文章编号:1004-0609(2008)02-0231-06

纳米压痕法测定微铸件硬度及弹性模量

任明星1, 2,李邦盛1, 2,杨 闯1, 2,傅恒志1

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 微纳米技术研究中心,哈尔滨 150001)

摘 要:利用新的金属型微精密铸造工艺制备微米尺度的ZnAl4微齿轮铸件,并用纳米压痕仪测试微铸件的硬度和弹性模量。结果表明,微齿轮铸件不同部位的硬度表现出梯度性,随晶粒尺寸的增加而减小,弹性模量的值比较分散。与常规尺寸铸件的显微硬度相比,微铸件硬度明显提高,最大达到1.70倍,而弹性模量则下降约50%。分析表明快冷造成的非平衡凝固组织是性能改变的主要原因。

关键词:ZnAl4;合金微精密铸造;纳米压痕;纳米硬度;弹性模量

中图分类号:TG 2 文献标识码:A

Hardness and elastic modulus of microcastings by nanoindentation

REN Ming-xing1, 2, LI Bang-sheng1, 2, YANG Chuang1, 2, FU Heng-zhi1

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Micro/nano Technology Research Center, Harbin Institute of Technology, Harbin 150001, China)

Abstract: Micrometer scale gear was manufactured by new micro-precision casting technology based on metal mold, and its hardness and elastic modulus were measured by nanoindentation. The results show that the hardness of microcastings is dependent on the grain size, and decreases with the increase of the grain size. Value of elastic modulus scattered. The hardness of microcastings is higher than that of conventional castings, the maximum up to 1.70 times, but the elastic modulus decreases by about 50%。The property change is caused by the microstructure of non-equilibrium solidification from rapid cooling.

Key words: ZnAl4 alloy; micro-precision casting; nanoindentation; nanohardness; elastic modulus

随着微机械研究的深入和应用领域的扩展,具有复杂形状的金属微构件的制备越来越受到重视[1]。微精密铸造工艺是针对金属微构件制备而开发的一种新的微细加工工艺,德国的BAUMEISTER等提出了基于熔模铸造工艺的微熔模加压铸造工艺和微离心铸造工艺[2-4],随后韩国LG-RPC中心[5]和日本工业大学[6]的科学家也相继提出了新的微精密铸造工艺,并制备了轮廓尺寸在微米量级的微铸件。然而,上述微精密铸造工艺存在生产周期长,工艺重复性较差,以及自动化程度低等缺点,因此BAUMEISTER提出高自动化、高生产率的金属型微精密铸造是今后发展的方 向[4]。作者提出了基于金属型的微精密铸造工艺,并利用此工艺制备了具有三维复杂形状的微齿轮铸 件[7]。

微铸件质量的可靠性直接决定了其工业应用的前景,所以,对微铸件的显微组织和力学性能进行研究是微精密铸造工艺中非常重要的环节。然而,由于微铸件的整体尺寸仅在微米量级,常规的测试手段如单轴拉伸、冲击实验等都不适用,本文作者采用纳米压痕法[8-10]测定微铸件的力学性能。纳米压痕实验是近年来发展起来的针对小载荷、浅压深、微小构件的材料力学性能测试方法,该技术通过具有极高的力分辨率和位移分辨率的纳米硬度计,在压针压入过程中连续获得载荷—压深加载和卸载曲线,利用OLIVER和PHARR方法对加卸载曲线进行数学解析,获得最大压深处的载荷Pmax和接触投影面积Ac,即可得到材料的纳米硬度和弹性模量值。PETHICA、OLIVER和PHARR等[11-13]发展了纳米压痕测试手段,提出了连续刚度测量原理(CSM),利用动态刚度测量,可以在单个压入测试中获得随压入深度连续变化的硬度和模量值,这样就可以研究材料硬度和弹性模量的动态变化过程。

1 实验

1.1 微铸件的制备

微铸件材料为工业上常用的Zn-Al4合金,实际化学成分为(质量分数):3.79%Al,0.029%Mg,杂质量<0.2%,其余为Zn。取成分均匀的ZnAl合金铸锭,在中频感应炉中感应熔炼至460 ℃,降温至430 ℃时在微铸造成形机上铸造成形,成形微齿轮铸件如图1所示。其技术指标为:齿顶直径为600 μm,齿轮轴直径为300 μm,长400 μm。由图1可见,微齿轮成形良好,轮廓清晰,各部分充型完整。常规尺度铸件试样从微齿轮铸件的浇注系统上截取。

