DOI:10.19476/j.ysxb.1004.0609.2018.12.02

Mg-6Zn-1Cu-0.5Ce镁合金的非枝晶组织演变及机理

黄晓锋1, 2,马振铎1,张 玉1,毕广利1,李 雅1

(1. 兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要:半固态金属坯料部分重熔是半固态金属触变成形工艺的重要技术环节,采用等温热处理法对Mg-6Zn-1Cu-0.5Ce镁合金在部分重熔过程中的非枝晶组织演变过程和机理进行研究。结果表明:在半固态重熔初始阶段,Mg-6Zn-1Cu-0.5Ce合金沿晶界分布的共晶相逐渐向α-Mg基体中扩散溶解,达到共晶熔化温度后,剩余部分开始熔化。随着保温时间的进一步延长,为了降低系统的界面能,颗粒将发生合并长大。其中,非枝晶颗粒的分离是由液相沿亚晶界浸渗和根部重熔两种机制起主导作用。Mg-6Zn-1Cu-0.5Ce合金的最佳等温热处理工艺为保温温度600 ℃和保温时间25 min,采用该工艺处理后所得非枝晶颗粒平均尺寸为57μm,形状因子为1.16,固相率为68%。

关键词:Mg-6Zn-1Cu-0.5Ce镁合金;部分重熔;半固态;非枝晶组织;演变机理

文章编号:1004-0609(2018)-12-2404-09 中图分类号:TG 146.22 文献标志码:A

镁合金具有密度小,比强度、比刚度高、尺寸稳定、电磁屏蔽性能好及价格稳定等优点,被普遍认为是一种最具开发和应用潜力的“绿色材料”[1]。镁是活性金属,在熔融状态下容易剧烈氧化,发生燃烧,一般的成形方法难以克服这类现象,而采用半固态成形,液相比例小又能进行低温作业,氧化和燃烧的危险明显减少[2]。因此,镁合金半固态成形技术为解决这一难题提供了一种有效途径。另外,采用半固态成形时,金属浆料以层流充型,可大幅降低缩孔和氧化夹杂的出现[3-5],提高了铸件致密度,后续热处理效果得到极大改善。半固态成形主要包括触变成形和流变成形[6-8],其区别在于流变成形将制浆和成形联系在一起,而触变是将两者分开。目前,触变成形应用较多,主要原因如下:该方法工艺可控性强、易实现自动化操作,便于组织大批量生产。触变成形包括半固态坯料的制备、部分重熔和触变成形3个重要环节,其中坯料的部分重熔最为关键,能否获得非枝晶颗粒圆整、细小的半固态组织是制备良好半固态成形制品的前提[7-8]。合金化是改善镁合金组织与性能的主要途径之一[9],通常添加Zn、Cu、Al、Zr及稀土等元素来提高镁合金性能。Mg-Zn合金是典型的时效硬化型合金,Cu元素的加入,能进一步提高共晶温度[10],固溶温度的提高将导致合金元素更易于固溶进入基体;在时效过程中,Cu元素还有利于促进析出相的形核,增大析出相的密度[11-14],时效硬化效果提高显著。将Mg-Zn-Cu系合金用于半固态成形,有利于发挥半固态压铸成形件可在后续进行热处理的优势。但Mg-Zn-Cu合金铸态组织粗大,而非枝晶平均颗粒直径的大小与原始组织有关,细化原始组织成为制备良好半固态浆料的关键。本文作者通过添加0.5%的Ce元素来细化Mg-6Zn-1Cu合金的原始铸态组织,获取了细小的半固态非枝晶颗粒,同时对合金在部分重熔过程中的非枝晶组织演变过程以及演变机理也进行了分析,所获得的最佳等温热处理工艺既可以为后期的触变压铸成形提供参考依据,也对同类Mg-Zn-Cu合金的半固态非枝晶组织形成机理研究具有促进作用。

1 实验

制备Mg-6Zn-1Cu-0.5Ce镁合金的原材料为纯Mg、Zn、Cu锭(纯度>99.9%)以及Mg-30%Ce的中间合金。实验合金使用 SG2-7.5 KW型井式电阻炉熔炼,在熔炼过程中,采用RJ-2覆盖液面,炉膛充入Ar保护。待Mg锭熔化后,在680 ℃依次加入Cu、Zn和Mg-30%Ce中间合金。温度升高到720 ℃时,精炼除渣,静置10~15 min,待温度降至710 ℃时,浇入金属型模具,金属型模具提前预热至200 ℃。

半固态重熔实验在箱式电阻炉中进行,试样尺寸为直径15 mm×10 mm,等温热处理后,迅速水淬,经预磨、抛光后,采用体积分数为4%的硝酸酒精进行腐蚀。利用D/Max-2400型粉末X射线衍射仪检测合金的相组成。使用MeF-3型金相显微镜和SEM观察其半固态组织。利用Image-Pro Plus软件分析其固相率、非枝晶颗粒平均尺寸d0和非枝晶颗粒形状因子f0,所用的计算公式[2]如下: ,

