深冷轧制制备纳米6061铝合金的热稳定性评估

来源期刊:中国有色金属学报(英文版)2017年第4期

论文作者:M. ABBASI-BAHARANCHI F. KARIMZADEH M. H. ENAYATI

文章页码:754 - 762

关键词:力学性能表征;X射线衍射;铝合金;体变形;晶粒生长;晶粒细化

Key words:mechanical characterization; X-ray diffraction; aluminium alloy; bulk deformation; grain growth; grain refinement

摘 要:研究深冷轧制时效态纳米6061铝合金在100~500 °C下等温热处理过程的晶粒生长。透射电子显微镜观察结果表明经深冷轧制及在130 °C时效30 h,合金显微组织中含有61 nm的晶粒和50~150 nm的析出相,以及0.248%的点阵畸变。此外,由于形成细小的强化相和纳米晶粒,合金的拉伸强度达到362 MPa。在100~500 °C下进行热稳定研究,结果表明,点阵畸变得到减弱,析出相溶解,晶粒长大。X射线衍射结果表明,当退火温度高于300 °C时,Mg2Si相将消失。当退火温度低于200 °C时,晶粒长大不明显,力学性能下降也不明显。但在300~500 °C时,晶粒长大,析出相溶解和力学性能下降都比较明显。在100~200 °C时,晶粒长大的活化能为 203.3 kJ/mol,在300~500 °C时,活化能为166.34 kJ/mol。讨论了析出相溶解对铝点阵常数和XRD(111)面峰位位移的影响,也讨论了PLC对应力应变曲线的影响。

Abstract: Grain growth of nanostructured Al6061 produced by cryorolling and aging process was investigated during isothermal heat treatment in 100-500 °C temperature range. Transmission electron microscopy (TEM) observations demonstrate that after cryorolling and aging at 130 °C for 30 h, the microstructure contains 61 nm grains with dispersed 50-150 nm precipitates and 0.248% lattice strain. In addition, an increase in tensile strength up to 362 MPa because of formation of fine strengthening precipitation and nano-sized grains was observed. Thermal stability investigation within 100-500 °C temperature range showed release of lattice strain, dissolution of precipitates and grain growth. According to the X-ray diffraction (XRD) analysis, Mg2Si precipitates disappeared after annealing at temperatures higher than 300 °C. According to the results, due to the limited grain growth up to 200 °C, there would be little decrease in mechanical properties, but within 300-500 °C range, the grain growth, dissolution of strengthening precipitates and decrease in mechanical properties are remarkable. The activation energies for grain growth were calculated to be 203.3 kJ/mol for annealing at 100-200 °C and 166.34 kJ/mol for annealing at 300-500 °C. The effect of precipitation dissolution on Al lattice parameter, displacement of Al6061 (111) XRD peak and Portevin-LeChatelier (PLC) effect on stress-strain curves is also discussed.

Trans. Nonferrous Met. Soc. China 27(2017) 754-762

M. ABBASI-BAHARANCHI, F. KARIMZADEH, M. H. ENAYATI

Department of Materials Engineering, Isfahan University of Technology, Isfahan 84156-83111, Iran

Received 2 January 2016; accepted 12 October 2016

Abstract: Grain growth of nanostructured Al6061 produced by cryorolling and aging process was investigated during isothermal heat treatment in 100-500 °C temperature range. Transmission electron microscopy (TEM) observations demonstrate that after cryorolling and aging at 130 °C for 30 h, the microstructure contains 61 nm grains with dispersed 50-150 nm precipitates and 0.248% lattice strain. In addition, an increase in tensile strength up to 362 MPa because of formation of fine strengthening precipitation and nano-sized grains was observed. Thermal stability investigation within 100-500 °C temperature range showed release of lattice strain, dissolution of precipitates and grain growth. According to the X-ray diffraction (XRD) analysis, Mg2Si precipitates disappeared after annealing at temperatures higher than 300 °C. According to the results, due to the limited grain growth up to 200 °C, there would be little decrease in mechanical properties, but within 300-500 °C range, the grain growth, dissolution of strengthening precipitates and decrease in mechanical properties are remarkable. The activation energies for grain growth were calculated to be 203.3 kJ/mol for annealing at 100-200 °C and 166.34 kJ/mol for annealing at 300-500 °C. The effect of precipitation dissolution on Al lattice parameter, displacement of Al6061 (111) XRD peak and Portevin-LeChatelier (PLC) effect on stress-strain curves is also discussed.

