DOI:10.19476/j.ysxb.1004.0609.2018.12.14

织物结构对2.5D-Cf/Al复合材料微观组织与力学性能的影响

胡银生,余 欢,王振军,徐志锋,董敬涛

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:选用浅交弯联、浅交直联、层联结构的M40碳纤维机织物为增强体材料,采用真空气压浸渗法制备纤维体积分数为48%,基体合金为ZL301的2.5D编织M40碳纤维增强铝基复合材料(2.5D-Cf/Al),研究织物结构对2.5D-Cf/Al 复合材料微观组织与力学性能的影响。结果表明:复合材料的致密度随着织物结构的改变而变化,其中浅交直联结构的2.5D-Cf/Al复合材料的致密度最大为98.5%;织物结构对复合材料的经向拉伸强度有较大影响,浅交直联结构的2.5D-Cf/Al复合材料经向拉伸强度最高,为414.85 MPa,其拉伸断口参差不齐,呈现出适中的界面结合强度;织物结构对复合材料纬向拉伸强度的影响较小,拉伸断口形貌差异不明显。

关键词:织物结构;2.5D-Cf/Al 复合材料;真空压力浸渗法;微观组织;力学性能

文章编号:1004-0609(2018)-12-2512-11 中图分类号:TB331 文献标志码:A

三维编织增强铝基复合材料由于其特殊的纤维编织方法,使增强纤维在三维空间内相互交织、搭接在一起形成不分层的整体结构,不仅克服了单向和二维增强复合材料的抗冲击性能差且易于发生横向开裂和分层问题[1-2],还具有高比强度、高比模量和结构-功能可设计性强等优点[3],正逐渐发展成为极具应用潜力的先进金属基复合材料,在21世纪航空航天、先进武器、汽车、电子等领域作为高强度、高模量、抗老化和耐高温材料显现出巨大的应用潜力[4-5]。

2.5D织物复合材料是三维编织复合材料领域的一个分支,与2D叠层结构相比,2.5D织物结构层间和整体性能更好;与3D编织结构相比,2.5D机织结构的机织工艺相对更为简单,降低了制造成本并缩短了制造周期,且能够编织出各种类型的复杂结构件[6-7]。李明[8]研究2.5D机织复合材料在受冲击后的剩余强度并与二维平面层合板进行了对比,研究结果表明2.5D机织复合材料与2D叠层复合材料相比,抗冲击载荷能力明显更强;焦亚男等[9]制备了五种不同经/纬向纤维体积比例的2.5D织物复合材料,研究了经/纬向纤维体积比例与复合材料力学性能的关系,研究结果证实了2.5D机织复合材料的经向和纬向的拉伸、弯曲、压缩强度与该方向上的纤维体积比例成正比;董伟锋等[10]在对已有2.5D编织复合材料分析研究基础上,建立了一种新的有限元模型,有效地模拟出了2.5D编织结构内部经纱和纬纱的轮廓及走向,并通过有限元模拟计算与实验值的比较论证了该模型可以预报2.5D编织复合材料的有效弹性性能。然而,这些大都是有关2.5D织物增强陶瓷基和树脂基复合材料的研究,而关于2.5D织物增强铝基复合材料的研究鲜见有关报道[11-12]。对于2.5D碳纤维织物增强铝基复合材料,其宏观力学性能除了取决于界面结合状态外,还取决于其增强织物的细观结构[13],目前还缺乏关于2.5D织物增强铝基复合材料织物结构对其各向力学性能和断裂失效行为影响的研究[14]。

因此,本文作者选用M40碳纤维的2.5D机织物为增强体材料,以铝镁系ZL301合金为基体,采用真空辅助压力浸渗法制备体积分数为48%的2.5D-Cf/Al复合材料,研究浅交弯联、浅交直联和层联三种典型的2.5D织物结构复合材料的致密度和微观组织,测试三种复合材料经向和纬向的极限抗拉强度,并采用SEM、XRD对不同织物结构的2.5D-Cf/Al复合材料拉伸断口形貌进行了研究和分析,为深入掌握2.5D-Cf/Al复合材料微观组织及细观结构与力学性能之间内在关系,进一步合理设计其织物结构和制备工艺提供理论依据。

1 实验

1.1 实验材料

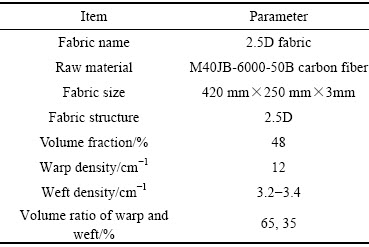

实验选用东丽公司生产的M40碳纤维编制得到的2.5D纤维预制体为增强体材料,2.5D编织纤维预制体尺寸为420 mm×250 mm×3 mm,M40碳纤维性能参数如表1所列,其机织工艺参数见表2,2.5D预制体织物及细观结构模型如图1所示。基体合金为ZL301,元素成分含量如表3中所列,其中所含主要的合金元素是含量为9.5%~11.0%的Mg(质量分数),目的是有效降低铝液的表面能,降低界面能,改善铝液与碳纤维之间的润湿性,同时一定程度上抑制Al4C3相的生成,阻挡有害的界面反应,对纤维起到一定的保护作用[15]。

