DOI:10.19476/j.ysxb.1004.0609.2018.05.03

基于二维X射线衍射技术的铝箔织构在线检测

何飞1,王健1,徐金梧1,陈冷2

(1. 北京科技大学 钢铁共性技术协同创新中心,北京,100083;

2. 北京科技大学 材料科学与工程学院,北京,100083)

摘 要:搭建一套基于二维X射线衍射技术的材料微结构在线检测系统,通过对系统实时采集的衍射数据沿方位角方向积分,对电解电容器铝箔材料立方织构进行在线检测,建立了衍射半峰宽、总衍射强度、织构体积量与铝箔立方织构含量间的关系,与传统离线的蚀坑定量检测法对比,立方织构含量绝对误差控制在2%,满足在线检测需求。最后,进行了系统相关因素对在线检测结果影响程度的研究。结果表明:运动速度和样品高度的变化对结果影响较小,而运动方向与轧向夹角以及机构倾角对结果影响较大,实际检测中应严格控制。

关键词:铝箔;二维X射线衍射;立方织构;在线检测

文章编号:1004-0609(2018)-05-0880-08 中图分类号:TG115.22 文献标志码:A

铝是有色金属中应用最广泛的一类金属,其产量仅次于钢铁。铝箔因其优良的特性,广泛用于食品、香烟、药品等包装材料,建筑、车辆、船舶等绝热材料以及电解电容器材料[1-2]。电解电容铝箔中立方织构体积分数对其电学性能有很大影响,需要很强的立方织构。常规的立方织构检测方法有单点X射线衍射法、亮晶度法、蚀坑定量检测法等[3-5]。蚀坑定量检测法是目前国内通行的检测方法,一般取铝箔的中部、两侧进行抽检[6]。传统的取样抽检方法是静态、离线和滞后的检测方式,只能给出铝箔的局部情况,且无法在整个生产过程中对铝箔的织构进行全程实时监控,难以适应现代化生产需要[7]。因此,需要一种快速、无损的织构检测技术实现实时在线监控,并尽可能满足在线监控高速、高效和高精度的需求。

二维X射线探测技术是一种新型的衍射记录方法,可以在二维空间内瞬时记录大量的衍射数据。这种记录技术明显优于传统的单点式衍射的记录模式,使得织构的检测的速度大大提高,也为织构及性能的在线检测提供了新的手段和可行性[8-9]。本文在二维X射线衍射基础上,深入研究了材料织构在线检测原理,设计并构造了一套基于二维X射线衍射的铝箔织构在线检测系统,并对其应用进行了深入探讨。

1 二维X射线衍射的材料微结构在线检测系统原理与构造

1.1 X射线衍射原理

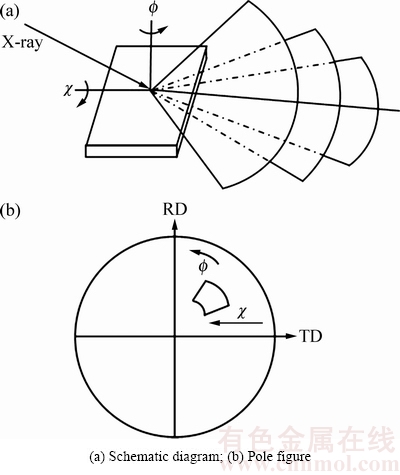

图1所示为二维X射线衍射探测器采集极图数据原理示意图。根据X射线衍射的布拉格方程,当一束单色X射线照射多晶体试样后,会在一系列衍射圆锥方向上产生X射线衍射花样[10],如图1(a)所示,对试样做χ角或者φ角转动,即调整面探测器的记录方位可以获得不同的衍射线分布及沿衍射线上强度的变化。

参照图1(b)可以看出,在测量过程中做φ角转动即可在极图平面内获得二维极密度分布,做χ角转动即可覆盖整个二维极图平面。此外,还应该注意到,由于二维探测器采集衍射数据的范围与试样到二维探测器的距离有关,所以当试样到面探测器的距离足够近时,面探测器就可以同时采集试样多个不同(hkl)晶面的衍射信息,即可以同时采集多个极图数据[11-12]。

