挤压力对真空吸渗挤压制备2D-Cf/Al复合材料的影响

来源期刊:中国有色金属学报(英文版)2013年第7期

论文作者:马玉钦 齐乐华 郑武强 周计明 鞠录岩

文章页码:1915 - 1921

关键词:比压;真空吸渗挤压;C/Al复合材料;碳纤维;性能

Key words:specific pressure; vacuum and pressure infiltration; C/Al composite; carbon fiber; properties

摘 要:碳纤维增强铝基复合材料(Cf/Al)具有众多优良性能,因而受到广泛重视和应用。采用一体化成形且能够保证高真空度和高浸渗压力的真空吸渗挤压工艺制备二维碳纤维增强铝基复合材料(2D-Cf/Al)。通过微观组织观察,研究不同挤压力(比压)下复合材料的浸渗质量,得到最佳的比压值。结果表明:采用该工艺能够制备出浸渗质量良好的Cf/Al复合材料,最佳比压为75 MPa。此时,铝合金充填均匀,纤维损伤和铸造缺陷较少,浸渗情况良好,复合材料的力学性能最佳,其最大拉伸强度与基体合金相比提高138.9%。

Abstract: Carbon fiber reinforced aluminum matrix (Cf/Al) composite has many excellent properties, and it has received more and more attention. Two-dimensional (2D) Cf/Al composites were fabricated by vacuum and pressure infiltration, which was an integrated technique and could provide high vacuum and high infiltration pressure. The effect of specific pressure on the infiltration quality of the obtained composites was comparatively evaluated through microstructure observation. The experimental results show that satisfied Cf/Al composites could be fabricated at the specific pressure of 75 MPa. In this case, the preform was infiltrated much more completely by aluminum alloy liquid, and the residual porosity was seldom found. It is found that the ultimate tensile strength of the obtained Cf/Al composite reached maximum at the specific pressure of 75 MPa, which was improved by 138.9% compared with that of matrix alloy.

Trans. Nonferrous Met. Soc. China 23(2013) 1915-1921

Yu-qin MA1, Le-hua QI1,2, Wu-qiang ZHENG1, Ji-ming ZHOU1,2, Lu-yan JU1

1. School of Mechanical Engineering, Northwestern Polytechnical University, Xi’an 710072, China;

2. Key Laboratory of Contemporary Design and Integrated Manufacturing Technology of Ministry of Education, Northwestern Polytechnical University, Xi’an 710072, China

Received 30 January 2013; accepted 6 May 2013

Abstract: Carbon fiber reinforced aluminum matrix (Cf/Al) composite has many excellent properties, and it has received more and more attention. Two-dimensional (2D) Cf/Al composites were fabricated by vacuum and pressure infiltration, which was an integrated technique and could provide high vacuum and high infiltration pressure. The effect of specific pressure on the infiltration quality of the obtained composites was comparatively evaluated through microstructure observation. The experimental results show that satisfied Cf/Al composites could be fabricated at the specific pressure of 75 MPa. In this case, the preform was infiltrated much more completely by aluminum alloy liquid, and the residual porosity was seldom found. It is found that the ultimate tensile strength of the obtained Cf/Al composite reached maximum at the specific pressure of 75 MPa, which was improved by 138.9% compared with that of matrix alloy.

Key words: specific pressure; vacuum and pressure infiltration; C/Al composite; carbon fiber; properties

1 Introduction

Carbon fiber reinforced aluminum matrix (Cf/Al) composites have low density, high specific strength, high specific stiffness, good dimensional stability and so on, which have attracted widespread attention in the aerospace and automobile industries. At present, there are many studies on unidirectional Cf/Al composites. DAOUD [1] fabricated nickel coated Cf/2014Al alloy composite by pressure infiltration method, and the pressure applied was 50 kPa. WANG et al [2,3] obtained Cf/Al composite with SiC coating by pressure infiltration, and infiltration quality was desirable under the pressure of 1.5 MPa. However, unidirectional Cf/Al composites have anisotropic properties and it can only guarantee composites with high performance in the axial direction of the carbon fibers. In this respect, 2D-Cf/Al composites have stronger bearing capacity in the two-dimensional directions of carbon fibers. Therefore, 2D-Cf/Al composite has also received some attention, and there have been a few studies on 2D-Cf/Al composites. ZHANG et al [4] prepared two-dimensional Grf/Al composites with squeeze casting, and the mechanical properties of the composites were better than those of the matrix. Carbon fiber cloth has woven structure, and it is also one kind of typical two dimensional carbon fiber materials. It is very dense and uniform, and it has the characteristics of high density and high volume fraction which are beneficial to the preparation of metal matrix composites with high density and high strength.