,  。其中:A0为非枝晶颗粒面积;P0为非枝晶颗粒周长;形状因子f0的范围:1≤f0<∞。f0愈趋近于1,表明得到的非枝晶颗粒愈圆整。

。其中:A0为非枝晶颗粒面积;P0为非枝晶颗粒周长;形状因子f0的范围:1≤f0<∞。f0愈趋近于1,表明得到的非枝晶颗粒愈圆整。

2 结果与分析

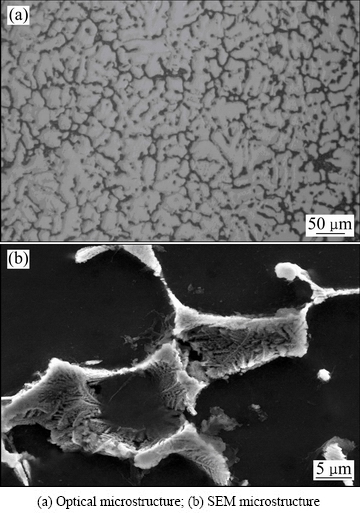

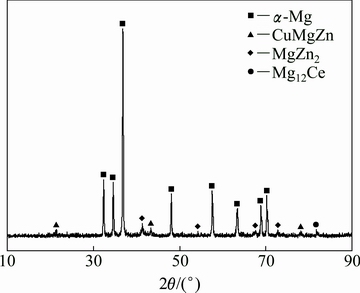

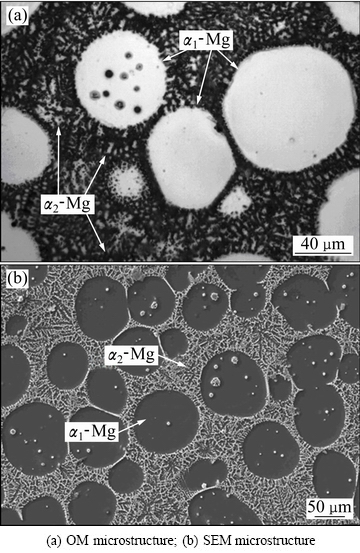

2.1 铸态显微组织

图1(a)所示为Mg-6Zn-1Cu-0.5Ce镁合金铸态的光学显微组织,结合XRD谱(见图2)可知,合金主要由呈白色的α-Mg基体和呈黑色的共晶组织组成,其中共晶组织由α-Mg、CuMgZn、MgZn2、Mg12Ce组成,并以不连续网状沿晶界分布。对共晶组织进行SEM 观察,如图1(b)所示,共晶组织有层片状和孤立的颗粒状两种形态,即分别为层片共晶组织和离异共晶组织。当温度降低至液相线温度时,α-Mg相析出,溶质原子不断排出,降低至共晶温度后,共晶相析出。根据XRD谱所示(见图2),Mg12Ce相对应的衍射峰较少,这说明添加微量稀土元素形成的稀土相很少,这与稀土加入量较少有关。