用X射线照射晶体时,衍射效应呈现中心对称性。

因此,虽然极图上的数据量很大,但是原则上只要获得织构的一个密度峰的特征数据就可以推断出其他密度峰的分布状况。设这些密度峰在极图上呈正态分布,则只要获取相应正态分布函数的关键参数,就可以根据极图投影的几何原理推演出完整的极图。面探测器一次可以获取若干个极图上某一弧段上极密度分布的数据,若面探测器所探测的相关极图弧段能够同时穿过织构各一个密度峰,则可根据该弧段上的数据特征及密度峰正态分布的原则推演出整个极图[13-15]。假设织构组分的衍射峰呈正态分布,只要获得衍射峰正态分布的关键参数(如体积量和散布宽度)就可以根据极图几何原理模拟完整极图,从而计算取向分布函数,正态分布方程为

(1)

(1)

式中:S0是该织构组分在正态分布函数中心位置处的密度函数值;ψ是从极图中心横向的偏转角;ψa表示该织构组分正态分布函数中心位置的偏转角;ψ0表示正态分布函数的散布宽度[3]。

图1 二维X射线面探测器采集极图数据原理示意图

Fig. 1 Schematic diagrams of two-dimensional data collected by area detector

1.2 系统机械设计

为了对材料中某种或某几种织构类型进行实时监控,研发了基于二维X射线衍射的微观组织在线检测仪,整个检测仪安装在一个实验台上,实验台可以上下移动以适应在线检测中不同厚度规格的样品。检测仪具有半圆环支架,整个半圆环支架相对实验台可做定轴转动以调整其与实验台平面即样品表面的角度。两根移动杆安装在半圆环支架上且可沿半圆环做圆弧运动,X射线发射源和二维X射线探测器分别安装在两个移动杆上并可以沿移动杆做平移运动,以调节离开样品的距离。

检测不同的材料并调节图2(a)中的m角以满足X射线衍射的布拉格方程[16],并采集不同的晶面衍射数据,调节图2(b)中的机构倾角q采集不同类型的织构信息。材料在履带试样台上做连续运动,实现系统对材料参数的动态采集和监测。

图2 材料微结构在线检测系统机械构造

Fig. 2 Mechanical structure of on-line detection system for micro structure of materials

1.3 系统参数设计原理

1.3.1 m角的计算原理

X射线衍射的基本几何规律可以由Bragg公式给出:

(2)

(2)

式中:d是晶面间距;θ是入射线或反射线与反射面之间的夹角[17];n是干涉级数,为任意正整数;λ是X射线波长,由阳极靶的材料决定[18-19]。而m角取为

(3)

(3)

1.3.2 q角的计算原理

q角决定了{hkl}织构晶面法向与极图晶面的夹角。以测{110}极图上的{100}立方织构为例,q角即为{100}织构晶面法向与{110}晶面的夹角,查表可得45°[20]。

此外,根据检测材料选择合适的靶材,并设定合适的X射线发射电压和电流值等系统参数。

2 铝箔实验结果对比

2.1 铝箔的系统参数设定

根据参数设计原理,测绘铝箔的{110}极图,由Bragg公式确定m=38°;铝箔{100}织构晶面法向与{110}晶面的夹角确定q=45°。根据晶体对称性和正交样品对称性,织构在极图中的很多位置出现等价的极密度峰。图3是铝箔立方织构在{110}极图的位置,只要测得立方织构中众多重复等效位置中的一个密度峰的衍射特征数据就可以推断出其它密度峰的分布情况,确定γ角测定范围为255°~285°,即确定测定范围为图3圆环所示范围。

