文章编号:1004-0609(2011)10-2639-11

镁合金低压脉冲磁场晶粒细化

杨院生,付俊伟,罗天骄,汪 彬,冯小辉,童文辉,李应举

(中国科学院 金属研究所, 沈阳 110016)

摘要:提出一种低压脉冲磁场合金晶粒细化技术,分析常规铸造和半连续铸造条件下,低压脉冲磁场对镁合金凝固组织的影响。结果表明:脉冲磁场对AZ31、AZ91D、AZ80、AM60、AS31和Mg-Gd-Y-Zr镁合金均有显著的细化效果。施加脉冲磁场后,初生α-Mg形态发生明显球化,由粗大、发达的枝晶变为细小的蔷薇状,且溶质偏析显著降低。采用商用ANSYS软件分析了电磁力、流场以及焦耳热对熔体的影响规律,从形核和生长角度分析了脉冲磁场下镁合金晶粒细化机制,依据界面稳定性理论提出了脉冲磁场下镁合金晶粒球化模型。

关键词:镁合金;组织;晶粒细化;脉冲磁场

中图分类号:TG113.1 文献标志码:A

Grain refinement of magnesium alloys under

low-voltage pulsed magnetic field

YANG Yuan-sheng, FU Jun-wei, LUO Tian-jiao, WANG Bin, FENG Xiao-hui, TONG Wen-hui, LI Ying-ju

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: A new approach, low-voltage pulsed magnetic field (LVPMF) technique, to refine metal materials was developed. The effect of the LVPMF on the solidified structure of magnesium alloys under common casting and direct casting conditions was investigated. The results show that the grain refinement effects on AZ31, AZ91D, AZ80, AM60, AS31 and Mg-Gd-Y-Zr alloys under the LVPMF are obvious. Meanwhile, the morphology of α-Mg is transformed from developed dendrite to fine rosette with the application of LVPMF. The solute segregation in the alloys decreases obviously under the LVPMF. The magnetic force, flow field and Joule heat with the application of LVPMF were analyzed using the ANSYS element software. The grain refinement mechanism of magnesium alloys was discussed in terms of nucleation and growth theories. A model for spheroidization of developed dendrite α-Mg under LVPMF was developed by analyzing the growth behavior of α-Mg dendrite.

Key words: Mg alloy; microstructure; grain refinement; pulsed magnetic field

镁合金作为最轻的金属结构材料,具有较高的比强度、比刚度和良好的导热、减震、电磁屏蔽等性能,对于减轻质量和节能具有独特的优势,在交通工具、电子通讯、民用家电、航空航天和国防军工等领域具有极其重要的应用价值,是当今世界发展最快的轻合金[1]。

通常,镁合金属于HCP结构,其强度和塑性变形能力较差,限制了镁合金的大规模应用,因此,提高镁合金的强度及塑性成为研究的重点。根据Hall-Petch理论,镁合金的晶粒细化可以同时提高其强度和塑性,大量研究也已表明晶粒细化是提高镁合金性能的有效途径。在常规铸造条件下,镁合金凝固组织枝晶发达,晶粒粗大,铸件的强度和塑性均较低。所以,凝固晶粒细化对于提高铸件的力学性能极为重要。另外,晶粒细化对于变形镁合金的铸锭制备也很有意义,可使铸锭的变形能力提高,从而将非常有利于后续挤压、轧制等塑性加工过程。因此,人们对镁合金的凝固组织控制和晶粒细化给与极大的关注。

镁合金的凝固组织细化方法主要有变质法和合金化法等,研究工作主要集中于寻找有效的镁合金晶粒细化剂和变质剂。在不含铝的镁合金中添加Zr可以细化晶粒,然而,对于含Al、Si、Mn、Ni、Fe的镁合金,Zr则不能细化[2]。对于Mg-Al合金,过热或加入碳变质剂均可以起到细化效果[3]。然而,过热容易导致氧化,加入碳变质剂则会引入含碳化合物。迄今,还没有用于Mg-Al系镁合金的理想变质剂[4]。另外,稀土元素(RE) 可以有效细化镁合金[5-8],然而,高昂的价格使得应用稀土元素细化受到限制。因此,在不改变合金成分的前提下,开发镁合金凝固组织细化技术,成为镁合金细化的一个重要方向。

近年来的研究表明,利用脉冲电磁场可以控制凝固过程,有效细化金属或合金的凝固组织[9-20]。NAKADA等[9]首先在Sn-15%Pb合金凝固过程中施加脉冲电流,发现施加脉冲电流后凝固晶粒显著细化,枝晶逐渐退化。BARNAK等[10]在Sn-40%Pb和Sn-37%Pb 合金中的凝固过程中施加脉冲电流,亦发现同样的现象,且高密度脉冲电流可以细化Sn-Pb合金共晶尺寸。进一步的研究表明,脉冲电流还可以细化纯铝和铝合金的凝固组织[12-17],并且可以细化镁合金的凝固组织[18]。然而,由于合金凝固过程中施加脉冲电流比较困难,迄今为止,脉冲电流仍未在工业上广泛应用。