表1 M40碳纤维的性能参数

Table 1 Property index of M40 carbon fiber

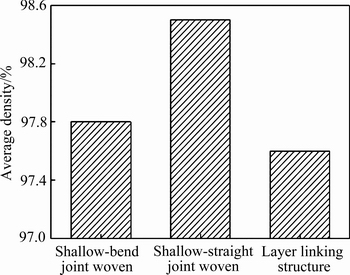

表2 2.5D碳纤维织物机织工艺参数

Table 2 Weaving process parameters of 2.5D carbon fiber fabric

表3 基体铝合金的化学成分

Table 3 Chemical composition of aluminum

图1 2.5D纤维织物及机织结构示意图

Fig. 1 2.5D fabric appearance and architecture

1.2 实验方法

采用真空气压浸渗法制备2.5D-Cf/Al复合材料,将精炼好的铝液在纯氩气保护气氛中继续加热至720 ℃,纤维预制体预热温度为530 ℃,浸渗过程使用氮气进行加压,压力为8 MPa,保压时间20 min,2.5D-Cf/Al复合材料中M40碳纤维所占的体积分数为48%,所制备的试样为420 mm×250 mm×3 mm的2.5D-Cf/Al复合材料板状试样。

真空气压浸渗法是根据反重力成型原理来实现复合材料的近净成型,真空气压浸渗装置与模具如图2所示。复合材料浸渗所使用的设备是川西机器厂生产的ZYQ250/400型真空气压浸渗设备。真空气压浸渗设备的上下罐温度和压力等都可通过控制系统全程自动控制。真空气压浸渗设备的技术指标为真空度小于210 Pa,最高设定温度1000 ℃,最大充型压力10 MPa,密封性好;气体的充填与卸压过程平稳,最小速度可调节至100 kPa/s,压力可在0~10 MPa内任意调节。设备内温度采用双热电偶分别对金属液和炉膛进行实时温度控制,温度误差范围可控制在±5 ℃。

图2 真空气压浸渗装置与模具示意图

Fig. 2 Schematic diagram of vacuum pressure impregnation method

1.3 性能测试

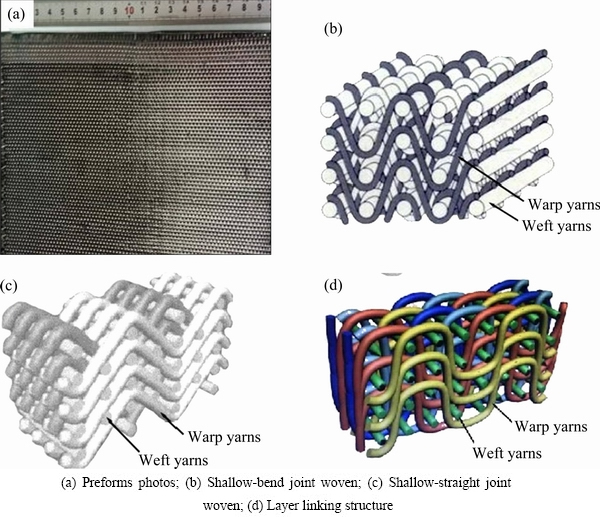

根据GB/T 1447—2005纤维增强塑料拉伸性能试验方法,运用电火花线切割机分别沿经向和纬向将所制备的420 mm×250 mm×3 mm的2.5D-Cf/Al复合材料板状材料切割成标准拉伸试样,拉伸试样如图3所示;采用Instron5543型单立拉伸材料试验机测试复合材料的纬向和经向拉伸力学性能;采用阿基米德排水法测定复合材料试样的实际密度,并计算复合材料的致密度;采用D8ADVANCE型X射线衍射仪(XRD)分析复合材料物相组成及其相对含量;采用Quanta2000型扫描电镜(SEM)观察分析试样微观组织和断口形貌。

