DOI: 10.11817/j.ysxb.1004.0609.2021-37747

钒渣亚熔盐法钒铬共提工艺清洁生产评价

王少娜1,吕页清1,刘 彪1,杜 浩1, 2,白 丽3,王海旭3,王新东4,李兰杰3,张 懿1

(1. 中国科学院过程工程研究所,绿色过程与工程重点实验室,北京 100190;

2. 中国科学院大学 国际学院,北京 100049;

3. 河钢股份有限公司承德分分公司,承德 067102;

4. 河钢集团有限公司,石家庄 050023)

摘 要:针对现有钒渣钠化焙烧提钒工艺钒提取率低、铬不能提取、三废环境治理代价高等难题,中科院过程工程研究所和河钢承钢开发钒渣亚熔盐法钒铬共提清洁生产工艺,于2017年建成5万t生产线,目前已运行两年以上,取得可靠的工业化运行和环境保护检测数据。本文通过选取资源能源利用、生产工艺技术、污染物排放、资源综合利用、产品特征、环境管理6类一级指标及其下属的27个二级指标,对该工艺进行清洁生产水平分析。结果表明:工艺清洁生产指数达98.02,属于清洁生产先进水平。工艺可在温和条件下实现钒铬的高效清洁提取,为我国36亿t高铬型钒钛磁铁矿的利用提供关键解决方案,可引领钒化工产业的绿色升级。

关键词:亚熔盐;钒铬共提;清洁生产;钒钛磁铁矿

文章编号:1004-0609(2021)-03-0736-12 中图分类号:X383 文献标志码:A

引文格式:王少娜, 吕页清, 刘 彪, 等. 钒渣亚熔盐法钒铬共提工艺清洁生产评价[J]. 中国有色金属学报, 2021, 31(3): 736-747. DOI: 10.11817/j.ysxb.1004.0609.2021-37747

WANG Shao-na, Lü Ye-qing, LIU Biao, et al. Assessment for cleaner production of vanadium and chromium co-extraction from vanadium slag by sub-molten salt method[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 736-747. DOI: 10.11817/j.ysxb.1004.0609.2021-37747

钒、铬是世界公认的紧缺资源和重要战略金属,广泛应用于钢铁、化工、航空航天、新能源、军工、电子技术、原子能等重要领域[1-4],其中钒被称为“现代工业的味精”,铬与国民经济15%的商品品种相关[5],它们在国民经济中的重要作用不可替代。钒钛磁铁矿为我国重大特色战略金属矿产资源[6-7],特别是我国36亿t特色高铬型钒钛磁铁矿,为钒、钛、铁、铬等多金属共伴生,其中钒资源量达1600万t,占全国钒储量的62%;铬资源量达900万t[8],占全国铬储量的80%,由于缺乏钒铬资源高效清洁利用技术,难以大规模开发。钒铬高效清洁利用技术的突破,有利于支撑我国优势战略资源综合利用产业的可持续发展。

钒钛磁铁矿冶炼过程中生成钒、铬富集的冶金渣,简称钒渣,是国内外提钒的主要原料[9-10],占全球钒产量的80%。在我国,高温氧化焙烧是钒渣提钒的主流工艺,工艺成熟,钒产品质量稳定,但是焙烧过程会产生有害窑气(>50亿m3/a),铵盐沉钒过程会产生大量高盐氨氮废水(>240万t/a)[11-12],是大气和水体的潜在污染源。特别是我国钒渣资源普遍含铬量高,采用高温焙烧工艺难以经济性提取,不仅是对我国战略紧缺铬资源的严重浪费,而且产生大量含铬工业尾渣(>60万t/a),无害化消纳代价大。可见,采用传统高温焙烧工艺处理钒渣三废末端治理代价大,区域环境承载压力接近极限。设计全新反应体系及流程,实现钒铬资源的高效绿色提取及污染源头控制,是支撑我国钒产业生态化可持续发展的国家战略需求。

为破解钒渣中钒铬资源高效清洁利用这一世界难题,中国科学院过程工程研究所提出了以活性氧(包括  、

、 、O2-、

、O2-、 、OH·等)量化调控为核心的亚熔盐非常规介质新理论,形成了两性金属矿产资源亚熔盐绿色反应分离平台[13-16],以含铬钒渣为重点,与河钢集团合作,共同开发了以亚熔盐原子经济性反应-钒铬清洁相分离-钒产品绿色短流程制备-尾渣全量化增值利用为特色的具有自主知识产权的钒的清洁提取与产品绿色制造新技术,并建成国际首套5万t/a钒渣亚熔盐法高效提钒示范工程,实现工业稳定运行[17]。

、OH·等)量化调控为核心的亚熔盐非常规介质新理论,形成了两性金属矿产资源亚熔盐绿色反应分离平台[13-16],以含铬钒渣为重点,与河钢集团合作,共同开发了以亚熔盐原子经济性反应-钒铬清洁相分离-钒产品绿色短流程制备-尾渣全量化增值利用为特色的具有自主知识产权的钒的清洁提取与产品绿色制造新技术,并建成国际首套5万t/a钒渣亚熔盐法高效提钒示范工程,实现工业稳定运行[17]。