研究者发现,合金凝固阶段施加脉冲磁场也可以细化晶粒,而且,施加脉冲磁场不与熔体直接接触,避免污染熔体。ZI等[19]研究了强脉冲磁场(SPMF)对2024铝合金凝固组织的影响,发现施加强脉冲磁场后,合金组织得到显著细化,细化效果优于脉冲电流处理。GAO等[20]在纯铝凝固阶段施加强脉冲磁场,也获得了显著的细化效果。近来,研究者们在合金凝固过程中施加低压脉冲磁场(LVPMF),研究其细化晶粒效果[21-34]。结果表明:无论是对于镁合金、铝合金或者镍基高温合金,均能显著细化凝固晶粒。且施加脉冲磁场后,初生相由粗大的枝晶变为细小的蔷薇 状[21, 26],有利于降低偏析,提高力学性能。基于研究结果开发的低压脉冲磁场细化技术,具有无污染、操作安全、设备简单的优点,具有极大的工业应用前景。

本文作者介绍近几年围绕镁合金低压脉冲磁场晶粒细化开展的工作,从形核和长大两方面分析了脉冲磁场细化镁合金凝固组织的机理,并且通过数值模拟分析了脉冲磁场对熔体中的电磁力分布及流动的影响。最后,指出了脉冲磁场下镁合金晶粒细化的发展方向。

1 实验

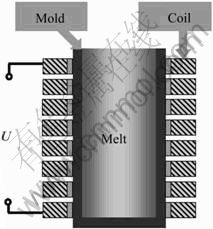

实验材料为工业用AZ31、AZ91D、AZ80、AM60、AS31以及Mg-Gd-Y-Zr合金。采用自行研制的脉冲磁场凝固装置进行实验,装置示意图如图1所示,主要由脉冲磁场发生器、水冷系统及隔热系统组成。脉冲发生器在线圈(Coil)中产生随时间变化的脉冲电流,脉冲电流在线圈内部激发脉冲磁场,从而使放置于坩埚中的熔体在脉冲磁场的作用下凝固。

实验时,先将实验用镁合金在电阻炉中熔化至993 K并保温15 min,然后浇注到置于脉冲磁场凝固装置中预热至一定温度的石墨坩埚中,石墨坩埚内径和高度分别为60 mm和140 mm。浇铸完毕后立即启动脉冲磁场发生装置,使镁合金熔体在脉冲磁场作用下凝固,大约5 min后熔体凝固完毕,关闭脉冲磁场。熔体凝固时施加SF6+CO2 混合气体保护。

为了分析脉冲参数对凝固组织的影响,实验时脉冲磁场频率固定,电压分别选择100、200和300 V;脉冲电压固定时,脉冲频率分别选择为2.5、5、10和20 Hz。另外,为了对比分析,在未加脉冲磁场条件下制备了相同凝固条件下的铸锭。为了分析晶粒细化原因,采用在坩埚内放置不锈钢筛网的方法来研究铸锭心部晶粒细化情况,以了解心部晶核的来源。在石墨坩埚内壁异质形核的晶核被该筛网阻止,不能进入熔体中心。筛网实验中石墨坩埚尺寸为d 32 mm× 140 mm。

在凝固铸锭1/2 高度的横截面中心部位制备金相试样,利用光学显微镜观察凝固组织,采用SISC-IAS软件、截线法统计平均晶粒尺寸。沿直径方向将铸锭沿纵截面截开,观察凝固铸锭的顶部宏观形貌。

图1 脉冲磁场装置示意图

Fig.1 Schematic diagram of casting process using LVPMF apparatus

2 结果与分析

2.1 脉冲磁场对凝固组织的影响

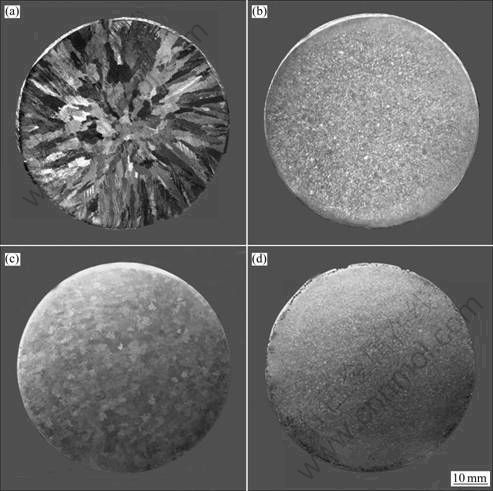

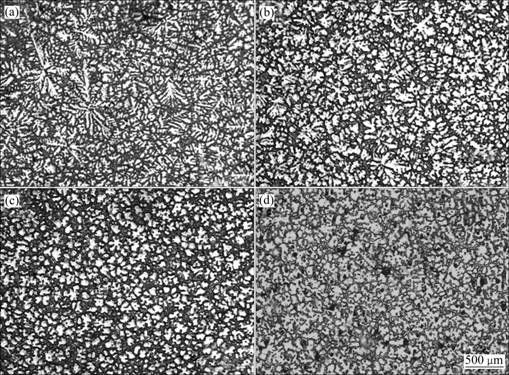

脉冲磁场作用下AZ31和AZ91D镁合金凝固的宏观组织如图2所示。可以看出,施加脉冲磁场前,AZ31镁合金由发达的柱状晶组成,晶粒十分粗大,如图2(a)所示。施加脉冲磁场后,AZ31镁合金的晶粒得到显著细化,而且施加脉冲磁场后晶粒十分均匀,如图2(b)所示。同样,施加脉冲磁场后,AZ91D镁合金晶粒也得到了明显的细化,如图2(c)、(d)所示。分析图2可知,利用脉冲磁场技术可以获得晶粒细小均匀的镁合金凝固组织。