Key words: mechanical characterization; X-ray diffraction; aluminium alloy; bulk deformation; grain growth; grain refinement

1 Introduction

In recent years, ultra-fine grained/nanostructured (UFG/NS) materials have received a great attention due to their superb mechanical properties[1-4]. However, structural changes, including grain growth and phase transformations as a result of increasing in working temperature will affect attractive properties of the mentioned materials. Generally, severe plastic deformation (SPD) processes are used to produce bulk UFG/NS materials. Recently, UFG/NS materials developed by equal channel angular pressing (ECAP), accumulative roll bonding (ARB), friction stir processing (FSP), high pressure torsion (HPT) and cryorolling (CR) have shown high strength and hardness as compared to coarse-grained structures [5]. Highly unstable microstructure containing non-equilibrium grains and high dislocation density are the main characteristics of severe plastic deformed materials. During recent years, for aluminum alloys cryorolling process followed by optimum heat treatment is introduced as an effective process to develop bulk UFG/NS Al alloys. The excellent mechanical properties during cryorolling is obtained from suppression of dynamic recovery due to deformation at cryorolling temperature, which follows by optimal heat treatment and hence stable UFG/NS materials would be produced, which are suitable for structural and thermomechanical applications. DAS et al [6] have reported the improved tensile strength and impact toughness of the cryorolled Al7075 alloy due to grain refinement, and ultra-fine grain formation by multiple cryorolling passes. According to their results, the yield strength and impact toughness of the cryorolled Al7075 alloy up to 70% thickness reduction have increased by 108% and 60% respectively compared to the starting material. CHENG et al [7] have reported simultaneous increases in strength, work-hardening ability and ductility of cryorolled Al2024 alloy. The effect of deformation at the cryogenic temperatures during rolling of Al6061 and Al6063 was investigated by RAO et al [8,9]. According to the results, the pre-CR solid solution treatment combined with post-CR aging treatment for Al6061 alloy results in enhancing mechanical properties and 360 MPa tensile strength along with 10% elongation were reported. Furthermore, HUANG et al [10] reported that cryorolling process of Al6061 alloy changes the precipitation sequence of strengthening phases and cryorolled samples followed by peak aging treatment shows a significant increase in mechanical properties.

However, as mentioned before, high working temperature results in microstructural changes and affects the UFG/NS materials properties. According to the literature, the thermal stability of UFG/NS materials depends on grain growth kinetics, which is influenced by grain boundary segregation [11], second phase drag and solute drag [12]. The grain growth kinetics of different UFG/NS materials developed by SPD processes have been studied [13-18]. According to the results, two different activation energies for grain growth of SPDed Al alloys were reported, i.e., the low temperature activation energy for grain growth at temperature below 300 °C which is within 5-30 kJ/mol range and the high temperature grain growth activation energy in 300-500 °C which is in 90-163 kJ/mol range. It is reported that the former is the activation energy required to obtain a fully recrystallized UFG/NS microstructure, and the latter is the activation energy required for grain growth from UFG/NS to coarse microstructure. However, no work has been reported until today on the study of the grain growth kinetics on cryorolled Al6061 alloy followed by optimal aging heat treatment. In this study, the thermal stability of nanostructured Al6061 alloy developed by cryorolling and optimal aging process was investigated.

2 Experimental

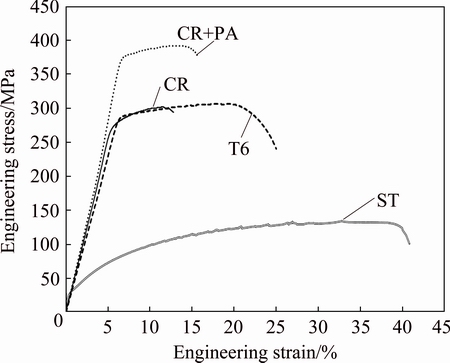

The chemical composition of the commercial Al6061 alloy used in this study is presented in Table 1. Before cryorolling process, the Al6061 alloy was solution treated at 530 °C for 3 h followed by water cooling down to room temperature by water quenching. Then the cryorolling process was carried out under conditions listed in Table 2. Finally, the cryorolled samples were aged at 130 °C for 30 h.

Table 1 Chemical composition of Al6061 alloy (mass fraction, %)

To study the thermal stability, mechanical and

microstructural changes of cryorolling and peak aging (CR+PA) samples, they were annealed at different temperatures in the range of 100-500 °C for 1, 2 and 3 h followed by water quenching. The microstructural features of the Al6061 CR+PA sample were examined by TEM with mechanical polishing up to 0.1 mm followed by electrojet polishing. Philips CM120 FEG TEM with an accelerating voltage of 120 kV was used for microstructural analysis. Also the microstructures were analysed by using scaning electron microscope (SEM, JEOL 7001F)/electron backscatter diffraction (EBSD) analysis. In order to investigate the structural changes as a result of cryorolling process, aging treatment and isothermal heat treatment, X-ray diffractometry (XRD) was used. A Philips diffractometer (40 kV) with Cu Kα radiation was used for XRD measurements. The grain size and lattice strain were estimated from broadening of XRD peaks using Williamson-Hall formula [19]. The optical microscopy is also used for structural evaluations. The dislocation density (ρ) was estimated by the following formula [20]:

(1)

(1)

where b is the Burgers vector of dislocations, ε is the lattice strain and D is the subgrain size estimated by Williamson-Hall method. In order to evaluate the hardness of the material, Vickers microhardness tests were conducted on samples with a load of 50 g and dwell time of 10 s. At least 5 different readings for each sample were obtained to ensure repeatability of the results. For the tensile tests, samples were machined into the ASTM subsized specimens with 25 mm gage length. Uniaxial tensile tests were conducted with an Instron machine operated at constant 2.5 mm/min cross head speed. Also the mechanical properties were investigated in the cross-section of samples using a nano-indenter NHTX S/N:01-03119 produced by CSM Inc.