图3 所测范围(圆环)在{110}极图上的位置

Fig. 3 Locations of cube texture in pole figure {110}

2.2 实验数据对比

取5张织构含量不同铝箔,用蚀坑定量检测法分别检测立方织构含量,结果如表1所列。

表1 铝箔样品立方织构含量

Table 1 Ratio of cubic texture of aluminum foil

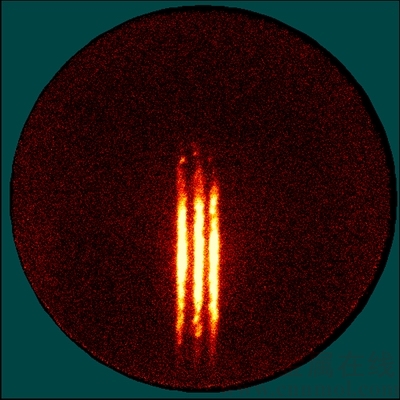

当样品以一定速度匀速运动时,可视为样品上大量晶体参与衍射,可以有效表征样品立方织构含量和分布状况。图4给出了衍射图以及衍射图像沿方位角γ方向进行积分得到衍射强度曲线,红色曲线为衍射强度曲线的正态拟合曲线,半峰宽为拟合曲线通过峰高取值一半的位置作平行于峰底的直线,与峰两侧相交两点之间的距离;总衍射强度为拟合曲线与X轴之间的面积;织构体积量即对于某一正态分布的织构组分来说,其表示为

(4)

(4)

式中:Z为织构组分的重复次数;S0为正态分布函数组织组分中心的取向密度函数值;ψ为取向密度由中心的S0降为S0e-1时偏离中心的角度[3]。

图4 衍射强度积分曲线

Fig. 4 Integral curve of diffraction intensity

取样品1~5号,以相同的速度匀速检测,分别采集衍射图像,对图像沿方位角γ方向进行积分得出积分曲线并拟合,计算每幅图像的半峰宽、总衍射强度、织构体积量,并得出表2结果。由表2可知,立方织构含量越高,半峰宽越小。半峰宽从一定程度上表示了样品晶粒间取向差的离散程度,取向差越小,立方织构越集中,半峰宽越小;立方织构含量越高,总衍射强度与织构体积量越大,即同样的检测面积条件下,立方织构含量越多,参与衍射的晶粒越多,接收的衍射强度也就越强,织构体积量越大。

表2 积分曲线各项数据

Table 2 Data of integral curve

图5给出了半峰宽、总衍射强度和体积量与立方织构含量的关系图和线性拟合结果,线性拟合的复测定系数分别为0.9943、0.9508和0.9756。实验和拟合结果表明,半峰宽与立方织构含量成反比,织构体积量和总衍射强度与立方织构含量成正比关系,3种表征量的线性回归效果均较为理想。

取未知20块铝箔样品采集X射线衍射图像,并积分得到半峰宽、总衍射强度以及体积量数据,并利用线性回归方程计算立方织构含量,并与传统坑蚀法求得的含量进行对比,两者计算的织构含量绝对误差结果如图6所示。可以看到,基于二维X射线在线检测结果与传统方法相比,绝对误差基本控制在2%以内,可以满足现场在线检测需求。

3 在线结果影响因素的探究

为了研究各可变实验因素对在线检测结果的影响程度,本文选取运动速度、样品高度、运动方向与轧向夹角以及机构倾角4个因素,利用衍射强度积分曲线的平均强度和半峰宽来表征其对检测结果的影响程度。

3.1 速度

对同一铝箔样品,设置了3个样品运动速度(2、1和0.5 m/s),分别得出平均衍射强度、半峰宽数据,如表3所列。由表3可以看出,3幅衍射图像的平均强度以及半峰宽并没有明显的变化,可见速度改变并不影响织构的检测结果。

图5 X射线衍射环的半峰宽、总衍射强度和体积量与立方织构含量的关系

Fig. 5 Relationship between peak width at half height, total diffraction intensity, texture volume and ratio of cubic texture

