文章编号:1004-0609(2011)06-1285-07

放电等离子烧结合成晶化相增强的块状

Ti66Nb18Cu6.4Ni6.1Al3.5细晶复合材料

陈维平1,伍雪梅1,杨 超1,吕 瑛2,屈盛官1,陈敏丹1

(1. 华南理工大学 国家金属材料近净成形工程技术研究中心,广州 510640;

2. 内蒙古第一机械制造(集团)有限公司 车辆工程研究院,包头 014030)

摘要:基于改进的非晶形成合金体系,选取Ti66Nb18Cu6.4Ni6.1Al3.5合金为研究对象,通过放电等离子烧结机械合金化制备的非晶合金粉末,结合非晶晶化法,合成以高Nb含量的晶化β-Ti(Nb)延性相为基体的块状细晶复合材料。利用X射线衍射(XRD)、差示扫描量热仪(DSC)、扫描电子显微镜(SEM)、透射电子显微镜(TEM)和万能材料试验机等手段对合成的非晶合金粉末和细晶复合材料进行表征分析。结果表明:球磨60 h后,初始混合粉末绝大部分转变成了非晶相,其玻璃转变温度、晶化温度、晶化峰值温度和熔化温度分别为750 K、830 K、847 K和1422 K,表明Nb含量的增加显著提高合金体系的热稳定性。另外,合成的块状钛基细晶复合材料的显微结构为β-Ti延性相包围(Cu, Ni)-Ti2相,其相区尺寸均大于1 μm。当升温速率为167 K/min、烧结温度为1 373 K时,合成的复合材料密度、屈服强度、断裂强度和断裂应变分别为5.64 g/cm3、1 705.8 MPa、2 126.4 MPa和5.4%。

关键词:非晶复合材料;机械合金化;放电等离子烧结;晶化

中图分类号:TB331 文献标志码:A

Bulk Ti66Nb18Cu6.4Ni6.1Al3.5 fine grain composites reinforced by crystallized phases fabricated by spark plasma sintering

CHEN Wei-ping1, WU Xue-mei1, YANG Chao1, L? Ying2, QU Sheng-guan1, CHEN Min-dan1

(1. National Engineering Research Center of Near-net-shape Forming for Metallic Materials,

South China University of Technology, Guangzhou 510640, China;

2. Automobile Engineering Academy, Inner Mongolia First Machinery Group Corporation, Baotou 014030, China)

Abstract: Ti66Nb18Cu6.4Ni6.1Al3.5 alloy system was selected as the study object based on modified amorphous alloy system. The bulk Ti66Nb18Cu6.4Ni6.1Al3.5 fine grained composites with matrix of crystallized β-Ti(Nb) ductile phase were fabricated by spark plasma sintering of mechanical alloyed amorphous alloy powders coupled with the method of crystallization of amorphous phase. X-ray diffractometer (XRD), differential scanning calorimeter (DSC), scanning electron microscopy (SEM), transmission electron microscopy (TEM) and universal materials tester were employed to investigate the alloyed amorphous powders and the fabricated composites. The results show that the initial mixed powders are predominately alloyed into amorphous structure after milling for 60 h. The crystallization temperature (Tx), crystallization peak temperature (Tp) and melting point (Tm) of the alloyed amorphous powders are 750 K, 830 K, 847 K and 1 422 K, respectively. This indicates that the increased Nb content enhances significantly the thermal stability of alloyed powders. In addition, the fabricated composites has a microstructure of (Cu, Ni)-Ti2 phase surrounded by ductile β-Ti phase. The scale of the two phase regions is above 1 μm. Under a heating rate of 167 K/min and a sintering temperature of 1 373 K, the fabricated composite has a density of 5.64 g/cm3, a yield stress of 1 705.8 MPa, a fracture stress of 2 126.4 MPa and a fracture strain of 5.4%.