图3 2.5D-Cf/Al复合材料拉伸实物图

Fig. 3 Tensile physical drawing of 2.5D-Cf/Al composite material

2 结果与分析

2.1 织物结构对2.5D-Cf/Al复合材料致密度的影响

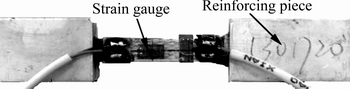

复合材料的致密度是反映真空气压浸渗制备复合材料完整性的重要指标,是决定复合材料性能的重要参数。根据阿基米德原理,采用阿基米德排水法对截取的复合材料试样进行密度测试,并结合该材料的理论密度计算2.5D-Cf/Al复合材料试样的致密度。图4所示是织物结构和2.5D-Cf/Al复合材料平均致密度的关系图。由图4可以看出,三种织物结构的2.5D-Cf/Al复合材料的平均致密度均达到97%以上,说明采用真空气压浸渗的浸渗效果较好,复合材料组织完整性良好。在同种工艺条件下,随着2.5D织物结构的改变,所制备的2.5D-Cf/Al复合材料中浅交直联结构的复合材料的平均致密度最大,达到98.5%,而层联结构的2.5D-Cf/Al复合材料最低,为97.6%。2.5D-Cf/Al复合材料的平均致密度随着2.5D织物结构的变化而略有变化,主要是2.5D织物的结构差异所造成的。2.5D织物结构的紧密程度即纤维束之间的间隙大小,从高到低依次为层联、浅交弯联、浅交直联。在同种制备工艺条件下,2.5D织物结构越紧密,浸渗过程中的毛细阻力也就越大,这样铝合金液进入到纤维间距较小的区域时需要克服更大的阻力,加大了浸渗难度,使得该区域难以得到完全浸渗,致使复合材料产生一些微缺陷从而影响其致密度。其次,在浸渗过程中由于2.5D织物结构的紧密程度不同,在相同的制备工艺和体积分数条件下,2.5D织物的紧密程度越高,铝合金液接触到碳纤维的面积比例也就更大。由于熔融铝合金与碳纤维织物存在一定的温度差,铝液接触碳纤维的面积越大其冷却速度也就越快,使得铝合金在没有完整填充2.5D织物时就在间隙较小处出现局部凝固现象,阻碍了铝液的流动,出现细微孔隙缺陷,影响复合材料的致密度。

图4 织物结构与平均致密度的关系图

Fig. 4 Relationship between woven fabric structure and average relative density

2.2 织物结构对2.5D-Cf/Al复合材料微观组织的影响

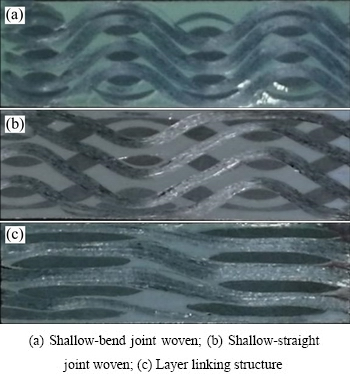

图5所示是三种织物结构2.5D-Cf/Al复合材料的细观结构图。由图5可以看出,三种2.5D织物结构制备的复合材料没有明显的细观结构畸变,都较好地保持了预先设计好的编制构型,表明真空气压浸渗制备复合材料可以最大程度地避免织物结构变形并保持细观结构的完整性。