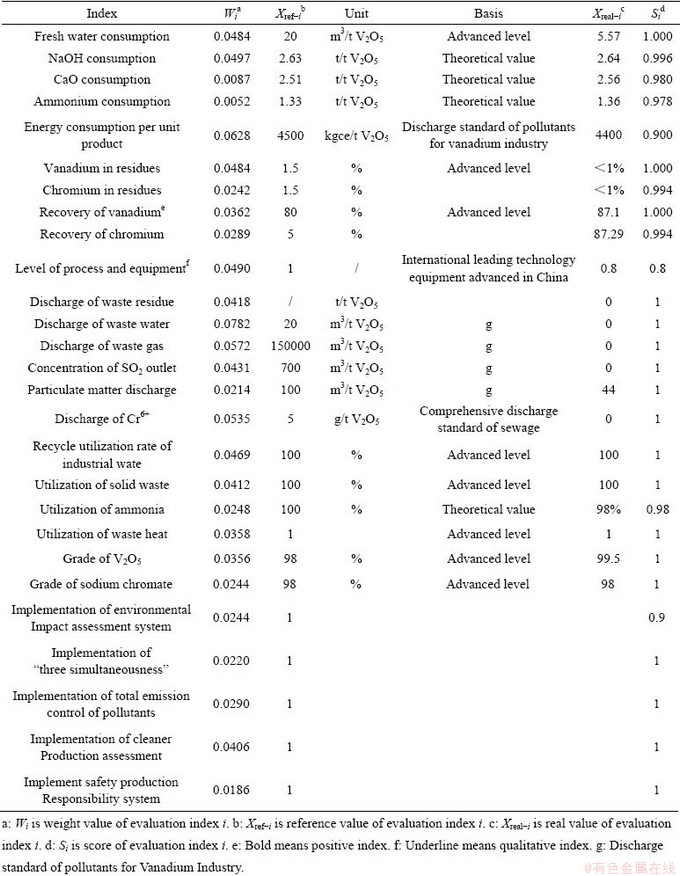

本文基于现有钒渣提钒行业清洁生产指标评价体系构建了适用于钒渣钒铬共提过程的评价体系, 所构建体系共包含5个资源能源消耗指标、5个生产技术特征指标、6个污染物指标、4个资源综合利用指标、2个产品特征指标和5个环境管理指标,其中定量指标20个, 定性指标7个。采用该指标体系对钒渣亚熔盐法钒铬共提工艺进行了清洁生产评价。

1 清洁生产评价指标体系

清洁生产评价指标体系是由相互独立,又相互联系、互为补充的一系列用于评价清洁生产绩效的评价指标集合而成,除可用于衡量企业清洁生产绩效外,还可用于发现企业实际生产过程中存在的问题,为企业找出最佳生产技术和解决方案,帮助企业实现可持续发展。自国家2005年7月《国务院关于加快发展循环经济的若干意见》(国发[2005] 22号)中“制定重点行业清洁生产评价指标体系和涉及循环经济的有关污染控制标准”的要求下发以来,国家发改委已陆续组织编制并发布了包括氮肥、电池、包装、电石等在内的三十多个重点行业的清洁生产评价指标体系。然而作为我国特色产业,尽管国家及地方政府已先后发布多个针对钒行业的政策法规,但迄今为止,钒渣提钒行业依然尚未形成统一有效的绿色制造评价指标体系。近年来,我国都是依据《工业清洁生产评价指标体系编制通则》(GB/T 20106—2006)对有关钒渣利用的企业进行清洁生产定性,缺乏一定的针对性和专业性。研究人员针对石煤行业进行了清洁生产指标体系的建立[18-23],但石煤提钒与钒渣提钒原料、工艺路线完全不同,不具有通用指导性。特别是钒渣亚熔盐钒铬共提工艺中铬也是重要目标元素,需以产品生命周期评价理论为指导,针对该工艺制定具有科学性、有效性的清洁生产评价指标体系,促进钒渣亚熔盐法钒铬共提工艺技术的绿色提升及工艺装备的改造升级。

2 钒渣亚熔盐法钒铬共提工艺简介

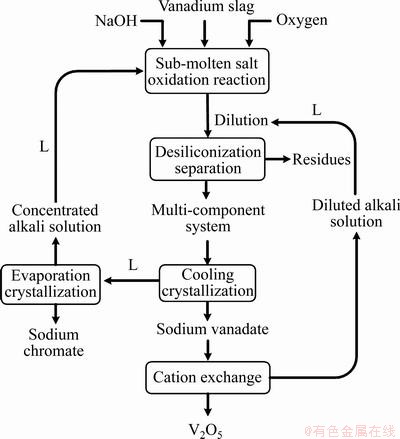

钒渣亚熔盐法钒铬共提工艺为中科院过程所与河钢承钢联合开发的全湿法提钒流程,工艺流程见图1,包括以下三个关键部分。

1) 液相氧化钒铬高效溶出。钒渣中钒铁、铬铁尖晶石在亚熔盐介质中被氧气/活性氧氧化,转化为可溶性的钒酸钠、铬酸钠。采用微气泡强化技术,提升介质中活性氧含量及介质氧化活性,实现低温(≤150 ℃)常压下钒、铬的高效转化(钒转化率>90%、铬转化率大于80%),获得低钠尾渣,可全量化用于配矿炼铁。

钒铁、铬铁尖晶石在亚熔盐介质中的反应方程式为:

FeO·V2O3+6NaOH+5/4O2=1/2Fe2O3+3H2O+2Na3VO4 (1)

FeO·Cr2O3+4NaOH+7/4O2=1/2Fe2O3+2H2O+2Na2CrO4 (2)

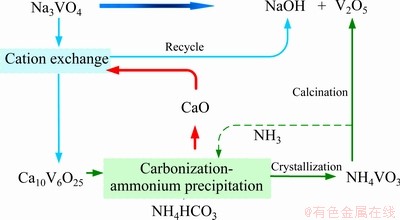

2) 钒产品高效分离及清洁转化。通过介稳区精确调控,冷却结晶获得纯度高、易分离的钒酸钠晶体,后经梯级阳离子置换获得高纯五氧化二钒产品,同时实现Na+介质的封闭循环回用,源头避免了钒化工高盐氨氮废水的产生。

3) 铬酸钠结晶分离及碱介质循环。根据铬酸钠在碱介质中溶解度变化规律,通过蒸发结晶分离铬酸钠产品,结晶后母液直接返回液相氧化工序,实现铬酸钠结晶与介质循环的低能耗协同运行。