Key words: amorphous alloy composite; mechanical alloying; spark plasma sintering; crystallization

通常情况下,大块非晶合金在室温断裂时形成单一的剪切带从而发生脆性断裂,这限制了其作为结构材料这一巨大的潜在应用前景[1-3]。为了改善其脆性断裂模式,通常采用熔体凝固法制备具有较高塑性的大块非晶复合材料[1, 4-6]。根据第二相的引入方式,高塑性的大块非晶复合材料的制备方法可分为外加增强相法和内生增强相法。外加增强相法是在非晶形成体系中加入难熔的金属或陶瓷颗粒;内生增强相法是通过原位反应获得延性增强相。第二相的引入将阻碍单一剪切带的滑移,促使多重剪切带的产生和滑移,从而使复合材料的塑性得到提高[7-9]。

机械合金化和随后的粉末固结法,包括放电等离子烧结(Spark plasma sintering, SPS)[10-11]、挤压和热压等方法[12-13],是一种有效的制备非晶合金及其相关复合材料的方法。这是因为机械合金化能在熔体凝固法难以形成非晶的成分范围内合成非晶合金粉末,同时,合成的非晶粉末在其较宽的过冷液相区内具有低粘滞性。因此,利用粉末固结法可制备出较大尺寸的非晶合金及其复合材料[14-15]。

根据Ti-Nb二元相图,Nb可以无限固溶于Ti。因此,本文作者在前期合金成分[16]的基础上增加组元Nb的含量,把合金成分设定为Ti66Nb18Cu6.4Ni6.1Al3.5,利用机械合金化和放电等离子烧结合成含晶化β-Ti(Nb)相的块状钛基细晶合金材料,研究了球磨时间对粉末的非晶形成的影响和升温速率对块状合金微观结构和力学性能的影响规律。

1 实验

1.1 机械合金化的试验

初始粉末纯度为99.9%(Al纯度为99.4%,质量分数),粒度分别为50 μm的Ti、Cu、Ni粉,75 μm的Al粉和100 μm的Nb粉。合金成分选为Ti66Nb18Cu6.4Ni6.1Al3.5,在室温的伪三元相图[17]上主要晶化相为β-Ti(Nb)。行星球磨机型号为QM-2SPS0,罐体材料和球磨材料均为不锈钢。球料比为9?1,转速为3.8 r/s。球磨过程中,球磨罐内充高纯氩气保护(99.99%,0.5 MPa)。球磨每隔5 h,将粉体冷却至室温,取出一定的粉末(大约5 g)用于粉末的各种表征测试。

机械合金化(MA)过程中,用Philips x'Pert MPD Pro X射线衍射仪(XRD, Cu Kα)对球磨的合金粉末进行相转变分析。用NETSCH STA449C差示扫描量热仪(DSC, Germany),充入高纯氩气保护,对球磨的合金粉末进行热物性分析。实验前,用空的Al2O3坩埚建立基线,然后用相同的Al2O3坩埚装上合金粉末在相同的条件下进行热物性分析。用S-520(Hitachi)扫描电子显微镜分析粉末的形貌特征和颗粒尺寸。

1.2 放电等离子烧结的试验方法

粉末固结设备为320MKⅡ SPS系统(Sumitomo coal mining Co,Tokyo,Japan)。先预压非晶合金粉末到50 MPa,抽真空到3 Pa,充氩气保护,5 min后加热到100 ℃,然后以不同的升温速率加热到终点烧结温度(Ts)1 373 K固结Ti66Nb18Cu6.4Ni6.1Al3.5非晶合金粉末。烧结和冷却过程中的压力始终为50 MPa。烧结的试样为d 10 mm×12 mm的圆柱。