图5 三种织物结构的细观结构图

Fig. 5 Microstructure characteristics of three woven fabric structures

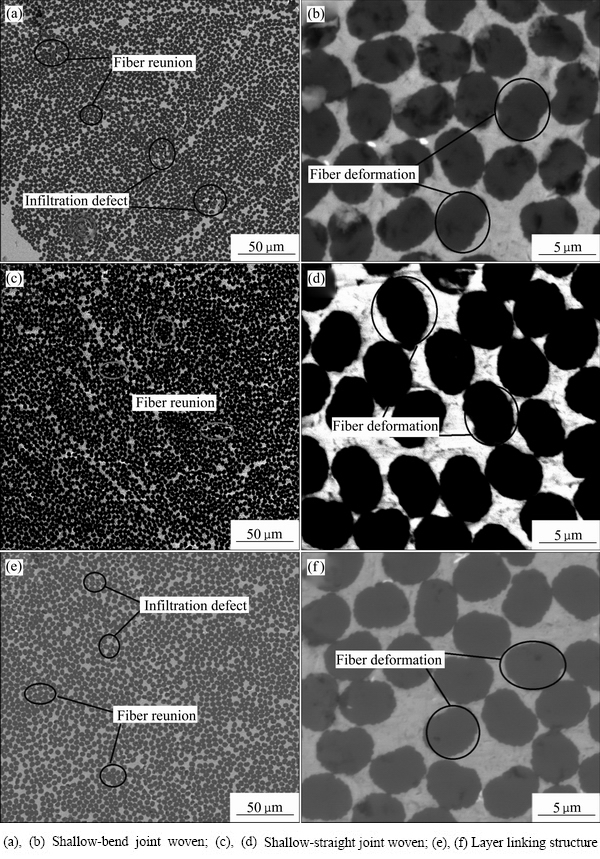

图6所示为不同织物结构的2.5D-Cf/Al复合材料的微观组织图。由图6可以看出,三种织物结构的2.5D-Cf/Al复合材料纤维排布较均匀,束与束之间浸渗完好,基体铝合金充满了纤维束之间的间隙。由图6(a)和(e)可以发现,浅交弯联结构和层联结构的2.5D-Cf/Al复合材料内部存在局部的浸渗微裂纹,且有纤维分布不均匀现象。由图6(c)可以看出,浅交直联结构的2.5D-Cf/Al复合材料微观组织中没有浸渗微孔存在,但依然有局部的纤维团聚现象;观察图6(b)、(d)和(f)可以发现,三种2.5D织物结构复合材料中碳纤维丝浸渗前后的圆度均发生了不同程度的变化,碳纤维丝截面由浸渗前的圆形变成近似椭圆形。

由于三种2.5D织物结构的差异,与浅交直联和层联结构相比,浅交弯联织物结构的经纱弯曲程度更大,且在长度方向上移动相同的距离勾连的纬纱列数更多,这样使得浅交弯联结构更加的曲折。在浸渗过程中,熔融金属液对2.5D织物的充填首先开始于纤维束间,接着在纤维束内,铝液在充填结构紧密且弯曲程度大的地方时受到的阻力更大,容易在弯曲处造成浸渗缺陷,这也是浅交弯联结构的2.5D-Cf/Al复合材料内部存在局部浸渗微裂纹的原因。同时,由于浸渗开始时预制体内外巨大的压力差,铝液在压力作用下流动速度大,纤维在受到铝液的冲击作用后很容易发生变形且局部区域的纤维受冲击力后位置将发生微小的错动而形成纤维偏聚现象。同样,层联结构的2.5D-Cf/Al复合材料的紧密程度最高,即纤维束之间的间隙小,浸渗过程中的毛细阻力较大,也较易出现局部细微孔隙缺陷。而造成纤维截面形状畸变的原因主要在于碳纤维与铝合金的热膨胀系数存在巨大的差异,高温下制备的复合材料降至常温的冷却过程中复合材料内部产生较大的残余应力[16-17],在该应力作用下使得纤维结构形貌发生了变化。

2.3 织物结构对复合材料力学性能的影响

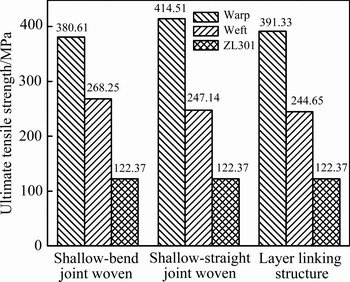

三种织物结构的2.5D-Cf/Al复合材料经向与纬向极限拉伸强度以及随炉制备的铸态ZL301拉伸强度对比如图7所示。由图7可见,随炉制备的铸态ZL301拉伸强度为122.37 MPa,三种2.5D-Cf/Al复合材料的经向拉伸强度依次为380.61、414.51和391.33 MPa;纬向拉伸强度依次为268.25、247.14和244.65 MPa;三种织物结构的2.5D-Cf/Al复合材料经向极限拉伸强度分别是铸态铝合金的3.11倍、3.39倍和3.20倍,其纬向极限拉伸强度分别是铸态铝合金的2.19倍、2.02倍和2.00倍,说明碳纤维增强铝基复合材料的增强效果明显,碳纤维是的主要承载相。织物结构对2.5D-Cf/Al复合材料经向和纬向拉伸强度均有一定影响。三种2.5D织物结构中经纱纤维的弯曲程度从大到小依次为浅交弯联、层联和浅交直联。由于在2.5D织物结构中纤维的屈曲会造成复合材料在该方向上的承载能力的下降,因此,与浅交弯联和层联复合材料相比,浅交直联复合材料经向拉伸强度更高。

图6 不同织物结构的2.5D-Cf/Al复合材料的微观组织

Fig. 6 Microstructure of 2.5D-Cf/Al composites with different fabric structures

图7 铸态ZL301和不同织物结构的2.5D-Cf/Al复合材料经/纬向的拉伸强度

Fig. 7 Tensile strength of ZL301 and 2.5D-Cf/Al composites of different woven fabric structure

