DOI: 10.11817/j.issn.1672-7207.2015.08.007

矿化剂对水热合成ZnS晶体结构及可浮性的影响

闵小波1, 2,王延1,柴立元1, 2,梁彦杰1, 2,柯勇1,陈杰1

(1. 中南大学 冶金与环境学院,湖南 长沙,410083;

2. 国家重金属污染防治工程技术研究中心,湖南 长沙,410083)

摘要:以某冶炼厂含锌废渣为研究对象,通过在水热硫化过程中添加矿化剂调控人造硫化矿晶体结构,提高人造硫化矿的可浮性。研究结果表明:添加矿化剂NaCl时,NaCl浓度0.1 mol/L为最佳浓度,Zn富集比从1.16提高到1.36;添加矿化剂CH3COONa时,CH3COONa浓度0.5 mol/L为最佳浓度,Zn富集比从1.16提高到1.62;添加矿化剂EDTA-2Na时,0.1 mol/L EDTA-2Na为最佳浓度,Zn富集比从1.16提高到1.69。矿化剂的添加对Zn回收率无明显影响,回收率仍在60%左右。添加矿化剂NaCl后,ZnS晶粒粒度从21.0 nm提高到35.9 nm;添加矿化剂CH3COONa使ZnS晶粒粒度从20.8 nm提高到35.3 nm;添加矿化剂EDTA-2Na使ZnS晶粒粒度从21.4 nm提高到37.6 nm。0.1 mol/L 的EDTA-2Na为最优矿化剂。在添加上述矿化剂后,ZnS晶体颗粒由无定型的絮状颗粒转变为致密粗大的颗粒,且加入矿化剂有利于减小ZnS与CaSO4晶体的团聚夹杂现象,从而有利于水热合成人造硫化锌晶体的浮选分离。

关键词:矿化剂;水热硫化;晶体结构;可浮性

中图分类号:X758 文献标志码:A 文章编号:1672-7207(2015)08-2812-07

Effect of mineralizer on crystal structure and floatability of ZnS formed in hydrothermal sulfidation

MIN Xiaobo1, 2, WANG Yan1, CHAI Liyuan1, 2, LIANG Yanjie1, 2, KE Yong1, CHEN Jie1

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Chinese National Engineering Research Center for Control and Treatment of Heavy Metal Pollution, Changsha 410083, China)

Abstract: In order to modify the crystal structure and improve the floatability of synthetic metal sulfide, mineralizers were added during the hydrothermal sulfidation of Zn-contained residue, discharged from a smelting plant. The results show that the enrichment ratio of ZnS increases from 1.16 to 1.36 after adding 0.1 mol/L NaCl, the enrichment ratio of ZnS increases from 1.16 to 1.62 after adding 0.5 mol/L CH3COONa, and the enrichment ratio of ZnS increases from 1.16 to 1.69 after adding 0.1 mol/L EDTA-2Na. The grain size of ZnS crystal increases from 21.0 nm to 35.9 nm after adding NaCl, increases from 20.8 nm to 35.3 nm after adding CH3COONa, and increases from 21.4 to 37.6 nm after adding EDTA-2Na. As a result it is concluded that EDTA-2Na is the optimal mineralizer, and the optimum concentration is 0.1 mol/L. The amorphous flocculent particles of ZnS turn into dense massive ZnS after the addition of mineralizers, and distinct decrease of the agglomeration between ZnS and CaSO4 can be observed, which is in favour of the flotation and separation of artificial sulfur ore.