However, high density and high volume fraction of carbon cloth introduces great challenges in fabrication of this kind of composite, such as high critical infiltration pressure, breakage of carbon fibers and interface reaction. In order to obtain composite with satisfied quality, high vacuum and infiltration pressure are necessary to the successful fabrication into small pores between adjacent fiber bundles and adjacent fibers in the same fiber bundle. Currently, there are many ways to fabricate 2D-Cf/Al composite, such as squeeze casting and gas pressure infiltration. However, it is difficult to provide high vacuum level to squeeze casting. The preparation period of pressure infiltration method is relatively long, which may induce adverse interface reaction. Therefore, traditional fabrication methods can not meet the mentioned experiment requirements. Extrusion directly following vacuum pressure infiltration technique is a kind of new technique for fabricating metal matrix composite, which is proposed by QI et al [5-7]. It combines the advantages of squeeze casting and gas pressure infiltration method, and can provide high vacuum level and high infiltration pressure. Thus, it is a kind of promising technique for fabricating 2D-Cf/Al composites. In this work, the technique is used to fabricate 2D-Cf/Al composite, and the effect of different specific pressure on infiltration quality is studied. Finally, the mechanical properties of composites are studied, too.

2 Experimental

2.1 Material

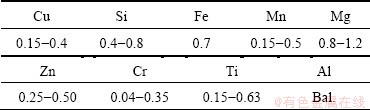

In this work, Al-Mg alloy was selected as matrix and its chemical compositions are shown in Table 1. Its density is 2.73 g/cm3, and its solidus and liquidus temperatures are 580 and 650 °C, respectively. Reinforcement was preform of 3K T300 carbon cloth laminated puncture, whose main properties are shown in Table 2.

Table 1 Chemical component of Al-Mg alloy (mass fraction, %)

Table 2 Physical properties of T300 carbon fibers

2.2 Fabrication process of carbon fiber preform

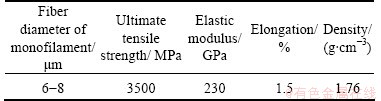

The specific fabrication process of the preform was given as follows. Firstly, soft 3K plain carbon cloth was cured and was cut into d45 mm flakes. Secondly, the flakes were stacked neatly and punctured with T300 carbon fibers. Finally, the preform was placed in CVD furnace to deposit pyrolytic carbon coating on the carbon fibers surface [8]. The process parameters of deposition experiment were listed as follows. The flow rate of N2 was 100-500 L/h. The flow rate of CH4 was 16-24 L/h. The deposition temperature was 1000-1200 °C, and the deposition time was 1-3 h. Ultimately, the preform was obtained as shown in Fig. 1, which shows that the carbon fibers had been coated with pyrolytic carbon.

Fig. 1 Preform of 3K carbon cloth laminated puncture

2.3 Extrusion directly following vacuum pressure infiltration technique

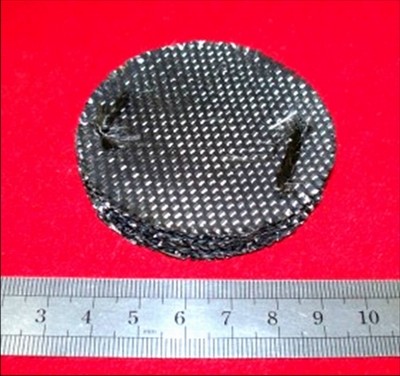

Extrusion directly following vacuum pressure infiltration technique is a kind of new integrated technique for fabricate Cf/Al composite, which integrates aluminum melting, pouring, infiltration, and liquid-solid forming under high infiltration pressure. QI et al [5-7] fabricated many kinds of magnesium and aluminum matrix composites successfully. In melting and pouring processes, the entire system was in sealed state to avoid the oxidization of aluminum alloy and carbon fibers. By controlling the valves, the melting process of aluminum alloy was converted to pouring process. By setting sealing module, the extrusion cavity was used as infiltration chamber in infiltration process. After pressure infiltration, sealing module was removed, and the matrix melt was forced to solidify under high squeezing pressure. The schematic diagram of this technique is shown in Fig. 2.