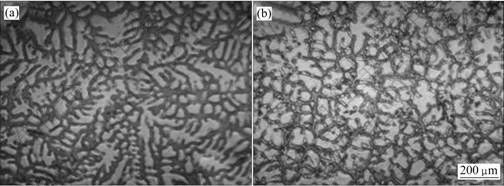

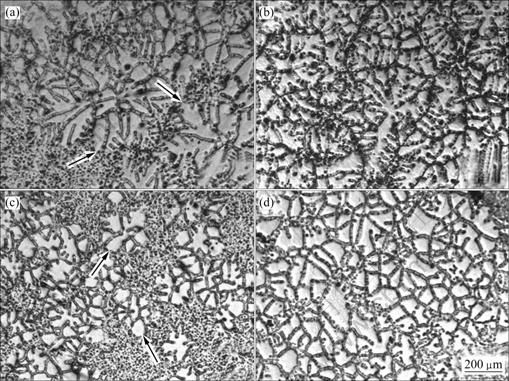

图3所示为脉冲磁场对AZ91D镁合金微观组织中枝晶形貌的影响。可以明显看出,施加脉冲磁场前,微观组织中初生α-Mg为粗大的等轴晶,枝晶二次臂十分发达,如图3(a)所示。施加脉冲磁场后,α-Mg 枝晶尺寸显著细化,枝晶明显退化,基本观察不到二次枝晶臂,如图3(b)所示。且施加脉冲磁场后,α-Mg 枝晶转变为蔷薇状,这种形貌有利于降低溶质元素偏析。

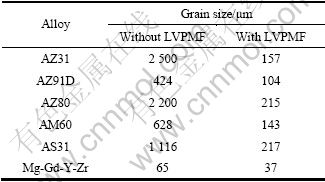

脉冲磁场对AZ80、AM60、AS31和Mg-Gd-Y-Zr 组织及晶粒尺寸的影响结果和AZ31、AZ91D相似,施加脉冲磁场后,晶粒得到显著细化。表1所列为脉冲磁场对AZ80、AM60、AS31和Mg-Gd-Y-Zr晶粒尺寸影响的统计结果。

2.2 脉冲参数的影响

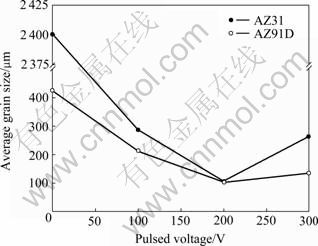

脉冲磁场控制凝固的磁场参数即脉冲电压和脉冲频率,对合金的凝固组织有着重要的影响。图4所示为脉冲频率为5 Hz时不同脉冲电压下AZ91D合金的凝固组织[21]。可以看出,脉冲电压对AZ91D的凝固组织有着双重的影响,随着脉冲电压的增加,AZ91D合金的晶粒尺寸先减小后增大,当脉冲电压为200 V时,晶粒尺寸最小。继续增加脉冲电压,晶粒尺寸有所增加。因此,在一定的脉冲频率时,脉冲电压存在一个最优值。图5所示为不同脉冲电压下AZ31和AZ91D合金晶粒尺寸的实验结果。

图2 施加脉冲磁场前后铸造态AZ31和AZ91D镁合金的宏观组织[24, 26]

Fig.2 Macrostructures of as-cast AZ31 and AZ91D Mg alloys: (a) Coarse grain in AZ31 without LVPMF; (b) Fine grain in AZ31 with LVPMF (5 Hz, 200 V); (c) Coarse grain in AZ91D without LVPMF; (d) Fine grain in AZ91D with LVPMF (5 Hz, 200 V)

表1 合金晶粒细化的统计结果

Table 1 Statistical results of grain size of alloys without and with LVPMF

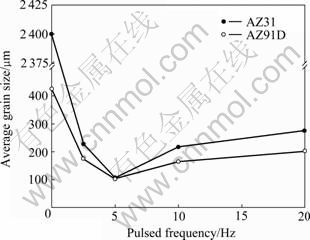

脉冲频率同样对镁合金的组织有着重要的影响,其影响规律和脉冲电压相似。随着脉冲频率的增加,AZ91D镁合金的晶粒尺寸也是先降低后增加。当脉冲频率为5 Hz 时,晶粒尺寸达到最小值,组织均匀。图6所示为脉冲电压为200 V时不同脉冲频率下AZ91D和AZ31镁合金晶粒尺寸的实验结果。