图1 微齿轮形貌图

Fig.1 Morphology of microgear

1.2 硬度、模量测试

实验所用的纳米压痕仪为美国MTS公司生产的nano indenter XP型,采用Berkovich型压头,系统的载荷分辨率为50 nN,位移分辨率为0.01 nm。实验加载过程如下:采用载荷控制模式,加载过程中保持加载速率/载荷( )恒定,本文取

)恒定,本文取 =0.05 s-1,直到压深达到1 000 nm,在最大值的位置停留30 s以去除蠕变带来的影响[13],然后以相同速率卸载至10%载荷处,保持1 min,消除热漂移影响,最后完全卸载。压痕形貌由扫描电镜照片给出,分别在微齿轮齿部和轴部的不同位置打点,检验性能差别,每个数据取3次实验的平均值。

=0.05 s-1,直到压深达到1 000 nm,在最大值的位置停留30 s以去除蠕变带来的影响[13],然后以相同速率卸载至10%载荷处,保持1 min,消除热漂移影响,最后完全卸载。压痕形貌由扫描电镜照片给出,分别在微齿轮齿部和轴部的不同位置打点,检验性能差别,每个数据取3次实验的平均值。

常规尺度铸件试样的硬度值由显微硬度给出。玻士压针和维氏压针的测试结果在理论上是可比的[14],当两者的接触深度相同时,纳米压入硬度和显微硬度理论比值为1.076。实验中,选用的载荷为0.5 N,得到的压痕对角线直径为11.32 μm,换算成深度约为1.06 μm,与压痕实验的压入深度相近。

2 实验结果

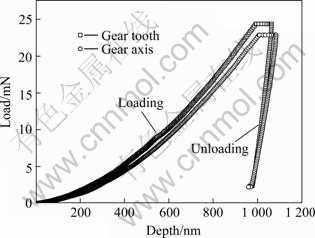

图2所示为微齿轮铸件齿部和轴部某一压痕点的载荷—压深加卸载曲线,其余各点的加卸载曲线类似。微齿轮齿部的最大加载载荷为24.4 mN,轴部的最大载荷为22.8 mN。微铸件的两部分在最大载荷处都表现出了明显的蠕变特性,有关微铸件蠕变特征研究将在后续的文章中作详细介绍。

