等径道角挤压预变形AZ61镁合金在半固态等温处理中的微观组织演变

来源期刊:中国有色金属学报(英文版)2012年第3期

论文作者:姜巨福 林鑫 王迎 曲建俊 罗守靖

文章页码:555 - 563

关键词:AZ61镁合金;半固态等温处理;等径道角挤压;微观组织演变

Key words:AZ61 magnesium alloy; semisolid isothermal treatment; equal channel angular extrusion; microstructural evolution

摘 要:

利用金相显微镜和图像分析设备对等径道角挤压预变形AZ61镁合金在半固态等温处理中的微观组织演变进行研究。先利用等径道角挤压对AZ61镁合金铸坯在310 ℃进行应变诱导,然后将其在半固态进行不同时间的等温处理。研究结果表明:挤压道次、等温处理温度和变形路径影响预变形AZ61镁合金在半固态等温处理中的微观组织演变过程。在将等温处理温度从530 ℃升高至560 ℃的过程中,合金的平均晶粒尺寸从22 μm增大到35 μm。当等温处理温度为575 ℃时,平均晶粒尺寸减小。当等径道角挤压的变形路径为BC时,预变形AZ61镁合金在半固态等温处理中获得的微观组织晶粒尺寸最小。

Abstract:

The microstructural evolution of AZ61 magnesium alloy predeformed by equal channel angular extrusion (ECAE) during semisolid isothermal treatment (SSIT) was investigated by means of optical metalloscopy and image analysis equipment. The process involved application of ECAE to as-cast alloy at 310 ℃ to induce strain prior to heating in the semisolid region for different time lengths. The results show that extrusion pass, isothermal temperature and processing route have an influence on microstructural evolution of predeformed AZ61 magnesium alloy during SSIT. With the increase of extrusion pass, the solid particle size is reduced gradually. When isothermal temperature increases from 530 ℃ to 560 ℃, the average particle size increases from 22 μm to 35 μm. When isothermal temperature is 575 ℃, the average particle size decreases. The particle size of microstructure of AZ61 magnesium alloy predeformed by ECAE at BC during SSIT is the finest.

![]()

Trans. Nonferrous Met. Soc. China 22(2012) 555-563

JIANG Ju-fu1, 2, LIN Xin2, WANG Ying3, QU Jian-jun3, LUO Shou-jing1

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University,Xi’an 710072, China;

3. School of Mechatronics Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 15 September 2011; accepted 30 November 2011

Abstract: The microstructural evolution of AZ61 magnesium alloy predeformed by equal channel angular extrusion (ECAE) during semisolid isothermal treatment (SSIT) was investigated by means of optical metalloscopy and image analysis equipment. The process involved application of ECAE to as-cast alloy at 310 °C to induce strain prior to heating in the semisolid region for different time lengths. The results show that extrusion pass, isothermal temperature and processing route have an influence on microstructural evolution of predeformed AZ61 magnesium alloy during SSIT. With the increase of extrusion pass, the solid particle size is reduced gradually. When isothermal temperature increases from 530 °C to 560 °C, the average particle size increases from 22 μm to 35 μm. When isothermal temperature is 575 °C, the average particle size decreases. The particle size of microstructure of AZ61 magnesium alloy predeformed by ECAE at BC during SSIT is the finest.

Key words: AZ61 magnesium alloy; semisolid isothermal treatment; equal channel angular extrusion; microstructural evolution