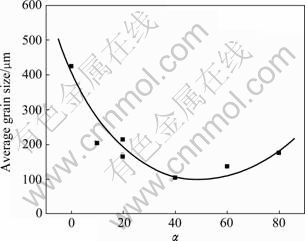

为了分析脉冲电压和脉冲频率对镁合金凝固组织的综合影响,可将脉冲电压与脉冲频率的比值定义为一个脉磁参数α。图7所示为参数α与AZ91D合金晶粒尺寸的关系。可以明显看出,参数α对AZ91D合金的晶粒尺寸也具有双重影响。当参数α小于40 V?s 时,随着α的增加,AZ91D合金晶粒尺寸逐渐减小;当参数α大于40 V?s时,随着参数α的增加,AZ91D合金晶粒尺寸逐渐增加。参数α的最优达到40 V?s,此时,AZ91D合金的平均晶粒尺寸为104 μm。

图3 脉冲磁场对铸态AZ91D镁合金枝晶形貌的影响

Fig.3 Effect of pulsed magnetic field on dendrite morphologies of as-cast AZ91D Mg alloy: (a) Developed α-Mg dendrite without LVPMF; (b) Fine rosette α-Mg dendrite with LVPMF

图4 脉冲电压对AZ91D镁合金微观组织的影响

Fig.4 Effect of pulsed voltage on microstructures of AZ91D Mg alloy (w=5 Hz): (a) 0 V; (b) 100 V; (c) 200 V; (d) 300 V

图5 脉冲电压对AZ31和AZ91D镁合金晶粒尺寸的影响

Fig.5 Effect of pulsed voltage on average grain size of AZ31 and AZ91D Mg alloys (w=5 Hz)

图6 脉冲频率对AZ31和AZ91D镁合金晶粒尺寸的影响

Fig.6 Effect of pulsed frequency on average grain size of AZ91D and AZ31 Mg alloys (U=200 V)

2.3 脉冲磁场对枝晶生长的影响

枝晶是金属或合金中最常见的晶体形态,其形貌或尺寸对金属或合金的元素偏析和力学性能有着十分重要的影响。为了研究脉冲磁场对镁合金枝晶生长的影响,采用液淬技术保留了不同凝固阶段的枝晶形貌进行分析。图8所示为不同温度下AZ31镁合金液淬时的金相组织[24]。可以看出,脉冲磁场对AZ31镁合金的枝晶生长有着重要的影响。施加脉冲磁场前,在凝固初期α-Mg枝晶就比较粗大、二次臂很发达,而且,α-Mg枝晶尖端尖锐,如图8(a)和(b)所示;施加脉冲磁场后,α-Mg枝晶非常细小、枝晶明显退化,几乎看不到二次臂,且α-Mg枝晶尖端明显钝化,如图8(c)和(d)所示。由图8可以看出,施加脉冲磁场后,枝晶尺寸明显减小,且枝晶逐渐球化。这说明脉冲磁场不但可以提高形核率,还可以限制枝晶生长。

图7 参数α对AZ91D合金平均晶粒尺寸的影响

Fig.7 Relationship between parameter α and average grain size of AZ91D alloy

3 讨论

3.1 脉冲磁场对合金熔体的影响

根据电磁场理论可知,在凝固过程中施加外加磁场后,熔体中会产生感生电流,感生电流再和外加磁场相互作用就会产生电磁力。该电磁力会作用于熔体将导致熔体运动从而影响凝固组织。为了分析外加脉冲磁场后熔体的运动状况,采用ANSYS商用有限元软件,在给定边界和初始条件下,对麦克斯韦方程组、欧姆定律、连续性方程和动量方程进行综合求解,模拟计算了熔体中的电磁力、熔体的流动及焦耳热的分布[33]。

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

式中:J为电流密度; 为磁感应强度。

为磁感应强度。

图8 施加脉冲磁场前后AZ31镁合金不同凝固阶段的液淬组织

Fig.8 As-quenched microstructures of AZ31 alloy during solidification with and without LVPMF: (a) 610 ℃; (b) 550 ℃; (c) 610 ℃ (5 Hz, 200 V); (d) 550 ℃ (5 Hz, 200 V)

熔体中的电磁力可由欧姆定律得出:

(5)

(5)

通过分析方程(1)~(4),可以得到电磁力的数学表达式:

(6)

(6)

结合连续性方程、动量方程及熔体不可压缩条件可得方程(7)~(9):

(7)

(7)

(8)

(8)

(9)

(9)

式中的边界条件为:熔体上表面Vy=0;熔体底部和侧部:Vx=0、Vy=0;由轴对称条件有Vx=0。

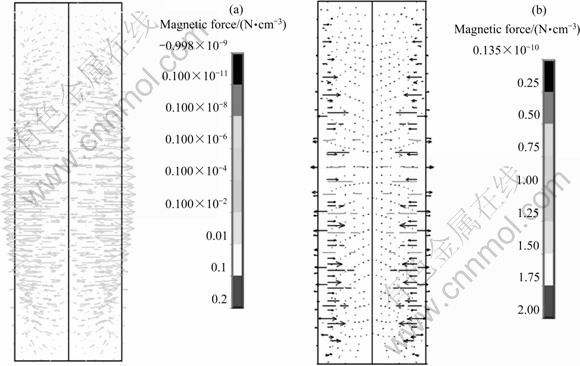

数值计算得到在熔体中的电磁力分布如图9 所示。可以看出,在脉冲充电阶段电磁力指向熔体内壁(见图9(a)),在放电阶段,熔体中的电磁力方向指向熔体心部(见图9(b))。随着脉冲磁场的连续施加,电磁力方向将呈现周期性的变化,从而对熔体产生电磁振荡效应。

