文章编号:1004-0609(2015)04-0883-07

复合碳变质剂对AZ91D镁合金的晶粒细化作用

卢敏敏,李 克,吴尚敏,周耐根,曾效舒

(南昌大学 机电工程学院,南昌 330031)

摘 要:采用OM、SEM、EDS、XRD等研究复合变质剂组成对AZ91D镁合金铸态和固溶态组织的影响,并分析晶粒细化作用机理。结果表明,适当加入三元复合碳变质剂可使AZ91D镁合金的晶粒尺寸显著减小,在相同的实验条件下,当3种碳化物组分MgCO3、SiC、C2Cl6的质量比为3:1:1时,能够获得最好的细化效果。一方面,MgCO3、C2Cl6在熔体中分解出的C与Al发生原位反应,生成的大量Al4C3颗粒均匀分散到熔体中,直接成为α-Mg的形核核心;另一方面,在α-Mg晶体生长过程中部分细小的Al4C3颗粒与SiC颗粒一起被固液界面推移至晶界,起到阻碍晶体长大作用,使α-Mg晶粒得到有效细化。

关键词:AZ91D镁合金;复合变质剂;Al4C3;晶粒细化

中图分类号:TG146.2 文献标志码:A

Effect of complex carbon inoculants on grain refinement of AZ91D magnesium alloys

LU Min-min, LI Ke, WU Shang-min, ZHOU Nai-gen, ZENG Xiao-shu

(School of Mechanical and Electrical Engineering, Nanchang University, Nanchang 330031, China)

Abstract: The effects of complex inoculants on the as-cast and solid-solution state microstructure of AZ91D magnesium alloy and the grain refinement mechanism were investigated by OM, SEM, EDS and XRD. The results show that the grain size of AZ91D magnesium alloy decreases effectively after the complex carbon inoculants are added. The best refinement result can be achieved when the mass ratio of MgCO3, C2Cl6 and SiC is set as 3:1:1. On one hand, the amount of Al4C3 particles induced by carbon-containing compound including MgCO3 and C2Cl6 can directly serve as the heterogeneous nucleus of primary α-Mg phase. On the other hand, some of the fine Al4C3 and SiC particles are pushed by solid-liquid interface between α-Mg phases and the melt, and distribute along the crystal boundary, so as to impede the growth of α-Mg grains, and the α-Mg grains are greatly refined finally.

Key words: AZ91D magnesium alloy; complex inoculants; Al4C3; grain refinement

镁合金被誉为21世纪的绿色工程材料,由于具有质轻、比强度、比刚度高及机械加工性能好等优点,使得镁合金被广泛应用于航天、汽车、电子领域[1-2]。但镁合金的密排六方结构决定了其塑性变形能力较差,以及自身的强度低、脆性大、耐腐蚀性差等缺点,限制了镁合金材料在工业中的进一步应用[3]。通过熔体处理提高镁合金的性能对其发展具有重大意义,其中晶粒细化是一种提高镁合金综合性能和改善镁合金成形性的有效手段[4]。目前,被广泛研究的晶粒细化技术主要有熔体过热法、熔剂处理法、添加合金元素法和熔体搅拌法[5]。已有研究表明,单独添加SiC[6-7]、MgCO3[8-9]、Al4C3[10-11]、C2Cl6[11]等含碳化合物均有一定的细化作用。姜向东等[6]研究发现,加入Mg-SiC混合粉末可使AZ91D镁合金组织得到明显细化,但SiC与Mg粉的混合物在熔体中不易分散均匀。LU等[10]研究表明,外加和原位反应生成的Al4C3粒子能够稳定并显著地细化Mg-3Al合金的晶粒。高声远等[9]研究发现,向AZ31镁合金中少量多次添加MgCO3的细化效果明显优于单次添加MgCO3的细化效果,表明控制MgCO3的分解反应与生成Al4C3的原位反应速度是提高细化效率的关键。针对Mg-Al合金的熔体实验结果表明,C2Cl6既能起到良好的晶粒细化效果,又具有精炼除气作用,因而能消除镁合金铸件的缺陷和提高其综合力学性能[11]。WALLACE等[12]也较系统地研究了C2Cl6、TiC、SiC、Al4C3作为晶粒细化剂对AZ91和AM50组织性能的影响,认为C2Cl6对镁合金具有更好的细化效果。