图1 亚熔盐非常规介质处理钒渣原则流程图

Fig. 1 Schematic diagram of sub-molten salt method for processing vanadium slag

图2 5万t钒渣亚熔盐法钒铬共提清洁生产示范工程

Fig. 2 50 kt/a demonstration project of high efficient extraction of vanadium and chromium by sub-molten salt method

3 钒渣亚熔盐法钒铬共提工艺清洁生产评价指标体系的建立

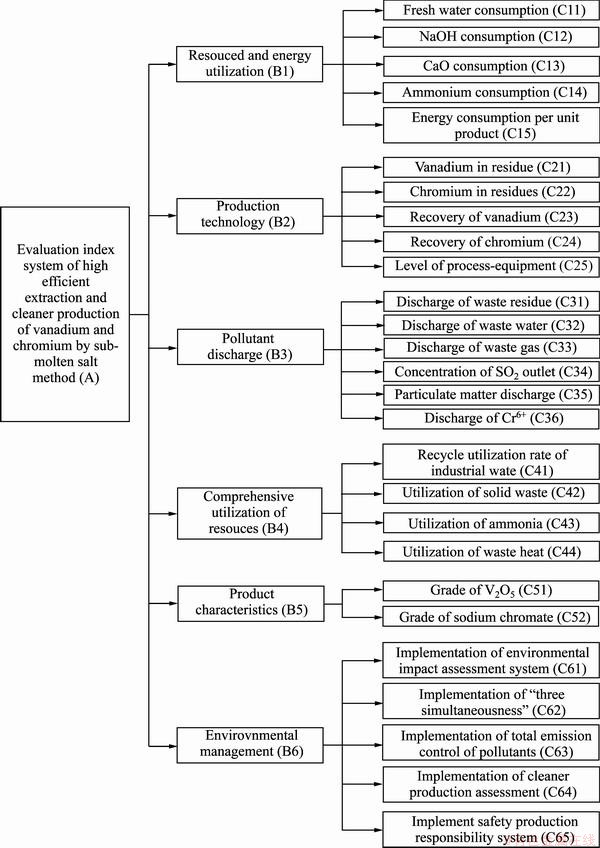

根据清洁生产指标体系的选取原则和指标的可度量性,结合本工艺特点,参考其他钒相关工艺清洁生产评价体系[18-23],构建了钒渣亚熔盐法钒铬共提工艺清洁生产评价指标体系。体系框架图见图3。

图3中清洁生产评价指标体系分为三个层次,即目标层、准则层和指标层。目标层即为钒渣钒铬共提清洁生产评价指标体系;准则层由相互独立、分别隶属于总系统层的一级定性或定量指标构成,包括资源能源消耗指标(B1)、生产技术特征指标(B2)、污染物指标(B3)、资源综合利用指标(B4)、产品特征指标(B5)和环境管理指标(B6)共6大类;指标层是隶属于准则层、可反映行业生产各工艺环节清洁水平具体可操作考核的二级指标,共27项。其中B1类一级指标包括新鲜水消耗量(C11)、NaOH消耗量(C12)、CaO消耗量(C13)、铵盐消耗量(C14)、单位产品综合能耗(C15)等5个定量指标;B2类一级指标共包含尾渣钒含量 (C21)、尾渣铬含量(C22)、钒总回收率(C23)、铬总回收率(C24) 4个定量指标和工艺与设备先进性(C25)这一定性或半定量指标;B3类一级指标共包含单位产品废渣排放量(C31)、单位产品废水排放量(C32)、单位产品废气排放量(C33)、SO2排放口浓度(C34)、颗粒物排放口浓度(C35)、六价格排放量共6个定量指标;B4类一级指标共包含工业用水重复利用率 (C41)、固体废渣综合利用率(C42)、氨气综合利用率(C43) 3个定量指标和余热综合利用率(C44)这一定性指标;B5类一级指标包含V2O5产品等级(C51)和铬酸钠产品等级(C52)2个定量指标;B6类一级指标共包含环境影响评价制度执行情况(C61)、环境保护“三同时”执行情况(C62)、污染物排放总量控制情况(C63)、清洁生产考核制度执行情况(C64)和建立实施安全生产责任制度(C65)共5个定性指标。

3.1 资源能源消耗指标解释及计算

资源能源消耗指标是反映企业在生产过程中资源能源消耗水平的指标,还可间接反映企业的工艺技术和管理水平。该类指标含有6个定量指标,均为逆向指标,即指标数值越大,生产过程中资源能耗消耗量越大,造成的环境影响也越大,指标越小,越有利于清洁生产。

1) C11 (新鲜水消耗量)

该指标系指每生产1 t合格钒产品所需要消耗的新鲜水量,包括配料、稀释、结晶、洗渣、钙化等各个环节消耗新鲜水量总和。在本工艺流程中,仅在配料环节需少量新鲜水输入,其他环节依靠介质循环即可满足用水需求,C11指标为5.57 m3/t V2O5。

图3 钒渣亚熔盐法钒铬共提工艺清洁生产评价指标体系

Fig. 3 Evaluation index system of high efficient extraction and cleaner production of vanadium and chromium by sub-molten salt method

2) C12 (NaOH消耗量)

该指标是指每生产1 t合格钒产品所需消耗的新鲜NaOH量。钒渣亚熔盐法钒铬共提清洁生产工艺该指理论值为2.63 t/t V2O5,实际运行过程消耗为2.64 t/t V2O5。

3) C13 (CaO消耗量)

该指标是指每生产1 t合格钒产品所需消耗的新鲜CaO量。钒渣亚熔盐法钒铬共提清洁生产工艺该指标理论值为2.51 t/t V2O5,实际运行过程消耗为2.56 t/t V2O5。

4) C14 (铵盐消耗量)

该指标是指每生产1 t合格钒产品所需消耗的新鲜铵盐量。钒渣亚熔盐法钒铬共提清洁生产工艺采用梯级阳离子置换实现钒酸钠向偏钒酸铵产品的转化,梯级阳离子置换是指通过Ca2+/ 的置换实现钒酸钠中Na/V的高效清洁分离,其中