1 Introduction

The combination of low density, high specific strength and stiffness, and excellent damping capacity qualifies magnesium alloy as ideal materials for lightweight constructions. The methods of manufacturing magnesium alloy components mainly involve die-casting (DC), high-pressure die-casting (HPDC), squeeze casting (SQC) and semisolid processing(SSP), and so on [1]. Compared with DC, HPDC and SQC, SSP has been paid more attention by many researchers from all over the world due to a lowered forming temperature, increased die life, reduced porosity and solidification shrinkage, improved mechanical properties, etc. SSP is divided into two categories, rheoforming and thixoforming. Three procedures, i.e., preparing the semisolid ingots, reheating the semisolid ingots and forming the semisolid ingots, are involved in thixoforming process. How to prepare high-quality semisolid billet is the key procedure of thixoforming process. Research on preparation of the semisolid ingots and the microstructural evolution of semisolid ingots (slurries) has been done by some researchers due to the importance to the quality of the final thixoformed parts. Various routes had been developed for fabricating the non-dendritic spheroidal microstructure, such as, semisolid isothermal treatment (SSIT) [2], mechanical stirring [3], electromagnetic stirring [4], strain induced melt activated (SIMA) [5], continuous semisolid extrusion process (CSEP) [6,7], and vibrating wavelike sloping plate process (VWSP) [8]. Various predeformation technologies were used in strain induction procedure of SIMA. Extrusion was a typical example of predeformation of AZ91D magnesium alloy [9]. Hot or cold upsetting predeformation also was employed to induce strain of AZ61 magnesium alloy [10-12]. In addition, some novel methods of preparation of semisolid billet (or slurry) were proposed. JI et al [13] reported preparation of semisolid slurry of Mg-9Al-Zn alloy by twin-screw slurry maker and found fine and spherical particles undergoing a coarsening process under low constant shear rate. JIANG et al [14, 15] developed firstly a new method called “new SIMA” in which equal channel angular extrusion (ECAE) was applied in predeformation of magnesium alloy. Processing parameters had an influence on the microstructure of ECAE-formed AZ91D magnesium alloy in the semisolid state [16]. AM60 magnesium alloy semisolid slurry with fine particles was also prepared by SSIT of predeformed material [17]. ASHOURI et al [18] and HOSSEIN-NEDJAD et al [19] employed the ECAE predeformation to prepare aluminum alloy semisolid and found that sphericity of particles increases with the increase of strain.

The above mentioned literatures show that the semisolid billet with fine spherical microstructure is key during the thixoforming technology. ECAE is a desirable predeformation technology of magnesium alloy, by which the microstructure can be refined well and good strain induction can be achieved. Moreover, semisolid isothermal treatment of as-cast predeformed by equal channel angular extrusion (ECAE) is a novel technology to fabricate high-quality AZ61 semisolid billet. It is required to know the characteristics of microstructural evolution of AZ61 magnesium alloy predeformed by ECAE in SSIT. It is beneficial to improve the mechanical properties and microstructure of the thixoformed parts. Research on microstructural evolution of AZ61 magnesium alloy predeformed by ECAE during SSIT was reported little.

Therefore, the present work was aimed to employ equal channel angular extrusion (ECAE) to predeform AZ61 magnesium alloy and study effects of extrusion pass, processing route and isothermal temperature on microstructural evolution of AZ61 magnesium alloy predeformed by ECAE during SSIT.

2 Experimental

Commercial AZ61 magnesium alloy ingots were used for experimental materials. The composition obtained from spectroscopic analysis was Mg-6.5%Al- 0.35%Zn-0.26%Mn-0.1%Si-0.01%Ni-0.02%Cu-0.003%Fe. Equal channel angular extrusion (ECAE) was employed to predeform the as-cast ingots of AZ61 magnesium alloy. Firstly, the as-cast ingots were machined into cylindrical samples with the diameter of 57 mm and the height of 110 mm. And then they were processed 1 pass to 6 passes at 310 °C by an equal-channel die that consisted of two equal cross-section channels, intersecting at an angle of 90°. The cylindrical specimens were predeformed by ECAE at four processing routes, which were termed as A, BA, BC and C according to the rotation angle about the longitudinal axis of sample or extrusion direction. Route A referred to pressing the billet repetitively without any rotation. Routes BA and BC referred to rotation of 90° in the opposite sense and in the same sense between consecutive passes, respectively. And route C referred to rotating by 180° between consecutive passes. The samples processed by ECAE were machined into some cylindrical specimens with the diameter of 10 mm and height of 10 min along the extrusion direction. Two materials including the AZ61 magnesium alloy predeformed by ECAE and original as-cast AZ61 magnesium alloy all were isothermally treated in the semisolid state in order to compare their difference in microstructure morphology. Specimens of AZ61 magnesium alloy predeformed by ECAE were isothermally treated for 10 min at 530, 545, 560 and 575 °C, respectively. Specimens of original as-cast AZ61 magnesium alloy also were isothermally treated in the semisolid state for 10 min at 530, 545, 560 and 575 °C, respectively.

After being isothermally treated in the semisolid state, the samples were quickly quenched into water to keep the microstructure morphology of the semisolid ingots. Samples used for microstructure observation were fabricated by the standard metallurgical technique, followed by etching in a solution of 4.2 g picronitric acid, 10 mL ethanediol, 70 mL ethanol and 10 mL distilled water. The microstructure of the alloy was observed by using an Olympus optical microscope. The average particle size and shape factor of the solid phases were measured using a digital image analysis system. Average particle size and shape factor (FS) of solid particles are calculated in each case by applying Eqs. (1) and (2) [20].

