文章编号:1004-0609(2016)-10-2110-08

半固态等温处理Ti48Zr18V12Cu5Be17非晶合金的显微组织演变

郭洪民1, 2,王 程1,温飞马1,杨湘杰2,章爱生2

(1. 南昌大学 材料科学与工程学院,南昌 330031;

2. 南昌大学 江西省高性能精确成形重点实验室,南昌 330031)

摘 要:采用水冷铜模吸铸法制备内生β-Ti晶体相增塑Ti48Zr18V12Cu5Be17块体非晶复合材料,研究该材料在半固态温度区间的显微组织演变及其动力学。结果表明:水冷铜模吸铸的铸态组织和半固态等温处理后的水淬组织均由β-Ti晶体相和基体非晶相组成。半固态等温处理温度和保温时间决定着β-Ti相的最终形态,提高等温处理温度将提高β-Ti相的演变速度。β-Ti相晶粒尺寸D3和保温时间t存在线性关系,生长动力学因子K=3.6 μm3/s,β-Ti相的球化过程是由溶质元素扩散控制的粗化行为。

关键词:非晶基复合材料;半固态;水冷铜模;显微组织

中图分类号:TG146.1;TG249.9 文献标志码:A

块体非晶材料因具有独特的结构和优异的性能,在机械、电子、化工、运动器材乃至国防军事上显示出广泛的应用前景[1]。块体非晶材料的强度基本接近于理论强度,但高度局域化的剪切行为使得绝大部分块体非晶在没有明显室温宏观塑性变形的情况下,以突然失效的方式发生断裂,这严重地制约着该类材料作为先进结构材料在工程中的应用[1-3]。目前提高块体非晶材料室温塑性的主要思路是开发非晶复合材料,即在非晶基体中引入第二相。在诸多方法中,通过成分调节和控制凝固使得合金熔体在冷却时先析出塑性晶体相,在后继冷却过程中剩余熔体形成非晶基体相的方法制备的内生晶体相增塑的块体非晶复合材料是目前备受关注的焦点。

目前,内生晶体相增塑的非晶基复合材料都是通过水淬、电弧熔炼喷铸和电弧熔炼吸铸等方法制备[4]。这些方法属于极端冷却,沿棒状试样径向的冷却速率不可控制,使得样品的表层冷却速率高,芯部冷却速率低,表层非晶含量高而芯部晶体含量高。近期,乔珺威等[5]利用Bridgman定向凝固技术在制备锆基内生晶体相增塑非晶体复合材料方面取得了很大成功,有效改善内生晶体在试样断面的分布。但上述方法只能制备坯锭,不能用于成形复杂零件。半固态成形是21世纪最具发展前景的材料精密成形技术之一[6-7],在控制凝固过程中先析出相的形态、尺寸和分布具有独特的优势,2009年以“非晶合金材料与物理”为主题的第347次香山科学会议将“非晶复合材料的半固态成形技术”列为块体非晶材料加工成形过程的关键技术问题之一[8]。

陈光等[9]将制备的Zr56.2Ti13.8Nb5.0Cu6.9Ni5.6Be12.5复合材料重新加热到液固两相区进行保温处理,调控复合材料的组织形态和分布,水淬后获得的复合材料的室温压缩屈服强度和断裂塑性应变分别达到了1325 MPa和12.0%,与未经调控的复合材料相比,分别提高了13%和20%。JOHNSON研究组[10-12]采用类似的液固两相区等温处理工艺对Zr-Ti- Ni-Cu-Be系和Ti-Zr-V-Cu-Be系块体非晶复合材料进行成分和组织调控,系统研究了室温力学性能、变形和断裂行为。以Ti57.3Zr26.4V9.8Cu4.9Be1.6为例[11]:晶体第二相体积分数60%、密度5.03 g/cm3、屈服强度1068 MPa、断裂强度1098 MPa、屈服应变2.1%、总应变9.8%、弹性模量83.7 GPa、剪切模量30.4 GPa、断裂韧性61.6 MPa/m2、泊松比0.377,体现了强度、塑性和断裂韧性的较好结合。MAKAYA等[13]在解决预制坯锭质量方面进行了探索,采用半固成形中的冷却斜坡法制备预制坯锭,但合金凝固时间极短,半固态金属的黏度非常高,在吸铸条件下无法完成充型,仅获得了尺寸很小的样品。最新成果[14-16]标志着半固态成形所用的合金从铝合金、镁合金、钛合金和黑色金属等真正地扩展到块体非晶材料。