3.2 高度

考虑板带运行波动,在仅考虑纵向高度变化时,在X射线面探测器可测高度的范围内,改变了样品的垂直高度,分别在高、中、低3个高度对同一样品进行检测,图7所示为衍射图像(左侧为高度为低的衍射环,右侧为高度为高的衍射环,中间为高度为中的衍射环)。分别对3条衍射环进行积分得出表4的平均衍射强度和峰宽数据。可以看出,衍射环因高度的不同从图像上来看发生了位置的平移,平均强度以及峰宽并没有明显的变化,在可测范围内高度改变并不影响织构的检测结果。

图6 织构含量的绝对误差值

Fig. 6 Absolute error of texture content

表3 不同速度的衍射环的平均强度和峰宽

Table 3 Average diffraction intensity and peak width at different speeds

图7 面探测器采集不同高度的衍射环图像

Fig. 7 Diffraction frame under different heights collected by area detector

表4 不同高度的衍射环的平均强度和峰宽

Table 4 Average diffraction intensity and peak width at different heights

3.3 运动方法与实验规定轧向的夹角

改变运动方向与实验规定轧向的夹角分别为5°、10°、15°、20°,分别对衍射环进行积分得出表5平均衍射强度和峰宽数据。

由表中平均强度数据可以得出偏转角度越大,平均强度越小,衍射信息越弱;夹角为5°时,半峰宽已经有了明显的改变,平均强度变小,因此在实际测量中应尽可能保证运行方向与轧向相一致。

3.4 倾角

根据参数设计原理,机构倾角q设定为45°,改变q的值为43°、45°、47°、50°、53°、55°,分别对衍射环进行积分得出表6平均衍射强度和峰宽数据。随着偏离角度增大,平均衍射强度减弱,半峰宽减少,实际检测中应设定合理的机构倾角。

表5 样品轧向与实验规定轧向不同夹角的衍射环的平均强度和峰宽

Table 5 Average diffraction intensity and peak width under different angle between sample and laboratory rolling

表6 不同q角的衍射环的平均强度和峰宽

Table 6 Average diffraction intensity and peak width under different q angles

4 结论

1) 对电子铝箔进行了立方织构的在线检测,统计了X射线衍射积分曲线的半峰宽、总衍射强度、织构体积量,建立了立方织构与三者间的关系。实验和拟合计算结果表明,半峰宽与立方织构含量成反比,织构体积量、总衍射强度与立方织构含量成正比关系,线性回归关系效果较好。立方织构含量绝对误差控制在2%以内,在线检测中可以利用三者来表征立方织构含量。

2) 在线检测因素中,样品的速度对检测结果影响较小,可以满足一定速度的实时检测;板带的高度对检测结果影响较小,可以保证在板带有垂直波动情况下的有效检测;样品运动方向与轧向的夹角、机构倾角对检测结果有较为明显的影响,实际检测中应严格控制,以确保实验结果的准确性。

REFERENCES

[1] 申 蓉, 卢 云, 杨邦朝, 冯哲圣. 高压铝阳极箔制备技术研究进展[J]. 材料导报, 2008, 22(11): 69-73.

SHEN Rong, LU Yun, YANG Bang-chao, FENG Zhe-sheng. Research development of preparation technology of high voltage anode aluminum foil[J]. Materials Review, 2008, 22(11): 69-73.

[2] 袁 嫄. 从“2013年欧洲铝箔奖”看铝箔新应用[J]. 世界有色金属, 2013(11): 68-69.

YUAN Yuan. Looked the new applications of aluminum foil from the 2013 European Aluminum Foil Award[J]. World Nonferrous Metals, 2013(11): 68-69.

[3] 毛卫民, 杨 平, 陈 冷. 材料织构分析原理与检测技术[M]. 北京: 冶金工业出版社, 2008.

MAO Wei-min, YANG Ping, CHEN Leng. Material texture analysis principle and testing technology[M]. Beijing: Metallurgical Industry Press, 2008.