(1)

(1)

(2)

(2)

where D, FS, A, N and P are the average particle size, shape factor, area, number and perimeter of solid particles, respectively. FS is a value close to 1, corresponding to better globularity of solid particles.

3 Results and discussion

3.1 Microstructure evolution of as-cast alloy during SSIT

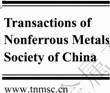

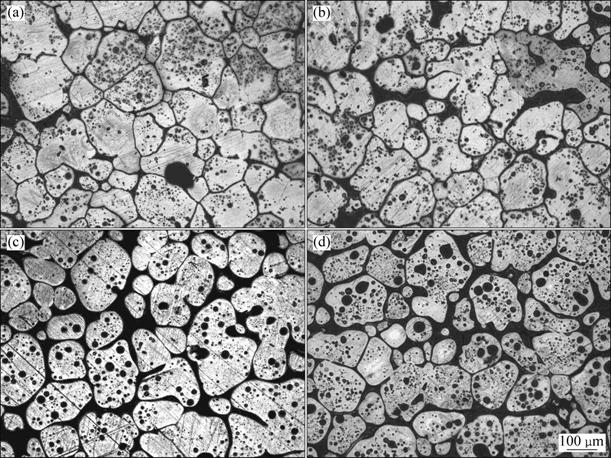

Figure 1 shows the morphological evolution of α-Mg particles of original as-cast AZ61 at various temperatures during SSIT. From the beginning of isothermal treatment (Fig. 1(a)), the distribution of solid particles was non-uniform and particle size was obviously different from each other. Some coarse particle and fine particle coexisted in microstructure. The size of some coarse solid particles was above 200 μm. However, the particle size of some relatively fine solid particles was only below 50 μm. The nonuniformity of particle size has an adverse effect on the thixotropic behavior of semisolid ingots. In addition, the semisolid ingot’s ability of filling into die cavity could be reduced due to coarse particle. More seriously, the qualities of the final thixoformed component such as mechanical properties and microstructure will be influenced by the poor semisolid ingots. With the increase of isothermal temperature (Figs. 1(b)-(d)), more liquid phase occurred in surrounding or inside the primary solid particles. Coalescence was found in some solid particles due to unstable energy state, which led to quick coarsening of primary solid grains. It could have an adverse effect on the thixoforming process. On the contrary, some solid particles became smaller and smaller, and disappeared finally (Fig. 1(d)). Average particle size and shape factor are shown in Fig. 2. As indicated in Fig. 2, with the increase of isothermal temperature, average particle size was firstly increased and followed by a decrease.

Fig. 1 Morphological evolution of original as-cast AZ61 during SSIT at various temperature: (a) 530°C; (b) 545 °C; (c) 560 °C; (d) 575 °C

When isothermal temperature was 530 °C, the average particle size was about 138 μm. When samples were heated to 545 °C and held for 10 min, the average particle size reached about 145 μm. With continuous elevation of isothermal temperature, the average particle size increased to about 160 μm. However, when samples

Fig. 2 Average particle size and shape factor of original as-cast AZ61 at various temperatures during SSIT

were heated to 575 °C and held for 10 min, the average particle size became a little smaller. Shape factor of as-cast ingot during SSIT varied from 0.4 to 0.75, indicating undesired spheroidization degree (Fig. 2). An important conclusion could be drawn that high-quality semisolid ingots, i.e., the semisolid ingots with fine and spherical solid particles, is difficult to be prepared by directly SSIT of as-cast AZ61 magnesium alloy.

