

(编辑 杨幼平)

收稿日期:2016-01-27;修回日期:2016-03-16

基金项目(Foundation item):重庆市应用开发计划项目(cstc2014yykfB100007);中央高校基本科研业务费专项资金资助项目(106112015CDJXY130016) (Project(cstc2014yykfB100007) supported by Chongqing Application and Development Project; Project (106112015CDJXY130016) supported by the Fundamental Research Funds for the Central Universities)

通信作者:任山,博士,从事高炉炼铁、资源综合利用和冶金环保方面研究;E-mail: shan.ren@cqu.edu.cn