综合上述分析,通过引入晶体相以形成块体非晶复合材料是解决非晶材料室温脆性的有效方法,而利用块体非晶复合材料在液固两相区的黏塑流变实现近净成形是解决块体非晶材料成形的新途径。半固态成形非晶复合材料的优点体现在:1) 液固两相区等温处理可有效控制溶质扩散、液固界面形貌、熔体成分与结构均匀化;2) 成形温度低,延长成形模具寿命,降低凝固收缩和内应力;3) 具有黏塑性的半固态金属在高压下具有很强的流动性,有望实现成形复杂零件。但非晶复合材料半固态成形的研究才刚刚起步,与之相关的基础研究尚未展开。本文作者重点研究β-Ti增塑Ti48Zr18V12Cu5Be17复合材料在半固态温度区间的显微组织演变及β-Ti晶体相的生长动力学。

1 实验

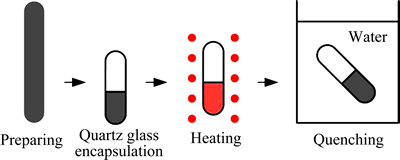

本文提出的半固态等温处理主要包括Ti48Zr18- V12Cu5Be17非晶基复合材料制备、石英管真空密封、等温处理和水淬4个步骤,如图1所示。选用Ti(99.5%)、Zr(99.6%)、V(99.9%)、Cu(99.99%)、Be(99.9%)纯金属组元,按照Ti48Zr18V12Cu5Be17的摩尔比进行配比,用非自耗真空炉并在高纯Ar保护下熔炼母合金纽扣锭,反复熔炼5次使合金成分均匀。将母合金锭机械打磨和超声波清洗后置于铜模坩埚内,抽真空至1×10-4 Pa后再充入高纯Ar至0.05 MPa,采用水冷铜模吸铸制备d 3 mm×100 mm的内生β-Ti增塑的块体非晶基复合材料试样。将试样打磨并切割成长度为6 mm高的圆柱体,封装在d 3 mm的石英管中,并抽真空至4×10-3~5×10-3 Pa 。将石英管放入已经加热至半固态处理温度的电阻炉内,保温预定时间后将石英管投入水中水淬。半固态等温处理温度选为760、800、860和900 ℃,保温时间选为1、3、5、10、20、30和40 min。

图1 半固态等温处理流程

Fig. 1 Procedure of isothermal holding process at semi-solid stage

水冷铜模吸铸和半固态等温处理制得的样品采用D8 Advance型X射线衍射仪(XRD,Cu Kα)进行相标定。通过配有能谱分析的Qaunta200F型扫描电镜(SEM)进行相成分分析。显微组织的观察采用Olymbus BX -51型光学显微镜完成,腐蚀剂为4%氢氟酸水溶液。采用图像分析软件Image-Pro Plus 6.0定量分析β-Ti相的体积分数φ、等效晶粒尺寸D和形状因子SF,分别采用式(1)、(2)和(3)计算:

(1)

(1)

(2)

(2)

(3)

(3)