而三种织物结构中的纬纱均处于平直状态,因此2.5D织物结构复合材料纬向力学性能受2.5D织物结构的影响并不大。值得注意的是,尽管层联结构的经纱屈曲程度小于浅交弯联结构的复合材料,但层联结构复合材料的经向拉伸强度更低。其主要原因在于层联结构的复合材料界面生成有较多的Al4C3脆性相,使得该复合材料产生过强的界面结合,无法有效发挥纤维承载能力以及界面滑移对载荷能量的耗散作用,最终导致该复合材料性能的下降。此外,三种织物结构的2.5D-Cf/Al复合材料的经向拉伸强度均高于其纬向拉伸强度,展现出更好的经向拉伸承载能力。其原因除了径向纤维的体积分数大之外,主要是由于纬向拉伸时经纱对平直的纬纱无约束作用,经纱未起到增强作用,使得纬纱和基体的界面在横向载荷作用下易于开裂,从而引起复合材料过早失效。而经向拉伸时屈曲的经纱在拉伸载荷作用下有伸直倾向,对纬纱与基体均具有挤压作用。这种压应力可以有效地传递载荷,抑制纬纱和基体界面的纵向开裂倾向,使复合材料展现出更好的经向拉伸承载能力。

图8 不同2.5D织物结构复合材料的XRD谱

Fig. 8 XRD patterns of 2.5D-SiCf/Al composite at different woven fabric structure

图8所示为三种织物结构的2.5D-Cf/Al复合材料的XRD谱。从图8中可以看出,三种2.5D织物结构的复合材料XRD谱线主要是由Al、C、Al4C3及Al3Mg2相的衍射峰组成。采用Bruker D8 X射线衍射仪自带的Topas软件,根据Rietveld多相全谱拟合方法近似计算了各个物相的相对含量。分析结果表明,浅交弯联结构2.5D-Cf/Al复合材料中Al4C3相的近似含量为2.1%;浅交直联结构2.5D-Cf/Al复合材料中Al4C3相的近似含量为1.2%;而层联结构2.5D-Cf/Al复合材料中Al4C3相的近似含量为5.8%。在2.5D-Cf/Al复合材料的制备过程中,界面处碳纤维与铝液会发生如下反应,其反应式如式(1)所示,生成脆性相 Al4C3且铝合金从高温冷却凝固的过程中将会析出脆性β相Al3Mg2,其反应式如式(2):

4Al(l)+3C(s)=Al4C3(s) (1)

-265000+95.06T

-265000+95.06T

式中: 为标准生成吉布斯自由能,kJ/mol;T为热力学温度,K。

为标准生成吉布斯自由能,kJ/mol;T为热力学温度,K。

3Al(l)+2Mg(l)=Al3Mg2(s) (2)

从热力学的角度进行分析,当浸渗温度高于500 ℃时,界面反应(1)就会发生,生成物为Al4C3脆性相。从图8中可以发现,三种2.5D织物结构的复合材料界面产物相近似但含量存在一定的差异,这是由于2.5D织物结构的紧密程度不同,紧密程度从高到低依次为层联、浅交弯联、浅交直联。在相同的浸渗条件下,织物结构越紧密,浸渗过程中铝合金液接触到的碳纤维的面积比例也就更大,界面反应的程度也就更大,所生成的界面脆性相Al4C3也就更多。界面相Al4C3的化学组成和物理性能与碳纤维和基体合金均不相同。图9所示为2.5D-Cf/Al复合材料界面的TEM分析结果,其中图9(a)所示为碳纤维/ZL301基体界面的微观形貌。从图中可以发现2.5D-Cf/Al复合材料界面层明显且较平整,碳纤维保存较完整而且边缘较光滑,界面上大多数区域较为干净,界面结合良好。这是由于ZL301中Mg元素含量高(见表3)且Mg元素对碳纤维具有较强的吸附性,在碳纤维与铝液接触时,Mg元素活性较高迅速吸附在纤维表面,阻碍碳纤维与铝液之间的元素扩散,可以有效控制界面反应[18]。通过对界面区域微观组织的进一步分析,发现了一些明显垂直于纤维的短棒状界面产物。该产物的电子衍射花样标定分析结果如图9(b)所示,可以看出该界面产物为具有斜方六面体晶体结构的Al4C3相。Al4C3相的形核机制为非均匀形核,依附于碳纤维表面形核,在界面处呈针状或片状,且一般垂直于纤维向基体生长生成的,会降低界面对载荷的传递作用;同时脆性的Al4C3在受力条件下容易成为裂纹源,降低纤维的承载能力,降低复合材料的强度。