Key words: mineralizer; hydrothermal sulfide; crystal structure; floatability

硫化技术处理重金属废渣不仅能将其中的重金属转化为硫化物,而且能通过浮选的方式加以回收,浮选回收产生的尾矿具有良好的稳定性。此技术兼顾了重金属废渣的资源化和稳定化,是重金属固体废弃物处理的一种新思路[1]。现有的硫化方法主要有表面硫化[2]、机械硫化[3-4]、焙烧硫化[5]等。然而,现有研究结果表明,硫化法产生的硫化物在晶体结构和表面性质上与天然硫化矿物存在较大差异[6-7],导致其浮选效果差、重金属回收率不高[8],可见人造硫化物晶体结构和表面性质调控是实现人造硫化物高效浮选回收的关键技术瓶颈之一[9]。天然硫化矿主要产生于地热过程中,其生长规律是先溶解再结晶,所以,在水热过程中提高金属溶解度和硫化物前驱体浓度对其晶体的生长有很大的影响[10]。然而,硫化物的溶解度较低,为了提高其溶解度,常常在水热过程中加入易溶于水的酸、碱或其他能与难溶组分形成络合物的可溶性物质,这些物质就是矿化剂。矿化剂的添加对不同晶体的生长调控有促进作用[11-13]。现有的研究结果表明,Cl-,CH3COO-和EDTA等离子对水热过程中硫化物的溶解度具有显著的提升作用[14]。Tagirov等[15]在研究Zn硫化物的热力学特征时发现Cl-在高温反应过程中能改变ZnS的溶解度,在不同温度与不同Cl-浓度下,对于ZnS的溶解度有不同影响。黄群等[16]在制备ZnS薄膜研究中发现EDTA等有机络合剂能与纳米级ZnS产生络合作用;在光电材料纳米级ZnS的制备中,也有研究表明[17]通过掺杂络合物EDTA-2Na会对ZnS的晶体性质(如形态、结构、强度等)产生显著变化。而宫海燕等[18]在研究杂质对晶体结构影响中指出CH3COO-对晶体过饱和度的影响较大。现有的矿化剂主要运用于功能材料研究中,其作用主要对晶体进行表面修饰和结构调控,而通过矿化剂调节硫化物晶体结构从而改善其可浮性的研究较少。前期研究表明,重金属废渣经水热硫化处理主要发生下列反应:

4S+6OH-=2S2-+S2O32-+3H2O (1)

Me(OH)2=Me2++2OH- (2)

Me2++S2-=MeS (3)

通过水热硫化,重金属转化为金属硫化物,钙等矿物转化为硫酸钙,然而,形成的硫化物晶粒细小,与钙等脉石矿物黏附严重,造成硫化物与脉石矿物分离困难。为了实现硫化物与脉石矿物的高效分离,关键使硫化物的结晶长大。为此,本文作者在前期研究基础上,开展矿化剂对合成ZnS晶体结构和可浮性的影响研究[19]。以某冶炼厂重金属含Zn废渣为对象,选取NaCl,CH3COONa和EDTA-2Na共3种络合效果显著、廉价易得的矿化剂,通过在水热硫化过程中添加矿化剂调控人造硫化矿晶体结构,弱化人造硫化矿与脉石矿物的界面作用,从而提高人造硫化矿的可浮性。以ZnS晶粒粒度、浮选回收率及富集比等为指标,考察不同矿化剂对ZnS的晶体结构及可浮性的影响;采用TEM分析添加矿化剂条件下ZnS的晶体结构与形貌变化。

1 实验材料及方法

1.1 实验材料

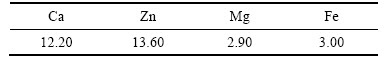

以株洲冶炼厂石灰中和法处理铅锌冶炼废渣废水产生的中和渣为研究对象。中和渣是一种含水量高且成分复杂的重金属废渣,其主要成分如表1所示。其中含有的重金属主要为Zn,其质量分数占13.6%,具有较大回收意义。此外,还存在大量的Ca,占12.2%。XRD分析表明,中和渣主要矿物相为碳酸钙和氢氧 化锌。

表1 中和渣中主要金属元素质量分数

Table 1 Mass fraction of heavy metal in neutralize sludge %

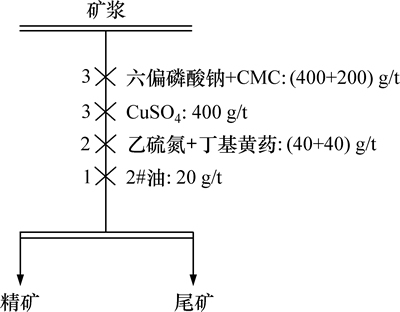

实验采用硫磺作为硫化剂。矿化剂选择化学分析纯的NaCl,CH3COONa和EDTA-2Na。浮选药剂均为工业纯,其中六偏磷酸钠为分散剂,CMC为钙抑制剂,CuSO4·5H2O为活化剂,乙硫氮和丁基黄药为锌捕收剂,2号油为起泡剂。