根据阿基米德定律,计算出合成的块状试样的测量密度m=m1/(m2-m3),其中m1、m2和m3分别为测试样品封蜡前后的质量和封蜡后在水中的质量。

用D/MAX-3A型射线衍射仪(XRD, Cu Kα)对块体材料进行相组成分析。金相抛光的样品用10%的氢氟酸腐蚀4 s,用Philips XL-30 FEG 扫描电子显微镜(SEM)及其附带的能谱装置观察其显微结构和微区成分含量。钛基试样压缩加载下的力学性能用MTS TestSstar 810来测试。测试过程中,用安装在上下WC压头之间的位移传感器来计量试样在压缩应力下的变形量,样品尺寸为d 3 mm×6 mm(长径比为2?1),应变速率为5×10-4 s-1。

2 结果与讨论

2.1 机械合金化制备钛基非晶合金粉末

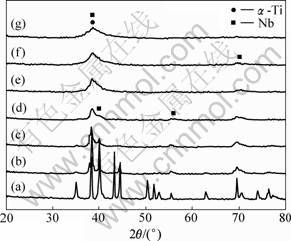

图1所示为不同球磨时间后Ti66Nb18Cu6.4Ni6.1Al3.5合金粉末的XRD谱。由图1可看出,随着球磨时间的增加,其衍射峰强度逐渐变弱,表明金属组元及其化合物在球磨过程中的晶粒尺寸逐渐变小;同时,粉末混合物的衍射峰逐渐变宽,表明晶体相的体积分数逐渐减少,非晶相逐渐形成。球磨25 h后,在位于2θ=39°开始出现漫散衍射峰(见图1(e)),意味着合金粉末开始形成非晶相;随着球磨时间的继续增加,合金粉末的非晶相逐渐增加,球磨60 h后,粉末的衍射峰变得非常圆滑(见图1(g)),意味着粉末试样绝大部分为非晶态。然而在合金粉末的XRD谱中,仍然可以发现很弱的α-Ti相和Nb相的衍射峰,这是达到稳态球磨后粉末试样的残留相。

图1 球磨不同时间后Ti66Nb18Cu6.4Ni6.1Al3.5合金粉末的XRD谱

Fig.1 XRD patterns of mechanically alloyed Ti66Nb18Cu6.4- Ni6.1Al3.5 powders after milling for different times: (a) 0; (b) 5 h; (c) 10 h; (d) 15 h; (e) 25 h; (f) 40 h; (g) 60 h

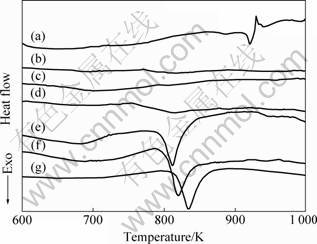

图2所示为加热速率20 K/min时球磨不同时间后Ti66Nb18Cu6.4Ni6.1Al3.5合金粉末的DSC曲线。再一次证实了合金粉末从合金化到非晶化的转变过程。且随着球磨时间的增加,表示非晶相形成的放热峰开始出现(见图2(e))。同时,其放热峰的面积随着球磨时间的增加而逐渐增大,这预示着非晶相体积分数逐渐增大。球磨60 h后,放热峰的强度达到最大值(见图2(g)),这进一步证实粉末试样绝大部分为非晶态。球磨60 h后非晶粉末的晶化焓?hx(其值为DSC曲线中晶化峰的积分面积)为1.24 kJ/mol,低于本课题组前期获得的非晶粉末的晶化焓(?hx=3.0 kJ/mol)[16]。这表明增加Nb含量以后明显地减小非晶合金粉末的?hx。

图2 球磨不同时间后Ti66Nb18Cu6.4Ni6.1Al3.5合金粉末的DSC曲线

Fig.2 DSC curves of mechanical alloyed Ti66Nb18Cu6.4- Ni6.1Al3.5 powders after milling for different times: (a) 0; (b) 5 h; (c) 10 h; (d) 15 h; (e) 25 h; (f) 40 h; (g) 60 h