图1 Mg-6Zn-1Cu-0.5Ce合金铸态显微组织

Fig. 1 As-cast microstructures of Mg-6Zn-1Cu-0.5Ce alloy

图2 Mg-6Zn-1Cu-0.5Ce镁合金的XRD谱

Fig. 2 XRD pattern of as-cast Mg-6Zn-1Cu-0.5Ce alloy

2.2 非枝晶组织演变过程

2.2.1 保温温度对非枝晶组织的影响

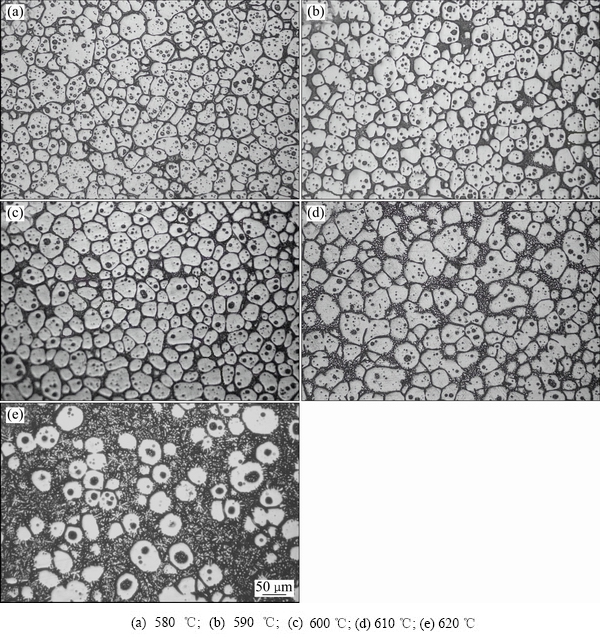

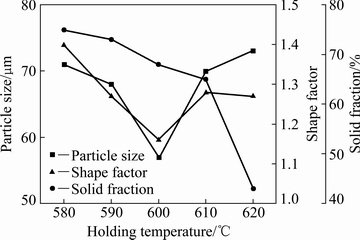

图3所示为Mg-6Zn-1Cu-0.5Ce合金在不同温度下保温25 min的非枝晶组织形貌,图 4 所示为非枝晶颗粒平均尺寸、形状因子和固相分数随保温温度变化的曲线。分析可知,当等温温度为580 ℃时,固相率较高,非枝晶颗粒尺寸较大,并且不圆整(见图3(a))。随着温度的升高,固相率逐渐降低,半固态颗粒尺寸有所减小且半固态颗粒逐渐变得较为圆整(见图3(b))。当等温温度达到600 ℃时,非枝晶颗粒尺寸和形状因子最小,分别为57 μm和1.16 (见图3(c))。当等温温度为610 ℃时,Mg-6Zn-1Cu-0.5Ce合金中的液相量显著增加,非枝晶颗粒平均尺寸和形状因子明显增大,主要是由于非枝晶颗粒之间的合并长大导致非枝晶颗粒平均尺寸增加。由于合并后的非枝晶颗粒形状并不规则,引起形状因子增大(见图3(d))。当保温温度达到620 ℃时,非枝晶颗粒尺寸和形状因子分别为73 μm和1.27(见图3(e)),此时,颗粒合并造成的颗粒不圆整因素有所降低,因此,形状因子较610 ℃时的略有减小。

图3 Mg-6Zn-1Cu-0.5Ce合金保温25 min的组织

Fig. 3 Microstructures of Mg-6Zn-1Cu-0.5Ce alloy heated at different temperatures for 25 min

图4 Mg-6Zn-1Cu-0.5Ce合金在不同温度保温25 min的颗粒平均尺寸、形状因子和固相率

Fig. 4 Particle size, shape factor and solid fraction of Mg-6Zn-1Cu-0.5Ce alloy heated at different temperatures for 25 min

2.2.2 保温时间对非枝晶组织的影响

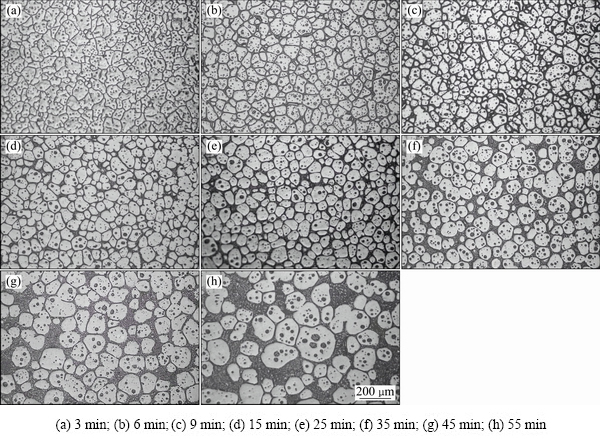

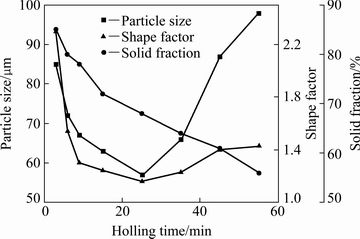

综上所述可知:Mg-6Zn-1Cu-0.5Ce合金在600 ℃保温25 min的半固态组织较为理想,故选择在600 ℃下研究保温不同时间的半固态非枝晶组织演变,如图5所示;图6所示为非枝晶颗粒平均尺寸、形状因子和固相分数随保温温度变化的曲线。保温3 min后,共晶组织迅速向α-Mg基体中固溶,组织中出现颗粒边界,但没有出现明显的液相区,如图5(a)所示。保温6 min时,颗粒之间的液相有所增加,颗粒之间出现明显的边界,如图5(b)所示。保温9 min时,二次枝晶臂开始缩颈熔断,与主干分离,形成不规则的块状组织固相颗粒尺寸明显减小且形状因子急剧降低,同时固相率降低,如图5(c)所示。保温15 min时,过于细小的破碎颗粒相熔化,颗粒之间的液相明显增加,颗粒形状因子继续减小,如图5(d)所示。当保温时间达到25 min时,细小的球状颗粒均匀地分布在液相中,此时半固态颗粒平均尺寸和形状因子均为最佳状态,颗粒平均尺寸达到57 μm,形状因子为1.14,如图5(e)所示。保温时间达到35 min时,颗粒之间的液相大幅度增加,颗粒之间开始出现合并现象,如图5(f)所示。进一步增加保温时间至45 min和55 min,进入颗粒熟化阶段,如图5(g)和(h)所示,液相量在此阶段急剧增加,小颗粒开始被大颗粒合并消失,固相颗粒数量开始减少,大颗粒明显粗化,固相颗粒平均尺寸大幅增大,达到98 μm。

图5 Mg-6Zn-1Cu-0.5Ce合金在600 ℃保温不同时间的非枝晶组织演变

Fig. 5 Non-dendritic microstructure evolution of Mg-6Zn-1Cu-0.5Ce alloy heated at 600 ℃ for different time

图6 Mg-6Zn-1Cu-0.5Ce合金在600 ℃保温不同时间的颗粒平均尺寸、形状因子和固相率

Fig. 6 Particle size, shape factor and solid fraction of Mg-6Zn-1Cu-0.5Ce alloy heated at 600 ℃ for different time