式中:Ai为第i个晶粒的面积;Pi为第i个晶粒的周长;A为视场面积;N为待测晶粒数目。

2 结果与讨论

2.1 铸态显微组织结构

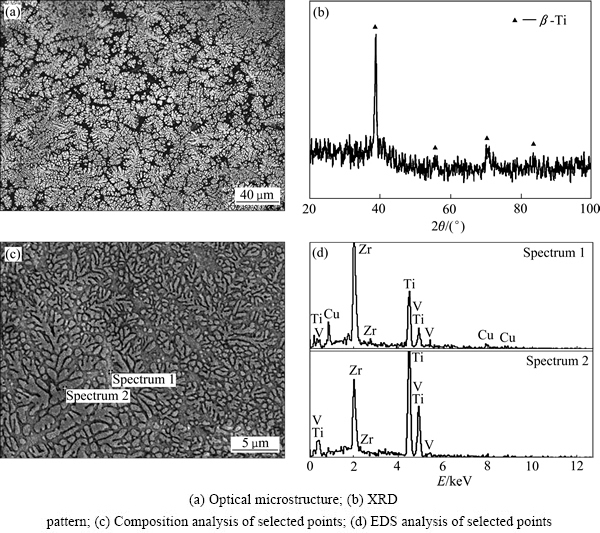

图2(a)所示为水冷铜模吸铸的Ti48Zr18V12Cu5Be17合金铸态显微组织,图2(b)所示为试样的XRD谱。可以看出衍射谱为漫散峰上叠加有晶体相的衍射峰,对应着BCC β-Ti相,表明显微组织由非晶基体和β-Ti固溶体两相组成。能谱分析给出β-Ti相的成分为Ti59Zr23V18,非晶基体的主要成分为Zr50Ti40V7Cu3,如图2(c)和(d)所示。

光学显微组织表明BCC β-Ti晶体相呈发达的树枝晶较均匀地分布在非晶基体上,测得树枝晶的一次臂轴的长度为30~78 μm,平均等效晶粒尺寸为33 μm,β-Ti相体积分数约为61%。高熔点的V对Ti48Zr18V12Cu5Be17合金铸态显微组织的形成主要起到两方面的作用:一方面促使β-Ti相形成并使其稳定;另一方面使得剩余液相中的原子扩散困难,加强非晶基体的形成能力。在凝固过程中,主元素Ti和Zr以及稳定性元素V在较高的温度下以固溶体的形式在合金溶体中形核并以树枝状生长,形成较细小的树枝晶,而剩余的合金溶体形成非晶基体。

图2 Ti48Zr18V12Cu5Be17合金铸造态显微组织

Fig. 2 As-cast microstructures of Ti48Zr18V12Cu5Be17 alloy produced by copper mould suction

2.2 半固态等温处理对Ti48Zr18V12Cu5Be17合金显微组织结构的影响

2.2.1 半固态等温处理温度的影响

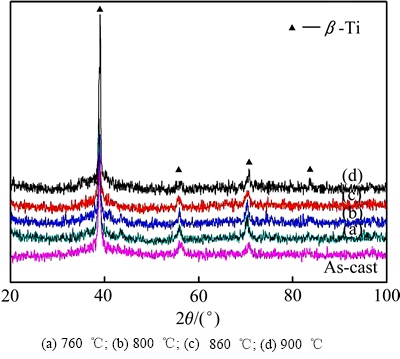

图3所示为Ti48Zr18V12Cu5Be17合金在760、800、860和900 ℃下半固态等温处理30 min水淬试样的XRD谱,均显示为具有典型非晶特征的漫散射峰上叠加着对应于晶体相的尖锐衍射峰,没有发现明显对应于其他晶体相的衍射峰。

图3 不同半固态等温处理温度下Ti48Zr18V12Cu5Be17合金的XRD谱

Fig. 3 XRD patterns of Ti48Zr18V12Cu5Be17 alloy which were as-cast and remelted to semi-solid stage and isothermally held for 30 min at different temperatures