3.2 Microstructural evolution of AZ61 magnesium alloy predeformed by ECAE during SSIT

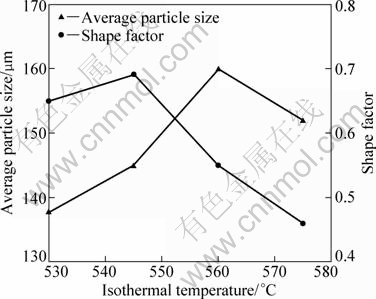

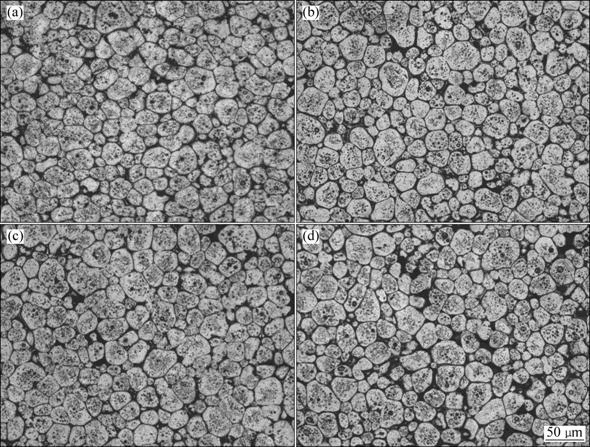

Figure 3 shows microstructure morphology of AZ61 magnesium alloy predeformed by ECAE for various extrusion passes during SSIT. As indicated in Fig. 3, with the increase of extrusion pass, the solid particle size of AZ61 magnesium alloy processed by ECAE during SSIT was reduced gradually. Furthermore, the distribution of solid particles also became uniform with the increase of extrusion passes. When one-pass or two-pass ECAE-processed AZ61 magnesium alloys were isothermally treated for 10 min (Figs. 3(a)-(b)), the distribution of solid particles was more uniform and the particle size was smaller than that of original as-cast during SSIT. With the increase of extrusion pass (Figs. 3(c) - (f)), the particle size was reduced gradually and most of the solid particles were spheroidized very well. In particular, when extrusion passes were more than 4, the microstructure of semisolid billet prepared by SSIT of predeformed material was very uniform and the particle size was very fine.

Fig. 3 Microstructures of AZ61 magnesium alloy predeformed by ECAE for various extrusion passes during SSIT: (a) 1 pass; (b) 2 passes; (c) 3 passes; (d) 4 passes; (e) 5 passes; (f) 6 passes

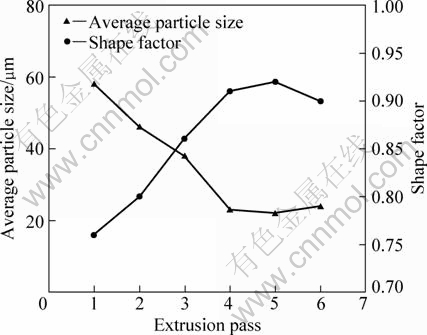

Figure 4 shows the average particle size and shape factor of predeformed AZ61 magnesium alloy during SSIT. It was demonstrated accurately that the average particle size of predeformed AZ61 magnesium alloy during SSIT was reduced gradually with the increment of extrusion passes. When AZ61 magnesium alloy was extruded one pass in the ECAE process, the 58 μm average particle size of semisolid billet could be obtained during the SSIT. When AZ61 magnesium alloy was processed 2 passes to 6 passes in ECAE process, the average particle sizes are 46, 38, 23, 22 and 24 μm, respectively. It is demonstrated that the average particle size of predeformed AZ61 magnesium alloy during SSIT was much finer than that of as-cast alloy.

Moreover, it could be found that when extrusion passes reach 5 or 6, the average particle size was only a

little changed, indicating that furthermore plastic deformation could not influence effectively the particle size of semisolid ingots. With the increase of extrusion passes, shape factor of predeformed AZ61 magnesium alloy during SSIT was changed obviously. When extrusion pass increased from 1 to 4, shape factor increased evidently. When extrusion passes were 4, the shape factor reached 0.91, indicating desired spheroidization effect of solid particles in semisolid ingots. When extrusion passes increased continuously to 5 or 6, the shape factor was changed little, indicating that plastic deformation had little impact on spheroidization of solid particles in semisolid ingots. Grains refinement of ECAE to the microstructure of as-cast ingots paves a wise way for obtaining a lot of fine and spherical solid particles in semisolid ingots. The total accumulated strain, or equivalent strain, also increased with the increment of extrusion passes, which resulted in increase of dynamic recrystallization velocity and further refinement of grains in processed materials [21].

Fig. 4 Average particle size and shape factor of predeformed AZ61 magnesium alloy extruded various passes during SSIT

With increasing the extrusion passes, more and more fine equiaxed grains occurred in the microstructure of processed materials by ECAE and the homogeneity of microstructure became better and better. Effective induced strain could be produced by the predeformation of ECAE technique [17]. The ECAE-processed material with fine and homogeneous microstructure is beneficial to prepare semisolid ingots with fine and spherical solid particles. In other word, it is easy to fabricate high-quality semisolid billets. Furthermore, thixoformed parts with high mechanical properties could be formed with the high-quality semisolid billets.