的置换实现钒酸钠中Na/V的高效清洁分离,其中 采用的是NH4HCO3[24-25],梯级阳离子置换流程见图4,NH4HCO3与钒酸钙反应可生成碳酸钙与NH4VO3,冷却结晶可获得NH4VO3产品。该指标数值理论量为1.33 t/t V2O5,实际运行过程消耗为1.36 t/t V2O5。

采用的是NH4HCO3[24-25],梯级阳离子置换流程见图4,NH4HCO3与钒酸钙反应可生成碳酸钙与NH4VO3,冷却结晶可获得NH4VO3产品。该指标数值理论量为1.33 t/t V2O5,实际运行过程消耗为1.36 t/t V2O5。

图4 多级阳离子置换清洁制备钒产品

Fig. 4 Cleaning production of NH4VO3 by multiple cation exchange method

5) C15 (单位产品综合能耗)

该指标是指每生产1 t合格钒产品所消耗的所有能量(包括电能、天然气、蒸汽、煤等)折合吨标煤的总量。5万t工程是世界首个湿法清洁提钒工业化示范项目,采用了诸多节能措施:闪蒸出的二次蒸汽用来预热物料,可有效减少加热物料消耗的能源;铬酸钠蒸发采用三效逆流蒸发,减少了蒸汽用量;采用工业循环水系统对水资源循环利用,循环水利用率为98%;采用自动化程度较高的DCS控制系统提高生产机械运行效率,降低能源损耗。项目在设备选型时选用国家公布推荐的节能产品,是同类型产品中效率相对较高的。因此,项目蒸汽、电耗等总能耗比现有工艺能耗有所降低。现场运行数据显示,该指标数值年平均值为4400 kgce/t产品,符合《钒工业污染物排放标准》(GB 26452—2011)要求。综合考虑,将C15指标值设定为1.0。

3.2 生产技术特征指标解释及计算

钒产品制备过程中对环境的友好度直接由生产工艺技术及装备的先进程度决定。生产工艺技术和设备越先进,污染物的产生量就越少,对环境的危害亦越小。生产技术特征指标是体现企业实施清洁生产情况的关键性指标,结合本工艺自身特点,生产技术特征设定4个量化指标和1个半量化指标,上述5个指标前两个尾渣钒、铬含量为反向指标,指标数值越小,生产过程越先进;另外三个钒总回收率、铬总回收率、工艺与设备先进性为正向指标,即指标数值越大,生产过程越先进、清洁程度越高。

1) C21 (尾渣钒含量)

钒转化率经常被作为评价反应的重要指标,液相氧化反应转化率是指钒铁尖晶石在亚熔盐介质中氧化后进入液相的百分比,计算公式见式(3):

(3)

(3)

式中:η为液相氧化反应转化率,%;mv为钒渣质量,t;wv为钒渣含钒量,%;ms为提钒尾渣质量,t;ws为提钒尾渣含钒量,%。

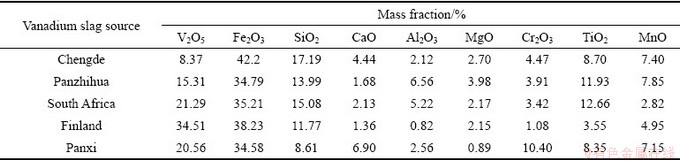

表1所列为作者所测定的全球几种典型钒渣成分。全球钒渣因产地、成因不同,钒含量差别较大,根据式(1)所示,使用液相氧化反应转化率来对工艺进行评价不可避免的缺陷是因初始钒含量不同导致反应转化率差别较大。因此,本文使用行业内更为通用的尾渣含钒量来对工艺进行评价较为客观。

表1 世界常见钒渣化学成分

Table 1 Chemical composition of common vanadium slag in world

钒渣亚熔盐法钒铬共提清洁生产工艺5万t工程该指标<1%,而钠化焙烧工艺该指标约为1.5%,按照现场运行钒渣成分计算,钒转化率比现有钠化焙烧工艺提高10%。

综合考虑,将C21指标值设定为1.0。

2) C22 (尾渣铬含量)

与尾渣钒含量类似,以尾渣铬含量来表征钒渣中伴生铬铁尖晶石的反应转化。钒渣亚熔盐法钒铬共提清洁生产工艺5万t工程该指标<1%,而钠化焙烧工艺基本不能提铬,按照现场运行钒渣成分计算,钒转化率比现有钠化焙烧工艺提高80%,铬的转化提取优势明显。但由于目前钒行业其他针对铬资源回收的工艺尚未进入示范工程阶段,无可对比指标,综合考虑,将C22指标值设为0.994。

3) C23 (钒总回收率)

钒总回收率是指在整个生产过程中,经过亚熔盐液相氧化-钒酸钠结晶-梯级阳离子置换所得五氧化二钒产品中钒元素占初始钒渣中钒元素的质量分数。钒的总回收率为87.10%,远高于行业先进水平80%,在钒的高效回收方面具有无可比拟的优势,综合考虑,将C23指标值设定为1.0。

4) C24 (铬总回收率)

铬总回收率是指在整个生产过程中,经过亚熔盐反应-钒分离-铬酸钠结晶所得铬酸钠产品中铬元素占初始钒渣中铬元素的质量分数。工艺中铬的总回收率为87.29%。由于目前行业尚未建立其它针对铬资源回收的示范工程,无可对比指标,综合考虑,将C24指标值设为0.994。

5) C25 (工艺与设备先进性)

该指标为定性指标或半定量指标,主要将所采用生产工艺及设备的节能性、自动化程度、安全性、生产效率等方面与国内外先进水平进行对比。若所采用工艺和设备达到国际先进水平,则分值设定为1.0,若达到国内先进水平,则分值设定为0.8,若采用传统设备和工艺,则分值设定为0.6,若采用淘汰设备和工艺,则分值设定为0.2。