Table 2 Process parameters of cryorolling and following aging process

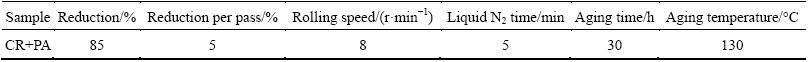

Fig. 1 TEM image (a) and EBSD image of as-cryorolled Al6061 alloy (b), TEM image (c) and EBSD image (d) of of Al6061 alloy after cryorolling and aging heat treatment

3 Results and discussion

3.1 Characterization of cryorolled peak aged Al6061 samples

The microstructural evaluation of Al6061 alloy after cryorolling and optimum aging process, was investigated by TEM and EBSD and the results are shown in Fig. 1. The starting material in solid solution treated (ST) condition exhibits coarse grains with an average grain size of 227.4 μm. Figure 1(a) shows the TEM image of cryorolled sample including elongated grains while the microstructure of cryorolled and peak aged sample (Fig. 1(c)) contains equiaxed grains with size of 61 nm.

As mentioned earlier, the crystallite size (d), and approximate upper limit of the lattice strain (ε) can be evaluated by XRD peak analysis according to Williamson-Hall relation [19]:

(2)

(2)

where β is the peak width at half the maximum intensity, θ is the position of peak maximum and λ is the X-ray wave length (λCu=1.54056 nm). Using this method, the grain size of Al6061 CR+PA sample was measured to be 48 nm which is in good agreement with the grain size calculated from TEM images. Also the EBSD images of grain orientation distribution of Al6061 alloy subjected to cryorolling and following peaked age heat treatment are illustrated in Figs. 1(b) and (d), respectively. According to the EBSD results, the cryorolled samples showed fragmented and elongated ultrafine grains along rolling direction, while, nano equiaxed grains are depicted in microstructure of the peak aged sample.

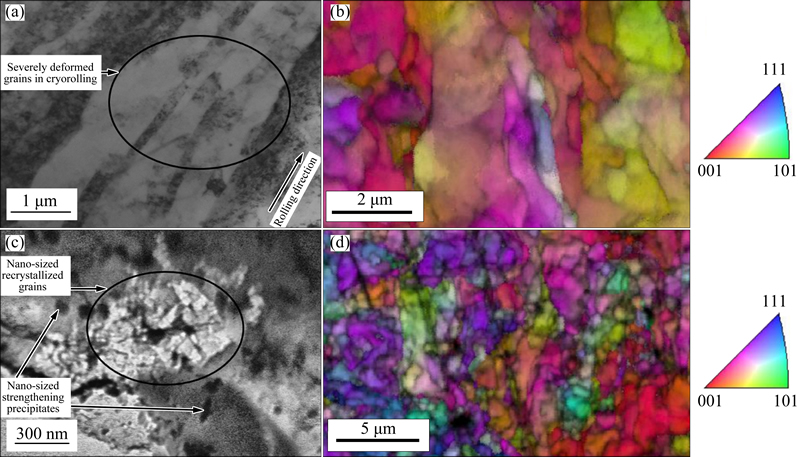

Figure 2 shows the engineering stress-strain curves of Al6061 alloy in different conditions, including solution treated (ST), T6 heat treated (T6), cryorolled (CR) and peak aged after cryroll (CR+PA) samples. The strength of the CR sample (σy=(271±16) MPa and σUTS=(297±18) MPa) was much higher than that of ST sample (σy=(50±6) MPa and σUTS=(134±10) MPa). This is due to the high density of dislocation accumulated as a result of plastic deformation at -196 °C temperature in deformation at cryogenic temperatures. Effective suppression of dynamic recovery resulted in a high density of dislocation in CR samples [21]. According to the results, cryorolling process followed by aging heat treatment caused a further increase in strength (σy=(362±15) MPa and σUTS=(388±17) MPa for CR+PA sample). Formation of fine strengthening precipitation and nano-sized grains plays an important role in enhancement of mechanical properties (Fig. 1(b)). For better evaluation of mechanical properties, nano indentation test was performed on Al6061-T6, CR and CR+PA samples. A comparison of hardness, HV (39±3.4), HV (118±3) and HV (137±2.5) in ST, CR and CR+PA samples respectively, showed that the cryorolling process followed by aging heat treatment has a great effect on enhancing mechanical properties of the Al6061 alloy. Also, elastic modulus of Al6061-T6, CR and CR+PA samples were measured to be 70.089, 75.707 and 73.558 GPa, respectively, by nano indentation tests.

Fig. 2 Engineering stress-strain curves of Al6061 alloy in different conditions

The follow stress of material in uniform plastic deformation region is presented by the Holloman relationship [22-25]:

σ=kεn (3)

where n is the strain hardening exponent, k is the strength coefficient, σ is true stress and ε is true strain.