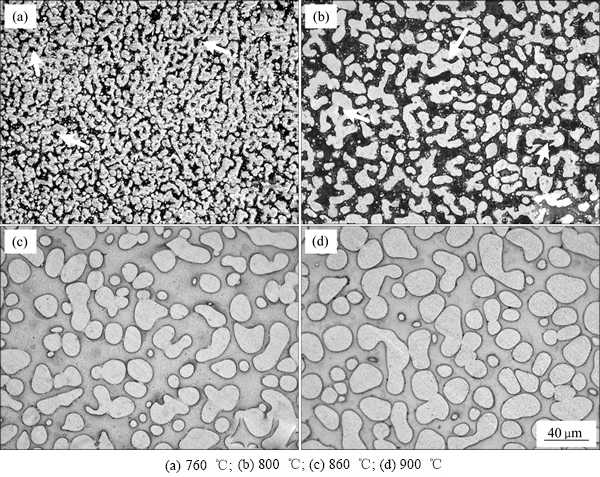

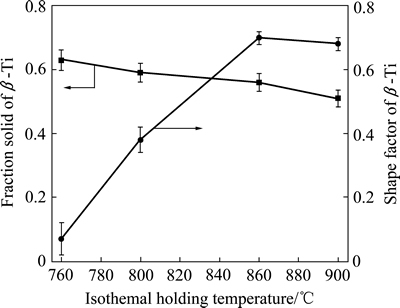

图4显示了半固态等温处理温度对Ti48Zr18V12- Cu5Be17合金显微组织的影响,图5所示为定量分析结果。表明本实验设计的半固态等温处理温度对复合材料的相组成没有影响,水淬试样具有β-Ti相和非晶基体两相显微组织,但严重影响着β-Ti相的晶粒形态。760 ℃保温30 min时,铸态条件下的β-Ti晶体相的二次树枝晶臂已经消失,在合并粗化的二次枝晶臂间形成液相的小岛(如图4(a)中箭头所示),并且部分β-Ti相晶粒彼此相连。处理温度升高到800 ℃时,β-Ti相树枝晶已经转变为不太圆整的颗粒状晶粒,晶粒中夹裹着较多的液相,如图4(b)所示。随着处理温度继续升高,β-Ti相晶粒更为圆整,晶粒内无夹裹的液相,但晶粒明显粗化。定量分析结果表明等温处理温度由760 ℃升高到900 ℃,β-Ti相的体积分数降低,形状因子由0.07增加到0.68,如图5所示。提高处理温度可以提高β-Ti晶体相的球化速度,在760 ℃或800 ℃下保温处理,即使等温处理40 min,β-Ti相树枝晶组织也不可能完全转变成完全理想的球形,而在860 ℃保温处理,仅需要3 min球化过程已经完成(见图6(b))。上述结果表明,对于Ti48Zr18V12Cu5Be17合金,最佳的半固态等温处理温度约为860 ℃左右。

图4 半固态等温处理温度对Ti48Zr18V12Cu5Be17合金显微组织的影响

Fig. 4 Evolved microstructures produced after remelting and isothermal holding for 30 min at different temperatures

图5 半固态等温处理温度对Ti48Zr18V12Cu5Be17合金β-Ti相的形态与体积分数的影响

Fig. 5 Effects of isothermal holding temperature on shape factor and fraction solid of β-Ti phase of Ti48Zr18V12Cu5Be17 alloy