该项目已完成科技成果评价,经干勇院士、邱定蕃院士、黄小卫院士、韩布兴院士等领域、行业专家组成的专家组评价为“国际领先水平”。本项目在设备选型过程充分考虑设备先进性,所采用的的主要设备如浆液氧化反应器、闪蒸槽、立式压滤机、三效蒸发系统等均为国内先进水平。

综合考虑,设定C25指标数值为0.8。

3.3 污染物指标解释及计算

污染物指标用于反映生产过程中污染物的产生、排放和治理情况。结合工艺自身特点选定6个量化指标用于考察工艺流程中污染物排放情况。所选定的6个指标均为逆向指标,其中前3个废渣、废水、废气为排放量类指标,后3个SO2、颗粒物、六价铬为排放浓度类指标。

1) C31 (单位产品废渣排放量)

该指标是指每生产1 t合格钒产品排放的固体废渣总量。亚熔盐工艺中,脱硅渣、碳酸钙渣返回至流程,与提钒尾渣合并成一股渣排放,该渣含铁较高,可返回河钢承钢炼铁系统作为烧结配料使用。因此整个工艺流程并无实质性外排废渣产生,可将C31指标数值设定为1.0。

2) C32 (单位产品废水排放量)

该指标是指每生产1 t合格钒产品排放的废水总量。得益于介质内循环设计,所生产废水返回系统作为工艺补充水,在钒渣钒铬共提整体工艺流程中并无任何废水排放出口,仅在提钒尾渣、偏钒酸铵及铬酸钠等固体滤饼中会夹带少量液体。上述固体渣或产物经进一步压滤或干燥操作后,所夹带液体可直接返回混料搅拌槽循环利用,实现了整个工艺废水零外排放,由此可将C32指标数值设为1.0。

3) C33 (单位产品废气排放量)

该指标是指每生产1 t合格钒产品排放的废气总量。本工程产生的尾气为含碱(微量)蒸汽及剩余氧气/空气的混合物,进入尾气洗涤塔(高30 m)经净化处理后达标排放。另外,原料准备工段设收尘系统,对料仓、料仓出料口、定量螺旋给料等产尘点进行收尘。本工程尾气经处理后达标排放对周边空气环境质量影响不大。根据《项目竣工环境保护验收检测报告》,废气的排放量符合《钒工业污染物排放标准》(GB 26452—2011),其中氮氧化物排放浓度符合《工业炉窑大气污染物排放标准》(DB 13/1640—2012)。因此C33指标数值可设定为1.0。

4) C34 (SO2排放口浓度)

该指标是指钒渣亚熔盐法钒铬共提工艺5万t示范工程涉及的有组织排放、无组织排放SO2排放口浓度。根据《项目竣工环境保护验收检测报告》,废气中二氧化硫排放浓度符合《钒工业污染物排放标准》(GB 26452—2011),因此C34指标数值可设定为1.0。

5) C35 (颗粒物排放口浓度)

该指标是指钒渣亚熔盐法钒铬共提工艺5万t示范工程涉及的有组织排放、无组织排放颗粒物排放口浓度。根据《项目竣工环境保护验收检测报告》,废气中颗粒物排放浓度符合《钒工业污染物排放标准》(GB 26452—2011),有组织排放颗粒物主要在钒渣球磨阶段产生,检测结果为44 mg/m3;无组织排放颗粒物检测结果为0.309 mg/m3,颗粒物上风向与下风向差值为0.009 mg/m3,均达到环保要求,因此可将C35指标数值设定为1.0。

6) C36 (六价铬排放量)

该指标每生产1 t合格钒产品排放废水中六价铬的总量。由于在整个工艺流程中无任何废水排放出口,即使提钒尾渣夹带的液体中含有少量六价铬,经洗涤后,洗涤水作为反应原料进行配料,保证无任何六价铬排放,因此可将C36指标数值设定为1.0。

3.4 资源综合利用指标解释及计算

该指标反映生产过程中对废弃物的回收、再利用和综合处理情况,该类指标共4个,均为正向指标,指标数值越高,表明企业资源综合利用率越高,清洁生产水平越高。

1) C41 (工业用水重复利用率)

工业用水重复利用率是指重复利用水量占生产过程中总用水量的百分比。按公式(4)计算:

(4)

(4)

式中:R为水的重复利用率,%;Vr为重复利用水量(包括循环用水量和串联使用水量),m3;Vt为生产过程中总用水量,m3。

本工艺通过介质内循环设计,无任何生产废水排放,工业用水重复利用率为100%,由此可设定C41指标值为1.0。

2) C42 (固体废渣综合利用率)

固体废渣综合利用率是指企业综合利用固体废渣量占企业生产过程中固体废渣产生量的质量分数。在本工艺中,生产所得富铁反应渣直接作为配料进行炼铁,实现整个工艺中废渣零排放,固体废渣综合利用率为100%,由此可设定C42指标值为1.0。

3) C43 (氨气综合利用率)

钒酸钙铵化阶段和偏钒酸铵煅烧阶段会有氨气释放,对所释放氨气都进行了稀硫酸氨吸收,可返回至钒钛磁铁矿利用大体系循环使用,原则上系统中没有无序氨气的排放。目前氨气综合利用率为98%,由此可设定C43指标值为0.98。

4) C44 (余热综合利用)

余热综合利用为定性指标,用于考核生产企业是否通过采用余热回收装置来实现余热回收利用,以降低生产过程中对能量的需求。本工艺中通过采用介质内循环形式来实现热物流携带热量的回收利用,大幅降低了工艺整体能量需求。由此将C44指标数值设定为1.0。

3.5 产品特征指标解释及计算

由于本工艺中以五氧化二钒和铬酸钠为最终产品形态,由此将产品特征指标分解为C51和C52两个,并按照其摩尔比取加权平均。

1) C51 (五氧化二钒产品等级)

该指标是指所生产五氧化二钒产品中V2O5的纯度。钒渣亚熔盐法钒铬共提工艺所生产五氧化二钒纯度可达99.5%以上,满足YB/T 5304—2011标准要求。将C51指标数值设定为1.0。