[4] 左 宏, 刘春明. 微量Zn对高压电解电容器阳极铝箔比电容的影响[J]. 中国有色金属学报, 2012, 22(11): 3129-3134.

ZU Hong, LIU Chun-ming. Influence of trace Zn on specific capacitance of high voltage aluminum anode foil used in high voltage electrolytic capacitors[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3129-3134.

[5] 张新明, 孟 亚, 周卓平, 周鸿章. Fe杂质对高纯铝箔再结晶织构及比电容的影响[J]. 中国有色金属学报, 1999, 19(1): 19-24.

ZHANG Xin-ming, MENG Ya, ZHOU Zhuo-ping, ZHOU Hong-zhang. Effects of Fe impurity on recrystallization textures and specific capacitances of high pure aluminium foils[J]. The Chinese Journal of Nonferrous Metals, 1999, 19(1): 19-24.

[6] 吕爱强, 黄 涛, 王 福, 左 良. 异步轧制高纯铝箔冷轧织构沿板厚的分布规律[J]. 中国有色金属学报, 2003, 13(1): 56-59.

Lü Ai-qiang, HUANG Tao, WANG Fu, ZUO Liang. Textures distribution along thickness after cross shear rolling of high purity aluminum foils[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 56-59.

[7] 杨 宏, 毛卫民. 铝电解电容器铝箔的研究现状和技术发展[J]. 材料导报, 2005, 19(9): 1-4.

YANG Hong, MAO Wei-min. Present research status and technology development of aluminum foil for electrolytic capacitor[J]. Materials Review, 2005, 19(9): 1-4.

[8] 郑盼盼, 陈 冷, 何 飞, 杨 荃. 金属板材织构在线检测技术的研究进展[J]. 材料科学与工程学报, 2014, 32(2): 293-300.

ZHENG Pan-pan, CHEN Leng, HE Fei, YANG Quan. Progress in on-line texture measurement technology of metal sheets[J]. Journal of Materials Science and Engineering, 2014, 32(2): 293-300.

[9] 杨传铮, 汪保国, 张 建. 二维X射线衍射及其应用研究进展[J]. 物理学进展, 2007, 27(1): 69-91.

YANG Chuan-zheng, WANG Bao-guo, ZHANG Jian. Progress in research of two-dimensional X-ray diffraction and its applications[J]. Progress in Physics, 2007, 27(1): 69-91.

[10] ABOUHILOU F, KHEREDDINE A, ALILI B, BRADAI D. X-ray peak profile analysis of dislocation type, density and crystallite size distribution in cold deformed Pb-Ca-Sn alloys[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 604-607.

[11] 毛卫民, 马全仓, 冯惠平, 陈昌云, 李吉彬. 冲压铝板塑性应变比的在线检测技术[J].中国有色金属学报, 2006, 16(7): 1149-1154.

MAO Wei-min, MA Quan-cang, FENG Hui-ping, CHEN Chang-yun, LI Ji-bin. On-line determination technology on Lankford parameter of deep drawing aluminum sheets[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1149-1154.

[12] MAO Wei-min, CHEN Leng, YANG Ping, FENG Hui-ping. Rapid texture measurement of annealed aluminum sheet based on X-ray diffraction[J]. Chinese Science Bulletin, 2004, 49(19): 2112-2114.

[13] 毛卫民, 陈 冷, 杨 平, 冯惠平. 退火铝板织构X射线快速检测原理[J]. 科学通报, 2004, 49(20): 2128-2129.

MAO Wei-min, CHEN Leng, YANG Ping, FENG Hui-ping. Principle of fast detection on X-ray of texture in annealed aluminum sheet[J]. Chinese Science Bulletin, 2004, 49(20): 2128-2129.

[14] 陈 冷, 毛卫民, 冯惠平, 余永宁. 无间隙原子钢冷轧板织构的快速检测[J]. 北京科技大学学报, 2003, 25(2): 156-159.