计算得到的电磁力引起熔体的流动情况如图10 所示。可以看出,脉冲磁场作用使熔体产生垂直方向上产生对流。

3.2 脉冲磁场下镁合金的细化机制

3.2.1 脉冲磁场对形核的影响

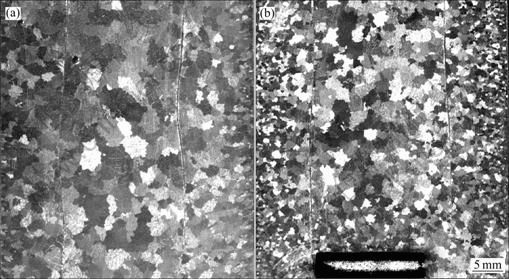

在金属凝固过程中,由于模壁的催化作用,通常形核在模壁处开始,发生异质形核。因此,增加模壁处的形核率或者将模壁形成的晶核有效地分散到熔体中都将提高金属或合金凝固的形核率,从而获得细晶的凝固组织。AZ80镁合金在有无脉冲磁场筛网条件下的实验结果如图11所示[26],可以看出,无论有无脉冲磁场作用,筛网外的晶粒明显比筛网内要细小,说明了模壁处的催化形核作用。这同时也说明脉冲磁场作用下的铸锭心部细化的晶粒源于模壁处形成的晶核,这些晶核由电磁力驱使的熔体流动进入心部。另外,施加脉冲磁场后,筛网外面部分的晶粒要比未施加脉冲磁场时明显细小,这说明脉冲磁场作用提高了模壁处的形核率。

图9 脉冲磁场下熔体中电磁力的分布

Fig.9 Magnetic force distribution in melt during pulsed period: (a) Charging stage; (b) Discharging stage

图10 施加脉冲磁场后电磁力引起熔体的流动

Fig.10 Flow field in melt during pulsed period

施加脉冲磁场后,形核率增加可能有多个因素导致。首先,通常凝固条件下,固液相体积能差只能抵消凝固形成固相表面能增加的2/3,另外的1/3 需要能量起伏来获得,施加脉冲磁场后,增加的磁场能可以部分抵消增加的表面量。其次,熔体中的电磁力也是提高形核率的重要因素,从上述电磁力的分析可知,交变电磁力形成的电磁振荡将促使模壁处形成的晶核加快脱落,在脉冲放电阶段,熔体中的电磁力方向指向熔体心部,此方向的电磁力可以促使模壁形成的晶核进入熔体中心,使熔体心部晶核数量增加,从而提高形核率。再者,电磁振荡还可以使枝晶的二次臂颈缩部分折断,从而形成新的晶核提高形核率。另外,脉冲磁场作用于熔体后产生的焦耳热对形核率也有一定的影响。一方面,焦耳热会降低熔体的冷却速度,使得熔体的过冷度降低,而形核率和过冷度是成正比的,从而降低形核率;另一方面,当熔体温度至低于合金的固相线时,凝固过程就宣告结束,而施加脉冲磁场后,释放的焦耳热可能使温度再次升高至合金固相线温度以上,这样又可以形核,使得形核率增加,也就是说焦耳热对形核起着双重的作用。因此,从形核角度考虑磁场能、电磁力、熔体的振荡和焦耳热都在一定程度上提高了形核率,使得镁合金组织细化。

图11 脉冲磁场对AZ80 镁合金形核的影响

Fig.11 Effect of LVPMF on macrostructure of AZ80 alloy with sieve in melt during solidification: (a) Grains outside sieve coarsening without LVPMF; (b) Grains outside sieve fining with LVPMF

3.2.2 脉冲磁场对枝晶生长的影响

脉冲磁场除了影响形核阶段外,对枝晶生长也将产生影响。根据麦柯斯韦电磁场理论,施加脉冲磁场后熔体中将产生焦耳热效应。在凝固过程中,由于枝晶尖端横截面积明显小于枝晶干的,施加脉冲磁场后在枝晶生长过程中大量的焦耳热将在枝晶尖端集中。另外,由于固相的电导率明显高于液相的,这也会导致电流在固相集中。而枝晶尖端又很细小,这样焦耳热就很容易使得细小的枝晶尖端熔化,导致枝晶尖端的曲率半径增加。枝晶尖端半径是枝晶生长过程最重要的尺度参数,它决定枝晶生长的行为以及最终的枝晶组织特征,而且枝晶尖端半径还直接影响枝晶的生长速度。枝晶尖端半径与枝晶生长速度的关系可以通过求解溶质和热传导方程,再加上一定的边界条件来获得。依据界面稳定理论和界面扩散条件给出了枝晶尖端半径与枝晶生长速度的关系[26],如方程(10)所示:

(10)

(10)