2) C52 (铬酸钠产品等级)

该指标是指铬酸钠产品中铬酸钠的质量分数,所得铬酸钠纯度可达98%以上,满足HG/T 4312—2012标准要求。但因所得铬酸钠产品需经精制后方可达标,综合考虑,将C52指标数值设定为0.8。

3.6 环境管理指标解释及计算

1) C61 (环境影响评价制度执行情况)

5万t钒渣亚熔盐法钒铬共提清洁生产示范工程编制了相应的环评报告,并获得环保部门的审批批文,竣工验收后进行了相应环保验收,环境影响评价制度执行情况良好。综合考虑,将C61指标值设为0.9。

2) C62 (环保“三同时”执行情况)

环保“三同时”指的是我国《环境保护法》第26条规定:建设项目中防治污染的措施,必须与主体工程同时设计、同时施工、同时投产使用。项目执行过程严格执行环保“三同时”。将C62指标值设为1.0。

3) C63 (污染物排放总量执行情况)

目前,钒行业污染物排放执行《钒工业污染物排放标准》(GB 26452—2011),本工艺不产生废水,蒸发出的浓碱液循环用于浸出,蒸发出的冷凝水循环用于洗涤尾渣,所以废水排放为0。废气排放也都相应进行了处理。废水、废气污染物排放总量符合《钒工业污染物排放标准》(GB 26452—2011)。将C63指标值设为1.0。

4) C64 (清洁生产考核制度执行情况)

企业已建立完备的清洁生产审核制度,于2010~2019年完成了各工序四轮清洁生产审核工作,并顺利通过验收。由清洁生产办公室负责清洁生产活动的日常管理工作,组织协调并监督审核提出的清洁生产方案,定期对员工进行清洁生产的教育和培训,负责清洁生产审核的实施。将C64指标值设为1.0。

5) C65 (建立实施安全生产责任制度)

河钢承钢认真贯彻“安全第一、预防为主、综合治理”的方针,牢固树立科学发展、安全发展的理念,以深化安全生产标准化建设为目的,以争创安全标准化作业区为载体,以作业区标准化100%达标为目标,认真落实作业区安全生产责任制,确保各项安全生产责任落到实处,推动企业安全生产。将C65指标值设为1.0。

4 权重值及基准值确定

钒渣提钒行业迄今为止并无统一的清洁生产评价指标体系,尽管针对焙烧法钒渣提钒过程清洁生产评价体系的建立已有相关报道,然而不同评价体系不尽相同,各有侧重,如在刘颖等建立的指标体系中,环境管理指标仅占据不足0.06的权重值,而在刘思邑等建立的评价指标体系中环境管理指标总权重值高达0.116。而对于湿法处理钒渣过程至今尚无任何相关报道。为此,本文在对现有钒渣提钒清洁生产指标评价体系进行对比的基础上,对多种评价指标体系进行规整,结合本工艺自身特点,剔除焙烧法特有指标,对其他相关指标进行修正和补充,并依据总权重不变的原则,将剔除和修正的指标的权重值按比例调整至其他指标中,得到图3中各指标的权重值,如表2第2列所示。同时,在综合考虑现有钒渣提钒清洁生产指标评价体系基准值基础上,结合现有亚熔盐法钒渣处理技术现场生产结果或理论计算结果等,对图3中各评价指标的基准值进行确定,如表2第3~5列所示。

5 清洁生产综合评价

清洁生产综合考核是以一个生产年度为周期,对各定量、定性指标的实施情况进行计算,以得到评价指标的总分,进而判定工艺技术清洁生产等级。

5.1 定量指标考核方法

在图3所示的所有27个指标中,共包含20个定量指标,其中含有7个正向指标(生产技术特征指标、资源综合利用指标及产品特征指标)和13个逆向指标(资源能源消耗指标和污染物指标)。

对于正向指标i,其分值计算公式为

(5)

(5)

对于逆向指标,其分值计算公式为

(6)

(6)

采用上述方法对表1中所有指标得分值进行计算,特别地,在式(5)及(6)中,当Si >1时,将Si 赋值为1.000,结果列于表1第7列。

由此利用式7可计算得定量指标考核总分为91.32。

(7)

(7)

式中:P1为定量指标考核总分(百分制);n为参与考核的二级定量指标总数;Si和Wi分别为指标i的分值和权重值,如表1所列。

表2 钒渣亚熔盐法钒铬共提工艺清洁生产评价指标体系各指标的权重及基准值

Table 2 Weight and reference value of evaluation index system of SMS V and Cr co-extraction process

5.2 定性指标考核方法

在图3所示的27个指标中,共包含7个定性指标。其分值计算情况与定量指标计算方法同样,结果列于表1中第7列。由此可采用式8计算得定性指标考核总分为6.7分。

(8)

(8)

式中:P2为定性指标考核总分(百分制),其他参数意义同式(7)。

5.3 工艺清洁生产整体评价

由于在钒渣亚熔盐法钒铬共提工艺评价指标体系中同时包含定性指标和定量指标,由此其综合评价指标需同时包含二者,计算公式为

(9)

(9)

由以上计算可知,定量指标及定性指标总分值依次为91.32和6.7,由此可根据式(9)计算得钒渣亚熔盐钒铬共提工艺清洁生产评价指标总和为98.02。

结合相关文献可知,当P≥90时,属于清洁生产先进水平;当75≤P<90时, 属于基本水平;当P<75时,属于落后水平。由此可看出,钒渣亚熔盐钒铬共提工艺属于清洁先进水平,在整个生产过程中无任何“三废”排放,真正实现了从源头杜绝污染物的产生。

