DOI:10.19476/j.ysxb.1004.0609.2018.08.04

等温热处理对Mg-7Zn-0.3V合金半固态组织演变的影响

黄晓锋1, 2,郭 峰1,张 玉1,杨健长1,马亚杰1,张乔乔1

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要:通过半固态等温热处理,研究保温温度和保温时间对Mg-7Zn-0.3V镁合金把固态组织演变的影响。结果表明:保温温度和保温时间对Mg-7Zn-0.3V非枝晶组织的演变有重要的影响。提高保温温度或是延长保温时间,可以使Mg-7Zn-0.3V中的非枝晶组织转变为更加细小且分布均匀的球状颗粒。当保温温度过高或是保温时间过长时,半固态颗粒会出现合并和长大,其主要的演变机制与Ostwald熟化规律相符合。Mg-7Zn-0.3V合金的最佳等温热处理工艺是:保温温度605 ℃,保温时间40 min,非枝晶颗粒的平均尺寸为48.5 μm,形状因子为1.26。

关键词:Mg-7Zn-0.3V镁合金;半固态等温处理;非枝晶组织;演变机理

文章编号:1004-0609(2018)-08-1516-07 中图分类号:TG146.2 文献标志码:A

被誉为21世纪的绿色环保结构材料的镁及镁合金,作为目前应用最轻的金属结构材料,由于镁与镁合金的比强度、比刚度高、电磁屏蔽的效果好、零件尺寸稳定性好以及容易回收和质量轻等的优点,在航空航天领域、汽车工业领域、通讯产品领域得到了广泛的应用[1-6]。但是,在传统技术加工下的镁合金铸件各方面的性能较低,因此,急需改善其加工技术,来提高镁合金的性能,使其在工业中有更为广泛的应用。与传统的压铸方法获得的镁合金容易产生欠铸、气孔、裂纹、缩孔缩松等缺陷相比,半固态成形技术具有节能高效,所需成形温度低且模具使用的寿命长,铸件组织的致密性好,铸件质量高等优点[7]。因此,半固态成形技术有着很好的应用前景。半固态成形工艺目前有流变成与触变成形两种工艺[8-9],在触变成形工艺步骤中,非枝晶组织的制备锭料的制备是半固态成形技术的关键[10-11]。由于V具有细化晶粒的作用[12],本文作者在Mg-Zn二元合金的基础上,添加第三种组元V,制备了Mg-7Zn-0.3V合金,并采用等温热处理的方法研究了保温温度与保温时间对Mg-7Zn-0.3V合金非枝晶组织演变的影响,以得到最佳的等温热处理工艺,以期为后续的半固态成形提供实验依据。

1 实验

本实验中采用原材料为纯Mg、Zn锭以及小块状的V(纯度>99.9%)来制备Mg-7Zn-0.3V镁合金。用SG2-7.5kW 井式电阻炉进行Mg-7Zn-0.3V镁合金的熔炼,采用RJ-2溶剂和Ar保护气氛进行熔炼过程的防氧化保护,在500℃时,Mg锭熔化后,于680 ℃时加入Zn,当温度升至780 ℃时,加入金属V。待温度降到730 ℃时进行精炼除渣,静置15~20 min,待温度降至720 ℃时浇注于预热至200 ℃的金属型模具内,对熔炼以后得到的Mg-7Zn-0.3V镁合金材料进行了化学成分分析,结果如表1所列。

表1 Mg-7Zn-0.3V镁合金的成分

Table 1 Composition of Mg-7Zn-0.3V experimental alloys

半固态非枝晶组织的制备实验在箱式电阻炉中进行,棒状试样的尺寸为d 15 mm×15 mm,在等温热处理后,迅速水淬,经金属抛光机预磨、抛光后,用8%的硝酸酒精(体积分数)进行腐蚀。使用MeF-3金相显微镜和JSM-6700F扫描电镜(SEM)观察其半固态组织。用X射线衍射仪(D/max-2400)进行物相分析,并且通过Image-Pro Plus软件分析其固相率、颗粒平均尺寸d0和形状因子f0,其所用计算公式[13]为d0= [∑2(A0/π)1/2]/n, f0=[∑P02/(4πA0)]/n,其中A0为颗粒面积;P0为颗粒周长;f0为形状因子,f0愈趋近于1,表明得到的固相颗粒越圆整。其中,棒状试样的获得如图1所示。