3.3 Microstructural evolution of AZ61 magnesium alloy predeformed by ECAE at various temperatures during SSIT

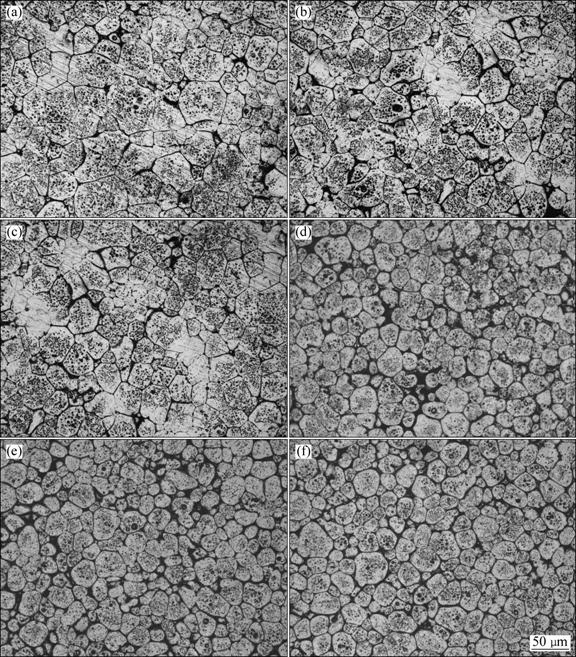

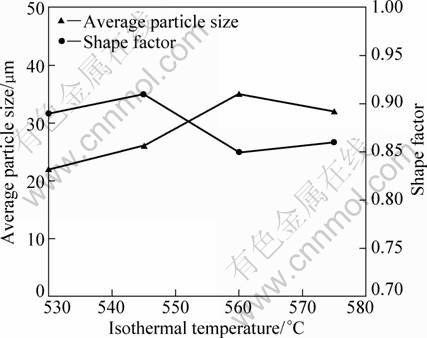

Figure 5 shows the microstructural evolution of predeformed AZ61 magnesium alloy at various temperatures during SSIT. Compared with the microstructure of semisolid billets fabricated by SSIT of as-cast alloy (Fig. 1), the microstructure with fine and uniform grain size could be found in the semisolid billet prepared by SSIT of predeformed as-cast alloy. Moreover, good spheroidization could be achieved in the semisolid billet prepared by SSIT of predeformed as-cast alloy. It is demonstrated that predeformation of ECAE is very beneficial to obtain high-quality semisolid ingots with fine and spherical solid particles. Isothermal temperature has an important influence on thixotropic behavior of semisolid ingots. High isothermal temperature could reduce the retaining and carriage ability of semisolid ingots during the thixoforming process. On the contrary, low isothermal temperature could lead to the increment of viscosity of semisolid billets. As a result, high deformation resistance increased evidently during thixoforming process. As shown in Fig. 5, semisolid billet with fine and spherical solid particles is suitable to be prepared at isothermal temperature ranging from 530 to 575 °C. The average particle size and shape factor are shown in Fig. 6. As indicated in Fig. 6, with the increase of isothermal temperature, the average particle size was firstly increased and then decreased. When isothermal temperature increased from 530 to 560 °C, the average particle size of predeformed AZ61 magnesium alloy during SSIT also increased from 22 μm to 35 μm. When isothermal temperature was 575 °C, the average particle size decreased. When isothermal temperature increased, two trends, i.e., coarsening trend and melting trend, coexisted in the microstructure of semisolid ingots [14].

Fig. 5 Microstructural evolution of predeformed AZ61 magnesium alloy during SSIT at various temperatures: (a) 530 °C; (b) 545 °C; (c) 560 °C; (d) 575 °C

Fig. 6 Average particle size and shape factor of predeformed AZ61 magnesium alloy at various temperatures during SSIT

When predeformed AZ61 magnesium alloy was treated isothermally for 10 min at 530, 545 and 560 °C, coarsening trend was predominant, which led to increment of average particle size. When AZ61 magnesium alloy processed by ECAE was treated isothermally at 575 °C for 10 min, melting trend was predominant. As a result, average particle grain size was reduced. Shape factor also was affected by isothermal temperature (Fig. 6). Shape factor varied from 0.85 to 0.91. The value of shape factor was close to 1, indicating closing ideal spheroids. Although the average particle size of predeformed AZ61 magnesium alloy during SSIT was changed with increase of isothermal temperature, they still varied from 22 μm to 35 μm.