2.2.2 半固态等温处理时间的影响

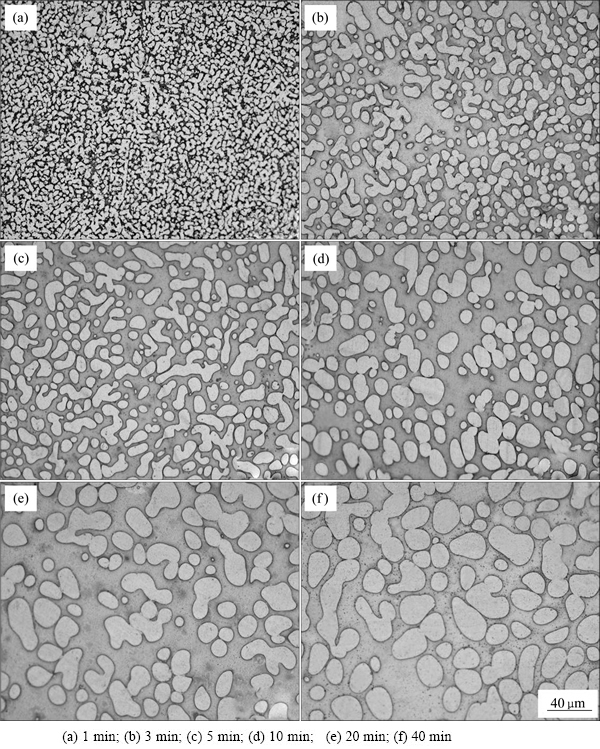

图6所示为Ti48Zr18V12Cu5Be17合金在860 ℃半固态等温处理不同时间水淬后的显微组织,展示了β-Ti晶体相的演变过程。在860 ℃保温1 min后,β-Ti相树枝晶的二次臂明显粗化,树枝状形态已经不明显,大部分二次枝晶臂已经熔断,如图6(a)所示。当保温时间延长至3 min,树枝状晶粒全部消失,β-Ti相晶粒已经演变成近球形颗粒,如图6(b)所示。当保温时间超过3 min后,β-Ti相的晶粒形状进一步向球形演变,并且随着保温时间的延长,细小的球形颗粒逐渐消失,粗大的球形颗粒进一步长大。与低温等温处理相比较(见图4(a)和图4(b)),860 ℃等温处理时,在β-Ti晶体相的演变过程中,β-Ti相的晶粒中未发现夹裹的液相。

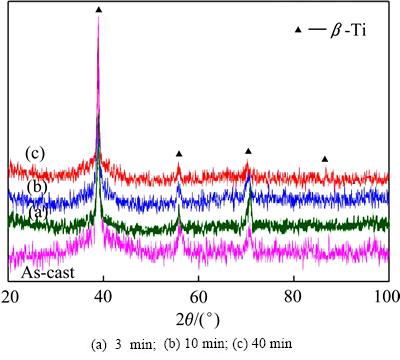

图7所示为Ti48Zr18V12Cu5Be17合金在860 ℃下半固态等温处理3、10和40 mim水淬试样的XRD谱,表明不同保温时间后水淬试样均由β-Ti晶体相和非晶基体相组成。采用式(1)的定量金相分析表明,860 ℃保温1 min后β-Ti相的体积分数为60%,保温3 min后体积分数为56%,保温时间进一步增加后,β-Ti相的体积分数基本保持不变,表明此时体系达到平衡状态。

图6 860 ℃半固态等温处理条件下β-Ti晶体相的演变

Fig. 6 Evolution of β-Ti phase during isothermal holding at 860 ℃ for different time

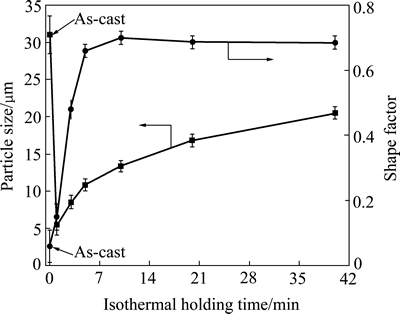

图8所示为β-Ti相的形状因子和平均等效晶粒尺寸与保温时间的关系。860 ℃保温1 min后,β-Ti相晶粒尺寸急剧减小,说明在此保温阶段树枝晶的二次枝晶臂发生断裂。之后随着保温时间的延长,形状因子和晶粒尺寸迅速增加,保温时间超过5 min后,增加趋势变得平缓。

2.3 半固态等温处理生长动力学

图7 Ti48Zr18V12Cu5Be17合金在860 ℃保温不同时间下的XRD谱

Fig. 7 XRD patterns of Ti48Zr18V12Cu5Be17 as-cast and isothermally held at 860 ℃ for different time

图8 半固态等温处理时间对β-Ti相形态和晶粒尺寸的影响

Fig. 8 Effects of isothermal holding time interval on shape factor and particle size of β-Ti phase