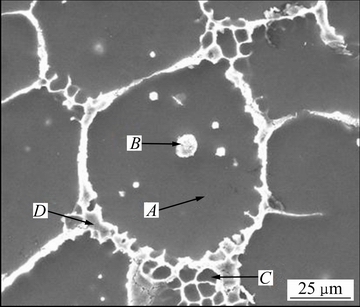

2.3 非枝晶组织特征

Mg-6Zn-1Cu-0.5Ce合金非枝晶组织由固相和液相组成。其中固相水淬后转化为球状的初生α1-Mg相,而液相通过水淬形成二次凝固组织α2-Mg相及共晶组织。水淬后形成的细小二次凝固组织α2-Mg和共晶组织均匀分布在初生的α1-Mg相之间。初生颗粒表面有“毛刺”状组织,如图7(a)所示,原因是重熔过程是处于动态平衡过程,熔化和凝固同时进行,部分α2-Mg会在初生α1-Mg表面形核和长大。共晶组织呈网状分布并且将初生α1-Mg固相颗粒及二次凝固组织α2-Mg隔离。共晶组织在半固态组织中以3种形式分布:在固相颗粒内部以小液滴形式出现;两晶粒边界呈液态薄膜以直线型或弧线型分布;3个晶粒间呈液态熔池以不规则块状形状分布。

通过EDS分析表明,C点对应α2-Mg中溶质的含量明显要高于A点对应的初生相α1-Mg,如表1所列。这是因为非枝晶组织液相所含溶质元素多于半固态颗粒,而α1-Mg来源于初生半固态颗粒,α2-Mg由液相经水淬得到的。另外,B、D两点所含的Zn和Cu两种溶质的含量很高,表明该区域属于共晶组织。其中B点对应的是初生半固态颗粒内部的小液滴。

在后期的保温过程中,该区域不断向基体中扩散和熔化,形成包裹在晶粒内部的小液滴。而D点对应的是液态薄膜、熔池。位于晶界及亚晶界低熔点的共晶相率先熔化,促使液相生成,并首先以点状形式存在,随后不断扩展发展形成液相薄膜。而颗粒外部的液态熔池主要是由于枝晶根部高溶质浓度的区域熔化,一般分布于若干个颗粒的交界处。

图7 Mg-6Zn-1Cu-0.5Ce合金经600 ℃保温35 min后水淬显微组织

Fig. 7 Quenching microstructures of Mg-6Zn-1Cu-0.5Ce alloy heated at 600 ℃ for 35 min

图8 Mg-6Zn-1Cu-0.5Ce合金600 ℃保温25 min后的SEM组织

Fig. 8 SEM image of Mg-6Zn-1Cu-0.5Ce alloy heated at 600 ℃ for 25 min

表1 图8中各点的EDS分析结果

Table 1 EDS analysis results of points in Fig. 8

3 讨论

3.1 非枝晶组织演变机理

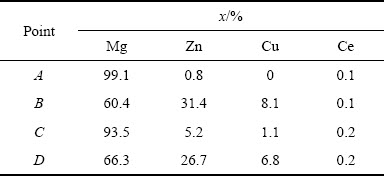

3.1.1 非枝晶组织的分离及分离后的颗粒形貌

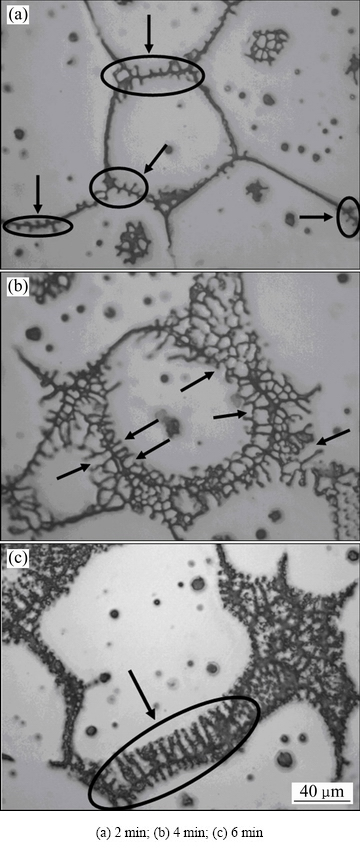

在部分重熔初期阶段,经历了枝晶粗化并开始分离后,均质扩散处于主导地位。随着温度的逐渐升高,由于固溶体中存在能量及成分起伏,亚晶界将在固溶体中出现。这些固溶体的出现,加速了颗粒的分离,在保温3 min的Mg-6Zn-1Cu-0.5Ce合金中,出现的亚晶界如图9中的箭头所示。在半固态演变初期,晶界与亚晶界共同提供了液相渗透路径,加速了溶质原子的扩散。在随后的保温过程中,在亚晶界附近富集的溶质原子有利于大颗粒分离成小颗粒,这种驱动力的出现加速了Mg-6Zn-1Cu-0.5Ce合金的熔化与分离。