1.2 实验方法

硫化反应在KCF-1L型高压釜中进行。首先配备不同浓度的矿化剂溶液650 mL,然后,加入140 g中和渣和11.8 g硫磺,一起转入到高压反应釜中,在260 ℃反应4 h后自然冷却至室温。取出、抽滤、烘干得到人造硫化矿。对人造硫化矿进行XRD分析和浮选实验。浮选采用一次扫选工艺(如图1所示),浮选机为RK/FD 0.5型单槽浮选机,浮选参数如下:矿浆质量分数为14.3%,浮选温度为60 ℃,pH为8~10。

1.3 分析方法

1.3.1 浮选富集比及回收率测定

可浮性以浮选富集比和回收率为评价指标。浮选原矿(人造硫化矿)、精矿、尾矿通过王水消解后,采用ICP分析消解液中Zn2+浓度,经计算得到原矿、精矿、尾矿锌品位,分别以k,k1和k2表示。浮选得到的精矿和尾矿的质量分别为m1和m2,回收率w按以下公式计算得到:

(4)

(4)

富集比p的计算公式为

p=k1/k (5)

图1 浮选工艺流程

Fig. 1 Process flow sheet of flotation

1.3.2 XRD分析及晶粒粒度计算

通过X线衍射(XRD D/max2550 VB+ 18 kW)分析经改进的水热硫化过程中ZnS的晶粒粒度变化及水热后原矿成分。通过谢乐公式计算3个不同晶面(111,220,331)的ZnS晶体粒度并计算其平均晶体粒度。晶粒粒度计算公式如下:

(6)

(6)

其中:d为晶粒粒度;k为XRD检测波长;β为修正半角后的衍射峰; 为衍射角峰值。

为衍射角峰值。

1.3.3 表面特征分析

通过透射电镜(TEM JEM-2100F)分析水热过程后ZnS晶体外貌特征及形态变化。

2 结果与讨论

2.1 NaCl的影响

2.1.1 NaCl对ZnS浮选回收的影响

考察添加不同浓度NaCl对水热合成硫化锌可浮性的影响,结果如图2所示。从图2可见:在未添加矿化剂时,浮选后Zn的富集比为1.16;在添加NaCl作为矿化剂时,Zn的富集比整体提高(由1.16提高到1.30以上);随着NaCl浓度增大,Zn的富集比呈先增大后减小的趋势,在NaCl浓度为0.1 mol/L时,Zn富集比最大,为1.36。添加不同浓度的NaCl对Zn的回收率没有明显影响,其回收率稳定在62%~68%之间。

图2 NaCl浓度对浮选富集比和回收率的影响

Fig. 2 Effect of NaCl concentration on enrichment ratio and recovery percent of flotation

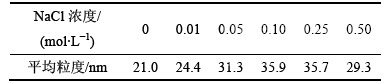

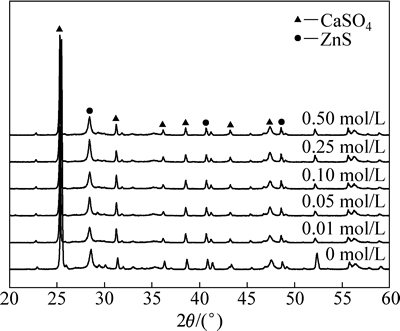

2.1.2 NaCl对ZnS结晶长大的影响

通过X线衍射分析考察在水热过程中不同浓度的NaCl对ZnS晶粒粒度或晶型改变的影响,结果如图3所示。从图3可见:在未添加矿化剂时,ZnS的衍射峰峰形较差,衍射强度小,宽化严重,这表明在未添加任何矿化剂进行水热硫化后产生的ZnS晶型差,晶粒粒度较小;而CaSO4的衍射峰衍射强度大,峰形尖锐;在添加不同浓度的NaCl进行水热反应后,ZnS衍射强度明显增强,峰形变尖锐。这表明通过矿化剂NaCl的添加,水热生成的 ZnS晶型有所改变,晶粒粒度有所增大。但NaCl浓度的变化对ZnS的衍射峰影响效果不明显。