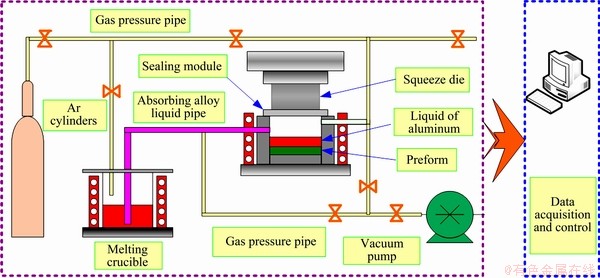

Fabrication of 2D-Cf/Al composite by the technique was as follows: 1) Preform was fabricated and deposited with pyrolytic carbon coating. 2) Mold and melting device of alloy were installed. 3) Mold and preform were preheated to 600-650 °C, and aluminum alloy was melted higher than 750 °C. 4) The process of vacuum pouring was started, and vacuum level was maintained at 0.01-0.05 MPa. 5) Gas pressure was increased to 0.1-0.7 MPa. After the molten alloy was cooled to 580-620 °C, hydraulic machine was started to drive the punch to achieve the final infiltration. 6) After the mold was cooled to room temperature, composite was obtained from the mold. 2D-Cf/Al composite fabricated by extrusion directly following vacuum pressure infiltration technique is shown in Fig. 3, and the volume fraction of 2D-Cf/Al composite is 48%.

Fig. 2 Schematic diagram of extrusion directly following vacuum pressure infiltration technique

Fig. 3 2D-Cf/Al composite fabricated by pressure infiltration technique

3 Results and discussion

3.1 Effect of specific pressure on filtration quality of composite

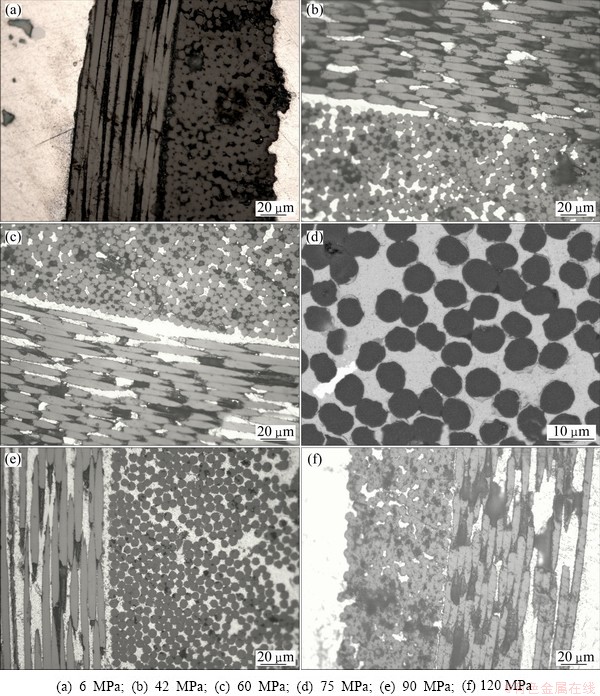

2D-Cf/Al composites were fabricated by several experiments under different specific pressures, such as 6, 42, 60, 75, 90 and 120 MPa. Micrographs of composite are shown in Fig. 4.

Figure 4(a) shows the infiltration quality of alloy in preform when the specific pressure is 6 MPa. The gray part is aluminum alloy, and the dark black part is the two-dimensional carbon fibers. The cutting plane of two staggered arrangement bundles of carbon fibers is shown in the figure. The experimental results show that lots of aluminum alloys fill the pores around the fiber bundles of staggered arrangement. This indicates that a lot of aluminum alloys exist among adjacent bundles, due to the bigger gap.

It shows that the specific pressure has reached critical infiltration pressure among the fiber bundles. However, aluminum alloy can not be seen in the pores inside the fiber bundles. Fibers maintain the original morphology, and the undesirable phenomena such as break, drift and damage of fiber almost can not be found, which is due to the high fiber density inside the bundles. Meanwhile, the fiber bundles of staggered arrangement cause different spaces when they are weaved. This results in non-uniform infiltration. In a word, when the specific pressure is 6 MPa, it has not yet reached the critical infiltration pressure inside the fiber bundle, and the speed of aluminum alloy is not large enough to overcome the infiltration resistance to fill and infiltrate. In order to infiltrate successfully between fibers and fibers within the same fiber bundle, the specific pressure should be increased.