图2 微铸件典型的载荷—压深加卸载曲线

Fig.2 Typical load—depth curves of microcastings

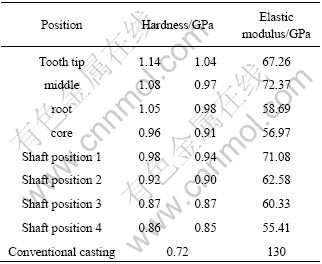

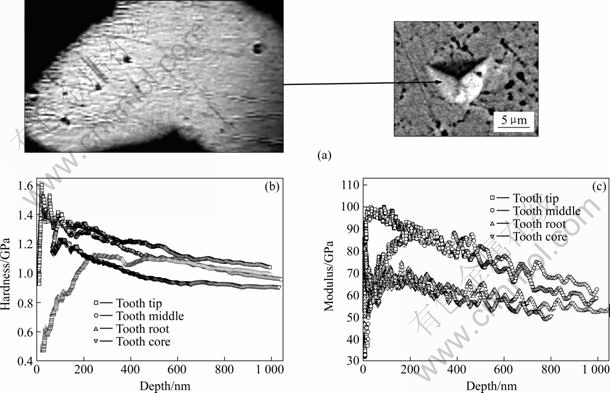

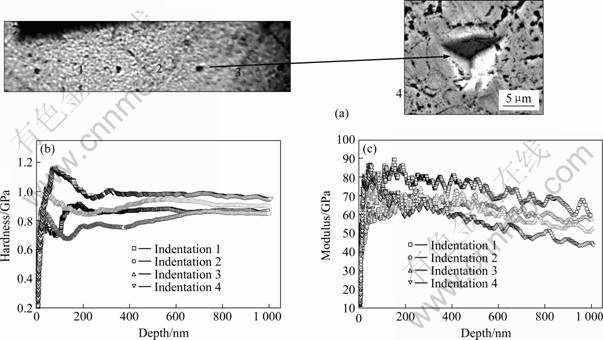

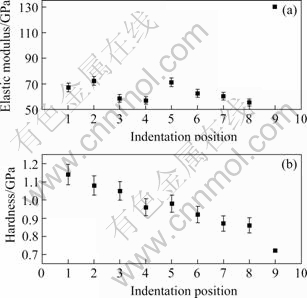

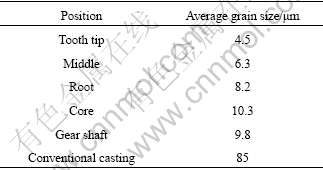

图3所示为微齿轮铸件齿部压痕实验结果,图4所示为微齿轮铸件轴部的压痕实验结果。其中图4(a)、4(b)和4(c)分别为压头压入的位置、硬度-压深曲线和弹性模量-压深曲线。不同位置处的具体的力学参数列于表1,同时表中也列出了常规铸件的力学参数。

表1 微铸件及常规铸件硬度对比

Table 1 Comparison between hardness of microcastings and conventional castings

图3 微齿轮铸件齿部的实验结果

Fig.3 Experiment results of microgear teeth: (a) Nanoindentation positions; (b) Hardness—depth curves; (c) Elastic modulus— depth curves

图4 微齿轮铸件轴部的实验结果

Fig.4 Experimental results of microgear shaft: (a) Nanoindentation positions; (b) Hardness—depth curves; (c) Elastic modulus— depth curves

2.1 微齿轮铸件的纳米硬度

由图3(b)和图4(b)可见,在浅压深处硬度值有突兀的变化,这是由于试样表面状况,如表面粗糙度、机械抛光强化层等都会影响材料的硬度测试,所以表层的数据是不准确的,在对实验数据处理时,取压深从300 nm到1 000 nm时的硬度的平均值。此外,实验过程压痕产生的凸起或者凹陷会影响压痕接触面积的测量精度,从而影响硬度的计算精度,但从图3(a)和 图4(a)所示的压痕形貌上看,微铸件压痕未表现出明显的凸起或凹陷。表1中的硬度值第1列是图3(b)和图4(b)中硬度的平均值,第2列是最大压深1 000 nm处的硬度值。可见,微铸件的硬度随齿顶向齿心的过渡逐渐减小,表现出了明显的梯度性,最大为1.14 GPa,最小为0.86 GPa,梯度值可达1?1.32。齿轮轴部分的硬度要小于齿部,这与微齿轮铸件的凝固顺序有关。此外,与常规铸件相比,即使微铸件的最小硬度(压痕4处)也是常规硬度的1.3倍,而齿顶处的硬度值更是达到了常规铸件的1.7倍,微铸件的性能得到了极大的提升。

2.2 微齿轮铸件的弹性模量

弹性模量曲线同硬度曲线类似,故也取压深300 nm到1 000 nm时的平均值。此外,弹性模量曲线非常不稳定,呈周期性的波动,且有随压深增加而下降的趋势,文献[15]指出,在纳米压痕实验中,即便对于均匀的单晶材料,其测定的模量值也会随着载荷条件(压入深度)变化而发生变化,原因和材料的均匀程度以及微尺度构件的“尺寸效应”有关。由表1中微铸件和常规铸件的弹性模量数据可知,微铸件的弹性模量数值比较分散,并未表现出明显的规律性,齿部和轴部的数值差别不大,都在55~73 GPa之间,但与常规尺寸铸件的130 GPa相比却显著降低。图5给出了不同压点处(与表1的顺序相同,横坐标中的1~9分别对应齿顶~常规铸件)弹性模量和硬度的分布,从图中可以更为清楚地看到上述的分析结果。