本文作者在前期研究[8]的基础上,综合利用MgCO3、SiC、C2Cl6 3种含碳化合物各自的优势,按不同的配比制成复合碳变质剂,研究复合碳变质剂对AZ91D镁合金晶粒的影响及作用机理。

1 实验

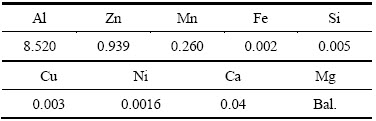

实验中熔炼合金所用坩埚为不锈钢材质,并用碳化硼耐高温涂料对坩埚内表面进行喷涂,防止熔炼时Fe元素进入熔体而影响晶粒的细化效果。实验合金原材料为AZ91D镁合金,其中各元素的含量如表1所列。

表1 AZ91D镁合金各元素含量

Table 1 Chemical composition of AZ91D Mg alloy (mass fraction, %)

配制碳变质剂的原料为:分析纯MgCO3、分析纯C2Cl6和平均粒径为1 μm的SiC颗粒。将3种含碳化合物按不同的质量比混合和球磨制成多组变质剂。

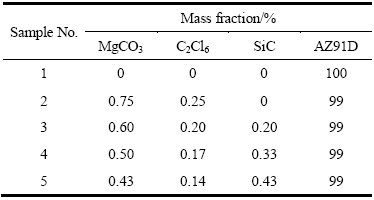

称取约200 g AZ91D镁合金锭,用丙酮清洗干净。按镁合金质量的1%称量复合变质剂,干燥后用铝箔包裹压实。将干燥好的镁合金放入井式电阻炉中进行熔炼,为防止镁合金氧化燃烧,采用干燥的CO2和SF6混合气体作为保护气氛。待合金熔化并升温至720 ℃,用钟罩把复合变质剂压入到熔体中,并缓慢移动钟罩使变质剂能够充分均匀反应。反应完成后保温10 min,然后降温至720 ℃,浇注到预热温度约为200 ℃的雷诺标准高尔夫T型铸模中,制得直径为5 cm的金属铸锭,然后在铸锭底部靠上5 cm处取样分析。表2所列为添加不同含量复合变质剂的AZ91D镁合金的成分。

表2 添加不同含量复合变质剂的AZ91D镁合金的成分

Table 2 Chemical composition of AZ91D Mg alloys with different compound inoculants

铸态试样经砂纸打磨、抛光后,用4%硝酸(体积分数)和酒精的混合溶液进行腐蚀处理,为了能够清晰看到合金的晶界,对试样进行了415 ℃保温8 h的固溶处理。固溶试样经打磨、抛光后用苦味酸腐蚀,在光学显微镜下观察显微组织。按GB-T6394用截线法测定α-Mg的晶粒度,采用英国Bede公司生产的XRD DISYSTEM型X射线衍射仪进行物相鉴别,采用日本电子株式会社生产的场发射扫描电子显微镜(JSM-6701F型)进行合金显微组织观察,并进行EDS能谱分析。在HV-1000A型显微硬度仪上测量合金硬度,载荷为0.98 N,保荷时间为15 s,每个试样选取5个分散的点进行测试,得到试样的平均硬度。