图1 棒状样品制备示意图

Fig. 1 Schematic diagram of preparation of rod-like sample (Unit: mm)

2 实验结果

2.1 铸态合金显微组织

图2所示为Mg-7Zn-0.3V镁合金的显微组织。结合XRD谱可知,Mg-7Zn-0.3V合金主要是由呈现白色的α-Mg基体和沿晶界分布呈黑色的共晶组织组成,共晶组织呈颗粒状与断絮状弥散地分布在基体中,且共晶组织分布的较为均匀,没有出现明显的团聚现象,经计算,铸态Mg-7Zn-0.3V镁合金的平均晶粒尺寸为178 μm。黑色共晶组织主要是由Mg102.08Zn39.60和Mg7Zn3构成。

2.2 半固态非枝晶组织

2.2.1 保温温度对半固态非枝晶组织的影响

图2 Mg-7Zn-0.3V合金铸态显微组织

Fig. 2 As-cast microstructures of Mg-7Zn-0.3V alloy

图3 Mg-7Zn-0.3V镁合金XRD谱

Fig. 3 XRD pattern of as-cast Mg-7Zn-0.3V alloy

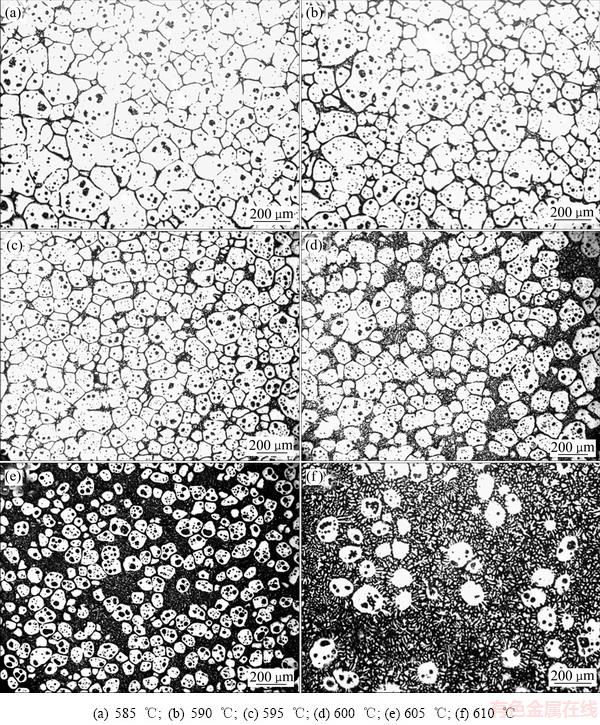

图4 不同温度下保温40 min的Mg-7Zn-0.3V合金半固态组织

Fig. 4 Semi-solid microstructures of Mg-7Zn-0.3V alloy heated at different temperatures for 40 min