图9 Mg-6Zn-1Cu-0.5Ce合金经600 ℃保温3 min后的显微组织

Fig. 9 Microstructure of Mg-6Zn-1Cu-0.5Ce alloy heated at 600 ℃ for 3 min

图10 Mg-6Zn-1Cu-0.5Ce合金600℃保温组织

Fig. 10 Microstructure of Mg-6Zn-1Cu-0.5Ce alloy heated at 600 ℃ for different time

在颗粒之间形成明显的边界后,颗粒边界出现由边界延伸入颗粒内部的“小枝”,如图10(a)中箭头所指圆圈部位。随着颗粒边界逐渐分开,这些“小枝”变的更为粗大,密集的排布在分离开的颗粒周围,如图10(b)箭头所指示部位。随着颗粒的进一步分离,这种“小枝”会变成明显的“长枝”,如图10(c)中箭头所指圆圈部位。由热力学理论可知:由于固液界面张力的作用,颗粒表面固相平衡熔点与曲率部位有关。平衡熔点ΔTr随曲率变化的关系式为[15-16]:ΔTr=  (式中:σ为固/液界面张力;Tm为固液界面的熔点;Vs为固相摩尔体积;ΔHm为固液转变时摩尔焓;k为固液界面曲率)。故固相颗粒表面凸出的地方曲率半径小,熔点低,在重熔过程中容易优先熔化,从而使颗粒趋于圆整。

(式中:σ为固/液界面张力;Tm为固液界面的熔点;Vs为固相摩尔体积;ΔHm为固液转变时摩尔焓;k为固液界面曲率)。故固相颗粒表面凸出的地方曲率半径小,熔点低,在重熔过程中容易优先熔化,从而使颗粒趋于圆整。

3.1.2 非枝晶组织的根部重熔与小液池

根部重熔在非枝晶组织的形成过程中也占据了重要地位。在重熔过程中,根部的高溶质含量区域不断地熔化,出现颈缩现象,如图11圆圈部分所示。继续延长保温时间,液相进一步增加,根部会进一步颈缩,最后发生熔断使得一个枝晶臂颗粒转变成几个小颗粒或者是一个大颗粒变成几个小颗粒。引起根部重熔的根本原因是溶质原子的扩散,根部的溶质不断向基体扩散,使得根部区域的熔点降低,从而造成根部的颈缩、熔断。

图11 Mg-6Zn-1Cu-0.5Ce合金600 ℃时的保温组织

Fig. 11 Microstructure of Mg-6Zn-1Cu-0.5Ce alloy heated at 600 ℃

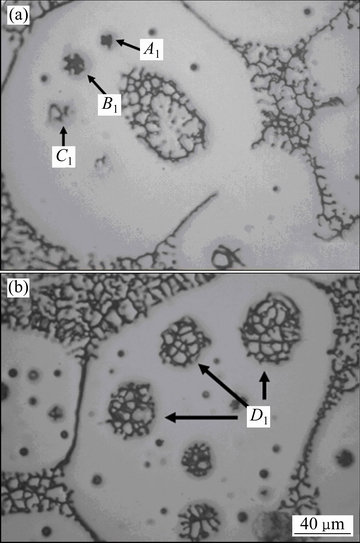

虽然非枝晶颗粒的形成,以根部重熔及亚晶界的作用为主,但颗粒内部的小液池形成、扩展也是大颗粒分离成小颗粒的一个重要方式。小液池的形成主要有两种途径:首先是富集于晶粒内部的高浓度的Zn和Cu元素在升温的初始阶段没有完全固溶于基体中,而在随后的保温过程中得到熔化;另外是在初期扩散过程中,枝晶臂的搭接包裹了部分的共晶组织。颗粒分离初期,在很多大颗粒内部出现小块状的小液池,如图12(a)中的A1点。随着时间的推移,能量起伏的增大,有些小液池会迅速扩展,例如图12(a)中的B1点。有些小液池起始形貌会形成类似河流状,例如图12(a)中的C1点。当这种小液池在能量起伏能满足扩展要求时,这种小液池就会继续扩展,形成图12(b)的D1点箭头所示。但这种扩展方式有较多局限性,因此,有较多的非枝晶颗粒表面虽然也出现了类似图12(a)中的A1点类液池,但始终无法扩展,具体的原因还有待于进一步研究。