2 结果和分析

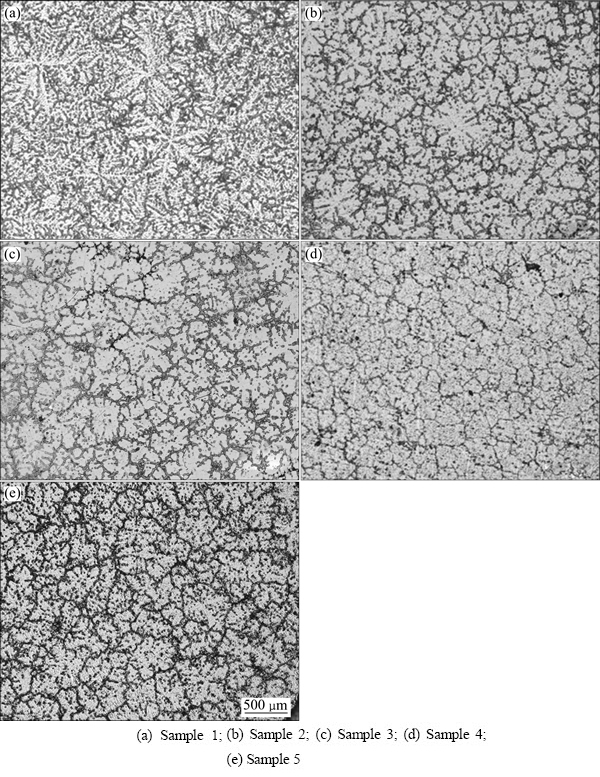

2.1 铸态显微组织

图1所示为对表2中试样1~5进行变质处理得到的AZ91D镁合金试样的铸态显微组织。从图1中可以看出,变质前后的铸态组织主要由α-Mg基体和β-Mg17Al12相构成,组织均匀而致密。添加了含碳变质剂后,显微组织发生了很明显的变化。其中,未添加变质剂的试样1显微组织中的α-Mg呈粗大的树枝状分布,同时可以看到较多的二次枝晶。而添加了变质剂后,α-Mg呈细小的蔷薇状分布,β-Mg17Al12相在α-Mg基体中的分布更加均匀。未添加SiC的试样2中仍有少量二次枝晶,试样3~5的复合变质剂中添加了SiC,其铸态组织中的α-Mg晶粒得到进一步细化,二次枝晶基本消失。然而随着SiC含量的增加,未明显提高晶粒细化效果。姜向东等[6]和CHEN等[7]研究发现,向AZ91D镁合金中添加质量分数为0.2%的SiC时细化效果最好,增加SiC的含量对晶粒的细化基本不起作用。本实验结果与其研究结果相似。