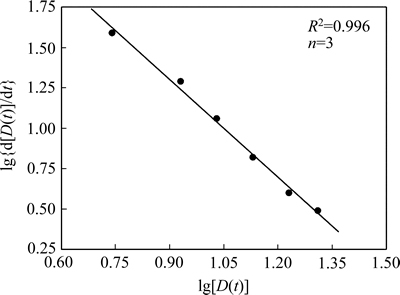

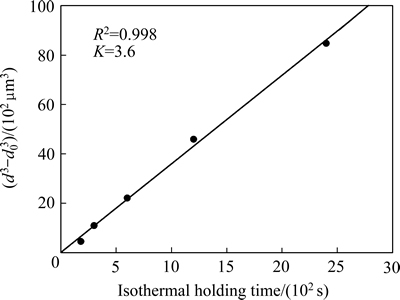

在半固态温度区间,晶体相球化是由界面能驱动的自发过程[17]。学者们已经详细研究了铝合金和镁合金在半固态温度区间的显微组织演变和相关机理[18-21]。根据晶粒尺寸与保温时间之间的抛物线关系一般表达式,半固态等温处理生长动力学可以用式(4)描述:

(4)

(4)

式中:D0为初始晶粒尺寸;n为晶粒生长指数; K生长动力学因子;t为保温时间。将式(4)对时间进行求导,并对等式两边取对数,整理后得到式(5):

(5)

(5)

以图6和图8的定量分析结果为基础,根据式(5)绘制图9,获得晶粒生长指数n=3。因此,在半固态温度区间Ti48Zr18V12Cu5Be17合金中β-Ti晶体相的生长行为满足LSW模型[22-24],即β-Ti晶体相的球化过程是由溶质元素扩散控制的粗化行为。根据式(4),将860 ℃下β-Ti晶体相晶粒直径D3和保温时间t进行线性回归。图10表明D3和t之间呈很好的线性关系,进一步说明半固态等温处理中β-Ti晶体相的粗化行为符合LSW模型。根据图10计算得到生长动力学因子K=3.6 μm3/s。

图9 Ti48Zr18V12Cu5Be17合金860 ℃半固态等温处理时晶粒生长指数n值求解图

Fig. 9 Calculation of n value in Ti48Zr18V12Cu5Be17 alloy isothermally held at 860 ℃

图10 保温时间和β-Ti相晶粒尺寸的立方之间的关系曲线

Fig. 10 Relationship between isothermal holding time interval and cubic particle size of β-Ti phase at isothermal holding temperature of 860 ℃

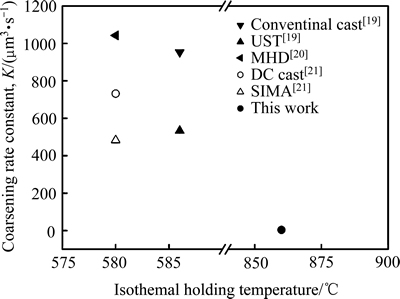

综合上述实验结果和讨论,与传统的铝合金和镁合金相比较,Ti48Zr18V12Cu5Be17合金在半固态温度区间的显微组织演变行为具有如下3个特点:1) 两者具有一致的显微组织演变机理,晶体相的球化过程均符合LSW模型;2) 初始阶段(0~3 min)演变速度快,如图8所示,而传统铝合金和镁合金在此阶段需要约10 min。主要原因在于铜模吸铸过程中冷却速度快,铸态显微组织细小;3) 生长动力学因子K非常小。对于传统铝合金和镁合金,K值的范围为500~1500 μm3/s,如图11所示。生长动力学因子是与扩散系数、界面能等材料热物理性能有关的速度量。为了获得较高的非晶形成能力,液态的非晶材料具有很高的黏度。可以预见,虽然均处于半固态温度区间,Ti48Zr18V12Cu5Be17合金具有更高的黏度,原子扩散速度更慢,具有小的K值。

图11 半固态等温处理条件下Al-Si合金与Ti48Zr18V12-Cu5Be17合金生长动力学因子数值比较

Fig. 11 Coarsening rate constant for Al-Si alloys in other studies and for Ti48Zr18V12Cu5Be17 alloy in this work

3 结论

1) 半固态等温处理对Ti48Zr18V12Cu5Be17非晶基复合材料的相组成没有影响。水冷铜模吸铸的铸态组织和半固态等温处理后的水淬组织均由β-Ti晶体相和基体非晶相组成。

2) 半固态等温处理温度和保温时间决定着β-Ti晶体相的最终形态,提高等温处理温度将提高β-Ti相的演变速度。对于Ti48Zr18V12Cu5Be17合金,最佳的半固态等温处理温度约为860 ℃。

3) 在半固态温度区间,Ti48Zr18V12Cu5Be17合金中β-Ti晶体相的生长行为满足LSW模型,与传统的铝合金和镁合金具有相同的显微组织演变机理,但前者在初始阶段(0~3 min)演变速度更快,并且具有更小数值的生长动力学因子。

REFERENCES

[1] 惠希东, 陈国良. 块体非晶合金[M]. 北京: 化学工业出版社, 2007.