Also the hardening capacity (Hc) of a material can be presented by the following normalized equation by considering σUTS and σy [26]:

(4)

(4)

The calculated strain hardening exponents and hardening capacities of Al6061-T6, CR and CR+PA samples are presented in Table 3.

Table 3 Strain hardening exponents and hardening capacity of Al6061-T6, CR and CR+PA samples

The strain hardening of the material after yielding is related to the dislocation strain field interactions. An increase in the number of dislocations during the cryorolling as a result of suppression in dynamic recovery, decreases the spacing among dislocations and their interaction becomes repulsive. By increasing the number of dislocations, the resistance to the dislocation movement increases and the stress required to deform the materials becomes higher with increasing deformation or cold work [27]. Based on the above discussion and calculated strain hardening exponent for Al6061-T6, CR and CR+PA samples, the highest value was obtained for CR sample which has the highest dislocation density, then CR+PA (the nanostructured sample) and finally Al6061-T6 sample. According to the literature, hardening capacity of the material is associated with its grain size affecting yield strength [22,27,28].

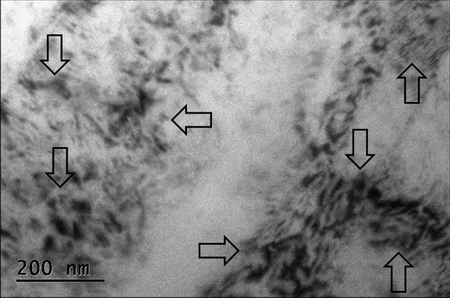

In explaining strain hardening behaviors, grain size and dislocation strengthening is considered. In this regard, the following equation was introduced in recent strain hardening model [25,29]:

σ=σ0+σHP+σd (5)

where σ0 is the frictional contribution, σHP=kd-1/2 is the Hall-Petch contribution and σd=MaGbρ1/2 is the Taylor dislocation contribution (ρ is dislocation density, α is a constant, M is Taylor factor, G is the shear modulus, and b is the Burgers vector). The applied stress necessary to deform a material after yielding is proportional to the dislocation density inside the material. Due to an increase in the number of dislocations during deformation, the resistance to the dislocation movement increases and the stress required to deform the material becomes higher with increasing deformation [27]. So, it can be concluded that the high initial dislocation density and dislocation tangles in the CR sample as a result of cryorolling process (Fig. 3) act like barriers against the dislocation movement. Moreover, according to Fig. 1(a), the CR sample contains long ultra-fine grained microstructure. On the other hand, in CR+PA sample despite of the fact that aging process results in decreasing dislocation density, but ultra-fine grains and nanometric strengthening precipitates, act as barriers for dislocation movement. So, for CR and CR+PA samples, the strain hardening behavior appeared to be large with varying slope in the plastic domain.

Fig. 3 TEM image of as-cryorolled Al6061 alloy after 85% thickness reduction, containing dislocation tangling zones (areas which are shown by black arrows)

3.2 Structural changes of nanostructured Al6061 alloy during annealing

As illustrated in previous section, cryorolling of Al6061 alloy followed by aging heat treatment led to the formation of stable nanostructured Al6061 alloy with grain size of 61 nm and fine 50-150 nm precipitates.

Thermal stability of Al6061 alloy after the cryorolling process and aging was investigated by heat treating the samples in 100-500 °C temperature range for 1 to 3 h. Changes of the dislocations density and crystallite size (obtained by using Williamson-Hall method) versus temperature are presented in Fig. 4. According to the results, dislocations annealing seriously started at 300 °C and continues to 500 °C. On the other hand, nanostructured Al6061 alloy would be kept up to 200 °C. According to the literature in Al6061 alloy with increasing temperature from 300 °C, β′ and β″ precipitates are dissolved in the structure. By increasing the annealing temperature, the driving force for the grain boundaries migration would increase [30]. During the annealing up to 300 °C, due to the presence of nanometric precipitates in the structure of CR+PA sample and due to the grain boundaries pinning by precipitates, migration of grain boundaries would be prevented, and thus the microstructure of material would not be changed even at 200 °C. The effect of precipitates on preventing the grain boundaries migration depends on the size and distribution volume of the precipitates which are expressed according to the following equation [29]:

(6)

(6)

where k is the coherency coefficient, λ is interface energy between grain boundary and precipitate, f is the volume fraction of precipitates, r is the mean radius of precipitates and FZis Zener drag force. According to Eq. (6), the finer the dispersed precipitates, the higher the Zener drag force is. Therefore, it can be concluded that by increasing the annealing temperature and time, due to the growth of precipitates, the value of grain boundaries pinning force would decrease due to the decrease in (f/r) ratio and subsequently, grain growth occurs.