式中:v为枝晶生长速度;R为枝晶尖端半径;DL为液相中溶质的扩散系数;Γ为Gibbs-Thompson系数;mL为液相线斜率;C0为合金的初始成分;k0为溶质平衡分配系数。

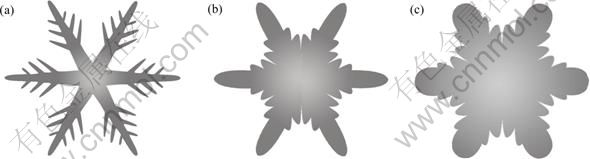

方程(10)清晰揭示了枝晶尖端半径与枝晶生长速度的关系。可以明显看出,两者不是各自独立的,枝晶尖端半径改变将影响枝晶生长的速度。而且枝晶尖端半径的平方和枝晶生长速度的乘积为一个常数,该常数由合金本身决定。在枝晶生长过程中,施加脉冲磁场后,焦耳热导致枝晶尖端半径增加,根据方程(10)可知,枝晶的生长速度将会降低,从而限制枝晶生长,使得枝晶球化。基于上述分析,可以确认,枝晶球化是由焦耳热在枝晶尖端集中使得枝晶尖端半径增加导致的。图12所示为脉冲磁场施加后α-Mg形貌变化过程示意图。首先,焦耳热在枝晶尖端集中使得枝晶尖端熔化,导致枝晶尖端半径增加、枝晶尖端钝化,枝晶逐渐退化,如图12(b)所示;随着焦耳热的释放枝晶进一步退化,最后逐渐变为蔷薇状,即枝晶球化,如图12(c)所示。

枝晶球化也可以从溶质扩散角度来分析。枝晶生长由扩散控制,枝晶生长的过程就是溶质扩散的过程。在凝固过程中,固液界面的形状,即固液界面的曲率半径对溶质扩散起着决定性的作用[35]。扩散界面的曲率半径和扩散驱动力的关系如方程(11)所示:

(11)

(11)

式中: 为溶质扩散过程的化学位梯度,即扩散的驱动力;

为溶质扩散过程的化学位梯度,即扩散的驱动力; 为α相的摩尔分数;γ为界面能;r为扩散界面的曲率半径。从方程(11)可知,扩散的驱动力和扩散界面的曲率半径成反比,增加扩散界面的曲率半径,溶质的扩散驱动力就会降低。施加脉冲磁场后,在枝晶生长过程中,焦耳热使得枝晶尖端曲率半径增加,溶质扩散驱动力降低,使得溶质在固液界面堆积,将导致枝晶生长速度降低。这样,发达的枝晶生长受到限制,逐渐球化。另外,施加脉冲磁场后,焦耳热在枝晶尖端附近集中,将提高固液界面附近液相的温度梯度。根据温度梯度与生长速度的关系,可知温度梯度的提高要降低生长速度,从这个角度分析,施加脉冲磁场后焦耳热也可以限制枝晶生长。且焦耳热的释放将明显降低枝晶生长过程中的过冷度,而熔体中的过冷度和枝晶生长速度近似呈正比关系。因此,焦耳热将提高熔体温度降低过冷度,限制枝晶生长。需要指出的是,尽管利用低压脉冲磁场细化金属材料技术在镁合金、高温合金等的晶粒都取得了显著的细化效果,然而,脉冲磁场细化金属凝固组织的研究还处于初始阶段,许多工作有待于进一步深入研究。例如,脉冲电压和脉冲频率与最优晶粒细化效果的内在联系和影响机制还不明了;焦耳热导致枝晶尖端温度升高还需要细致计算和精确测量;脉冲磁场对二次相析出的影响也需要进一步研究。

为α相的摩尔分数;γ为界面能;r为扩散界面的曲率半径。从方程(11)可知,扩散的驱动力和扩散界面的曲率半径成反比,增加扩散界面的曲率半径,溶质的扩散驱动力就会降低。施加脉冲磁场后,在枝晶生长过程中,焦耳热使得枝晶尖端曲率半径增加,溶质扩散驱动力降低,使得溶质在固液界面堆积,将导致枝晶生长速度降低。这样,发达的枝晶生长受到限制,逐渐球化。另外,施加脉冲磁场后,焦耳热在枝晶尖端附近集中,将提高固液界面附近液相的温度梯度。根据温度梯度与生长速度的关系,可知温度梯度的提高要降低生长速度,从这个角度分析,施加脉冲磁场后焦耳热也可以限制枝晶生长。且焦耳热的释放将明显降低枝晶生长过程中的过冷度,而熔体中的过冷度和枝晶生长速度近似呈正比关系。因此,焦耳热将提高熔体温度降低过冷度,限制枝晶生长。需要指出的是,尽管利用低压脉冲磁场细化金属材料技术在镁合金、高温合金等的晶粒都取得了显著的细化效果,然而,脉冲磁场细化金属凝固组织的研究还处于初始阶段,许多工作有待于进一步深入研究。例如,脉冲电压和脉冲频率与最优晶粒细化效果的内在联系和影响机制还不明了;焦耳热导致枝晶尖端温度升高还需要细致计算和精确测量;脉冲磁场对二次相析出的影响也需要进一步研究。