图4所示为保温40 min时,不同保温温度条件下的Mg-7Zn-0.3V合金的半固态非枝晶组织形貌。图5所示为Mg-7Zn-0.3V合金半固态非枝晶组织的圆整度、固相率以及颗粒尺寸的变化规律。由图4和图5可知,保温时间为40 min时,在保温温度为585 ℃条件下,铸态的枝晶组织已经消失,取而代之的是非枝晶组织,非枝晶颗粒尺寸为100.2 μm,虽较铸态晶粒度有所减小,但仍较大,圆整度不是很好且固相率非常高,同时,非枝晶组织内部已有许多的小液滴生成(见图4(a))。随着保温温度的进一步升高,非枝晶组织颗粒的尺寸逐渐变小,并且固相率也逐渐降低,颗粒的圆整度也逐渐变好,同时,颗粒内部的小液滴也逐渐增多(见图4(b),(c));当保温温度继续升高到600 ℃时,非枝晶组织的固相率明显降低并且液相增加,颗粒逐渐变得圆整(见图4(d));当保温温度升高到605 ℃时,非枝晶组织的形状因子和颗粒平均尺寸达到最小,分别为1.26和48.5 μm,同时,固相率也降低到51%(见图4(e));保温温度继续升高到610 ℃时,Mg-7Zn-0.3V合金半固态非枝晶组织的液相率进一步升高,由于Ostwald熟化作用[14],导致颗粒的合并与长大,颗粒形状依然保持近球状,但其颗粒的平均尺寸有所增加,其形状因子和颗粒平均尺寸分别为1.27和61 μm(见图4(f))。在相同的保温时间,不同的保温温度下,随着保温温度的升高,晶界上的共晶组织重熔后,形成了颗粒状的组织。对于组织形貌的这种变化规律,李元东等[15]认为一方面是由于温度的升高导致晶粒内部成分均匀化及固溶度提高;其次是由于枝晶臂之间的曲率不同,导致其附近的溶质浓度有差别,曲率半径越小的枝晶,其附近溶质浓度越低,这样,在两个枝晶臂(一次枝晶臂与二次枝晶臂之间)建立起一个扩散偶,由于溶质梯度的存在将促使溶质从粗大的枝晶处向细枝晶处扩散,造成细枝熔化或溶解,甚至从细枝根部熔断;最后,在先前的凝固过程中,低熔点的相后凝固而存在于枝晶间或晶粒之间,熔化时这些组织首先发生熔化。

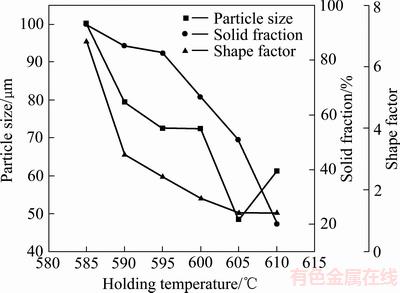

图5 Mg-7Zn-0.3V合金在不同温度保温40 min的颗粒平均尺寸、形状因子和固相率

Fig. 5 Particle size, solid fraction and shape factor of Mg-7Zn-0.3V alloy heated at different temperatures for 40 min

2.2.2 保温时间对半固态非枝晶组织的影响

在保温40 min时,Mg-7Zn-0.3V合金在605 ℃获得的半固态组织比较理想,所以选择在605 ℃下研究不同保温时间对半固态非枝晶组织演变的影响。图6和图7所示分别为保温时间对半固态非枝晶组织演变的影响和保温时间对Mg-7Zn-0.3V合金半固态非枝晶组织的固相率、形状因子以及平均尺寸的变化规律曲线。在保温5 min时,组织已经出现了颗粒边界,颗粒已经初步分离,但是液相区不是特别明显,颗粒内部有少量小液滴产生,如图6(a)所示;保温10 min时,组织已经形成不规则块状的固相颗粒,组织的液相有所增加,颗粒之间的边界逐渐清晰,颗粒内部的小液滴的数量也明显增多,如图6(b)所示;保温20 min时,组织已经出现了较多的液相,块状的颗粒逐步向球状颗粒演变,颗粒的圆整度也有了较大的提高,其形状因子为1.98,如图6(c)所示;当保温30 min时,组织液相进一步增多,颗粒与颗粒已经基本分离且逐渐圆整,其形状因子达到了1.52,如图6(d)所示;当保温时间进一步增加到40 min时,此时组织的颗粒的平均尺寸达到了最小为48.5 μm,其分布也较为均匀,其固相率约为51%,颗粒也相对圆整,形状因子为1.26,且在颗粒内部也出现了很明显大小不一的熔池;当保温时间达到50 min时,颗粒的平均尺寸由于颗粒与颗粒之间合并长大的作用而增大,达到了71 μm,形状因子也有所增加,达到了1.5,固相率约为43%。冯凯等[16]研究认为,这种变化的原因在于高温下,块状颗粒的亚晶界的存在为颗粒的演变提供了驱动力,促进了半固态合金的熔化与分离的过程。