5.4 亚熔盐法与其他工艺的对比

截止目前为止,5万t亚熔盐法钒铬共提工程为全球唯一产业化钒铬共提工程。攀钢在研的钠化焙烧钒铬共提工艺试验或技术已经完成中试,该技术以钠化焙烧为基础研发,仍需衔接后续废水处理技术。与之前报道的钒渣钠化焙烧提钒工艺清洁生产评价结果相比[26],钒渣亚熔盐法钒铬共提工艺在新鲜水消耗量、钒总回收率、工艺与设备先进性、单位产品废水及废气排放量、工业用水重复利用率等均大大优于原有钒渣钠化焙烧提钒工艺中的指标。

6 结论

构建了适用于钒渣亚熔盐法钒铬共提工艺的清洁生产评价体系,所构建体系共包含资源能源消耗、生产技术特征、污染物、资源综合利用、产品特征和环境管理等六大类指标及其下属的27个二级指标。对钒渣亚熔盐法钒铬共提工艺进行清洁生产水平分析,综合评估分析结果表明,钒渣亚熔盐法钒铬共提工艺清洁生产指数达98.02,属于清洁生产先进水平,工艺实现了介质的内循环,在整个生产过程中无任何“三废”排放。

REFERENCES

[1] 杨守志. 钒冶金[M]. 北京: 冶金工业出版社, 2010.

YANG Shou-zhi. Vanadium metallurgy[M].BeiJing: Metallurgical Industry Press, 2010.

[2] 黄道鑫. 提钒炼钢[M]. 北京: 冶金工业出版社, 2000: 10-13.

HANG Dao-xin. Mention of vanadium steel[M]. Beijing: Metallurgical Industry Press, 2000: 10-13.

[3] MOSKALYK R R, AlFANTAZI A M. Processing of vanadium: A review[J]. 2003, 16(9): 793-805.

[4] 刘国强, 徐 宁, 曾潮流, 等. 锂离子蓄电池钒系正极材料的研究进展[J]. 电源技术, 2002(2): 114-118.

LIU Guo-qiang, XU Ning, ZENG Chao-liu, et al. Development of vanadium-based compounds used as cathode for lithium ion battery[J]. Chinese Journal of Power Fources, 2002(2): 114-118.

[5] 郑明贵, 赖亮光. 中国铬矿需求情景分析[J]. 资源与产业, 2011, 13(4): 43-49.

ZHENG Ming-gui, LAI Liang-guang. Scenario analysis of China’s demand for chrome ore[J]. Resources & Industries, 2011, 13(4): 43-49.

[6] 杨绍利. 钒钛材料[M]. 北京: 冶金工业出版社, 2007.

YANG Shao-li. Vanadium titanium[M]. Beijing: Metallurgical Industry Press, 2007.

[7] 孙朝晖. 钒新技术及钒产业发展前景分析[J]. 钢铁钒钛, 2012, 33(1): 1-7.

SUN Chao-hui. Analysis on new vanadium technologies and prospects of vanadium industry[J]. Iron Steel Vanadium Titanium, 2012, 33(1): 1-7.

[8] 朱明玉, 王成辉, 王登红, 等. 中国铬矿主要矿集区及其资源潜力探讨[J]. 中国地质, 2013, 40(4): 995-1006.

ZHU Ming-yu, WANG Cheng-hui, WANG Deng-hong, et al. The major chromium concentration areas in China and a discussion on their resource potential[J]. Geology in China, 2013, 40(4): 995-1006.

[9] TAYLOR P R, SHUEY S A, VIDAL E E. Extractive metallurgy of vanadium containing titaniferous magnetite ores: A review[J]. Minerals & Metallurgical Processing, 2006, 23: 80-86.

[10] 刘挥彬, 杜 浩, 刘 彪, 等. KOH亚熔盐中钒渣的溶出行为[J]. 中国有色金属学报, 2013, 23(4): 1129-1139.

LIU Hui-bin, DU Hao, LIU Biao, et al. Dissolution behavior of vanadium slag in KOH sub-molten salt[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1129-1139.

[11] 陈 迪, 张 强. 我国钒产业概况及其环境问题[J]. 冶金丛刊, 2009(5): 39-42.

CHEN Di, ZHANG Qiang. The profiles of vanadium industry in China and its environmental problems[J]. Metallurgical Collections, 2009(5): 39-42.

[12] 陈 华, 郭永刚, 齐莉君. 钒厂废水资源化利用研究[J]. 北方钒钛, 2012(4): 20-24.

CHEN Hua, GUO Yong-gang, QI Li-jun. Study on resource utilization of waste water from vanadium plant[J]. Beifang Fan Tai, 2012(4): 20-24.

[13] 王新东, 李兰杰, 杜 浩, 等. 亚熔盐高效提钒铬清洁生产技术产业化应用[J]. 过程工程学报, 2020, 20(6): 667-677

WANG Xin-dong, LI Lan-jie, DU Hao, et al. Industrialized application of high efficient extraction of vanadium and chromium by sub-molten salt method[J]. The Chinese Journal of Process Engineering, 2020, 20(6): 667-677.

[14] 刘龙杰. 微气泡强化亚熔盐液相氧化法基础及应用研究[D]. 北京: 中国科学院大学, 2018.

LIU Long-jie. Fundamental and applied study of fine bubble intensified liquid phase oxidation technology in sub-molten salt medium[D]. Beijing: University of Chinese Academy of Sciences, 2018.

[15] 王少娜, 王亚茹, 杜 浩, 等. 活性炭强化氧化亚熔盐介质中钒渣分解机理[J]. 中国有色金属学报, 2017, 27(8): 1729-1737.

WANG Shao-na, WANG Ya-ru, DU Hao, et al. Decomposition mechanism of vanadium slag by sub-molten salt medium with active carbon catalytic oxidation[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(8): 1729-1737.

[16] LIU Long-jie, DU Hao, ZHANG Yang, ZHENG Shi-li, ZHANG Yi. Leaching of chromite ore in concentrated KOH by catalytic oxidation using CuO as catalyst[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(4): 891-900.