Fig. 4 Changes in density of dislocations and crystallite size as function of temperature in CR+PA sample

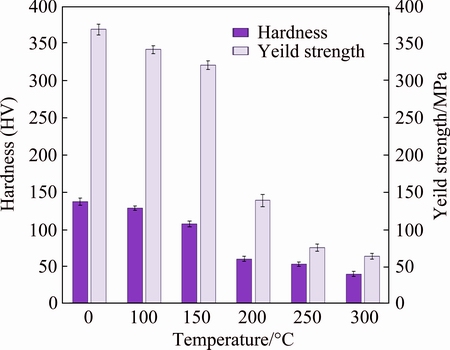

Fig. 5 Changes in hardness and tensile properties of CR+PA sample, after annealing at 100 °C to 500 °C for 1 to 3 h

Figure 5 shows changes in hardness and tensile properties of CR+PA sample, after annealing at 100 °C to 500 °C for 1 to 3 h. The general trend is the reduction of mechanical properties by increasing the temperature and the time of annealing heat treatment which is due to the grain growth and dissolution of the strengthening precipitates.

X-ray diffraction patterns of CR+PA sample after annealing at 100-500 °C for 1 to 3 h are illustrated in Fig. 6. The dissolution of precipitates in the samples annealed at temperatures higher than 300 °C is remarkable. Furthermore, according to Fig. 7(a) by heat treating the CR+PA sample, the (111) peak position did not change significantly. In addition, as it is presented in Fig. 7(c), lattice parameter of Al is almost constant after heat treatment of up to 200 °C. The main reason is the resistance of stable structure of CR+PA sample, which is due to applying optimum aging treatment after cryorolling process, in which grain growth and significant dissolution of the precipitates do not occur up to 200 °C even after 3 h. As mentioned for X-ray diffraction patterns of heat-treated samples, dissolution of the Mg2Si precipitates and the significant strength reduction are the main changes during heat treatment at temperatures higher than 200 °C. This is accompanied by displacement of (111) aluminum X-ray peak to lower angles (Fig. 7(b)) and also increasing the lattice parameter of Al (Fig. 7(c)), which represents the dissolution of intermetallic compounds at temperatures higher than 300 °C.

Fig. 6 X-ray diffraction patterns of CR+PA sample after annealing at 100-500 °C for 1 to 3 h

Fig. 7 Displacement of (111) aluminum peak after heat treatment at 100-200 °C (a), at 300-500 °C (b) and changes in lattice parameter of Al as function of heat treatment time and temperature (c)

3.3 Grain growth kinetics

Based on Fig. 5, with increasing annealing temperature and time, the loss of properties would be increased and grain growth plays an important role in decreasing mechanical properties. Grain growth in an exothermic process is inherent because it reduces the energy of the system. However, in any case, this process requires a driving force which is provided from microstructural changes or absorbed heat by the environment. Generally, grain growth kinetics is based on an empirical relation according to the following equation [17]:

(7)

(7)

where d is grain size at time t, d0 is the initial grain size, t is annealing time, n is grain growth exponent and k is a parameter corresponding to the migration of grain boundaries at the interface. Equation (7) indicates isothermal growth in ideal condition and is based on two assumptions. First, there is a direct correlation between the rate of grain growth and interfacial free energy per unit volume [13]. And second, there is an inverse relationship between the rate of grain boundaries migration and grain boundary curvature [14]. Based on these assumptions for ideal grain growth, the amount of grain growth exponent (n) has an approximate value of 2 [16]. In Fig. 8, the values of the isothermal grain growth exponent (n) are plotted versus annealing temperature. The value of n was obtained by fitting the isothermal grain growth data mathematically using a nonlinear general curve fitting to Eq. (7). According to the results, the amount of n decreases by increasing the temperature. However, it indicates two different behaviors in the temperature range of 100-200 °C and 300-500 °C, which may be due to the effect of dispersed nanometer precipitations on pinning of grain boundaries [31]. According to the results, the value of n is equal to 7.5 and 2 in the temperature ranges of 100-200 °C and 300-500 °C, respectively.

Fig. 8 Changes in n value of Eq. (7) versus temperature

Grain growth rate is dependent on the grain boundaries mobility factor (k) which is dependent on temperature according to Eq. (8) [31]:

(8)

(8)

where k0 is an independent factor of temperature and time, R is the gas constant, T is the temperature of the material, Q is the mobility activation energy of grain boundaries, which is related to the driving force for starting the grain growth. By combining Eqs. (7) and (8), Eq. (9) is obtained as follows:

(9)

(9)