Without ECAE, the grains evolved in the AZ61 magnesium alloy by SSIT are almost 6 times larger than ones predeformed by ECAE. It is revealed that the isothermal treatment of AZ61 magnesium alloy under certain condition, i.e., after ECAE, in semisolid region (temperature and time), produced very fine equiaxed grains with near globular shapes. It is demonstrated that SSIT of AZ61 magnesium alloy predeformed by ECAE is an ideal method for preparing high-quality semisolid ingots.

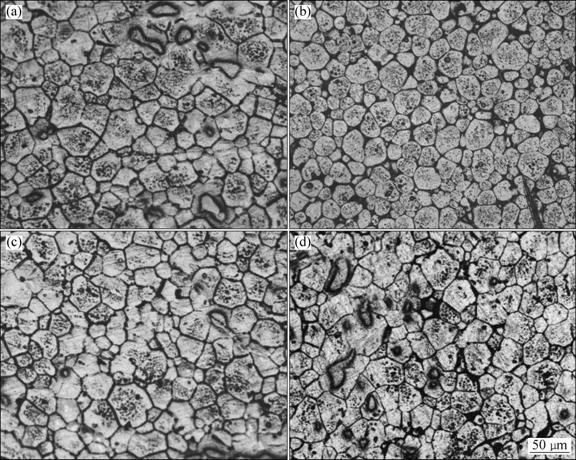

3.4 Microstructural evolution of AZ61 magnesium alloy predeformed by ECAE under various processing routes during SSIT

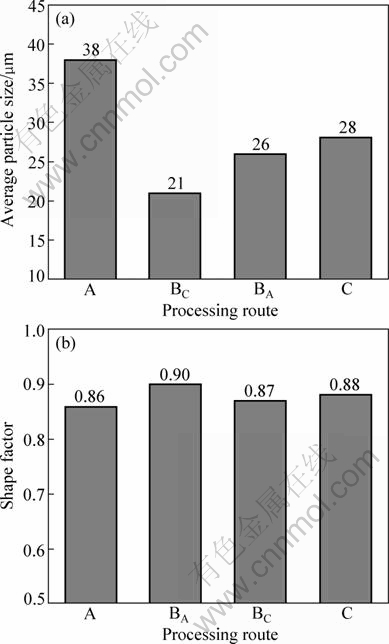

Figure 7 shows the microstructure morphology of predeformed AZ61 magnesium alloy at various processing routes during SSIT. The isothermal temperature was 530 °C. It was found that the particle size of microstructure of AZ61 magnesium alloy predeformed by ECAE at route Bc during SSIT is the finest and the distribution of solid particles is the most uniform among the microstructures of AZ61 magnesium alloy predeformed by ECAE at four processing routes during SSIT.

Different microstructures achieved at various processing routes in ECAE result in various semisolid microstructure of AZ61 alloy in SSIT. When as-cast materials were processed by ECAE, fine grains were achieved due to dynamic recrystallization relative to severe plastic deformation [18]. Furthermore, at route BC, the velocity of dynamic recrystallization was higher than that of materials at other processing routes. It had been demonstrated that the most effective method of forming a fine-grain structure by severe plastic deformation is to maintain route BC [22]. With a constant clockwise 90? rotation (route BC) the sample was also deformed on two alternate shear planes and in this case each shear was reversed out of sequence after deforming the billet on the alternate shear plane. This appeared to be much more effective means of forming new high angle boundaries than other processing routes. Hence route BC could enhance the degree of dynamic recrystallization effectively. As a result, the finest grains could be obtained at route BC. High-quality semisolid billets with fine and spherical solid particles could be prepared successfully by treating isothermally the AZ61 magnesium alloy predeformed by ECAE at processing route BC.

Fig. 7 Microstructure morphology of predeformed AZ61 magnesium alloy during SSIT at various processing routes: (a) A; (b) BA; (c) BC; (d) C

Figure 8 shows the accurate values of the average particle size and shape factor of AZ61 magnesium alloy predeformed by ECAE at various processing routes during SSIT. As shown in Fig. 8, the average particle sizes of AZ61 magnesium alloy predeformed by ECAE at processing route A, route BA, route BC and route C during SSIT were 38 μm, 26 μm, 21 μm and 28 μm, respectively. The shape factors were 0.86, 0.90, 0.87, 0.88, respectively. The results of average particle size and shape factor indicated that ECAE-processed predeformation at route BC could be beneficial to prepare high-quality semisolid billets in the following SSIT process.