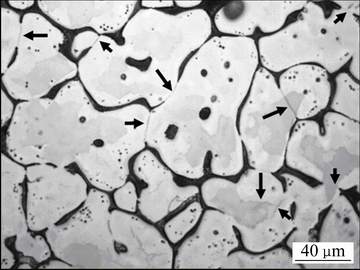

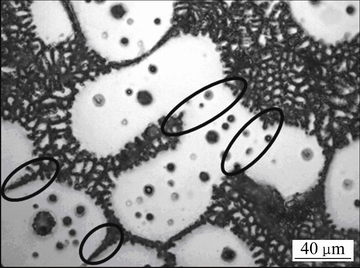

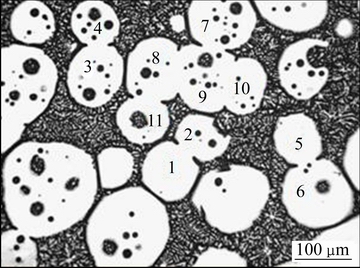

3.2 固相颗粒合并、熟化

对于半固态材料而言,固相与液相的平衡是一种动态平衡。当固相率较高时,长时保温状态下,比较容易观察到颗粒之间的合并;固相率较低时,在颗粒偏聚部位,往往是若干个颗粒集中在一起,颗粒之间的合并也可以观察到。对于非枝晶颗粒,合并的关键原因在于非枝晶颗粒之间的晶界及晶体学取向。如果非枝晶颗粒之间以小角度晶界相邻时,且小角度晶界符合γss<2γsl[17](其中,γss为固/固界面能,γsl为固/液界面能)时,由于固/液界面之间的表面张力作用,相邻晶粒将通过晶界迁移,合并为一个较大的晶粒。非枝晶颗粒的合并也是在一定条件下才可能发生的,当非枝晶颗粒具有相近的晶体学取向时,这种合并更容易发生。这主要是由于在非枝晶颗粒晶体学结构相似时,非枝晶颗粒之间的取向差更小,如果非枝晶颗粒发生合并,系统的能量将会降低,更利于系统的稳定[18-20]。多数情况下,颗粒之间的合并在两个颗粒之间,如图13中标示的颗粒1与2,颗粒3与4,颗粒5与6。但也有几个团聚在一起的非枝晶颗粒同时发生合并的现象,这种合并更利于系统能量的降低,如图13中标示的颗粒7、8、9、10和11。在枝晶熔断初期,也有合并现象,但以熔断为主,表现为分离,在长时间保温阶段,固液相达到平衡,长时间保温时,将以合并为主。从非枝晶颗粒形貌来看,熔断初期的颗粒表面有大量绒毛状凸起,如图10(a)和(b)所示;但长时间保温时,非枝晶颗粒表面圆整,没有大量的绒毛状凸起,如图13中的颗粒所示。

图12 Mg-6Zn-1Cu-0.5Ce合金600 ℃时的保温组织

Fig. 12 Microstructure of Mg-6Zn-1Cu-0.5Ce alloy heated at 600 ℃

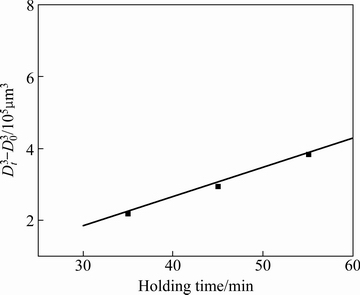

用于半固态成型的合金处于固/液两相时,只有在某一温度保持了足够时间才能达到固/液两相平衡。此时,界面能的降低是通过非枝晶颗粒之间的合并实现的。颗粒合并长大的机制主要为:Ostwald熟化[21-22],即 。其中,Dt为t时刻的平均非枝晶颗粒尺寸;D0为非枝晶颗粒的原始尺寸;K为粗化常数。对Mg-6Zn-1Cu-0.5Ce合金在600 ℃保温35~55 min的非枝晶颗粒利用上述机制进行拟合,如图14所示,Mg-6Zn-1Cu-0.5Ce合金的非枝晶颗粒粗化完全符合该机制。

。其中,Dt为t时刻的平均非枝晶颗粒尺寸;D0为非枝晶颗粒的原始尺寸;K为粗化常数。对Mg-6Zn-1Cu-0.5Ce合金在600 ℃保温35~55 min的非枝晶颗粒利用上述机制进行拟合,如图14所示,Mg-6Zn-1Cu-0.5Ce合金的非枝晶颗粒粗化完全符合该机制。

图13 Mg-6Zn-1Cu-0.5Ce合金经600 ℃保温45 min后的显微组织

Fig. 13 Microstructure of Mg-6Zn-1Cu-0.5Ce alloy heated at 600 ℃ for 45 min

图14 Mg-6Zn-1Cu-0.5Ce合金 与保温时间的关系

与保温时间的关系

Fig. 14 Relationship between  and holding time for Mg-6Zn-1Cu-0.5Ce alloy

and holding time for Mg-6Zn-1Cu-0.5Ce alloy

非枝晶颗粒平均直径较小时,其比表面积也小,界面能较高,在长时间保温的过程中,随着固/液平衡的进行,将不断熔化或消失。在半固态重熔的过程中,随着溶质扩散的进行,大颗粒表面优先沉积,曲率半径相对较小的非枝晶颗粒与曲率半径较大的非枝晶颗粒之间将形成溶质的扩散偶[15]。最终的结果将是:平均直径较小的非枝晶颗粒不断溶解或合并,半固态浆料的非枝晶颗粒平均直径显著增大(见图5(h));保温时间延长到55 min时,非枝晶平均颗粒直径长大至98 μm。