[17] 李兰杰, 高明磊, 陈东辉, 等. 世界首条亚熔盐法清洁提钒生产线建设及初步运行情况分析[J]. 北方钒钛, 2017, 126(3): 5-9.

LI Lan-jie, GAO Ming-lei, CHEN Dong-hui, et al. The world’s first sub-molten salt method extract Vanadium Production line construction and preliminary operation analysis[J].Northern Vanadium and Titanium, 2017, 126(3): 5-9.

[18] 刘 颖. 钒行业清洁生产评价指标体系的构建及实例研究[D]. 西安: 西北大学, 2012.

LIU Ying. The construction and a case study on cleaner production assessment index system of vanadium industry[D]. Xi’an: Northwest University, 2012.

[19] 刘 颖, 王伯铎, 陈 雷, 等. 陕西省钒行业清洁生产水平分析[J]. 环境科学与管理, 2013, 38(1): 171-176.

LIU Ying, WANG Bo-duo, CHEN Lei, et al. Analysis on cleaner production level of vanadium industry in shaanxi province[J]. Environmental Science and Management, 2013, 38(1): 171-176.

[20] 杨 林, 林金辉, 王 雷, 等. 含钒岩石清洁提钒工艺评价[J]. 金属矿山, 2010(11): 130-135.

YANG Lin, LIN Jin-hui, WANG Lei, et al. Evaluation of V recovering process from vanadium containing rock[J]. Metal Mine, 2010(11): 130-135.

[21] 张青梅, 尤翔宇, 刘 湛. 湖南省石煤提钒冶炼行业清洁生产评价指标体系[J]. 湖南有色金属, 2014, 30(5): 67-70.

ZHANG Qing-mei, YOU Xiang-yu, LIU Zhan. Study on recovering copper from a copper mines slime and its industrial implementation[J]. Hunan Nonferrous Metals, 2014, 30(5): 67-70.

[22] 李 佳, 张一敏, 刘 涛. 石煤提钒行业清洁生产评价方法研究[J]. 环境科学与技术, 2013, 36(8): 200-205.

LI Jia, ZHANG Yi-min, LIU Tao. Assessment method for cleaner production of vanadium extraction from stone coal[J]. Environmental Science & Technology, 2013, 36(8): 200-205.

[23] 郑桂花. 石煤提钒工艺清洁生产评价的研究[D]. 武汉: 武汉理工大学, 2009.

ZHENG Gui-hua. Study On cleaner production assessment on process of vanadium extraction form stone coal[D]. Wuhan: Wuhan University of Technology, 2009.

[24] 王少娜, 杜 浩, 郑诗礼, 等. 钒酸钠钙化-碳化铵沉法清洁制备钒氧化物新工艺[J]. 化工学报, 2017, 68(7): 2781-2789.

WANG Shao-na, DU Hao, ZHENG Shi-li, et al. New technology from sodium vanadate to vanadium oxide by calcification and carbonization-ammonium process[J]. CIESC Journal, 2017, 68(7): 2781-2789.

[25] YAN Hong, DU Hao, WANG Shao-na, et al. Solubility data in the ternary NH4HCO3-NH4VO3-H2O and (NH4)2CO3-NH4VO3-H2O systems at (40 and 70) ℃[J]. Journal of Chemical & Engineering Data, 2016, 61(7): 2346-2352.

[26] 刘思邑. 钒渣资源综合利用行业清洁生产指标体系建立[D]. 成都: 西南交通大学, 2013.

LIU Si-yi. Building a cleaner production index system on the comprehensive utilization of vanadium slag resources industry[D]. Chengdu: Southwest Jiao tong University, 2013.

Assessment for cleaner production of vanadium and chromium co-extraction from vanadium slag by sub-molten salt method

WANG Shao-na1, Lü Ye-qing1, LIU Biao1, DU Hao1, 2, WANG Hai-xu3, WANG Xin-dong4, LI Lan-jie3, ZHANG Yi1

(1. CAS Key Laboratory of Green Process and Engineering, Institute of Process Engineering, Chinese Academy of Sciences, Beijing 100190, China;

2. International College, University of Chinese Academy of Sciences, Beijing 100049, China;

3. Chengde Iron and Steel Group Co., Ltd., HBIS Group Co., Ltd., Chengde 067102, China;

4. HBIS Group Co., Ltd., Shijiazhuang 050023, China)

Abstract: The traditional sodium roasting process has a number of disadvantages including low vanadium and chromium extraction rate, generation of waste water and toxic residue. Recently, a new vanadium production process based on the sub-molten salt (SMS) technology was developed by IPE, CAS and HBIS Group Co., Ltd. And a 50 kt demonstration plant was built in 2017. After two years operation, many reliable industrial data were obtained. In this paper, the cleaner production level of new technology was analyzed by selecting six first-class indexes, i.e. resource and energy utilization, production technology, pollutant discharge, comprehensive utilization of resources, product characteristics, environmental management and 27 second-class indexes under them. The analysis results show that the cleaner production level of new process is 98.02, which means that this technology belongs to high level of cleaner production. The new technology could realize efficient extraction of both vanadium and chromium under mild reaction condition, providing technical supports for the effective utilization of the 3.6 billion tons of high-chromium containing vanadium titano-magnetite ores in China and can be the green production leader of vanadium chemical industry.

Key words: sub-molten salt; vanadium and chromium co-extration; cleaner production; vanadium-titanium magnetite

Foundation item: Projects(19044011Z, 20373808D, 206Z4401G, B2019318015) supported by S&T Program of Hebei, China

Received date: 2020-03-27; Accepted date: 2020-12-04

Corresponding author: DU Hao; Tel: +86-10-82544857; E-mail: hdu@ipe.ac.cn

(编辑 王 超)

基金项目:河北省省级科技计划资助项目(19044011Z,20373808D,206Z4401G,B2019318015)

收稿日期:2020-03-27;修订日期:2020-12-04

通信作者:杜 浩,研究员,博士;电话:010-82544857;E-mail:hdu@ipe.ac.cn