考察添加矿化剂NaCl后不同晶面上ZnS的晶粒粒度变化,分析结果如表2所示。从表2可见:在添加NaCl反应后ZnS晶粒粒度都有所增大,最大时提高近30%;随着NaCl浓度增大,晶粒粒度有先增大后减小的趋势,在NaCl浓度为0.1 mol/L时,ZnS平均粒度最大,为35.9 nm,这也与浮选富集比的结果相一致。

图3 添加不同浓度NaCl水热反应后人造硫化矿的XRD谱

Fig. 3 XRD patterns of artificial sulfide ore after hydrothermal with different concentrations of NaCl

表2 NaCl浓度对ZnS晶粒粒度的影响

Table 2 Effect of NaCl concentration on grain size of ZnS

2.2 CH3COONa的影响

2.2.1 CH3COONa对ZnS浮选回收的影响

实验考察不同浓度矿化剂CH3COONa的添加对水热合成硫化锌可浮性的影响,结果如图4所示。从图4可见:未添加矿化剂时(即浓度为0 mol/L CH3COONa),Zn富集比为1.16;当添加0.01 mol/L CH3COONa进行水热反应后,Zn富集比提高到1.28;随着CH3COONa浓度的继续增大,其富集比也随之增大,在CH3COONa浓度达到0.5 mol/L时,达到最大值1.62。研究结果表明:在添加矿化剂CH3COONa进行水热反应后对Zn的富集比有大幅度提高,并且随着CH3COONa浓度增大,其富集比提高幅度越大。但添加CH3COONa作为矿化剂进行水热反应对Zn的回收率无明显影响,其回收率依然稳定在62%~68%之间。

2.2.2 CH3COONa浓度对ZnS晶体的影响

本研究通过X线衍射分析考察水热过程中矿化剂CH3COO-的添加对ZnS的晶粒粒度或晶型改变的影响,结果如图5所示。从图5可见:在添加矿化剂CH3COONa后,ZnS的衍射峰较未添加时略微增强,CaSO4的峰形明显减弱。这表明添加矿化剂CH3COONa后,ZnS的晶粒粒度略微增大,晶体形貌有所改变。

图4 CH3COONa浓度对浮选富集比和回收率的影响

Fig. 4 Effect of CH3COONa concentration on enrichment ratio and recovery ratio of flotation

图5 添加不同浓度CH3CONa水热反应后人造硫化矿的XRD谱

Fig. 5 XRD patterns of artificial sulfide ore after hydrothermal with different concentrations of CH3COONa

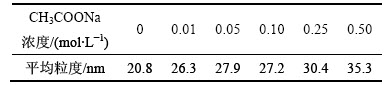

通过XRD分析水热后ZnS晶粒粒度变化,结果如表3所示。从表3可见:在添加矿化剂CH3COONa进行水热硫化过程后,ZnS晶体平均粒度由20.8 nm提高到30.0 nm左右;随着CH3COONa浓度的提高,ZnS晶粒粒度有略微增大趋势,但增幅较小;当CH3COO-浓度为0.5 mol/L时,ZnS晶体平均粒度最大为35.3 nm。

表3 CH3COONa浓度对ZnS晶粒粒度的影响

Table 3 Effect of CH3COONa concentration on grain size of ZnS

2.3 EDTA-2Na浓度的影响

2.3.1 EDTA-2Na浓度对ZnS浮选回收的影响

考察不同浓度矿化剂EDTA-2Na的添加对水热合成硫化锌可浮性的影响,结果如图6所示。从图6可见:在添加EDTA-2Na作为矿化剂进行水热反应并经过后续浮选工艺后的Zn富集比与添加EDTA-2Na时相比均有所提高;随着EDTA-2Na浓度提高,富集比的提高趋势呈先增大后减小的趋势,且在EDTA-2Na浓度为0.1 mol/L时,最大富集比最大达1.69;不同浓度矿化剂EDTA-2Na对Zn回收率影响不大,稳定在62%~68%之间。

图6 EDTA-2Na浓度对浮选富集比和回收率的影响

Fig. 6 Effect of EDTA-2Na concentration on enrichment ratio and floatation recovery

2.3.2 EDTA-2Na浓度对ZnS结晶长大的影响

考察不同浓度矿化剂EDTA-2Na的添加对水热合成硫化锌可浮性的影响,结果如图7所示。从图7可见:在添加矿化剂EDTA-2Na进行水热反应后的ZnS晶体衍射峰衍射强度变大,峰宽变窄。这表明添加此矿化剂后,ZnS的晶粒粒度有所增大。