图5 弹性模量和硬度的分布

Fig.5 Distribution diagrams of elastic modulus and hardness

3 分析与讨论

性能的改变往往反应在组织的变化上。众所周知,铸件的散热能力正比于其散热表面积与体积的比值,在微精密铸造条件下,由于微铸件的尺寸微小,使得这个比值可达常规铸件的千倍甚至万倍以上,相应的散热能力也比常规铸件提高成千上万倍。因此,在同等凝固条件下,微铸件的冷却速度极快,约在10-4~10-5数量级,在凝固过程中表现出了强烈的非平衡凝固特征,得到了典型的非平衡凝固组织。

3.1 微齿轮铸件的晶粒尺寸对硬度的影响

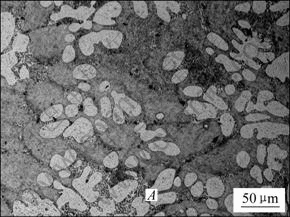

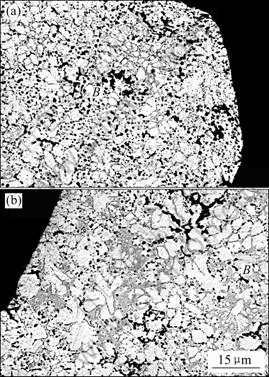

图6和图7分别为常规铸件和微齿轮铸件显微组织的SEM像,选择了对比较明显的齿顶和齿心处的微铸件的组织说明。对比图6、图7,可发现微铸件的晶粒尺寸明显细化,即使在齿心处也只有宏观组织的1/8左右,具体值见表2,且随着从齿顶到齿心过渡(图7(a)~(b)),晶粒尺寸又表现出了逐渐粗化的特征,由齿顶的4.5 μm 过渡到齿心处的10.3 μm,齿轮轴是最后凝固的部位,所以晶粒尺寸相对较大,与齿心处相似,达到9.8 μm。

图6 常规铸件的显微组织的SEM像

Fig.6 SEM image of microstructure of conventional casting

图7 微齿轮铸件显微组织的SEM像

Fig.7 SEM images of microstructures of microgear casting: (a) Tooth tip; (b) Tooth core

表2 微齿轮铸件不同部位的晶粒尺寸

Table 2 Grain sizes of different sites of microgear casting

常规状态下材料的硬度对组织形态表现出依赖性,大部分材料都符合Hall-Petch公式[1, 17],即随着晶粒尺寸的减小,材料的硬度增加。由此可见,微齿轮铸件组织的细化是硬度提高的主要原因,而齿轮硬度的提升能有效的防止齿轮塑性变形失效。

3.2 微齿轮铸件组织形态对弹性模量的影响

弹性模量是原子间结合力的一种表征,对材料的组织不十分敏感。但对固溶体合金而言,当溶质的原子尺寸较大时会引起合金晶格膨胀,导致合金的弹性模量下降[18]。同时,当溶质元素的原子价高于溶剂元素时,也会导致合金弹性模量的下降[18]。针对本实验中使用的材料ZnAl4合金,Zn、Al原子的半径分别为0.274 0、0.286 0 nm,原子价分别为+2价、+3价,所以提高Al原子在Zn基体中的固溶度或者增加固溶体的数量都会引起材料弹性模量的下降。

对比图6与图7,可发现微齿轮铸件初生β-Zn相(图中A区和B区)的体积分数明显增加。从图7(a)~(b)可清楚地观察到:在微齿轮铸件的各部位,初生β-Zn相的数量都极大地增加,尤其是在齿顶处,几乎已达到90%以上;即使是在数量较少的齿心和轴部β-Zn相的体积分数也达到了70%以上,均远大于平衡凝固时的45%。此外,对初生β-Zn相进行EDS分析,结果表明在β-Zn相中Al的质量分数约为6%左右,远大于平衡凝固时室温下的固溶度。由以上分析可知,快速冷却过程造成的非平衡凝固组织是引起微铸件弹性模量下降的主要原因。

4 结论

1) 微齿轮铸件的硬度优于常规铸件,最大提高了约1.7倍,且在微齿轮的齿心、齿根及齿尖等不同部位,硬度表现出对晶粒尺寸的依赖性,随着晶粒尺寸的细化,由0.86 GPa过渡到1.14 GPa。

2) 微齿轮铸件的弹性模量低于常规尺寸铸件,只为常规值的一半左右。分析表明,快速冷却引起的初生β-Zn相体积分数增加和Al在Zn中固溶度的增加是主要原因。

REFERENCES

[1] RUPRECHT R, BENZLER T, HANEMANN T, M?LLER K, KONYS J, PIOTTER V, SCHANZ G, SCHMIDT L, THIES A, W?LLMER H, HAUβBELT J. Various replication techniques for manufacturing three- dimensional metal microstructures[J]. Microsyst Technol, 1997(4): 28-31.