图6 Mg-7Zn-0.3V合金在605℃保温不同时间的非枝晶组织演变

Fig. 6 Non-dendritic microstructure evolution of Mg-7Zn-0.3V alloy heated at 605 ℃ for different time

图7 Mg-7Zn-0.3V合金在605 ℃保温不同时间的颗粒平均尺寸、形状因子和固相率

Fig. 7 Particle size, solid fraction and shape factor of Mg-7Zn-0.3V alloy heated at different time for 605 ℃

2.3 非枝晶组织的扫描电镜及能谱分析

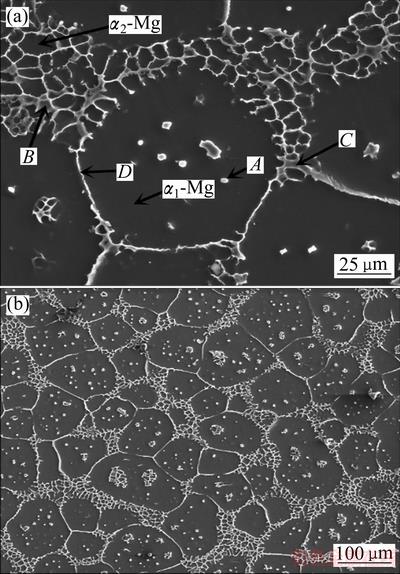

Mg-7Zn-0.3V合金的非枝晶组织是由固相和液相组成。为了进一步确定Mg-7Zn-0.3V非枝晶组织的特征及其成分,采用了SEM和EDS微区成分分析,研究了其组织的形貌以及相的成分。图8所示为Mg-7Zn-0.3V合金半固态非枝晶组织在保温温度为605 ℃时,保温40 min下的SEM像。由图8可以看出,非枝晶组织的边缘呈现出锯齿状,整体上表现出类似于蜂窝状的组织,其非枝晶组织主要是由初生的α1-Mg组织颗粒与二次凝固组织α2-Mg颗粒构成,结合EDS组织分析表可知(见表2),二次凝固组织α2-Mg颗粒中的Zn含量比初生的α1-Mg组织颗粒中的Zn含量比要高,这主要是因为,在合金等温重熔过程中,非枝晶组织的演变处于一个熔化和结晶的动态平衡之中,由于存在能量梯度,初生的共晶组织中的原子在获得大量的能量下,极易向晶内发生迁移,并且可能是因为空位浓度梯度的存在,有利于晶界处的原子向晶体内部迁移,导致了二次凝固组织α2-Mg颗粒中的Zn含量比初生的α1-Mg组织颗粒中的Zn含量比要高一些。结合图8(a)与表3可知,A点的Zn含量要高于B点和C点的,这是因为在晶界处浓度较高的原始共晶组织,在等温重熔时,由于枝晶臂的合并而包裹,在二次凝固的过程中,溶质原子已经无法扩散,导致了其A点颗粒的Zn含量比B点和C点的Zn的含量要高。B点与C点处的Zn含量明显要高于D点处Zn含量,这可能是因为由于在等温重熔的过程中,B点与C点的组织是由于二次凝固得到的,而在等温重熔的过程中,D点因为扩散驱动力的影响,其中的部分Zn原子扩散到了基体中。

图8 Mg-7Zn-0.3V合金在605 ℃保温40 min显微组织

Fig. 8 Microstructure of Mg-7Zn-0.3V alloy after holding at 605 ℃ for 40 min

表2 图8(a)中的初生颗粒及二次凝固颗粒的EDS分析

Table 2 EDS analysis results of primary particle and α2-Mg particle formed the solidification in Fig. 8(a)

表3 图8(a)中显微组织的EDS分析

Table 3 EDS analysis results of microstructure in Fig. 8(a)