通过XRD分析水热后ZnS晶粒粒度变化,结果如表4所示。从表4可见:与未添加矿化剂EDTA-2Na进行水热反应相比,ZnS的晶粒粒度均有所增大,晶粒粒度由21.4 nm增大至30.0 nm以上;通过添加不同浓度的EDTA-2Na,ZnS的晶体粒度呈现先增大后减小的趋势,在0.10 mol/L时最大晶粒粒度达37.6 nm。

图7 添加不同浓度EDTA-2Na水热反应后人造硫化矿XRD谱

Fig. 7 XRD patterns of artificial sulfide ore after hydrothermal with different concentrations of EDTA-2Na

表4 EDTA-2Na浓度对ZnS晶粒粒度的影响

Table 4 Effect of EDTA-2Na concentration on grain size of ZnS

由水热过程中添加矿化剂的浮选结果及XRD分析结果可知:3种矿化剂对ZnS的浮选富集及晶粒粒度均有提高;3种矿化剂中,0.10 mol/L的EDTA-2Na对Zn的富集比提高效果最大(从1.16提高至1.69),其对ZnS晶粒粒度增大有最优效果(从21.0 nm提高至37.6 nm)。考察矿化剂对ZnS晶粒粒度的影响时发现NaCl和EDTA-2Na对其晶粒粒度提高有明显效果,而CH3COONa效果则较差。而考察ZnS富集比时发现EDTA-2Na对于ZnS的富集效果则远优于NaCl的富集效果。这也说明提高ZnS的晶粒粒度是提高其富集比的影响因素但不是唯一影响因素。Zn与脉石矿物的分散性也是影响其富集回收的原因之一。

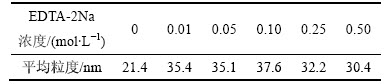

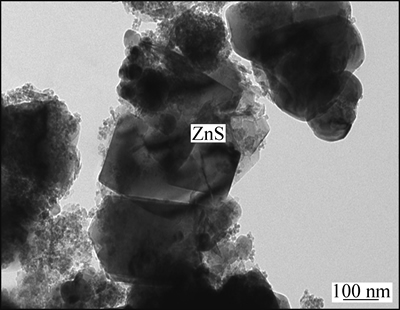

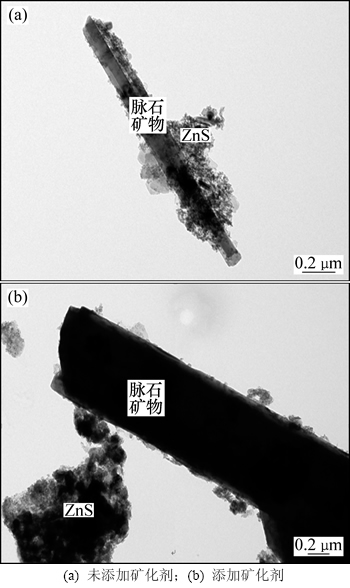

2.4 晶体外貌分析

通过透射电镜考察矿化剂的添加对ZnS的晶体结构、外面特征及其与脉石矿物界面作用的影响。综合考察实验中3种不同矿化剂对ZnS的晶体生长及可浮性的影响,结果表明:浓度为0.10 mol/L的EDTA-2Na作为矿化剂进行水热反应有最优效果。本研究选取添加0.10 mol/L的EDTA-2Na水热硫化-浮选工艺后的Zn精矿与未添加矿化剂反应后的Zn精矿进行对比实验,结果如图8~10所示。从图8可见:未添加矿化剂反应后,ZnS形状和粒度不一,晶粒分散,其中粒度较大的ZnS为50 nm左右而粒度较小的ZnS粒度不超过10 nm。从图9可见:添加矿化剂EDTA-2Na反应后,ZnS晶粒粒度都有不同程度增大,其中最大粒度达300 nm以上。TEM结果表明:在水热硫化过程中,矿化剂EDTA-2Na的添加能提高ZnS晶粒粒度。从图10(a)可见:未添加任何矿化剂进行反应后,ZnS围绕CaSO4的团聚现象严重,由于ZnS粒度小,大多吸附在CaSO4四周,使Ca与Zn的分离难度较大,从而导致后续浮选工艺中Zn难以富集。而从图10(b)可见:加入矿化剂进行反应后,ZnS围绕CaSO4的团聚现象较少,ZnS的晶粒粒度增大,这也在工艺上减小了Ca与Zn分离的难度,从而使Zn更容易富集。