图10所示为三种织物结构的2.5D-Cf/Al复合材料经向拉伸断口形貌。由图10可以看出,三种复合材料拉伸断口中纤维均呈现出不同程度的起伏状态,断口参差不齐有纤维拔出痕迹且拔出长度较长,经向拉伸断口主要由经纱纤维的拔出和断裂为主。从图10(a)可以发现,经纱断裂位置发生在经纬纱相交处,纬纱则主要表现为沿拉伸方向的束内横向开裂,经向拉伸中在经纬纱相交处易于发生破坏而导致复合材料失效。对比图10(b)、(d)和(f)可以发现,浅交弯联复合材料经向拉伸断口与浅交直联和层联结构的2.5D-Cf/Al复合材料相比,其经纱的断裂更加参差不齐且经纱纤维拔出数量更多。这表明在浅交弯联结构的复合材料中,经纱纤维因屈曲程度较大而在经纬纱交接处受剪切应力作用,更容易发生断裂。此外,层联结构的2.5D-Cf/Al复合材料较其他两种结构的复合材料具有较高的界面相含量,较高的界面结合强度不利于发挥纤维承载能力以及界面滑移对载荷能量的耗散作用,其拉伸断裂后形成较为平齐的断口,展现出脆性断裂特征,拉伸强度较低。

图9 2.5D-Cf/Al复合材料界面的TEM像

Fig. 9 TEM images on interface in 2.5D-Cf/Al composites

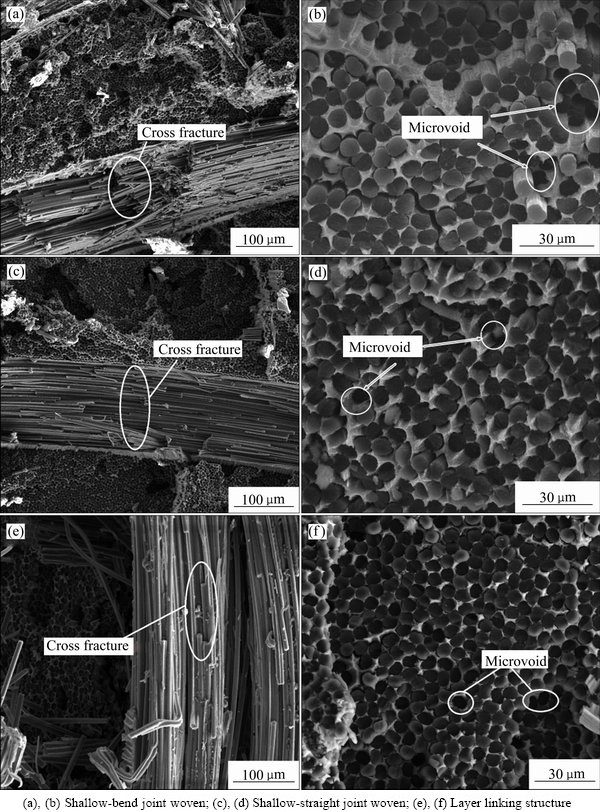

图11所示为三种织物结构2.5D-Cf/Al复合材料纬向拉伸断口形貌。从图11(b)、(d)和(f)可以发现,2.5D-Cf/Al复合材料纬向拉伸断口较经向拉伸断口更为平齐,基体合金中仅存在少量因纤维拔出形成的孔洞。此外,三种织物结构复合材料的纬向拉伸断口形貌差异不明显,这是由于三种2.5D织物结构中纬纱均处于平直分布,弯曲的经纱对纬纱无任何约束作用,2.5D织物结构复合材料的纬向力学性能受2.5D织物结构的影响并不大。2.5D-Cf/Al复合材料的经纱纤维束几乎完全横向开裂,存在因经纱开裂而造成的纤维横向折断现象。2.5D机织结构中经纱缠绕搭接在平直分布的纬纱上(如图1所示),当纬向拉伸时纬纱对经纱缺乏约束作用,平行于拉伸方向的纬纱承受着主要拉伸载荷,应力随应变增加而迅速上升,经纱纤维与基体界面在横向拉伸载荷作用下容易发生开裂。界面横向开裂萌生的裂纹扩展至纬纱界面后,引起界面应力集中并最终导致纬向纤维断裂和经纱纤维整体的横向折断,复合材料达到其极限强度并最终断裂失效。

图10 三种织物结构的2.5D-Cf/Al复合材料经向拉伸断口形貌

Fig. 10 Warp tensile fracture morphology of 2.5D-Cf/Al composites at different woven fabric structures

图11 三种织物结构的2.5D-Cf/Al复合材料纬向拉伸断口形貌

Fig. 11 Weft tensile fracture morphology of 2.5D-Cf/Al composites at different woven fabric structures

3 结论

1) 织物结构是2.5D-Cf/Al复合材料性能的重要影响因素。随着织物结构的改变,2.5D-Cf/Al复合材料的致密度也随之变化。浅交直联结构的2.5D-Cf/Al复合材料致密度最大为98.5%,碳纤维在ZL301中的分布也最均匀,没有明显的浸渗缺陷。