图12 施加脉冲磁场后枝晶球化过程示意图

Fig.12 Schematic diagram of transformation mechanism of α-Mg morphology with LVPMF: (a) Developed α-Mg dendrite; (b) α-Mg dendrite with shortened and degenerated primary arms owing to accumulation of Joule heat at dendrite tip; (c) Undeveloped rosette dendrite

4 结论

1) 利用开发的低压脉冲磁场合金晶粒细化技术,显著细化AZ31、AZ91D、AZ80、AM60、AS31和Mg-Gd-Y-Zr镁合金的凝固组织,获得脉冲磁场参数的影响规律与最佳参数范围。

2) 施加脉冲磁场后晶粒细化的主要原因在于电磁振荡导致模壁的形核率增加,电磁振荡促使枝晶的二次臂折断和焦耳热对提高也起到重要作用。

3) 施加脉冲磁场后,初生α-Mg形态由粗大、发达的枝晶变为细小的蔷薇状。焦耳热在枝晶尖端集中是枝晶球化的根源。依据界面稳定性理论提出脉冲磁场下镁合金晶粒球化模型。

REFERENCES

[1] KUROTA K, MABUCHI M, HIGASHI K. Review processing and mechanical properties of fine-grained magnesium alloys[J]. Journal of Materials Science, 1999, 34(10): 2255-2262.

[2] EMLEY E F. Principles of magnesium technology[M]. Oxford: Pergamon Press, 1966: 200-210.

[3] LEE Y C, DAHLE A K, STJOHN D H. The role of solute in grain refinement of magnesium[J]. Metallurgical and Materials Transactions A, 2000, 319: 2895-2906.

[4] STJOHN D H, QIAN M, EASTON M A, CAO P, HILDEBRAND Z. Grain refinement of magnesium alloys[J]. Metallurgical and Materials Transactions A, 2005, 36: 1669-1679.

[5] WANG Y S, WANG Q D, MA C J, DING W J, ZHU Y P. Effects of Zn and RE additions on the solidification behavior of Mg-9Al magnesium alloy[J]. Materials Science and Engineering A, 2003, 342(1/2): 178-182.

[6] WANG Y X, GUAN S K, ZENG X Q, DING W J. Effects of RE on the microstructure and mechanical properties of Mg-8Zn-4Al magnesium alloy[J]. Materials Science and Engineering A, 2006, 416(1/2): 109-118.

[7] WU L B, CUI C L, WU R Z, LI J Q, ZHAN H B, ZHANG M L. Effects of Ce-rich RE additions and heat treatment on the microstructure and tensile properties of Mg-Li-Al-Zn-based alloy[J]. Materials Science and Engineering A, 2011, 528(4/5): 2174-2179.

[8] CABIBBO M, SPIGARELLI S. A TEM quantitative evaluation of strengthening in an Mg-RE alloy reinforced with SiC[J]. Materials Characterization, 2011, 62(10): 959-969.

[9] NAKADA M, SHIOHARA Y, FLEMINGS M C. Modification of solidification structures by pulse electric discharging[J]. ISIJ International, 1990, 30(1): 27-33.

[10] BARNAK J P, SPRECHER A F, CONRAD H. Colony (grain) size reduction in eutectic Pb-Sn castings by electropulsing[J]. Scripta Metallurgica Materialia, 1995, 32(6): 879-884.

[11] LI J M, LI S L, LI J, LIN H T. Modification of solidification structure by pulse electric discharge[J]. Scripta Metallurgica Materialia, 1994, 31(12): 1691-1964.

[12] LIAO X L, ZHAI Q J, LUO J, CHEN W J, GONG Y Y. Refining mechanism of the electric current pulse on the solidification structure of pure aluminum[J]. Acta Materialia, 2007, 55: 3103-3109.

[13] GONG Y Y, LUO J, JING J X, XIA Z Q, ZHAI Q J. Structure refinement of pure aluminum by pulse magneto-oscillation[J]. Materials Science and Engineering A, 2008, 497: 147-152.

[14] LI J, MA J H, GAO Y L, ZHAI Q J. Research on solidification structure refinement of pure aluminum by electric current pulse with parallel electrodes[J]. Materials Science and Engineering A, 2008, 490(1/2): 452-456.

[15] MA J H, LI J, GAO Y L, ZHAI Q J. Grain refinement of pure Al with different electric current pulse modes[J]. Materials Letters, 2009, 63: 142-144.

[16] 班春燕, 崔建忠, 巴启先, 路贵民, 訾炳涛. 在脉冲电流或脉冲磁场作用LY12合金的凝固组织[J]. 材料研究学报, 2002, 16: 322-326.

BAN Chun-yan, CUI Jian-zhong, BA Qi-xian, LU Gui-min, ZI Bing-tao. Solidification structures of LY12 Al-alloy under pulsed current and pulsed magnetic field[J]. Chinese Journal of Materials Research, 2002, 16(3): 322-326.

[17] 何树先, 王 俊, 孙宝德, 周尧和. 高密度脉冲电流对A356铝合金凝固组织的影响[J]. 中国有色金属学报, 2002, 12: 426-429.