HUI Xi-dong, CHEN Guo-liang. Bulk metallic glass alloys[M]. Beijing: Chemical Industry Press, 2007.

[2] LIU Y H, WANG G, WANGR J, ZHANO D Q, PAN M X, WANG W H. Super plastic bulk metallic glasses at room temperature[J]. Science, 2007, 315: 1385-1389.

[3] 汪卫华. 非晶态物质的本质和特性[J]. 物理学进展, 2015, 33: 177-351.

WANG Wei-hua. The nature and properties of amorphous matter[J]. Progress in Physics, 2015, 33: 177-351.

[4] HAYS C C, KIM C P, JONHSON W L. Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions[J]. Physical Review Letters, 2000, 84: 2901-2904.

[5] QIAO J W, WANG S, ZHANG Y, LIAW P K, CHEN G L. Large plasticity tensile necking of Zr-based bulck-metallic-glass-matrix composites synthesized by Bridgman solidification[J]. Applied Physics Letter, 2009, 94: 151905.

[6] 管仁国. 金属半固态成形理论与技术[M]. 北京: 冶金工业出版社, 2005.

GUAN Ren-guo. Theories and techniques of semi-solid metal processing[M]. Beijing: Metallurgical Industry Press, 2005.

[7] 毛卫民. 半固态金属成形技术[M]. 北京: 机械工业出版社, 2004.

MAO Wei-min. Semi-solid metal processing and technology[M]. Beijing: China Machine Press, 2004.

[8] 潘峰. 非晶合金孕育第三次材料革命[EB/OL]. [2009-11-12]. http://www.xssc.ac.cn/ConfRead.aspx?ItemID=1332.

PAN Feng. The third revolution of materials would be inoculated and cultivated by amorphous alloys[EB/OL]. [2009-11-12]. http://www.xssc.ac.cn/ConfRead.aspx?ItemID=1332.

[9] SUN G Y, CHEN G, CHEN G L. Comparison of microstructures and properties of Zr-based bulk metallic glass composites with dendritic and spherical BCC phase precipitates[J]. Intermetallic, 2007, 15: 632-634.

[10] HOFMANN D C, SUH J Y, WIEST A, DUAN G, LIND M L, DEMETRIOU M D, JOHNSON W L. Designing metallic glass matrix composites with high toughness and tensile ductility[J]. Nature, 2008, 451: 1085-1089.

[11] LAUNEY M E, HOFMANN D C, SUH J Y, KOZACHKOV H, JOHNSON W L, RITCHIE R O. Fracture toughness and crack-resistance curve behavior in metallic glass-matrix composites[J]. Applied Physics Letters, 2009, 94, 241910.

[12] HOFMANN D C, SUH J Y, WIEST A, JOHNSON W L. New processing possibilities for highly toughened metallic glass matrix composites with tensile ductility[J]. Scripta Materialia, 2008, 59: 684-687.

[13] MAKAYA A, TAMURA T, MIWA K. Cooling slope casting process for synthesis of bulk metallic glass based composites with semisolid structure[J]. Metallurgical and Materials Transactions A, 2010, 41: 1646-1657.

[14] HOFMANN D C, KOZACHKOV H, KHALIFA H E, SCHRAMM J P, DEMETRION M D, VECCHIO K S, JOHNSON W L. Semi-solid induction forging of metallic glass matrix composites[J]. JOM, 2009, 61: 11-17.