2.4 等温热处理过程中半固态非枝晶组织演变分析

在等温热处理后,通过对Mg-7Zn-0.3V合金的非枝晶组织的演变研究发现,在改变保温温度或保温时间时,半固态非枝晶组织的演变经过了以下几个过程:1) 在初始阶段,由于溶质浓度梯度的存在,共晶组织在温度升高或是时间的延长下,不断地向基体α-Mg中扩散,导致α-Mg不断的粗化,枝晶逐渐消失,枝晶臂出现了合并,最终形成了大块状的组织颗粒;2) 随着保温温度或是时间的进一步增加下,块状的组织颗粒逐渐分离,由于固液界面张力的存在,使得分离后的块状颗粒逐渐趋于球状,并且颗粒的圆整度逐渐变好,固相与液相的比例也趋于均衡;3) 当保温温度继续升高或是保温时间继续延长,由于熟化作用的存在,最终导致了固相颗粒的合并与长大,且液相会明显地增多。

3 结论

1) Mg-7Zn-0.3V合金在半固态等温热处理下,铸态的共晶组织转变为球形颗粒,且随着保温时间或保温温度的变化,其非枝晶组织经历了由枝晶组织的粗化转变为块状的固相颗粒,然后进一步变为球状或近球状固相颗粒,最后颗粒出现了合并与长大;

2) 半固态组织主要由初生组织α1-Mg和二次凝固组织α2-Mg组成,球状固相颗粒的合并与长大符合Ostwald熟化理论;

3) Mg-7Zn-0.3V合金半固态成形的最佳等温热处理工艺是605 ℃,40 min;在该保温温度和保温时间下,可获得较为理想的半固态组织。其颗粒尺寸、圆整度和固相率分别为48.5 μm、1.26和51%。

REFERENCES

[1] DECKER R F. Renaissance in magnesium[J]. Advanced Materials & Processes, 1998, 154(3): 31-33.

[2] 吴国华, 陈玉狮, 丁文江. 镁合金在航空航天领域研究应用现状与展望[J]. 载人航天, 2016, 22(3): 281-292.

WU Guo-hua, CHEN Yu-shi, DING Wen-jiang. Current research, application and future prospect of magnesium alloys in aerospace industry[J]. Manned Spaceflight, 2016, 22(3): 281-292.

[3] MORDIKE B L. Magnesium properties applications potential[J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[4] BUHA J. Characterisation of precipitates in an aged Mg-Zn-Ti alloy[J]. Journal of Alloys and Compounds, 2009, 472(1/2): 171-177.

[5] 黄 巍, 李 荻. 300 ℃等温处理时间对AZ91D压铸镁合金组织和性能的影响[J]. 材料热处理学报, 2006, 27(2): 37-41.

HUANG Wei, LI Di. Effects of isothermal heat-treatment at 300 ℃ on microstructure and mechanical properties of AZ91D die cast magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2006, 27(2): 37-41.

[6] 周桂云. 镁合金铸件在汽车工业中的应用与研究状况[J]. 汽车工艺与材料, 2016(3): 56-60.

ZHOU Gui-yun. Application and research status of magnesium alloy castings in automobile industry[J]. Automobile Technology & Material, 2016(3): 56-60.

[7] 邓 辉, 郭学锋, 黄 丹, 崔红保. 镁合金半固态成形技术的研究和发展[J]. 热加工工艺, 2011, 40(23): 9-13.

DENG Hui, GUO Xue-feng, HUANG Dan, CUI Hong-bao. Research and development of semi-solid processing of magnesium alloy[J]. Hot Working Technology, 2011, 40(23): 9-13.

[8] FAN Z, LIU G, WANG Y. Microstructure and mechanical properties of rheo-diecast AZ91D magnesium alloy[J]. Journal of Materials Science, 2006, 41(12): 3631-3644.

[9] 毛卫民. 半固态金属成形技术[M]. 北京: 机械工业出版社, 2004.

MAO Wei-min. Semi-solid metal forming technology[M]. Beijing: China Machine Press, 2004.