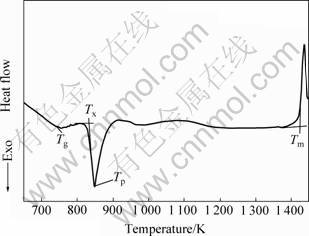

图3所示为从加热速率为40 K/min时的DSC曲线。其中Tg、Tx、Tp、Tm分别为750、830、847和1 422 K。通过机械合金化获得的Ti66Nb18Cu6.4Ni6.1Al3.5非晶粉末具有宽达80 K的过冷液相区,表明其具有很强的玻璃形成能力。

图3 球磨60 h的非晶粉末的DSC曲线

Fig.3 DSC curve of amorphous powder after milling for 60 h

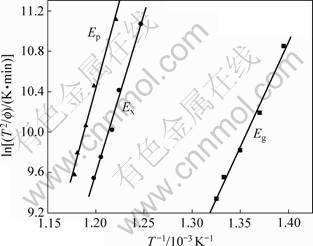

为了从能量上研究高Nb含量对非晶合金粉末的影响,有必要比较非晶合金粉末的玻璃转变激活能(Eg)、晶化激活能(Ex)以及晶化峰值激活能(Ep)。根据加热速率为10、20、30、40和50 K/min下球磨60 h的Ti66Nb18Cu6.4Ni6.1Al3.5非晶粉末的DSC曲线,通过Kissinger关系式,通过各拟合曲线的斜率值,可以获得其相应的各种激活能。Kissinger关系式可表示为

(1)

(1)

式中:T是在加热速率为 (K?min-1)时的特征温度;E为激活能;R为摩尔气体常数;C为常数。

(K?min-1)时的特征温度;E为激活能;R为摩尔气体常数;C为常数。

图4所示为Ti66Nb18Cu6.4Ni6.1Al3.5非晶合金粉末的Kissinger拟合曲线。计算得到的Eg、Ex和Ep分别为172.9、266.5和291.1 kJ/mol。本课题组前期制备的非晶Ti66Nb13Cu8Ni6.8Al6.2合金粉末[18]的Eg、Ex及Ep分别为169.5、343.1和281.5 kJ/mol。本研究获得的非晶合金粉末的Eg和Ep均高于非晶Ti66Nb13Cu8Ni6.8Al6.2合金粉末的,而Ex偏小。

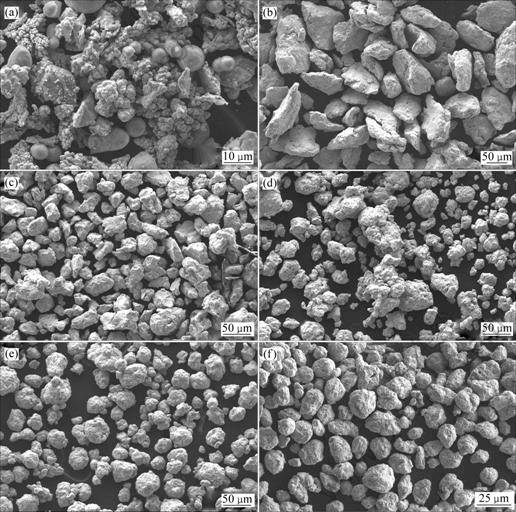

图5所示为不同球磨时间后Ti66Nb18Cu6.4Ni6.1Al3.5合金粉末的SEM像。原始粉末形貌为形状、大小不均一的混合物(见图5(a))。随着球磨时间的增加,粉末颗粒尺寸大致呈变小的趋势。由于粉末试样中含有较高的Nb含量,在球磨过程中生成的脆性金属间化合物,在剧烈碰撞中容易发生断裂,因此,在球磨初期,粉末颗粒尺寸持续变小(见图5(a)~(c));球磨25 h后,部分粉末颗粒尺寸大于球磨15 h后的粉末颗粒尺寸(见图5(c)和(d)),这归因于球磨25 h后,合金粉末开始形成非晶态,粘滞性的增加导致发生了团聚现象;在球磨25 h至60 h期间,粉末颗粒尺寸出现增大的趋势,主要原因是随着时间的增加,非晶态体积分数也不断增加,导致粉末粘滞性的连续增加。当球磨达到60 h以后,粉末颗粒尺寸达到极大值,说明粘滞性最大,这进一步证实球磨60 h后,粉末完全转变为非晶态。非晶态粉末的颗粒尺寸约为25 μm(见图5(f)),远小于本课题组前期制备的非晶Ti66Nb13Cu8Ni6.8Al6.2合金粉末的颗粒尺寸(约为60 μm[16])。这是由于本研究的合金成分比前期的合金成分多了一定的Nb含量,元素Nb在MA过程中容易生成脆性的金属间化合物,在球磨过程中,发生激烈的碰撞,这较之前期的合金成分,容易发生脆断,因此,在获得非晶粉末时,前者的粉末颗粒尺寸小。