4 Conclusions

1) Coarse and non-uniform microstructure is found in the semisolid billets prepared by SSIT of as-cast AZ61 magnesium alloy. The average particle size is more than 138 μm. On the contrary, high-quality semisolid billets with fine and spherical solid particles can be prepared successfully by isothermally treating the ECAE- processed AZ61 magnesium alloy. When AZ61 magnesium alloy predeformed by ECAE 4 passed at route BC is isothermally treated at 530 °C for 10 min, high-quality semisolid ingots with 21 μm average size and spherical particles can be prepared successfully.

Fig. 8 Average particle size and shape factor of predeformed AZ61 magnesium alloy at various processing routes during SSIT: (a) Average particle size; (b) Shape factor

2) Extrusion pass has an influence on microstructural evolution of AZ61 magnesium alloy predeformed by ECAE during SSIT. With the increase of extrusion pass, the solid particle size of AZ61 magnesium alloy predeformed by ECAE during SSIT is reduced gradually. Furthermore, when extrusion passes increase, the distribution of solid particles also becomes more uniform.

3) With the increment of isothermal temperature, the average particle size firstly increases and then decreases. When isothermal temperature increases from 530 to 560 °C, the average particle size of predeformed AZ61 magnesium alloy during SSIT also increases from 22 to 35 μm. When isothermal temperature is 575 °C, the average particle size decreases. When isothermal temperature increases, coarsening trend and melting trend coexisting in the microstructure of semisolid ingots lead to first increment and following decrease.

4) Processing route also has an influence on the quality of semisolid billets by isothermally treating AZ61 magnesium alloy predeformed by ECAE in semisolid state. The particle size of microstructure of AZ61 magnesium alloy predeformed by ECAE at BC during SSIT is the finest and the distribution of solid particles is most uniform among the microstructures of AZ61 magnesium alloys predeformed by ECAE at four processing routes during SSIT.

References

[1] KLEINER S, BEFFORT O, WAHLEN A, UGGOWITZER P J. Microstructure and mechanical properties of squeeze cast and semi-solid cast Mg-Al alloys [J]. Journal of Light Metals, 2002, 2(4): 277-280.

[2] YANG M B, PAN F S, CHENG R J, BAI L. Effect of semi-solid isothermal heat treatment on the microstructure of Mg-6A1-1Zn-0.7Si alloy [J]. Journal of Materials Processing Technology, 2008, 206(1-3): 374-381.

[3] SUKUMARAN K, PAI B C, CHAKRABORTY M. The effect of isothermal mechanical stirring on an Al–Si alloy in the semisolid condition [J]. Materials Science and Engineering A, 2004, 369(1-2): 275-283.

[4] KANG C G, BAE J W, KIM B M. The grain size control of A356 aluminum alloy by horizontal electromagnetic stirring for rheology forging [J]. Journal of Materials Processing Technology, 2007, 187-188: 344-348.

[5] ZHANG L, LIU Y B, CAO Z Y, ZHANG Y F, ZHANG Q Q. Effects of isothermal process parameters on the microstructure of semisolid AZ91D alloy produced by SIMA [J]. Journal of Materials Processing Technology, 2009, 209(2): 792-797.

[6] GUAN R G, CHEN L Q, LI J P, WANG F X. Dynamical solidification behaviors and metal flow during continuous semisolid extrusion process of AZ31 alloy [J]. Journal of Materials Science and Technology, 2009, 25(3): 395-400.

[7] GUAN Ren-guo, ZHAO Zhan-yong, SUN Xiao-ping, HUANG Hong-qian, DAI Chun-guang, ZHANG Qiu-sheng. Fabrication of AZ31 alloy wire by continuous semisolid extrusion process [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S3): 729-733.

[8] GUAN R G, CAO F R, CHEN L Q, LI J P, WANG C. Dynamical solidification behaviors and microstructural evolution during vibrating wavelike sloping plate process [J]. Journal of Materials Processing Technology, 2009, 209(5): 2592-2601.

[9] XIA M X, ZHANG H M, YUAN S, LI J G. Recrystallization of preformed AZ91D magnesium alloys in the semisolid state [J]. Materials & Design, 2005, 26(4): 343-349.

[10] CHEN G P, ZHOU T R, YAN H, ZHANG F Y. Effect of predeformation manner on semi-solid structure of AZ61 magnesium alloy in Sima process [J]. Acta Metallurgica Sinica, 2008, 21(3): 197-204.

[11] WANG J G., LIU P, WANG H Y, LIU J F, JIANG Q C. Semisolid microstructure evolution of the predeformed AZ91D alloy during heat treatment [J]. Journal of Alloys and Compound, 2005, 395(1-2): 108-112.