图8 未添加矿化剂水热反应后ZnS晶体TEM分析

Fig. 8 TEM image of ZnS with no mineralizer in progress in hydrothermal

图9 添加EDTA-2Na水热反应后ZnS晶体TEM分析

Fig. 9 TEM images of ZnS with EDTA-2Na after hydrothermal reaction in hydrothermal

图10 脉石矿物与ZnS的团聚TEM图像

Fig. 10 TEM images of agglomeration of mineral and ZnS

3 结论

1) 在水热过程中添加3种不同浓度矿化剂都能有效调控水热过程中ZnS晶体的结晶长大,提高人造硫化矿的可浮性。

2) 综合考察3种不同矿化剂的添加进行水热硫化-浮选工艺,其对ZnS晶粒粒度的变化及ZnS富集比均有所提高。其中,EDTA-2Na在3种矿化剂中有最优效果。添加的EDTA-2Na浓度0.10 mol/L为实验选取的不同浓度中的最佳浓度。ZnS的晶体粒度由未添加时的21.0 nm提高到37.6 nm,浮选后ZnS的富集比由未添加时的1.16提高到1.69。

3) 加入矿化剂后ZnS晶粒粒度增大,与脉石矿物夹杂情况减少,提高了ZnS的分散性,有利于人造ZnS与脉石矿物分离。

参考文献:

[1] 董保澍. 我国工业固体废弃物现状和处理对策[J]. 中国环保产业, 2001, 10(5): 20-21.

DONG Baoshu. The current situation and treatment countermeasure of industry solid waste in China[J]. China Environmental Protection Industry, 2001, 10(5): 20-21.

[2] Kuchar D, Fukuta T, Onyango M S, et al. Sulfidation of zinc plating sludge with Na2S for zinc resource recovery[J]. Journal of Hazardous Materials, 2006, 137(1): 185-191.

[3] WANG Jun, LU Jinfeng, ZHANG Qiwu, et al. Mechanochemical sulfidization of nonferrous metal oxides by grinding with sulfur and iron[J]. Industrial & Engineering Chemistry Research, 2003, 23(42): 5813-5818.

[4] KE Yong, CHAI Liyuan, LIANG Yanjie, et al. Sulfidation of heavy-metal-containing metallurgical residue in wet-milling processing[J]. Minerals Engineering, 2013, 53: 136-143.

[5] 任占誉, 王吉坤, 魏昶, 等. 低品位氧化铅锌矿的硫化及浮选[J]. 云南冶金, 2009, 38(1): 27-30.

REN Zhanyu, WANG Jikun, WEI Xu, et al. Sulphuration and flotation of low-grade oxidized lead-zinc ore[J]. Yunnan Metallurgy, 2009, 38(1): 27-30.

[6] 张海静, 闵小波, 柴立元, 等. 水热合成金属硫化物的浮选行为及微观性质分析[J]. 中南大学学报(自然科学版), 2012, 43(9): 3332.

ZHANG Haijing, MIN Xiaobo, CHAI Liyuan, et al. Hydrothermal synthesis and flotation performance and microscopic properties of metal sulfides[J]. Journal of Central South University (Science and Technology), 2012, 43(9): 3332.

[7] CHEN Ye, CHEN Jianhua, LAN Lihong, et al. The influence of the impurities on the flotation behaviors of synthetic ZnS[J]. Minerals Engineering, 2012, 27/28: 65-71.

[8] LIANG Yanjie, CHAI Liyuan, LIU Hui, et al. Hydrothermal sulfidation of zinc-containing neutralization sludge for zinc recovery and stabilization[J]. Minerals Engineering, 2012, 25(1): 14-19.

[9] MIN Xiaobo, YUAN Cuiyu, CHAI Liyuan, et al. Hydrothermal modification to improve the floatability of ZnS crystals[J]. Minerals Engineering, 2013, 40: 16-23.

[10] 施尔畏, 陈之战, 元如林, 等. 水热结晶学[M]. 北京: 科学出版社, 2004: 48-52.