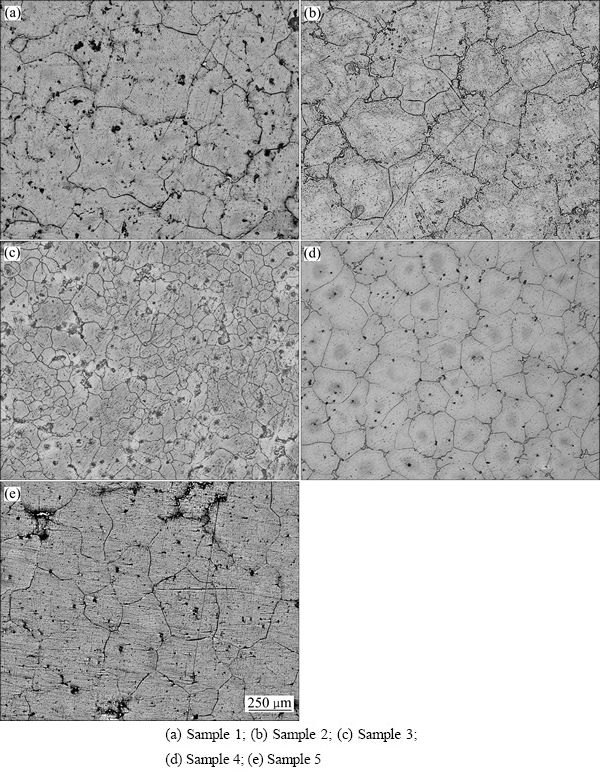

2.2 固溶态试样显微组织

由图1可知,镁合金的铸态组织中α-Mg晶粒形状复杂,晶界存在许多β-Mg17Al12相,致使α-Mg晶粒轮廓不清晰,难以准确测量其尺寸,因此对铸态试样进行固溶处理,使大部分β-Mg17Al12相固溶到基体中,以便获得清晰的晶界。图2所示为固溶态试样显微组织。试样1由于未添加变质剂,晶粒比较粗大。添加了成分为MgCO3和C2Cl6的复合变质剂的试样2晶粒较未加变质剂的试样晶粒要细小。当复合变质剂中加入了SiC时,对合金的细化效果更加明显,同时可以看出晶粒的细化也更加均匀。而随着SiC的含量的增加,晶粒有长大的趋势。但晶粒仍比未添加SiC的试样晶粒细化效果好。其原因是在相同温度下MgCO3、C2Cl6比SiC更容易受热分解产生C元素,所以MgCO3和C2Cl6会先发生反应。MgCO3和C2Cl6分解释放的气体能够使SiC均匀分布,因此可以看到晶粒更加细小而均匀。当加入的SiC过多时,部分发生团聚,不能充分发生反应,而且密度较大的SiC颗粒在镁熔体中会逐渐下沉,团聚后更易下沉,因此细化效果有所降低。

图1 不同AZ91D镁合金试样的铸态显微组织

Fig. 1 As-cast microstructures of different AZ91D Mg alloy samples

图2 不同AZ91D镁合金试样的固溶态显微组织

Fig. 2 Solid-solution microstructures of different AZ91D Mg alloy samples

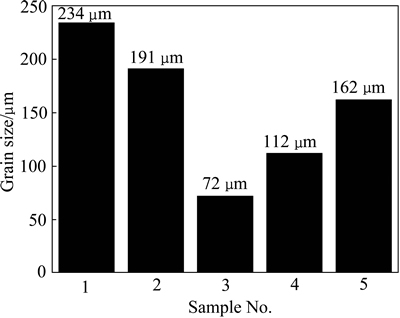

图3所示为采用直线截线法测量得到的固溶态试样晶粒尺寸。由图3可知未添加变质剂的AZ91D基体晶粒尺寸为234 μm,添加了变质剂的试样晶粒都得到了细化。其中添加不含SiC的复合变质剂,晶粒尺寸为191 μm。复合变质剂中加入SiC后,晶粒尺寸进一步减小到72 μm。但随着SiC的含量增加,晶粒尺寸反而有所增加,分别为112和162 μm。由此可知试样3的细化效果是最好的。

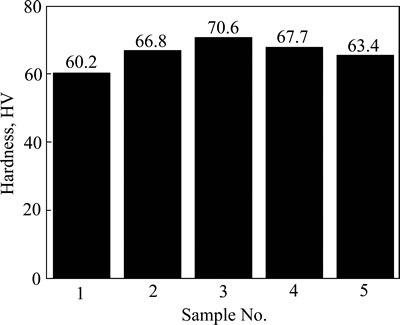

图4所示为不同AZ91D镁合金试样的维氏硬度。由图4可知,未添加变质剂的合金硬度为60.2 HV,经变质处理后合金的硬度都有所提高,试样3硬度达到了70.6 HV。对比试样2和3得出,SiC的加入使合金的硬度进一步提高,但硬度并不会随着SiC含量的增加而提高,反而会呈下降趋势。综上所述,含SiC三元复合变质剂的试样细化效果优于不含SiC的二元复合变质剂试样细化效果,当MgCO3、C2Cl6和SiC质量比为3:1:1时,对AZ91D镁合金的细化效果最好。