[12] HONG Y, ZHOU B F. Thixotropic deformation behavior of semi-solid AZ61 magnesium alloy during compression process [J]. Materials Science and Engineering B, 2006, 132(1-2): 179-182.

[13] JI S, ROBERTS K, FAN Z. Isothermal coarsening of fine and spherical particles in semisolid slurry of Mg-9Al-1Zn alloy under low shear [J]. Scripta Materilia, 2006, 55(11): 971-974.

[14] JIANG Ju-fu, LUO Shou-jing. Reheating microstructure of refined AZ91D magnesium alloy in semi-solid state [J]. Transactions of Nonferrous Metals Society of China, 2004, 14(6): 1074-1078.

[15] JIANG J F, WANG Y, LUO S J. Application of equal channel angular extrusion to semi-solid processing of magnesium alloy [J]. Materials Characterization, 2007, 58(2): 190-196.

[16] LUO S J, CHEN Q, ZHAO Z D. Effects of processing parameters on the microstructure of ECAE-formed AZ91D magnesium alloy in the semi-solid state [J]. Journal of Alloys and Compound, 2009, 477(1-2): 602-607.

[17] JIANG J F, WANG Y, QU J Q, DU Z M, SUN Y, LUO S J. Microstructure evolution of AM60 magnesium alloy semisolid slurry prepared by new SIMA [J]. Journal of Alloys and Compound, 2010, 497(1-2): 62-67.

[18] ASHOURI S, NILI-AHMADABADI M, MORADI M, IRANPOUR M. Semi-solid microstructure evolution during reheating of aluminum A356 alloy deformed severely by ECAP [J]. Journal of Alloys and Compound, 2008, 466(1-2): 67-72.

[19] HOSSEIN-NEDJAD N, MEIDANI H, NILI-AHMADABADI M. Effect of equal channel angular pressing on the microstructure of a semisolid aluminum alloy [J]. Materials Science and Engineering A, 2008, 475(1-2): 224-228.

[20] SEO P K, KANG C G. The effect of raw material fabrication process on microstructural characteristics in reheating process for semi-solid forming [J]. Journal of Materials Processing Technology, 2005, 162-163: 402-409.

[21] JIANG J F, WANG Y, DU Z M, QU J J, SUN Y, LUO S J. Enhancing room temperature mechanical properties of Mg-9Al-Zn alloy by multi-pass equal channel angular extrusion [J]. Journal of Materials Processing Technology, 2010, 210(5): 751-758.

[22] GHOLINIA A, PRANGNELL P B, MARKUSHEV M V. The effect of strain path on the development of deformation structures in severely deformed aluminium alloys processed by ECAE [J]. Acta Materialia, 2000, 48(5): 1115-1130.

姜巨福1, 2,林 鑫2,王 迎3,曲建俊3,罗守靖1

1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 西北工业大学 凝固技术国家重点实验,西安 710072;

3. 哈尔滨工业大学 机电工程学院,哈尔滨 150001

摘 要:利用金相显微镜和图像分析设备对等径道角挤压预变形AZ61镁合金在半固态等温处理中的微观组织演变进行研究。先利用等径道角挤压对AZ61镁合金铸坯在310 °C进行应变诱导,然后将其在半固态进行不同时间的等温处理。研究结果表明:挤压道次、等温处理温度和变形路径影响预变形AZ61镁合金在半固态等温处理中的微观组织演变过程。在将等温处理温度从530 °C升高至560 °C的过程中,合金的平均晶粒尺寸从22 μm增大到35 μm。当等温处理温度为575 °C时,平均晶粒尺寸减小。当等径道角挤压的变形路径为BC时,预变形AZ61镁合金在半固态等温处理中获得的微观组织晶粒尺寸最小。

关键词:AZ61镁合金;半固态等温处理;等径道角挤压;微观组织演变

(Edited by YANG Hua)

Foundation item: Project (51075099) supported by the National Natural Science Foundation of China; Project (E201038) supported by Natural Science Foundation of the Heilongjiang Province, China; Project (20090460884) supported by the China Postdoctoral Science Foundation; Project (SKLSP201121) supported by the Fund of the State Key Laboratory of Solidification Processing in NWPU, China; Project (2011RFQXG010) supported by the Harbin City Young Scientists Foundation, China; Project (LBH-T1102) supported by the Specially Postdoctoral Science Foundation of Heilongjiang Province, China

Corresponding author: JIANG Ju-fu; Tel: +86-451-86415464; E-mail: jiangjufu@hit.edu.cn

DOI: 10.1016/S1003-6326(11)61213-2