2) 织物结构对2.5D-Cf/Al复合材料的经向拉伸性能有一定的影响。浅交直联结构的2.5D-Cf/Al复合材料的经向拉伸强度达到414.51MPa,比随炉制备的铸态铝合金的抗拉强度提高了339%。由于2.5D机织结构的特点,织物结构对复合材料的纬向拉伸强度影响不大,三种机织结构复合材料的纬向拉伸断口形貌差异不明显。

3) 浅交直联结构2.5D-Cf/Al复合材料的经向拉伸断口参差不齐且有一定数量的纤维拔出,载荷可以有效传递,呈现出适中的界面结合。而层联结构的2.5D-Cf/Al复合材料经向拉伸断裂后形成较为平齐的断口,展现出脆性断裂特征。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J].中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[2] 上官倩芡, 蔡柳华. 碳纤维及其复合材料的发展及应用[J]. 上海师范大学学报. 2008, 37(3): 27-279.

SHANGGUAN Qian-qian, CAI Liu-hua. Development and application of carbon fiber and its composites[J]. Journal of Shanghai Normal University, 2008, 37(3): 27-279.

[3] 王振军, 董敬涛, WANG Gui, 余 欢, 徐志锋, DARGUSCH M S. 2.5维织物Cf/Al复合材料制备及其经纬向拉伸变形力学行为研究[J]. 稀有金属材料与工程, 2017(12): 3744-3752.

WANG Zhen-jun, DONG Jin-tao, WANG Gui, YU Huan, XU Zhi-feng, DARGUSCH M S. Preparation of 2.5-D Cf/Al composites and mechanical behavior of warp and weft stretch deformation[J]. Rare Metal Materials and Engineering, 2017(12): 3744-3752.

[4] 周珍珍, 徐志锋, 余 欢, 王振军. 编织结构对3D-Cf/Al复合材料显微组织和力学性能的影响[J]. 中国有色金属学报, 2016, 26(4): 774-780.

ZHOU Zhen-zhen, XU Zhi-feng, YU Huan, WANG Zhen-jun. Effect of braiding structure on fiber structure and mechanical properties of 3D-Cf/Al composites [J]. Chinese Journal of Nonferrous Metals, 2016, 26(4): 774-780.

[5] 袁秀妹, 余 欢, 王振军, 徐志锋, 朱世学. 纤维预热温度对2.5D-Cf/Al复合材料致密度和强度的影响[J]. 特种铸造及有色合金, 2016, 36(3): 278-282.

YUAN Xiu-mei, YU Huan, XU Zhi-feng, WANG Zhen-jun. Effect of fiber preheating temperature on density and strength of 2.5D-Cf/Al composites[J]. Special Casting and Nonferrous Alloys, 2016, 36(3): 278-282.

[6] YUE T M, CHADWCK G A. Squeeze casting of light alloys and their composites[J]. Journal of Materials Processing Technology, 1996, 58: 302-307.

[7] MACANDER A B, CRANE R M, CAMPONESCHI E T. Fabrication and mechanical properties of multi-dimensionally (X-D) braided composite materials[J]. Composite Naterials: Testing and Design (7tConf.). Philadelphia: American Society for Testing Material, 1986: 422-443.

[8] 李 明. 2.5D机织复合材料冲击后剩余强度研究[D]. 南京: 南京航空航天大学, 2010.

LI Ming. Study on residual strength of 2.5D woven composites after impact[D]. Nanjing: Nanjing University of Aeronautics & Astronautics, 2010.

[9] 焦亚男, 仇普霞, 纪高宁, 徐雪伟. 经纬向纤维体积比例对2.5D机织复合材料力学性能的影响[J]. 天津工业大学学报, 2015, 34(3): 1-5.

JIAO Ya-nan, QIU Pu-xia, JI Gao-ning, XU Xue-wei. Effect of volume ratio of warp to weft on mechanical properties of 2.5D woven composites [J]. Journal of Tianjin University of Technology, 2015, 34(3): 1-5.

[10] 董伟锋, 肖 军, 李 勇. 2.5维编织复合材料力学性能的有限元分析[J]. 材料科学与工程学报, 2007, 25(5): 658-666.

DONG Wei-feng, XIAO Jun, LI Yong. Finite element analysis of mechanical properties of 2.5 dimensional braided composites [J]. Journal of Materials Science and Engineering, 2007, 25(5): 658-666.

[11] 刘秋云, 费维栋, 姚忠凯, 赵连城. 金属基复合材料的热残余应力研究进展[J]. 宇航材料工艺, 1998, 28(3): 1-6.

LIU Qiu-yun, FEI Wei-dong, YAO Zhong-kai, ZHAO Lian-cheng. Development of thermal residual stress in metalmatrix composite[J]. Aerospace Materials & Technology, 1998, 28(3): 1-6.