在半固态重熔过程中,Mg-6Zn-1Cu-0.5Ce合金主要经历3个阶段:1) 枝晶熔断阶段,在这个过程中,树枝晶合并粗化;随着温度的进一步升高或者保温时间的延长,在溶质含量相对较高的部位开始熔化,树枝晶分离成不规则的块状组织,此时,根部重熔占主导地位。2) 晶界与亚晶界共同提供了液相渗透路径,颗粒内部出现大量小液池,部分小液池在能量起伏的作用下,加速大颗粒分解成小颗粒,随着时间的延长,颗粒趋向圆整。3) 在固/液接近平衡时,熔化停止,溶质扩散驱动力降低,扩散速度减缓。非枝晶颗粒通过合并及长大进一步降低系统的能量。

4 结论

1) Mg-6Zn-1Cu-0.5Ce铸态组织主要由合金主要由呈白色的α-Mg基体和呈黑色的α-Mg、CuMgZn、MgZn2、Mg12Ce共晶组织组成,共晶组织以不连续网状沿晶界分布。

2) Mg-6Zn-1Cu-0.5Ce合金的非枝晶组织中,固相主要由α1-Mg相和由水淬形成的二次凝固α2-Mg相组成。

3) Mg-6Zn-1Cu-0.5Ce合金在600 ℃保温25 min可获得理想的半固态组织,其颗粒尺寸、圆整度和固相率分别为57 μm、1.16 和 68%;保温35 min后,非枝晶颗粒开始合并和长大,符合Ostwald熟化机制。

4) 非枝晶颗粒初始形成阶段,颗粒之间液相量较少,亚晶界的形成在颗粒分离过程中。随着非枝晶颗粒的分离,颗粒间隙液相量增加,根部重熔将占主导地位。初始分离的颗粒表面不光滑,有许多小凸起。大颗粒内部会出现小液池,部分小液池在能量起伏的作用下迅速扩展,加速大颗粒的分解。固/液平衡阶段,非枝晶颗粒发生Ostwald熟化。

REFERENCES

[1] 冯 凯, 黄晓锋, 马 颖, 吕 峥, 李兴鹏, 郝 远. Al 含量对Mg-7Zn 合金非枝晶组织的影响[J]. 中国有色金属学报, 2013, 23(11): 3039-3047.

FENG Kai, HUANG Xiao-feng, MA Ying, Lü Zheng, LI Xing-peng, HAO Yuan. Effect of Al content on non-dendritic microstructure of Mg-7Zn magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(11): 3039-3047.

[2] 张红安, 陈 刚. 铜/铝复合材料的固-液复合法制备及其界面结合机理[J]. 中国有色金属学报, 2008, 18(3): 414-420.

ZHANG Hong-an, CHEN Gang. Fabrication of Cu/Al compound materials by solid-liquid bonding method and interface bonding mechanism[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 414-420.

[3] CHEN Qiang, LIN Jun, SHU Da-yu, HU Chuan-kai, ZHAO Zu-de, KANG Feng, HUANG Shu-hai, YUAN Bao-guo. Microstructure development, mechanical properties and formability of Mg-Zn-Y-Zr magnesium alloy[J]. Materials Science and Engineering A, 2012, 554: 129-141.

[4] FAN Z, LIU G, WANG Y. Microstructure and mechanical properties of rheo-diecast AZ91D magnesium alloy[J]. Journal of Materials Science, 2006, 41(12): 3631-3644.

[5] ZHANG Liang, WU Guo-hua, WANG Shao-hua, DING Wen-jiang. Effect of cooling condition on microstructure of semi-solid AZ91 slurry produced via ultrasonic vibration process[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2357-2363.

[6] CHEN Qiang, YUAN Bao-guo, ZHAO Gao-zhan, SHU Da-yu, HU Chuan-kai, ZHAO Zu-de, ZHAO Zhi-xiang. Microstructural evolution during reheating and tensile mechanical properties of thixoforged AZ91D-RE magnesium alloy prepared by squeeze casting-solid extrusion[J]. Materials Science and Engineering A, 2012, 537: 25-38.

[7] 张小立, 李廷举, 藤海涛, 谢水生, 金俊泽. 等温热处理过程中铸态AZ91镁合金的微观组织演化[J]. 铸造, 2007, 56(10): 1048-1052.

ZHANG Xiao-li, LI Ting-ju, TENG Hai-tao, XIE Shui-sheng, JIN Jun-ze. Microstructure evolution of as-cast AZ91 magnesium alloy during isothermal heat treatment[J]. Foundry, 2007, 56(10): 1048-1052.

[8] ZHAO Hu, HE Liang-ju, LI Pei-jie. Microstructure of asymmetric twin-roll cast AZ31 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(11): 2372-2377.

[9] 刘 正, 张 奎, 曾小勤. 镁基轻质合金理论基础及其应 用[M]. 北京: 机械工业出版社, 2002.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Academic basis and applications of the magnesium based light alloy[M]. Beijing: China Machine Press, 2002.

[10] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2005.

LI Wen-xian. Magnesium and magnesium alloy[M]. Changsha: Central South University Press, 2005.