图4 Ti66Nb18Cu6.4Ni6.1Al3.5非晶合金球磨60 h后的Kissinger曲线

Fig.4 Kissinger plots of mechanically alloyed amorphous Ti66Nb18Cu6.4Ni6.1Al3.5 powders after milling for 60 h

图5 球磨不同时间后Ti66Nb18Cu6.4Ni6.1Al3.5合金粉末的SEM像

Fig.5 SEM images of mechanically alloyed Ti66Nb18Cu6.4Ni6.1Al3.5 powders after milling for different times: (a) 0; (b) 5 h; (c) 15 h; (d) 25 h; (e) 40 h; (f) 60 h

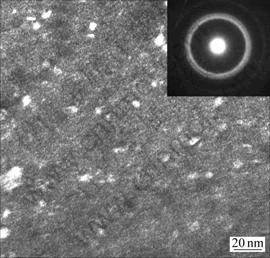

图6所示为球磨60 h的Ti66Nb18Cu6.4Ni6.1Al3.5非晶合金粉末的TEM像。其微观形貌为呈迷宫状的结构,同时,其选区衍射图中表明非晶相衍射特征的光晕明显凸现,进一步证实粉末的非晶态结构。

2.2 SPS合成钛基块状合金

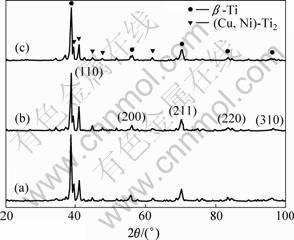

图7所示为不同的升温速率加热到1 373 K固结Ti66Nb18Cu6.4Ni6.1Al3.5非晶粉末后块状试样的XRD谱。显然,经过SPS固结之后,块状试样的晶化相都是β-Ti和(Cu, Ni)-Ti2。试样中β-Ti的晶格常数分别为3.277 ? (见图7(a))、3.245 ?(见图7(b))和3.258 ?(见图7(c))。同时,β-Ti衍射峰强度随升温速率的增大而没有明显的变化,这可能是因为随着升温速率的增大,β-Ti相的体积分数含量变化不大的缘故。而脆性相(Cu, Ni)-Ti2的衍射峰强度随着升温速率的增大呈现先增强后减弱的变化趋势。

图6 球磨60 h后Ti66Nb18Cu6.4Ni6.1Al3.5非晶合金粉末的TEM形貌和选区衍射谱

Fig.6 TEM images and corresponding SAD pattern of mechanically alloyed amorphous Ti66Nb18Cu6.4Ni6.1Al3.5 powder after milling for 60 h

图7 以不同的升温速率加热到1 373 K合成块状Ti66Nb18- Cu6.4Ni6.1Al3.5的XRD谱

Fig.7 XRD patterns of bulk Ti66Nb18Cu6.4Ni6.1Al3.5 alloys heated to 1 373 K at different heating rates: (a) 100 K/min; (b) 167 K/min; (c) 250 K/min