In Figs. 4(b) and (c), the infiltration effect of aluminum alloy into the preform is shown under the specific pressures of 42 and 60 MPa, respectively. There is much more aluminum alloy infiltrated successfully inside the fiber bundles. Break and fracture of fibers cannot be found, too. However, fiber dispersion is not very uniform. This indicates that part of the narrow pore region has not been successful infiltrated inside fiber bundle. Specific pressure is not large enough to overcome infiltration resistance of these pores. In order to get ideal infiltration quality, specific pressure needs further improvement.

Fig. 4 Infiltration quality under different specific pressures

Figure 4(d) shows the infiltration situation of aluminum alloy liquid in the preform when the specific pressure is 75 MPa. The result shows that aluminum alloy liquid distributes evenly inside the fiber bundles. Meanwhile, break and drift of fibers can seldom be found. Figure 4(e) shows the infiltration effect of aluminum alloy liquid in the preform when the specific pressure is 90 MPa. Compared with the previous experiment results, the infiltration quality has been greatly improved. The result shows that the infiltration quality of composite is better in the horizontal and vertical directions. The distribution of fiber and alloy liquid is homogeneous. However, there are some fiber breaks and drifts in composite. The specific pressure at this value has caused damage to the fibers. Too large specific pressure brings too high flowing and filling speed of aluminum alloy, and the force is too strong that it causes damage to fibers, which affects the prosperities of composite.

In Fig. 4(f), infiltration quality of aluminum alloy in the preform is shown under the specific pressure of 120 MPa. The result shows that aluminum alloy is distributed mainly among adjacent fiber bundles, but not much inside the fiber bundles and the infiltration quality is not satisfied. Meanwhile, there are much more defects such as break, drift and damage of fibers. These phenomena show that 120 MPa is beyond the limit of critical infiltration pressure. The flowing velocity of aluminum alloy is very large when it is filling in the preform, and the impact force is very large, too. This undermines the preform, and it is not suitable to fabricate excellent Cf/Al composites.

From above analysis, it is shown that the distribution of aluminum alloy liquid between different fiber bundles of carbon fiber cloth is relatively uniform when the specific pressure is 6 MPa, and it is difficult for aluminum alloy to fill inside the fiber bundles. Defects of carbon fibers are rare because specific pressure is low. With the increase of specific pressure to 42 MPa and 60 MPa, aluminum alloy begins to fill inside the carbon fiber bundles gradually, and the infiltration uniformity is also improved. At the same time, with the increase of specific pressure, aluminum alloy flows in fiber bundles, which leads to a small amount of fiber defects such as drift and break. When the specific pressure is 90 MPa, there is a lot of aluminum alloy filled inside the fiber bundles. Aluminum alloy is uniformly dispersed and the infiltration quality is satisfied. However, the composite also has some defects. Fiber break can be found because of larger pressure, which will affect the properties of composite. When the specific pressure reaches to 120 MPa, the infiltration quality is not ideal, which is due to the excessive specific pressure. When the specific pressure is 75 MPa, the infiltration quality is better and there is no obvious defect.

2D-Cf/Al composite can be fabricated, and the appropriate specific pressure is 75 MPa. If the specific pressure is smaller, the infiltration quality of aluminum alloy liquid is poorer. When the specific pressure is larger, the preform will be destroyed, break and drift of carbon fibers and uneven infiltration will appear [9].

3.2 Mechanical properties and reinforced mechanism

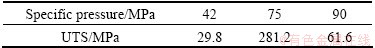

Through testing tensile strength of composite and alloy fabricated under specific pressure of 42, 75 and 90 MPa, and the ultimate tensile strength (UTS) values of transverse direction of composite are 29.8, 281.2 and 61.6 MPa, respectively, which are listed in Table 3.

Table 3 UTS values of composite under different specific pressures listed

From Table 3, when the specific pressure is lower than 75 MPa, infiltration is not sufficient, and UTS is not ideal because of the bad interfacial bonding of aluminum alloy and carbon fibers. If the specific pressure is higher than 75 MPa, UTS is also not satisfied because the preform has been destroyed and defects appear. The specific pressure of 75 MPa is the best value to fabricate Cf /Al composite, and the mechanical property is better than that of others.