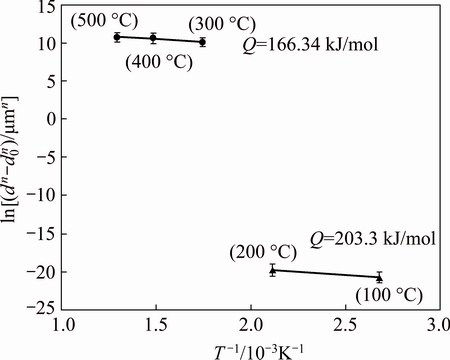

Now, there is a linear relation between  and the slope of

and the slope of  , and hence it is possible to calculate activation energy needed for grain growth in the CR+PA Al6061 alloy. According to the changes in grain size with the temperature in Fig. 4, it was observed that until 200 °C, major changes did not occur in the crystallite size. However, the significant growth occurs at temperatures higher than 300 °C. In Fig. 9, grain growth kinetics for CR+PA sample with the activation energy values calculated from the slope of the curves are given. Also, in Table 4, a comparison on the thermal stability of aluminum alloys produced by different methods is performed and the reported activation energy can be observed. According to the results, obtained activation energy for grain growth of CR+PA sample at the low temperatures is equal to 203.3 kJ/mol, which is significantly more than aluminum samples produced by cryomilling (CM), equal channel angular pressing (ECAP) and accumulative roll bonding (ARB). The main reason of this difference is that, in the low-temperature range in the mentioned cases in the literatures [14,16,17,29,32,33] due to the presence of unstable structure, less driving force is needed for the grain growth. However, due to the optimized aging process in the CR+PA sample, non-equilibrium structures are lost after cryorolling process. On the other hand, the amount of activation energy in the high temperature range (300-500 °C) is similar to that for nanostructured alloys produced by other processes and activation energy for self-diffusion of polycrystalline aluminum (143.4 kJ/mol [32]). Effective factors on activation energy are the presence of precipitates and their effect on pinning grain boundaries, which prevents the grain boundaries migration. However, by increasing the temperature due to the dissolution of strengthening precipitates and reduction in the effect of pinning the grain boundaries, the amount of activation energy is reduced.

, and hence it is possible to calculate activation energy needed for grain growth in the CR+PA Al6061 alloy. According to the changes in grain size with the temperature in Fig. 4, it was observed that until 200 °C, major changes did not occur in the crystallite size. However, the significant growth occurs at temperatures higher than 300 °C. In Fig. 9, grain growth kinetics for CR+PA sample with the activation energy values calculated from the slope of the curves are given. Also, in Table 4, a comparison on the thermal stability of aluminum alloys produced by different methods is performed and the reported activation energy can be observed. According to the results, obtained activation energy for grain growth of CR+PA sample at the low temperatures is equal to 203.3 kJ/mol, which is significantly more than aluminum samples produced by cryomilling (CM), equal channel angular pressing (ECAP) and accumulative roll bonding (ARB). The main reason of this difference is that, in the low-temperature range in the mentioned cases in the literatures [14,16,17,29,32,33] due to the presence of unstable structure, less driving force is needed for the grain growth. However, due to the optimized aging process in the CR+PA sample, non-equilibrium structures are lost after cryorolling process. On the other hand, the amount of activation energy in the high temperature range (300-500 °C) is similar to that for nanostructured alloys produced by other processes and activation energy for self-diffusion of polycrystalline aluminum (143.4 kJ/mol [32]). Effective factors on activation energy are the presence of precipitates and their effect on pinning grain boundaries, which prevents the grain boundaries migration. However, by increasing the temperature due to the dissolution of strengthening precipitates and reduction in the effect of pinning the grain boundaries, the amount of activation energy is reduced.

Fig. 9 Kinetics changes of grain growth for CR+PA sample

Table 4 Comparison between activation energy of grain growth in aluminum alloys produced by different methods

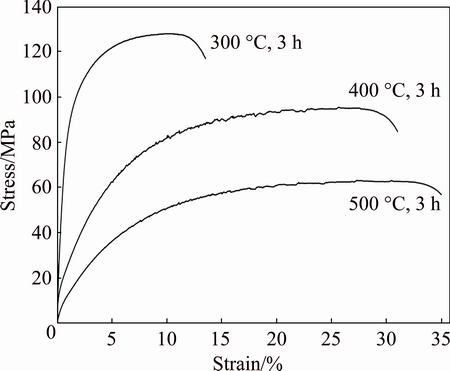

As it is presented in Fig. 10, the effect of Portevin- LeChatelier (PLC) or dynamic strain aging that causes appearance of indentation in the stress-strain curves, is one of the stress-strain characteristics of sample heat treated at 400-500 °C. This phenomenon appears when the solute atoms have good mobility. Under these conditions, the atoms can be placed below the dislocation line, so lock them and then by increasing the force this obstacle would be removed. According to the presented results in this field, for nanostructured Al-Mg-Si alloys, very fine precipitates dispersed in the structure act as a barrier to the movement of dislocations, and hence the PLC effect is not observed [34]. In other words, PLC effect arises when the stoppage time of dislocation behind obstacles (tw) is in the level of solute atoms to the dislocation line (td). Therefore, in the presence of very finely dispersed precipitates, PLC effect is not observed.

Fig. 10 Changes of stress-strain curves after aging in range of 400-500 °C for 3 h

4 Conclusions

1) A nanostructured Al6061 alloy with grain size of 61 nm and dispersed 50-150 nm sized strengthening precipitates was produced by cryorolling process followed by optimum aging heat treatment.

2) A significant increase was observed by applying cryorolling and aging process (CR+PA sample), such that yield strength, ultimate tensile strength and hardness of CR+PA sample were HV (118±3), 362 MPa and 388 MPa, respectively.

3) Evaluation of thermal stability of CR+PA sample within 100-500 °C temperature range, for 1 to 3 h showed that, up to 200 °C, the main structural characteristics of nanostructured Al6061 alloy including nanosized grains and dispersed fine Mg2Si precipitates and kept even after annealing for 3 h.