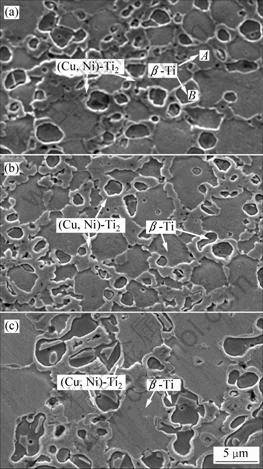

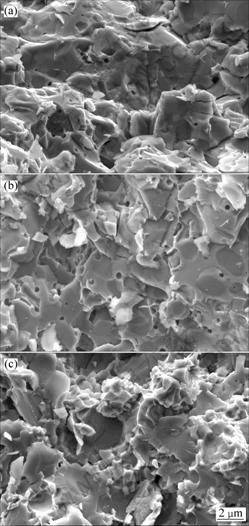

图8所示为50 MPa下,以不同的升温速率加热到1 373 K固结的Ti66Nb18Cu6.4Ni6.1Al3.5块状合金的SEM像。由图8可看出,块状试样的主要晶化相为延性相β-Ti和脆性相(Cu, Ni)-Ti2。试样的微观结构均为连续分布的脆性相(Cu, Ni)-Ti2包围长条状或不规则圆形的延性相β-Ti相B以及另一种基体延性相β-Ti相A,同时,延性相β-Ti的相区尺寸随着升温速率的增大而增大,尤其当升温速率为250 K/min时,β-Ti相A的相区尺寸从约5 μm(见图8(a))增大到约10 μm(见图8(c))。而当升温速率为167 K/min时,脆性相的相区尺寸达到最大值,约为2 μm,且其所占体积分数也达到最大值(见图8(b)),这与块状试样XRD结果中(Cu, Ni)-Ti2的衍射峰强度的变化趋势相一致。

图8 以不同的升温速率加热到1 373 K合成块状Ti66Nb18- Cu6.4Ni6.1Al3.5的SEM像

Fig.8 SEM images of bulk Ti66Nb18Cu6.4Ni6.1Al3.5 alloys heated to 1373K at different heating rates: (a) 100 K/min; (b) 167 K/min; (c) 250 K/min

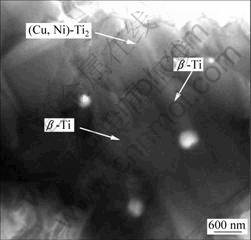

图9所示为167 K/min升温到1 373 K固结的块状Ti66Nb18Cu6.4Ni6.1Al3.5合金(见图8(b))的TEM像。微观结构由尺寸均大于1 μm的延性β-Ti相和脆性(Cu, Ni)-Ti2相区构成,进一步证实相区的晶粒尺寸均大于1 μm,因此,合成的块状合金为细晶合金。

图9 以167 K/min升温到1 373 K合成块状Ti66Nb18Cu6.4- Ni6.1Al3.5合金的TEM像

Fig.9 TEM images of bulk Ti66Nb18Cu6.4Ni6.1Al3.5 alloys heated to 1 373 K at 167 K/min

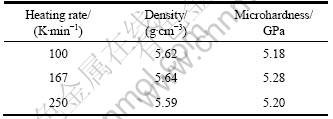

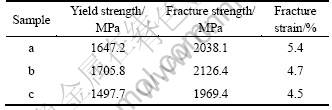

表1所列为以不同的升温速率加热到1 373 K固结Ti66Nb18Cu6.4Ni6.1Al3.5非晶粉末后块状试样的密度和显微硬度。由表1中的数据可知,当升温速率为167 K/min时,块状试样的密度和显微硬度均达到最大,分别为5.64 g/cm3和5.28 GPa。这与该试样的脆性(Cu, Ni)-Ti2相的衍射峰强度的变化趋势相一致,这进一步说明显微硬度与脆性相有关系。另外,密度随升温速率的变化而没有明显的变化,这可能是因为烧结温度较高,使试样都达到比较致密化的程度而造成的,同时,因为脆性(Cu, Ni)-Ti2相呈连续分布,所以其显微硬度变化也不是很明显。