[10] FLEMINGS M C. Behavior of metal alloys in the semisolid state[J]. Metallurgical and Materials Transactions A, 1991, 22(5): 957-981.

[11] 路贵民, 董 杰, 崔建忠, 王 平. 液相线半连续铸造7075Al合金二次加热与触变成形[J]. 金属学报, 2001, 37(11): 1184-1188.

LU Gui-min, DONG Jie, CUI Jian-zhong,WANG Ping. Study on the reheating and thixoforming of 7075 aluminum alloy cast by liquidus semi-continuous casting[J]. Acta Metallurgica Sinica, 2001, 37(11): 1184-1188

[12] 王建华. 合金元素对镁基干电池用Mg-Al-Zn-V合金性能的影响分析[J]. 热加工工艺, 2015(19): 84-86.

WANG Jian-hua. Effect of alloying element on properties of Mg-Al-Zn-V alloy for magnesium-based battery[J]. Hot Working Technology, 2015(19): 84-86.

[13] FAN Z. Semisolid metal processing[J]. International Materials Reviews, 2002, 47(2): 49-85.

[14] KANG M K, KIM D Y, NONG M H. Ostwald ripening kinetics of angular grains dispersed in a liquid phase by two-dimensional nucleation and abnormal grain growth[J]. Journal of the European Ceramic Society, 2002, 22(5): 603-612.

[15] 李元东, 郝 远, 陈体军, 阎峰云. 等温热处理工艺对AZ91D镁合金半固态组织演变和成形性的影响[J]. 中国有色金属学报, 2002, 12(6): 1143-1148.

LI Yuan-dong, HAO Yuan, CHEN Ti-jun, YAN Feng-yun. Effects of isothermal heat-treatment on microstructure evolution and formability of AZ91D magnesium alloy in semi-solid state[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1143-1148

[16] 冯 凯, 黄晓锋, 马 颖, 阎峰云, 郝 远. ZA74镁合金非枝晶组织的演变过程及机理[J]. 中国有色金属学报, 2013, 23(3): 635-644.

FENG Kai, HUANG Xiao-feng, MA Ying, YAN Feng-yun, HAO Yuan. Non-dendritic microstructure evolution process and mechanism of ZA74 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 635-644.

Effects of isothermal heat treatment on semi-solid microstructural evolution of Mg-7Zn-0.3V alloy

HUANG Xiao-feng1, 2, GUO Feng1, ZHANG Yu1, YANG Jian-chang1, MA Ya-jie1, ZHANG Qiao-qiao1

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys and Processing, Ministry of Education, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The effects of remelting temperature and holding time on microstructural evolution of Mg-7Zn-0.3V magnesium alloy were investigated by semi-solid isothermal heat treatment. The results indicate that the holding temperature and holding time have significant effects on microstructural evolution of the Mg-7Zn-0.3V alloy during isothermal temperature process. By increasing the holding temperature or prolonging the holding time, the non-endritic structures in Mg-7Zn-0.3V can be transformed into smaller and more uniform spherical particles.When the holding temperature is too high or holding time is too long, the semi-solid particles will combine and grow up, the microstructural evolution mechanism is consistent with the rule of Ostwald ripening mechansim. The best parameters of isothermal heat treatment are 605 ℃ holding temperature and 40 min holding time, obtaining the semi-solid microstructure with the average partial size of 48.5 μm and the roundness of 1.26.

Key words: Mg-7Zn-0.3V magnesium alloy; semi-solid isothermal heat treatment; non-endritic structure; evolution mechanism

Foundation item: Project(51464032) supported by the National Natural Science Foundation of China; Project (2010CB635106) supported by the National Basic Research Development Programof China

Received date: 2017-07-10; Accepted date: 2017-11-15

Corresponding author: HUANG Xiao-feng; Tel: +86-13609312769; E-mail: huangxf_lut@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51464032);国家重点基础研究发展计划资助项目(2010CB635106)

收稿日期:2017-07-10;修订日期:2017-11-15

通信作者:黄晓锋,副教授,博士;电话:13609312769;E-mail: huangxf_lut@163.com