4) By increasing the annealing temperature to more than 300 °C in thermal stability tests, according to XRD patterns, Mg2Si dissolved and grain growth occurred which resulted in decreasing mechanical properties.

5) Little differences in position of Al (111) peak and lattice parameters in XRD patterns of cryorolled Al6061 alloy within 100-200 °C temperature range is a good evidence for stable structure of nanostructured Al6061 alloy.

6) The activation energies for grain growth of nanostructured Al6061 alloy were calculated to be 203.3 kJ/mol for annealing at 100-200 °C and 160.34 kJ/mol for annealing at 300-500 °C. Furthermore, the isothermal grain growth exponent (n) was calculated to be 7.5 at 100-200 °C and 2 at 300-500 °C.

References

[1] LIU Man-ping, JIANG Ting-hui, WANG Jun, LIU Qiang, WU Zhen-jie, YU Ying-da, SKARET  C, ROVEN HANS J. Aging behavior and mechanical properties of 6013 aluminum alloy processed by severe plastic deformation [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 3858-3865.

C, ROVEN HANS J. Aging behavior and mechanical properties of 6013 aluminum alloy processed by severe plastic deformation [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 3858-3865.

[2] CHEN Yong-jun, WANG Qu-dong, LIN Jin-bao, LIU Man-ping, HJELEN J, ROVEN H J. Grain refinement of magnesium alloys processed by severe plastic deformation [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 3747-3754.

[3] LIU Man-ping, JIANG Ting-hui, XIE Xue-feng, LIU Qiang, LI Xue-feng, ROVEN H J. Microstructure evolution and dislocation configurations in nanostructured Al-Mg alloys processed by high pressure torsion [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 3848-3857.

[4] ZHANG Zhi-qiang, DONG Li-min, YANG Yang, GUAN Shao-xuan, LIU Yu-yin, YANG Rui. Microstructure refinement of a dual phase titanium alloy by severe room temperature compression [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2604-2608.

[5] SABIROV I, MURASHKIN M Y, VALIEV R Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development [J]. Materials Science and Engineering A, 2013, 560: 1-24.

[6] DAS P, JAYAGANTHAN R, SINGH I V. Tensile and impact- toughness behaviour of cryorolled Al 7075 alloy [J]. Materials and Design, 2011, 32: 1298-1305.

[7] CHENG S, ZHAO Y H, ZHU Y T, MA E. Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation [J]. Acta Materialia, 2007, 55: 5822-5832.

[8] RAO P N, KAURWAR A, SINGH D, JAYAGANTHAN R. Enhancement in strength and ductility of Al-Mg-Si alloy by cryorolling followed by warm rolling [J]. Procedia Engineering, 2014, 75: 123-128.

[9] RAO P N, PANIGRAHI S K, JAYAGANTHAN R. Effect of annealing and aging treatment on mechanical properties of ultrafine grained Al6061 alloy [J]. Materials Science and Technology, 2010, 26: 371-374.

[10] HUANG Y, YAN X, QIU T. Microstructure and mechanical properties of cryo-rolled AA6061 Al alloy [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 12-18.

[11] BANSAL C, GAO Z, FULTZ B. Grain growth and chemical ordering in (Fe, Mn)3Si [J]. Nanostructured Matererials, 1995, 5: 327-336.

[12] de CASTRO C L, MITCHELL B S. Crystal growth kinetics of nanocrystalline aluminum prepared by mechanical attrition in nylon media [J]. Materials Science and Engineering A, 2005, 396: 124-128.

[13] WANG J, IWAHASHI Y, HORITA Z, FURUKAWA M, NEMOTO M, VALIEV R Z, LANGDON T G. An investigation of microstructural stability in an Al-Mg alloy with submicrometer grain size [J]. Acta Materialia, 1996, 44: 2973-2982.

[14] ZHOU F, LEE J, DALLEK S, LAVERNIA E J. High grain size stability of nanocrystalline Al prepared by mechanical attrition [J]. Materials Research Society, 2011, 16: 3451-3458.

[15] PARK K T, KWON H J, KIM W J, KIM Y S. Microstructural characteristics and thermal stability of ultrafine grained 6061 Al alloy fabricated by accumulative roll bonding process [J]. Materials Science and Engineering A, 2001, 316: 145-152.

[16] ROY I, CHAUHAN M, LAVERINA E J, MOHAMED F A. Thermal stability in bulk cryomilled ultrafine-grained 5083 Al alloy [J]. Metallurgical and Materials Transactions A, 2006, 37: 721-730.

[17] MALOW T R, KOCH C C. Grain growth in nanocrystalline iron prepared by mechanical attrition [J]. Acta Materialia, 1997, 45: 2177-2186.

[18] ZHA Min, LI Yan-jun, MATHIESEN R,  R, ROVEN H J. Microstructure, hardness evolution and thermal stability of binary Al-7Mg alloy processed by ECAP with intermediate annealing [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2301-2306.

R, ROVEN H J. Microstructure, hardness evolution and thermal stability of binary Al-7Mg alloy processed by ECAP with intermediate annealing [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2301-2306.