SHI Erwei, CHEN Zhizhan, YUAN Rulin, et al. Hydrothermal crystallograhy[M]. Beijing: Science Press, 2004: 48-52.

[11] 王庆国. 添加剂对 KDP 晶体生长及结构影响研究[D]. 青岛: 青岛大学物理科学学院, 2009: 14-30.

WANG Qingguo. The effect of different additives on the structure and optical properties of KDP crystal[D]. Qingdao: Qingdao University. School of Physical Sciences, 2009: 14-30.

[12] 郝保红, 方克明, 向兰, 等. 添加剂对纳米AlOOH 晶体生长形态的影响[J]. 中国粉体技术, 2009, 15(3): 45-47.

HAO Baohong, FANG Keming, XIANG Lan, et al. Effect of additives on growth shape of AlOOH nano-crystal[J]. China Powder Science and Technology, 2009, 15(3): 45-47.

[13] 周利民, 张士宾. 二水硫酸钙晶体生长及添加剂对它的影响(II)[J]. 海湖盐与化工, 2001, 30(3): 8-10.

ZHOU Limin, ZHANG Shibing. Crystal growth of dihydrate calcium sulphate and effects of additive (II)[J]. Sea-Lake Salt and Chemical Industry, 2001, 30(3): 8-10.

[14] 汤会香, 严密, 张辉, 等. 不同络合剂对化学水浴法制备 ZnS 薄膜性能的影响[J]. 太阳能学报, 2006, 27(4): 373-376.

TANG Huixiang, YAN Mi, ZHANG Hui, et al. Different complexing agent on the properties of chemical water bath of ZnS thin film administered prepared[J]. Acta Energiae Solaris Sinica, 2006, 27(4): 373-376.

[15] Tagirov B R, Seward T M. Hydrosulfide/sulfide complexes of zinc to 250 C and the thermodynamic properties of sphalerite[J]. Chemical Geology, 2010, 269(3): 301-311.

[16] 黄群, 辛宝平, 陈实, 等. 纳米硫化锌的生物还原-化学沉淀耦合制备及其性能表征[J]. 无机化学学报, 2008, 24(6): 880-885.

HUANG Qun, XIN Baoping, CHEN Shi, et al. Nano sized ZnS particles:Ptical properties and preparation by coupling of biological reduction and chemical precipitation mediated with EDTA[J]. Chinese Journal of Inorganic Chemistry, 2008, 24(6): 880-885.

[17] 贾宝平, 贺跃辉. ZnS掺杂技术研究及应用现状[J]. 粉末冶金材料科学与工程, 2002, 7(2): 1-3.

JIA Baoping, HE Yuehui. Review of investigation and application of ZnS doping technology[J]. Materials Science and Engineering of Powder Metallurgy, 2002, 7(2): 1-3.

[18] 宫海燕, 李彩虹, 王佩佩, 等. 杂质对溶液结晶过程影响的研究进展[J]. 化学与生物工程, 2010, 27(3): 9-12.

GONG Haiyan, LI Caihong, WANG Peipei, et al. Research progress on the impact of impurities on solution crystallization process[J]. Chemistry & Bioengineering, 2010, 27(3): 9-12.

[19] LIANG Yanjie, MIN Xiaobo, CHAI Liyuan, et al, Hydrothermal sulfidation and floatation treatment of heavy-metal-containing[J]. Journal of Hazardous Materials, 2012, 25(1): 14-19.

(编辑 陈灿华)

收稿日期:2014-08-12;修回日期:2014-10-23

基金项目(Foundation item):国家公益性行业科研专项(201509050);国家自然科学基金资助项目(51474247);湖南省科技重大专项(2012FJ1010,2014FJ1011);湖南省研究生科研创新项目(CX2014B086)(Project (201509050) supported by the Special Program on Environmental Protection for Public Welfare; Project (51474247) supported by the National Natural Science Foundation of China; Projects (2012FJ1010,2014FJ1011) supported by the Key Projects of Science and Technology of Hunan Province; Project (CX2014B086) supported by the Hunan Provincial Innovation Foundation for Postgraduate)

通信作者:梁彦杰,博士,讲师,从事固体废弃物资源化及无害化的研究;E-mail: liangyanjie2013@163.com