图3 不同AZ91D镁合金试样的晶粒尺寸

Fig. 3 Grain sizes of different AZ91D Mg alloy samples

图4 不同AZ91D镁合金试样的维氏硬度

Fig. 4 Victor hardnesses of different AZ91D Mg alloy samples

2.3 细化机制

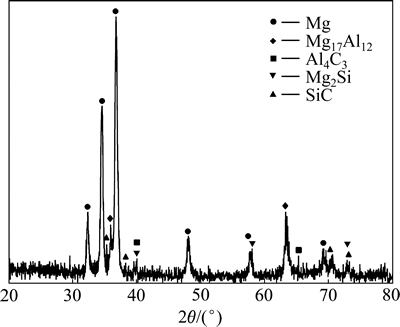

图5所示为试样3的XRD谱,检测发现AZ91D镁合金熔体主要由初生相α-Mg、β-Mg17Al12、Al4C3、Mg2Si和SiC组成。

图5 AZ91D镁合金试样3的XRD结果

Fig. 5 XRD pattern of AZ91D Mg alloys sample 3

将复合变质剂加入到熔体中,变质剂被熔体包裹并升温。由于C2Cl6的沸点为186 ℃,所以首先升华至气态将变质剂分散同时参与反应。C2Cl6在Mg-Al合金熔体中的反应方程式如下所示[11]:

C2Cl6=2C+3Cl2↑ (1)

3C+4Al=Al4C3 (2)

Cl2+Mg=MgCl2 (3)

式(1)中C2Cl6分解出游离的C原子和Cl2,游离的C原子和Al原子按照式(2)反应生成的Al4C3是在熔融镁合金中能够存在的难熔质点,其晶体结构为密排六方,晶格常数与α-Mg接近,在镁合金凝固过程中成为α-Mg的有效形核核心[11]。式(1)产生的Cl2不仅可以去除合金液中的H2,还能跟Mg反应生成MgCl2,MgCl2能覆盖在镁合金熔体表面起到精炼除渣的作用。

根据实用无机热力学数据手册[13]可知,MgCO3在温度低于492 ℃时以固相存在。另外根据文献[14]可知,MgCO3的分解温度为420 ℃,并在熔体中发生的化学反应如下所示[15]:

MgCO3=MgO+CO2↑ (4)

CO2+2Mg=C+2MgO (5)

式(4)本身是一个放热反应,反应过程中会使局部温度升高。式(5)中缓慢反应生成的C原子,也能按式(2)进一步反应生成高熔点的Al4C3。C2Cl6和MgCO3受热分解温度不高,所以相对于高熔点的SiC优先发生反应。综上所述,在反应过程中,C2Cl6和MgCO3受热分解产生的C原子活度较高,较易与合金液中的Al原子化合形成大量弥散的Al4C3质点,可作为α-Mg的有效形核核心,促进结晶,提高形核率,进而细化镁合金晶粒。

另外,SiC颗粒在熔体中参与的化学反应如下所示[7, 15]:

3SiC+4Al=Al4C3+3Si (6)

2Si+Mg=Mg2Si (7)

SiC颗粒的相对密度大于Mg金属液的,通常静置情况下容易聚集成团并下沉。式(1)和(4)产生的气体恰好起到了搅拌作用,使SiC颗粒得到充分分散。式(6)生成的部分Al4C3颗粒会与SiC颗粒一起被固液界面推移至晶界,起到阻碍晶体长大的作用,使α-Mg晶粒得到了有效细化。

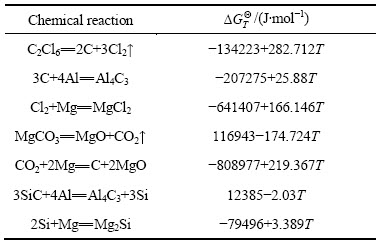

通过查找上述反应物、生成物的标准摩尔生成热和标准摩尔熵,然后计算得到反应的标准吉布斯自由能如表3所列。由表3中的计算结果可知,MgCO3和C2Cl6在分解温度时的吉布斯自由能远小于-40 kJ/mol,说明这两组反应能够自发进行,而其他反应在720~780 ℃时同样也能够进行。但要指出的是SiC和Al的反应在720~780 ℃时吉布斯自由能为正,理论上此反应是不会进行的。但本实验中得到的吉布斯自由能表达式与LU等[16]计算得到的类似,然而LU等[16]通过文献[17]补充并计算了其他参数,最后计算结果表明该反应是可以进行的。LEE等[18]的实验研究和理论计算同样表明SiC和Al可以进行上述反应。