[15] HOFMANN D C, ROBERTS S N, KOZACHKOV H. Infrared thermal processing history of a Ti-based bulk metallic glass matrix composite manufactured via semi-solid forging[J]. Acta Materialia, 2015, 95: 192-200.

[16] INOUE A, KONG F L, ZHU S L, SHALAAN E, AL-MARZOUKI F M. Production methods of engineering glassy alloys and composites[J]. Intermetallics, 2015, 58: 20-30.

[17] MARSH S P, GLICKSMAN M E. Overview of geometric effects on coarsening of mushy zones[J]. Metallurtical Materials Transaction A, 1996, 27: 557-568.

[18] WANG H, DAVIDSON C J, STJOHN D H. Semisolid microstructure evolution of AlSi7Mg alloy during partial remelting[J]. Materials Science and Engineering A, 2004, 368: 159-157.

[19] KHALIFA W, TSUNEKAWA Y, OKUMIYA M. Effect of reheating to the semisolid state on the microstructure of the A356 aluminum alloy produced by ultrasonic melt-treatment[J]. Solid State Phenomena, 2008, 141/143: 499-504.

[20] ZOQUI E J, SHEHATA M T, PAES M, KAO V, ES-SADIQI E. Morphological evolution of SSM A356 during partial remelting[J]. Materials Science and Engineering A, 2002, 325: 38-53.

[21] LOUE W R, SUERY M. Microstructure evolution during partial remelting of Al-Si7Mg alloys[J]. Materials Science and Engineering A, 1995, 203: 1-13.

[22] LIFSHITZ I M, SLYOZOV V V. The kinetics of precipitation from supersaturated solid solutions[J]. Journal of Physics and Chemistry Solid, 1961, 11: 35-50.

[23] WAGNER C Z. Theory of precipitation change by redissolution[J]. Elektrochem, 1961, 65: 581-591.

[24] UMANTSEV A, OLSON G B. Ostwald ripening in multicomponent alloys[J]. Scripta Materialia, 1993, 29: 1135-1140.

Microstructure evolution of Ti48Zr18V12Cu5Be17 bulk metallic glass matrix composite during isothermal holding at semi-solid stage

GUO Hong-min1, 2, WANG Cheng1, WEN Fei-ma1, YANG Xiang-jie2, ZHANG Ai-sheng2

(1. School of Materials Science and Engineering, Nanchang University, Nanchang 330031, China;

2. Key Lab of Near-Net Forming in Jiangxi Province, Nanchang University, Nanchang 330031, China)

Abstract: The Ti48Zr18V12Cu5Be17 in-situ bulk metallic glass matrix composite (BMGC) was prepared by copper mould suction process, and the evolution of microstructure of this kind of Ti based BMGC at semi-solid stage was investigated. The results show that microstructures of billets, produced by copper mould suction and water quenching after isothermal holding at semi-solid stage, mainly contain β-Ti phase and glass matrix. Isothermal holding temperature and time interval determine the final morphology of β-Ti phase, and the increasing of isothermal holding temperature increases microstructure evolution rate. A linear relationship between the cube grain size of β-Ti phase and isothermal holding time is found, and the value of coarsening rate is 3.6 μm3/s.

Key words: metallic glass matrix composite; semi-solid state; copper mould suction; microstructure

Foundation item: Project(11364031) supported by the National Nature Science Foundation of China; Project (20122BCB23001) supported the Jiangxi Province Young Scientists Cultivating Programs, China; Project(20133ACB21003) supported by the Key Nature Science Foundation of Jiangxi Province, China; Project (212091) supported by the Key Foundation of Science and Technology of Ministry of Education, China

Received date: 2015-11-10; Accepted date: 2016-03-30

Corresponding author: GUO Hong-min; Tel: +86-18070387190; E-mail: guohongmin@ncu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(11364031);江西省青年科学家资助计划资助项目(20122BCB23001);江西省自然科学基金重点项目(20133ACB21003);教育部科技重点项目(212091)

收稿日期:2015-11-10;修订日期:2016-03-30

通信作者:郭洪民,教授,博士;电话:18070387190;E-mail: guohongmin@ncu.edu.cn