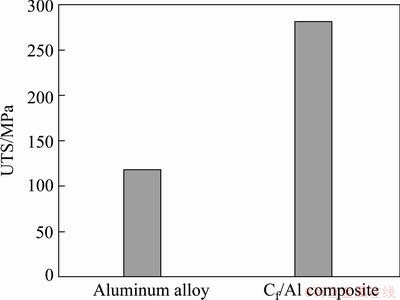

UTS of cast aluminum alloy is 117.7 MPa. UTS of 2D-Cf/Al composite of 281.2 MPa is improved by nearly 138.9% compared with that of matrix alloy under specific pressure of 75 MPa (Fig. 5)

Fig. 5 UTS of aluminum alloy and composite

At present, studies of carbon cloth reinforced metal matrix composites are very few [10-11], and the mechanical properties of the composites are not desired. The reasons are as follows possibly. In carbon cloth reinforced metal matrix composite, the main part of bearing tension is still the transverse fibers. In composite fabricated by 3K T300 carbon cloth laminated puncture preform, directions which can withstand large load are still two orthogonal fiber bundle directions. Although the volume fraction is half of the total volume fraction of composite in the two directions, reinforced mechanism of carbon cloth reinforced metal matrix composite is very different from orthogonal layers preform of unidirectional fiber bundles reinforced metal matrix composite. In the former composite, transverse fibers bear transverse tensile force and axial shear stress, because of the weaving structure of carbon cloth, and this is shown in Fig. 6(a). Shear strength of T300 carbon fibers is very small, and fibers are easy to break, which reduces the mechanical properties of the composite greatly. Meanwhile, fiber bundles have defects when they are weaving. To obtain satisfied composite, shear stress and weaving defects should be controlled effectively.

Fracture surface depends on the interface of the composites. If the interface bonding between carbon and alloy is weak, load can not be sufficiently transmitted and the property of composite is not high. On the contrary, fibers are easy to brittle fracture and the fracture of composite is flat. Therefore, to get ideal 2D-Cf/Al composite, the interface of carbon fibers and alloy should be appropriate, and the fracture should be uneven. Fracture surface of 2D-Cf/Al composite is shown in Figs. 6(a)-(d) under the specific pressure of 75, 42 and 90 MPa, respectively. In Fig. 6(b), some carbon fibers are pulled out and others are cut off. In Fig. 6(c), lots of carbon fibers are pulled out because of the insufficient infiltration quality and weak interface. In Fig. 6(d), most of the fibers are cut off and fracture surface is flat for the large specific pressure and shear force. It shows that the interface of carbon and alloy is not satisfied, and this leads to the ultimate tensile strength of the composite not ideal.

Fig. 6 SEM fracture surfaces of 2D-Cf/Al composite fabricated under different specific pressures

4 Conclusions

1) 2D-Cf/Al composite with satisfied infiltration quality can be fabricated by extrusion directly following vacuum pressure infiltration technique.

2) Appropriate specific pressure is 75 MPa to obtain ideal infiltration quality. Under this pressure, aluminum alloy fills uniformly, and defects can seldom be found in composite.

3) Ultimate tensile strength of 2D-Cf/Al composite is improved by nearly 138.9% compared with that of the matrix alloy at the specific pressure of 75 MPa.

References

[1] DAOUD A. Microstructure and tensile properties of 2014 Al alloy reinforced with continuous carbon fibers manufactured by gas pressure infiltration [J]. Materials Science and Engineering A, 2005, 391: 114-120.

[2] WANG Hao-wei, SHANG Bao-lu, ZHOU Yao-he. Fabrication of high-strength C/A1 composite of low pressure liquid metal infiltration [J]. Journal of Northwestern Polytechnical University, 1992, 10(3): 279-283. (in Chinese)

[3] WANG Hao-wei, ZHANG Guo-ding, WU Ren-jie. Fiber reinforced metal matrix composites liquid metal infiltration filling process [J]. Acta Materiae Compositae Sinica, 1995, 12(1): 38-41. (in Chinese)

[4] ZHANG Yun-he, WU Gao-hui. Microstructure and mechanical properties of 2D-Gr/Al composite [J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 1509-1512.

[5] QI L H, ZHOU J M, SU L Z, OUYANG H B, LI H J. Fabrication of Csf/Mg composites using extrusion directly following vacuum infiltration-part 2: Forming process study [J]. Solid State Phenomena, 2008, 141: 91-96.

[6] LIU J, QI L H, GUAN J T, MA Y Q, ZHOU J M. Compressive behavior of Csf/AZ91D composites by liquid–solid extrusion directly following vacuum infiltration technique [J]. Materials Science and Engineering A, 2012, 531: 164-170.