表3 不同反应的标准吉布斯自由能

Table 3 Standard Gibbs free energy of different chemical reactions

然而,较单独添加某一种碳化物,复合变质剂在熔体中的反应更加复杂。变质剂中各碳化物的反应顺序并不是意味着先发生反应的碳化物完全反应后其他碳化物才开始参与反应。因为熔体温度较高,变质剂升温速度较快,所以很大程度上是多种碳化物同时参与反应,而先后反应的时间间隔很小,所以复合变质剂能综合利用各组分的优势,获得比单一变质剂更好的细化效果。

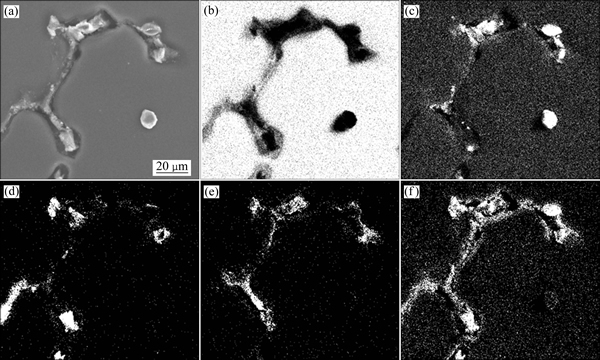

图6所示为经变质处理的AZ91D镁合金铸态组织的背散射像和元素面扫描分布电子像,由图6(b)看出Mg元素均匀分布在晶粒内,同时结合图6(c)可知以β-Mg17Al12为主的第二相分布在晶界上。观察图6(d)和(e)可以发现晶粒内部并没有看到大量的Si和C元素,说明SiC得到了充分分散;反而在晶界上分布大量的Si和C元素,说明最终大部分SiC颗粒在凝固过程中被推移至晶界,钉扎于晶界并阻碍晶粒长大。晶界是合金最后凝固的地方,由于溶质再分配,部分SiC颗粒与液相Mg发生反应生成了Mg2Si,所以在图6(b)和(d)中看到晶界的同一位置上都有Mg和Si元素。在晶界上同时分布大量的Al和C元素,也可能是因为SiC参与反应生成Al4C3。由图6(f)看出合金中还含有较多的O,一方面镁合金易于氧化生成MgO,同时MgCO3也易受热分解生成MgO,另一方面Al4C3与水接触后很容易分解并形成氧化物[10]。由上述分析可推断,晶界处分布有SiC、Mg2Si和MgO。

图6 经变质处理的AZ91D镁合金铸态组织的背散射及Mg、Al、Si、C、O元素面扫描电子像

Fig. 6 Back scatter electron image of as-cast microstructure of AZ91D alloy(a) and map scanning of elements Mg(b), Al(c), Si(d), C(e), O(f)

3 结论

1) 针对Mg-Al系合金的晶粒细化和精炼,利用含碳化合物C2Cl6、MgCO3和SiC制备的复合碳变质剂,可综合利用3种组分的优势,获得比单一变质剂更好的细化效果。

2) MgCO3和C2Cl6受热分解提供了大量游离的C,C会与熔体中的Al反应生成大量的Al4C3粒子,直接成为α-Mg的有效形核核心,大幅提高了形核率。反应产生的气体同时对熔体中细小的SiC颗粒起到了强烈搅拌作用,使之均匀分散于凝固组织中。

3) 不易反应的SiC颗粒以及α-Mg晶体生长过程中部分细小的Al4C3颗粒则在凝固过程中被推移并钉扎在固液界面上,阻碍α-Mg晶粒的长大。C2Cl6还能起到除气除渣的作用,提高镁合金铸件的综合性能。当MgCO3、C2Cl6、SiC质量比为3:1:1时,细化效果最好。

REFERENCES

[1] WANG Li-fei, HUANG Guang-sheng, LI Hong-cheng, ZHANG Hua. Influence of strain rate on microstructure and formability of AZ31B magnesium alloy sheets[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 916-922.