[12] RUSSELL-STEVENS M, TODD R, PAPAKYRIACOU M. Microstructural analysis of a carbon fibre reinforced AZ91D magnesium alloy composite[J]. Surface and Interface Analysis, 2005, 37: 336-342.

[13] 刘振国. 高性能复合材料管件制作工艺的比较及三维编织技术的应用[J]. 材料工程, 2009(S2): 109-118.

LIU Zheng-guo. Comparison of manufacturing technology of high performance composite pipe fittings and application of 3D braiding technology[J]. Material Engineering, 2009(S2): 109-118.

[14] 沈怀荣. 三维编织复合材料冲击实验与分析[J]. 装备指挥技术学院学报, 2002, 13(2): 84-86.

SHEN Huai-rong. Impact experiment and analysis of three braided composite materials[J]. Journal of Institute of Command and Technology of Equipment, 2002, 13(2): 84-86.

[15] 聂明明, 徐志锋, 余 欢, 王振军, 姚 箐. 基体合金对连续石墨纤维M40/Al复合材料纤维损伤及断裂机制的影响[J]. 复合材料学报, 2016, 33(12): 2797-2806.

NIE Ming-ming, XU Zhifeng, YU Huan, WANG Zhen-jun, YAO Jin. Effect of matrix alloy on fiber damage and fracture mechanism of continuous graphite fiber M40/Al composite[J]. Journal of Composite Materials, 2016, 33(12): 2797-2806.

[16] GUPTA N, NGUYEN N, ROHATGI P K. Analysis of active cooling through nickel coated carbon fibers in the solidification processing of aluminum matrix composites[J]. Composites Part B: Engineering, 2011, 42(4): 916-925.

[17] LI D, CHEN G, JIANG L, XIU Z, ZHANG Y, WU G. Effect of thermal cycling on the mechanical properties of Cf/Al composites[J]. Mat Sci Eng A, 2013, 586(1): 330-337

[18] 聂明明, 徐志锋, 余 欢, 王振军, 姚 菁. 基体对连续Cf/Al复合材料致密度和强度的影响[J]. 特种铸造及有色合金, 2015, 35(12): 1085-1089.

NIE Ming-ming, XU Zhi-feng, YU Huan, WANG Zhen-jun, YAO Jin. Influence of matrix on the density and strength of continuous Cf/Al composites[J]. Special Casting and Nonferrous Alloys, 2015, 35(12): 1085-1089.

[19] 林师朋, 刘金炎, 纪艳丽. CNTs增强铝基复合材料研究现 状[J]. 有色金属科学与工程, 2017, 8(2): 57-62.

LIN Shi-peng, LIU Jin-yan, JI Yan-li. Research status of CNTs reinforced aluminum matrix composites[J]. Nonferrous Metals Science and Engineering, 2017, 8(2): 57-62.

Effect of woven fabric structure on microstructure and mechanical properties of 2.5D-Cf/Al composites

HU Yin-sheng, YU Huan, WANG Zhen-jun, Xü Zhi-feng, DONG Jin-tao

(National Defence Key Discipline Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: The vacuum gas pressure infiltration was used to compose the 2.5D-Cf/Al composites with the volume fraction of 48%, of which the reinforced material was M40 carbon fiber with shallow-bend joint woven, shallow-straight joint woven and layer linking, the matrix alloy was ZL301, to find the effect of woven fabric structure on microstructure and mechanical properties of 2.5D-Cf/Al composites. The results show that the density of 2.5D-Cf/Al composites changes with woven fabric structure, the density of shallow-straight joint woven reaches maximum, 98.5%; the woven fabric structure has great influence on the warp tensile strength of the composites;the warp tensile strength of shallow-straight joint woven reaches maximum, 414.85 MPa, and its tensile fracture surface is uneven and shows moderate interfacial bonding strength; the fabric structure has little influence on the weft tensile strength of the composites, and the difference of tensile fracture surface is not obvious.

Key words: woven fabric structure; 2.5D-Cf/Al composite; vacuum gas pressure infiltration method; microstructure; mechanical property

Foundation item: Projects(51765045, 51365043) supported by the National Natural Science Foundation of China; Project(20171BAB201021) supported by the Natural Science Foundation of Jiangxi Province, China; Project(GJJ1607055) supported by the Research Foundation of Education Department in Jiangxi Province, China

Received date: 2017-10-23; Accepted date: 2018-03-12

Corresponding author: WANG Zhen-jun; Tel: +86-18970951974; E-mail: wangzhj@nchu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51765045,51365043);江西省自然科学基金资助项目(20171BAB201021);江西省教育厅科学技术研究基金资助项目(GJJ1607055)

收稿日期:2017-10-23;修订日期:2018-03-12

通信作者:王振军,副教授,博士;电话:18970951974;E-mail:wangzhj@nchu.edu.cn