[7] QI Le-hua, LIU Jian, GUAN Jun-tao, ZHOU Ji-ming, LI He-jun. Tensile properties and damage behaviors of Csf/Mg composite at elevated temperature and containing a small fraction of liquid [J]. Composites Science and Technology, 2012, 72: 1774-1780.

[8] LI Kun, PEI Zhi-liang, GONG Jun, SHI Nan-lin, SUN Chao.Efects of interfacial reaction on tensile strength of carbon fibre reinforced magnesium composites [J]. Chinese Journal of Space Science, 2009, 29(1): 6-9.

[9] WU Gao-hui, HUI Song-mei, NING Wang. The mechanical and thermal expansion properties of two-dimensional carbon fiber/ magnesium matrix composite [J]. Mechanical Engineering, 2008, 32(3): 69-72.

[10] NING Wang. Study of Grf/ZM6 composite mechanical and thermal expansion properties [D]. Harbin: Harbin Institute of Technology, China, 2007. (in Chinese)

[11] QI L H, SU L Z, ZHOU J M, GUAN J T, HOU X H, LI H J. Infiltration characteristics of liquid AZ91D alloy into short carbon fiber perform [J]. Journal of Alloys and Compounds, 2012, 527: 10-15.

[12] LI Hua-lun, MAO Zhi-ying, SHANG Bao-lu, ZHOU Yaohe. Cast high-strength C/Al composites [J]. Acta Materiae Compositae Sinica, 1991, 8(1): 21-25. (in Chinese)

[13] WANG Ji-wen, HONG Tao, LI Ge-yang, LI Peng-xing. A combined process of coating and hybridizing for the fabrication of carbon fiber reinforced aluminum matrix composites [J]. Composites, Part A, 1997, 28: 943-948.

[14] DENG K K, WU K, WU Y W, NIE K B, ZHENG M Y. Effect of submicron size SiC particulates on microstructure and mechanical properties of AZ91 magnesium matrix composites [J]. Journal of Alloys and Compounds, 2010, 504: 542-547.

[15] SONG Mei-hui, WU Gao-hui, CHEN Guo-qin, YANG Wen-shu. Thermal expansion and dimensional stability of unidirectional and orthogonal fabrication M40/AZ91D composites [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 47-53.

[16] RUSSELL-STEVENS M, PLANE D C, SUMMERSCALES J, SCHULZ P, PAPAKYRIACOU M. Effect of elevated temperature on ultimate tensile strength and failure modes of short carbon fibre reinforced magnesium composite [J]. Materials Science and Technology, 2002, 18(5): 501-506.

[17] YU Xue-bin, CHEN Jun, XU Geng, ZHANG Guo-ding, WU Ren-jie. Investigation of thermal expansion and internal stress of C/Al composites [J]. Acta Materiae Compositae Sinica, 1997, 14(1): 43-47. (in Chinese).

马玉钦1,齐乐华1,2,郑武强1,周计明1,2,鞠录岩1

1. 西北工业大学 机电学院,西安 710072;

2. 西北工业大学 教育部现代设计与集成制造技术重点实验室,西安 710072

摘 要:碳纤维增强铝基复合材料(Cf/Al)具有众多优良性能,因而受到广泛重视和应用。采用一体化成形且能够保证高真空度和高浸渗压力的真空吸渗挤压工艺制备二维碳纤维增强铝基复合材料(2D-Cf/Al)。通过微观组织观察,研究不同挤压力(比压)下复合材料的浸渗质量,得到最佳的比压值。结果表明:采用该工艺能够制备出浸渗质量良好的Cf/Al复合材料,最佳比压为75 MPa。此时,铝合金充填均匀,纤维损伤和铸造缺陷较少,浸渗情况良好,复合材料的力学性能最佳,其最大拉伸强度与基体合金相比提高138.9%。

关键词:比压;真空吸渗挤压;C/Al复合材料;碳纤维;性能

(Edited by Chao WANG)

Foundation item: Projects (51221001, 51275417) supported by the National Natural Science Foundation of China; Project (SKLSP201103) supported by the Fund of the State Key Laboratory of Solidification Processing; Project (B08040) supported by the Introducing Talents of Discipline to Universities, China

Corresponding author: Le-hua QI; Tel: +86-29-88460447; E-mail: qilehua@nwpu.edu.cn

DOI: 10.1016/S1003-6326(13)62677-1