表2所列为以不同的升温速率加热到1 373 K固结的Ti66Nb18Cu6.4Ni6.1Al3.5块状合金的室温力学性能。显然,由于脆性相(Cu, Ni)-Ti2呈连续分布,所有试样的塑性都较低,随着升温速率的增加,样品a、b和c的断裂应变分别为5.4%、4.7%和4.5%。块状试样的屈服强度随着升温速率的增大呈先增大后减小的变化,这与其脆性相的衍射峰强度的变化趋势一致(见图8),分别为1 647.2、1 705.8和1 497.7 MPa。这表明,试样屈服强度的变化趋势和脆性相的含量有关。此外,随着升温速率的增大,其断裂强度分别为2 038.1、2 126.4和1 969.4 MPa。

表1 以不同的升温速率加热到1 373 K固结Ti66Nb18Cu6.4- Ni6.1Al3.5非晶粉末后块状试样的密度和显微硬度

Table 1 Density and microhardness of bulk Ti66Nb18Cu6.4- Ni6.1Al3.5 alloys heated to 1 173 K at different heating rates

图10所示为图8中固结的块状合金的断裂形貌。从图10中可以看到,块状试样的断口基本为脆性材料的穿晶断裂和沿晶断裂,导致试样的塑性普遍较低,这与相区的显微结构(见图8)相符合,延性相β-Ti不连续,而脆性相呈连续分布。同时,其形貌证实合金的晶粒尺寸约为4 μm,也进一步证明块状试样为细晶合金。

表2 图7中固结的块状试样在室温时的力学性能

Table 2 Room-temperature mechanical properties of bulk Ti66Nb18Cu6.4Ni6.1Al3.5 alloys in Fig.7

图10 图8中固结的块状合金的断裂形貌

Fig.10 Fracture micrographs of bulk Ti66Nb18Cu6.4Ni6.1Al3.5 alloys in Fig.8: (a) 100 K/min; (b) 167 K/min; (c) 250 K/min

3 结论

1) 合金粉末在球磨60 h以后达到非晶态,获得绝大部分为非晶态和含有少量α-Ti和Nb残留相的Ti66Nb18Cu6.4Ni6.1Al3.5合金粉末。非晶态粉末的颗粒尺寸约为25 μm。当加热速率为40 K/min时,Tg、Tx、Tp以及Tm分别为750 K、830 K、847 K和1 422 K,?Tx宽达80 K。非晶态粉末的Eg、Ex和Ep分别为172.9、266.5、291.1 kJ/mol。

2) 在烧结压力为50 MPa时,以不同的升温速率加热到1 373 K固结Ti66Nb18Cu6.4Ni6.1Al3.5非晶粉 末,合成块状钛基细晶试样。当升温速率为167 K/min时,块状试样屈服强度和断裂强度分别为1 705.8 MPa和2 126.4 MPa。当升温速率为100 K/min时,块状试样的断裂应变为5.4%。

REFERENCES

[1] INOUE A. Stabilization of metallic supercooled liquid and bulk amorphous alloys[J]. Acta Mater, 2000, 48: 279-306.

[2] WANG W H, DONG C, SHEK C H. Bulk metallic glass[J]. Mater Sci Eng R, 2004, 44: 45-89.

[3] SALIMON A I, ASHBY M F, BRECHET Y, GREER A L. Bulk metallic glasses: what are they good for[J]. Mater Sci Eng A, 2004: 375-377.

[4] HE G, ECKERT J, L?SER W, SCHULTZ L. Novel Ti-base nanostructure-dendrite composite with enhanced plasticity[J]. Nat Mater, 2003, 2(1): 33-37.

[5] J?RGEN E, UTA K, JAYANTA D, SERGIO S, NICOLLE R. Nanostrutured composite materials with improved deformation behavior[J]. Advanced Engineering Materials, 2005, 7(7): 587-596.