CHEN Leng, MAO Wei-min, FENG Hui-ping, YU Yong-ning. Rapid measurement of texture for cold rolling interstitial free steel sheets[J]. Journal of University of Science and Technology Beijing, 2003, 25(2): 156-159.

[15] 刘 涛, 毛卫民, 冯惠平, 马全仓. 用X射线透射法测量热轧铝板整体织构[J]. 物理测试, 2005, 23(4): 11-14.

LIU Tao, MAO Wei-min, FENG Hui-ping, MA Quan-cang. Integrated texture measurement of hot rolled aluminum plate based on X-ray transmission technique[J]. Physics Examination and Testing, 2005, 23(4): 11-14.

[16] 刘粤惠. X射线衍射分析原理与应用[M]. 北京: 化学工业出版社, 2003.

LIU Yue-hui. The diffraction analysis principle on X-ray and its application[M]. Beijing: Chemical Industry Press, 2003.

[17] 毛卫民. 材料的晶体结构原理[M]. 北京: 冶金工业出版社, 2007.

MAO Wei-min. Structure principles of crystalline materials[M]. Beijing: Metallurgical Industry Press, 2007.

[18] HE B B. Two-dimensional X-ray diffraction[J]. Hoboken, NZ: John Wiley & Sons, Inc. 2009

[19] 李树棠. 晶体X射线衍射学基础[M]. 北京: 冶金工业出版社, 1990.

LI Shu-tang. Foundation of X-ray diffraction of crystal[M]. Beijing: Metallurgical Industry Press, 1990.

[20] 陈 冷, 毛卫民, 冯惠平, 余永宁. X射线二维衍射数据与晶体取向分布函数的关系研究[J]. 中国体视学与图像分析, 2002, 7(4): 202-206.

CHEN Leng, MAO Wei-min, FENG Hui-ping, YU Yong-ning. Relationship between X-ray two- dimensional diffraction data and crystal orientation distribution function[J]. Chinese Journal of Stereology and Image Analysis, 2002, 7(4): 202-206.

On-line detection of aluminum foil texture based on two-dimensional X-ray diffraction technology

HE Fei1, WANG Jian1, XU Jin-wu1, CHEN Leng2

(1. Collaborative Innovation Center of Steel Technology, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: A micro structure of materials online detection system based on the two-dimensional X-ray diffraction was developed. On-line detection of cubic texture of aluminum foil for electrolytic capacitor was realized, which computed the integral data of real time acquisition of diffraction. The relationships among diffraction peak width, total diffraction intensity, texture volume and the cubic texture of aluminum foil were established. The results of traditional texture detection and on-line texture detection were compared, the absolute error was controlled within 2%, which met the needs of on-line detection. Finally, the effect of related online factors on the results was studied. The results show that the variation of the velocity and height of the sample has little influence on the results, while the direction of motion, the angle between the rolling direction and the inclination of the mechanism have great influence on the results, which should be strictly controlled in actual detection.

Key words: aluminum foil; two-dimensional X-ray diffraction; cube texture; on-line detection

Foundation item: Project(2015BAF30B01) supported by the National Key Technology R&D Program of the 12th Five-year Plan of China; Project(FRF-BR-16-025A) supported by the Fundamental Research Funds for the Central Universities, China; Project(142060302012) supported by the Fundamental Research Funds of China Academy of Civil Aviation Science and Technology

Received date: 2017-03-14; Accepted date: 2017-06-02

Corresponding author: HE Fei; Tel: +86-10-62334255; E-mail: hefei@ustb.edu.cn

(编辑 何学锋)

基金项目:国家科技支撑计划资助项目(2015BAF30B01);中央高校基本科研业务费资助项目(FRF-BR-16-025A);航科院基本科研业务费资助项目(142060302012)

收稿日期:2017-03-14;修订日期:2017-06-02

通信作者:何 飞,副研究员,博士,电话:010-62334255;E-mail: hefei@ustb.edu.cn