[2] BAUMEISTER G, MUELLER K, RUPRECHT R, HAUSSELT J. Production of metallic high aspect ratio microstructures by microcasting[J]. Microsyst Technol, 2002(8): 105-108.

[3] BAUMEISTER G, RUPRECHT R, HAUSSELT J. Microcasting of parts made of metal alloys[J]. Microsyst Technol, 2004(10): 261-264.

[4] BAUMEISTER G, HAUSSELT J, ROTH S, RUPRECHT R. Microcasting[C]//L?HE D, HAUBELT J. Spec Ed advanced micro and nanosystems: Micro-engineering in metals and ceramics. 2005: 357-393.

[5] CHUNG S, PARK S, LEE L, JEONG H, CHO D. Replication techniques for a metal microcomponent having real 3D shape by microcasting process[J]. Microsyst Technol, 2005(11): 424-428.

[6] HIROYUKI N, SHINICHI A. Study on microcasting(1st Report)[J]. JSPE, 2003, 69(3): 125-129.

[7] 李邦盛, 任明星, 傅恒志. 微精密铸造工艺研究进展[J]. 铸造, 2007, 56(7): 673-678.

LI Bang-sheng, REN Ming-xing, FU Heng-zhi. Research progress of microprecision casting technology[J]. Foundry, 2007, 56(7): 673-678.

[8] CHUDOBA T, RICHTER F. Investigation of creep behaviour under load during indentation experiments and its influence on hardness and modulus results[J]. Surf Coat Technol, 2001(148): 191-198.

[9] Ghosh G. Elastic properties, hardness, and indentation fracture toughness of intermetallics relevant to electronic packaging[J]. J Mater Res, 2004, 19(5): 1439-1454.

[10] DENG X, KOOPMAN M, CHAWLA N, CHAWLA K K. Young’s modulus of (Cu, Ag)-Sn intermetallics measured by nanoindentation[J]. Mater Sci Eng A, 2004(364): 240-243.

[11] PETHICA J B, OLIVER W C. Tip surface interaction in STM and AFM[J]. Phys Scr, 1987(19): 61-68.

[12] PHARR G M, OLIVER W C, BROTZEN F R. On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation[J]. J Mater Res, 1992(7): 613-617.

[13] CHROMIK R R, VINCI R P, ALLEN S L, NOTIS M R. Nanoindentation measurements on Cu-Sn and Ag-Sn intermetallics formed in Pb-free solder joints[J]. J Mater Res, 2003, 18(9): 2251-2261.

[14] LI M, ZHANG T H, GAN C H, LIANG N G. Hardness Testing on surface layer of material and results analyzing contrastively[J]. Chin J Aeron, 2002, 15(2): 82-89.

[15] 张泰华. 微/纳米力学测试技术及其应用[M]. 北京: 机械工业出版社, 2005.

ZHANG Tai-hua. Test technology and applications of micro/nano-mechanics[M]. Beijing: China Machine Press, 2005.

[16] HALL E O. The deformation and ageing of mild steel: ⅢDiscussion of results[J]. Proc Phys Soc B, 1951(64): 747-753.

[17] PETCH N J. The cleavage strength of polycrystals[J]. J Iron Steel Inst, 1953(174): 25-28.

[18] 王俊陞. 合金化元素对弹性模量的影响[J]. 稀有金属, 1979(4): 1-11.

WANG Jun-sheng. Influence of alloying elements on the elastic modulus[J]. Chinese Journal of Rare Metals, 1979(4): 1-11.

基金项目:国家自然科学基金资助项目(50475028)

收稿日期:2007-07-28;修订日期:2007-11-13

通讯作者:任明星,博士;电话:0451-86402266; E-mail: hitrmx@163.com

(编辑 陈爱华)