HE Shu-xian, WANG Jun, SUN Bao-de, ZHOU Yao-he. Effect of high density pulse current on solidification structure of A356 alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 426-429.

[18] YANG Y S, ZHOU Q, HU Z Q. The influence of electric current pulses on the microstructure of magnesium alloy AZ91D[J]. Materials Science Forum, 2005, 488/489: 201-204.

[19] ZI B T, BA Q X, CUI J Z, XU G M. Study on axial changes of as-cast structures of Al-alloy sample treated by the novel SPMF technique[J]. Scripta Materialia, 2000, 43: 377-380.

[20] GAO Y L, LI Q S, GONG Y Y, ZHAI Q. Comparative study on structural transformation of low-melting pure Al and high-melting stainless steel under external pulsed magnetic field[J]. Materials Letters, 2007, 61: 4011-4014.

[21] WANG B, YANG Y S, ZHOU J X, TONG W H. Microstructure refinement of AZ91D alloy solidified with pulsed magnetic field[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(3): 536-540.

[22] 汪 彬, 杨院生, 周吉学, 童文辉. 脉冲磁场对Mg-Gd-Y-Zr合金凝固及力学性能的影响[J]. 稀有金属材料与工程, 2009, 38(3): 519-522.

WANG Bin, YANG Yuan-sheng, ZHOU Ji-xue, TONG Wen-hui. Effect of the pulsed magnetic field on the solidification and mechanical properties of Mg-Gd-Y-Zr alloy[J]. Rare Metal Materials and Engineering, 2009, 38(3): 519-522.

[23] WANG B, YANG Y S, MA X P, TONG W H. Simulation of electromagnetic-flow fields in Mg melt under pulsed magnetic field[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(2): 283-288.

[24] WANG B, YANG Y S, SUN M L. Microstructure refinement of AZ31 alloy solidified with pulsed magnetic field[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1685-1690.

[25] WANG B, YANG Y S, ZHOU J X, TONG W H. Structure refinement of pure Mg under pulsed magnetic field[J]. Materials Science and Technology, 2011, 27(1): 176-179.

[26] FU J W, YANG Y S. Formation of the solidified microstructure of Mg-Al-Zn alloy under a low-voltage pulsed magnetic field[J]. Journal of Materials Research, 2011, 26(14): 1688-1695.

[27] FU J W, YANG Y S. Microstructure and mechanical properties of Mg-Al-Zn alloy under a low-voltage pulsed magnetic field[J]. Materials Letters, 2012, 67(1): 252-255.

[28] WANG B, SUN M L, WEI Q. Effect of pulsed magnetic field on structure refinement of pure magnesium[J]. Advanced Materials Research, 2011, 154/155: 46-49.

[29] WANG B, SUN M L, CHEN J D, WEI Y B. Microstructural refinement process of pure magnesium by pulse magnetic field treatment[J]. Advanced Materials Research, 2011, 189/193: 3964-3967.

[30] MA X P, LI Y J, YANG Y S. Grain refinement effect of pulsed magnetic field on as-cast superalloy K417[J]. Journal of Materials Research, 2009, 24(8): 2670-2676.

[31] MA X P, LI Y J, YANG Y S. Grain refinement effect of pulsed magnetic field on solidified microstructure of superalloy IN718[J]. Journal of Materials Research, 2009, 24(10): 3174-3181.

[32] MA X P, Li Y J, YANG Y S. The origin of nuclei and the refinement mechanism for solidified superalloy IN718 under pulsed magnetic field[J]. Journal of Materials Research, 2009, 24(10): 3174-3181.

[33] MA X P, YANG Y S, WANG B. Effect of pulsed magnetic field on superalloy melt[J]. International Journal of Heat and Mass Transfer, 2009, 52(23/24): 5285-5292.

[34] LI Y J, MA X P, YANG Y S. Grain refinement of as-cast superalloy IN 718 under action of low voltage pulsed magnetic field[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(6): 1277-1282.

[35] WAKAI F, ALDINGER F. Sintering through surface motion by the difference in mean curvature[J]. Acta Materialia, 2003, 51: 4013-4024.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50774075,51034012)

收稿日期:2011-05-10;修订日期:2011-07-20

通信作者:杨院生,教授,博士;电话:024-23971728;E-mail: ysyang@imr.ac.cn

杨院生教授简介

杨院生,1956年出生,博士,中国科学院金属研究所研究员,博士生导师,学位委员会委员;中国科学院研究生院教授,材料专家组组长;山东省轻质高强材料设计与制备泰山学者;中国金属学会电磁冶金与强磁场材料科学分会委员,不锈钢与耐热钢学术委员会委员,材料计算与模拟学术委员会副理事长;全国镁合金联盟副秘书长、学术委员会副主任。长期从事新型金属材料及其制备工艺与性能等研究工作,主持过20余项国家和省部级重要研究项目,发表论文180余篇,参编专著4部,申请专利30余项。曾获省部级科技进步奖4项,获得政府特殊津贴专家、辽宁省优秀专家、沈阳市先进科研工作者、中国科学院研究生院优秀教师等荣誉称号。