[19] WILLIAMSON G K, HALL W H. X-ray line broadening from filed aluminium and wolfram [J]. Acta Metallurgica, 1953: 22-31.

[20] GUO De-feng, LI Ming, SHI Yin-dong, ZHANG Zhi-bo, ZHANG Hai-tian, LIU Xiao-man, WEI Bing-ning, ZHANG Xiang-yi. High strength and ductility in multimodal-structured Zr [J]. Materials and Design, 2012, 34: 275-278.

[21] PANIGRAHI S K, JAYAGANTHAN R. Development of ultrafine-grained Al 6063 alloy by cryorolling with the optimized initial heat treatment conditions [J]. Materials and Design, 2011, 32: 2172-2180.

[22] HOSFORD W F. Mechanical behavior of materials [M]. New York: Cambridge University Press, 2005.

[23] HERTZBERG R W. Deformation and fracture mechanics of engineering materials [M]. 4th ed. New York: John Wiley & Sons, 1996.

[24] RATKE L, WELCH P I. The differential work hardening coefficient and classical work hardening laws [C]//Proceedings of International Deep Drawing Research Group: Efficiency in Sheet Metal Forming, Melbourne, Australia, 1984: 427-435.

[25] HOLLOMON J H. Tensile deformation [J]. Transaction of American Institute of Mechanical Engineering, 1946, 162: 268-277.

[26] AFRIN N, CHEN D L, CAO X, JAHAZI M. Strain hardening behavior of a friction stir welded magnesium alloy [J]. Scripta Materialia, 2007, 57: 1004-1007.

[27] CALLISTER W D. Materials science and engineering: An introduction [M]. 7th ed. New York: John Wiley and Sons, 2007.

[28] DIETER G E. Mechanical metallurgy [M]. 3rd ed. Boston: Mc Graw-Hill, 1986.

[29] DOHERTY R D. Role of interfaces in kinetics of internal shape changes [J]. Metal Science, 1982, 16: 1-14.

[30] HOSSEINI N, ABBASI M H, KARIMZADEH F, ENAYATI M H. Structural evolution and grain growth kinetics during isothermal heat treatment of nanostructured Al6061 [J]. Materials Science and Engineering A, 2009, 525: 107-111.

[31] JAFARI M, ENAYATI M H, ABBASI M H, KARIMZADEH F. Thermal stability and structural changes during heat treatment of nanostructured Al2024 alloy [J]. Journal of Alloys and Compounds, 2009, 478: 260-264.

[32] MOHAMED F A, LANGDON T G. Deformation mechanism maps based on grain size [J]. Metallurgical Transactions, 1974, 5: 2339-2345.

[33] DHAL A, PANIGRAHI S K, SHUNMUGAM M S. Precipitation phenomena, thermal stability and grain growth kinetics in an ultra-fine grained Al 2014 alloy after annealing treatment [J]. Journal of Alloys and Compounds, 2015, 525: 107-111.

[34] DIERKE H, KRAWEHL F, GRAFF S, FOREST S,  J, NEUHAUSER H. Portevin-LeChatelier effect in Al-Mg alloys: Influence of obstacles-Experiments and modelling [J]. Computational Materials Science, 2007, 39: 106-112.

J, NEUHAUSER H. Portevin-LeChatelier effect in Al-Mg alloys: Influence of obstacles-Experiments and modelling [J]. Computational Materials Science, 2007, 39: 106-112.

M. ABBASI-BAHARANCHI, F. KARIMZADEH, M. H. ENAYATI

Department of Materials Engineering, Isfahan University of Technology, Isfahan 84156-83111, Iran

摘 要:研究深冷轧制时效态纳米6061铝合金在100~500 °C下等温热处理过程的晶粒生长。透射电子显微镜观察结果表明经深冷轧制及在130 °C时效30 h,合金显微组织中含有61 nm的晶粒和50~150 nm的析出相,以及0.248%的点阵畸变。此外,由于形成细小的强化相和纳米晶粒,合金的拉伸强度达到362 MPa。在100~500 °C下进行热稳定研究,结果表明,点阵畸变得到减弱,析出相溶解,晶粒长大。X射线衍射结果表明,当退火温度高于300 °C时,Mg2Si相将消失。当退火温度低于200 °C时,晶粒长大不明显,力学性能下降也不明显。但在300~500 °C时,晶粒长大,析出相溶解和力学性能下降都比较明显。在100~200 °C时,晶粒长大的活化能为203.3 kJ/mol,在300~500 °C时,活化能为166.34 kJ/mol。讨论了析出相溶解对铝点阵常数和XRD(111)面峰位位移的影响,也讨论了PLC对应力应变曲线的影响。

关键词:力学性能表征;X射线衍射;铝合金;体变形;晶粒生长;晶粒细化

(Edited by Yun-bin HE)

Corresponding author: M. ABBASI-BAHARANCHI; Tel: +98-3133915744; Fax: +98-3133912752; E-mail: m.abbasi@ma.iut.ac.ir

DOI: 10.1016/S1003-6326(17)60086-4