[6] LEE M H, LEE J Y, BAE D H, KIM W T, SORDELET D J, KIM D H. A development of Ni-based alloys with enhanced plasticity[J]. Intermetallics, 2004, 12: 1133-1137.

[7] GUO F Q, WANG H J, POON S J, SHIFLET G J. Ductile titanium based glassy alloy ingots[J]. Appl Phys Lett, 2005, 86(9): 091907-091907-3.

[8] KIM Y C, KIM W T, KIM D H. A development of Ti-based bulk metallic glass[J]. Mater Sci Eng A, 2004, 127: 375-377.

[9] WEI Q, JIA D, RAMESH K T, MA E. Evolution and microstruture of shear bands in nanostrutured Fe[J]. Appl Phys Lett, 2002, 81(7): 1240-1243.

[10] XIE G Q, LOUZGUINE-LUZGIN D V, KIMURA H, INOUE A, WAKAI F. Large-size ultrahigh strength Ni-based bulk metallic glassy matrix composites with enhanced ductility fabricated by spark plasma sintering[J]. Appl Phys Lett, 2008, 92(12): 121907-1-121907-3.

[11] 李元元, 杨 超, 陈维平, 李小强, 屈盛官, 夏 伟, 邵 明, 张 文. 一种高塑性钛基超细晶复合材料及其制备方法: 中国, 200810219203.4[P]. 2009-07-29.

LI Yuan-yuan, YANG Chao, CHEN Wei-ping, LI Xiao-qiang, QU Sheng-guan, XIA Wei, SHAO Ming, ZHANG Wen. A method to prepare Ti-based ultrafine-grained composites with high plasticity: CN, 200810219203.4[P]. 2009-07-29.

[12] BAE D H, LEE M H, KIM D H, SORDELET D J. Plasticity in Ni59Zr20Ti16Si2Sn3 metallic glass matrix composites containing brass fibers synthesized by warm extrusion of powders[J]. Appl Phys Lett, 2003, 83(12): 2312-2314.

[13] ZHANG L C, XU J, MA E. Consolidation and properties of ball-milled Ti50Cu18Ni22Al4Sn6 glassy alloy by equal channel angular extrusion[J]. Mater Sci Eng A, 2006, 434(1/2): 280-288.

[14] ECKERT J, REGER-LEONHARD A, WEI? B, HEILMAIER M, SCHULTZ L. Bulk nanostructured multicomponent alloys[J]. Adv Eng Mater, 2001, 3: 41-47.

[15] LI Y Y, YANG C, QU S G, LI X Q, CHEN W P. Nucleation and growth mechanism of crystalline phase for fabrication of ultrafine-grained Ti66Nb13Cu8Ni6.8Al6.2 composites by spark plasma sintering and crystallization of amorphous phase[J]. Mater Sci Eng A, 2010, 528: 486-493.

[16] LI Y Y, YANG C, CHEN W P, LI X Q. Effect of WC content on glass formation, thermal stability and phase evolution of a TiNbCuNiAl alloy synthesized by mechanical alloying[J]. Journal of Materials Research, 2008, 23(3): 745-754.

[17] ECKERT J, K?HN U, DAS J, SCUDINO S, RADTKE N. Nanostructured composite materials with improved deformation behavior[J]. Advanced Engineering Materials, 2005, 7(7): 587-596.

[18] LI Y Y, YANG C, CHEN W P, LI X Q, QU S G. High plastic Ti66Nb13Cu8Ni6.8Al6.2 composites with in-situ b-Ti phase synthesized by spark plasma sintering of mechanically alloyed glassy powders[J]. Materials Science Forum, 2010, 638/642: 1642-1647.

(编辑 李艳红)

基金项目:国家重点基础计划前期研究专项资助项目(2010CB635104);国家自然科学基金资助项目(50801028)

收稿日期:2010-06-28;修订日期:2010-10-18

通信作者:陈维平,教授,博士;电话:020-87113832;E-mail: cyang@scut.edu.cn