[11] CAO Li-jie, MA Guo-rui, TANG Chun-chong. Effects of isothermal process parameters on semid-solid microstructure of Mg-8%Al-1%Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2364-2369.

[12] ZHANG Y, WU G, LIU W, ZHANG L, PANG S, DING W. Microstructure and mechanical properties of rheo-squeeze casting AZ91-Ca magnesium alloy prepared by gas bubbling process[J]. Materials & Design, 2015, 67: 1-8.

[13] GUO H, ZHANG A, HU B, DING Y, LIU X. Refining microstructure of AZ91 magnesium alloy by introducing limited angular oscillation during initial stage of solidification[J]. Materials Science and Engineering A, 2012, 532: 211-219.

[14] ZHANG Liang, WU Guo-hua, WANG Shao-hua, DING Wen-jiang. Effect of cooling condition on microstructure of semi-solid AZ91 slurry produced via ultrasonic vibration process[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2357-2363.

[15] 乐启炽, 崔建忠, 路贵民, 欧 鹏. 两相区铸造 AZ91D 半固态坯料的部分重熔工艺与组织演变[J]. 中国有色金属学报, 2003, 13(6): 1488-1493.

LE Qi-chi, CUI Jian-zhong, LU Gui-min, OU Peng. Microstructure evolution and partially remelting processing of two-phase-region casting AZ91D semisolid slurry ingot[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1488-1493.

[16] XU Hong, ZHANG Xin, WANG Chang-shun, HU Jin-chuan, WANG Cheng, LIU Chang-hua, ZHANG Wei-hua. Semi-solid moulding of AZ91D magnesium alloy[J]. Materials Science Forum, 2016, 850(7): 790-801.

[17] YAN Hong, RAO Yuan-sheng, CHEN Guo-xiang. Rheological behavior of semi-solid AZ91D magnesium alloy at steady state[J]. Journal Wuhan University of Technology, 2015, 30(1): 162-165.

[18] ZHANG Ying, MA Qiang, XU Jin-hua, XIE Shui-sheng, GENG Mao-peng, GUO Hong-min, ZHAO Hai-bo. Numerical analysis on thermal field in rheocasting-rolling of semi-solid magnesium[J]. Materials Science Forum, 2011, 675(6): 957-960.

[19] MURAKAMI Y, OMURA N, LI M J, TAMURA T, MIWA K. Effect of injection speed on microstructure of AZ91D magnesium alloy in semi-solid injection process[J]. Materials Transactions, 2012, 53(6): 1094-1099.

[20] LI Dong-nan, CHEN Wen-zhe, TIAN Jun.Effect of heat treatment on microstructure and mechanical properties of semi-solid formed magnesium alloy AZ91D[J]. 2011, 148(11): 346-352.

[21] ZHAO Zu-de, CHEN Qiang, WANG Yan-bin, SHU Da-yu. Effect of predeformation on semi-solid microstructure of ZK60+RE magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 535-539.

[22] ZHANG Guang-an, MA Cui-yan, ZHOU Qi. Semi-solid billets of AZ91D magnesium alloy prepared by forward extrusion/equal-channel angular pressing[J]. Advanced Materials Research,2011, 299(9): 380-384.

Non-dendritic microstructure evolution process and mechanism of Mg-6Zn-1Cu-0.5Ce magnesium alloy

HUANG Xiao-feng1, 2, MA Zhen-duo1, ZHANG Yu1, BI Guang-li1, LI Ya1

(1. State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Nonferrous Metal alloys and Processing, Ministry of Education, Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: Partial remelting is the important part of semi-solid metal (SSM) ingots forming technology. The non-dendritic microstructure evolution process and mechanism of Mg-6Zn-1Cu-0.5Ce magnesium alloy during partial remelting were investigated by isothermal heat-treatment. The results indicate that the eutectic phases of Mg-6Zn-1Cu-0.5Ce alloy initial microstructure distribute on grain boundary, which gradually dissolves into α-Mg matrix due to the diffusion of the solute, and the remainder is melted when the temperature up to eutectic melted during the initial stage of partial remelting. With the heat preservation time further extending, the semi-solid particles will combine and grow up to reduce the surface energy of the system. Furthermore, the appearance of subboundary and root remelting are the predominant separation mechanisms of particles during partial remelting. The best parameters of isothermal heat treatment are 600 ℃ in holding temperature and 25 min in holding time, obtaining the semi-solid microstructure with the average partial size of 57 μm, the roundness of 1.16 and the solid fraction of 68%.

Key words: Mg-6Zn-1Cu-0.5Ce magnesium alloy; partial remelting; semi-solid; non-dendritic microstructure; evolution mechanism

Foundation item: Project(51464032) supported by the National Natural Science Fund

Received date: 2016-05-31; Accepted date: 2016-11-11

Corresponding author: HUANG Xiao-feng; Tel: +86-13609312769; E-mail: huangxf@lut.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51464032)

收稿日期:2016-05-31;修订日期:2016-11-11

通信作者:黄晓锋,副教授,博士;电话:13609312769;E-mail:huangxf@lut.cn