[2] 曾小勤, 丁文江, 应燕君, 邹建新. 镁基能源材料研究进展[J]. 中国材料进展, 2011, 30(2): 36-43.

ZENG Xiao-qin, DING Wen-jiang, YING Yan-jun, ZOU Jian-xin. Research progress of Mg-based energy materials[J]. Materials China, 2011, 30(2): 36-43.

[3] ZHU L Q, SONG G L. Improved corrosion resistance of AZ91D magnesium alloy by an aluminium-alloyed coating[J]. Surface and Coatings Technology, 2006, 200(8): 2834-2840.

[4] VINOTHA D, RAGHUKANDAN K, PILLAI U T S, PAI B C. Grain refining mechanisms in magnesium alloys: An overview[J]. Transactions of the Indian Institute of Metals, 2009, 62: 521-532.

[5] 杨明波, 潘复生, 李忠盛, 张 静. 镁合金铸态晶粒细化技术的研究进展[J]. 铸造, 2005, 54(4): 314-319.

YANG Ming-bo, PAN Fu-sheng, LI Zhong-sheng, ZHANG Jing. Research and development of the as-cast grain refinement technology of magnesium alloys[J]. Foundry, 2005, 54(4): 314-319.

[6] 姜向东, 陈体军, 马 颖, 郝 远. SiC对AZ91D镁合金晶粒细化效果的影响[J]. 特种铸造及有色合金, 2009, 29(8): 763-766.

JIANG Xiang-dong, CHEN Ti-jun, MA Ying, HAO Yuan. Effects of SiC on the grain refinement in AZ91D magnesium alloy[J]. Special Casting & Nonferrous Alloys, 2009, 29(8): 763-766.

[7] CHEN T J, JIANG X D, MA Y, LI Y D. Grain refinement of AZ91D magnesium alloy by SiC[J]. Journal of Alloys and Compounds, 2010, 496: 218-225.

[8] LI Ke, WANG fei, WANG Qian, ZHOU Nai-geng. Study on grain refining mechanism of carbon inoculation on Mg-Al alloy[J]. Journal of Shanghai Jiaotong University, 2012, 17(3): 301-305.

[9] 高声远, 张志强, 乐启炽, 贾 征, 崔建忠. MgCO3在AZ31镁合金中的细化效果及机理[J]. 材料科学与工艺, 2011, 19(3): 49-52.

GAO Sheng-yuan, ZHANG Zhi-qiang, LE Qi-chi, JIA Zheng, CUI Jian-zhong. Refining effect/mechanism of MgCO3 in AZ31 magnesium alloy[J]. Materials Science and Technology, 2011, 19(3): 49-52.

[10] LU L, DAHLE A K, STJOHN D H. Grain refinement efficiency and mechanism of aluminium carbide in Mg-Al alloys[J]. Scripta Materialia, 2005, 53: 517-522.

[11] KIM Y M, YIM C D, YOU B S. Grain refining mechanism in Mg-Al base alloys with carbon addition[J]. Scripta Materialia, 2007, 57: 691-694.

[12] WALLACE J F, SCHWAM D, ZHU Y. The influence of potential grain refiner on magnesium foundry alloys[J]. AFS Transactions, 2003, 111: 1061-1075.

[13] 叶大伦, 胡建华. 实用无机热力学数据手册[M]. 北京: 冶金工业出版社, 2002.

YE Da-lun, HU Jian-hua. Practical inorganic thermodynamic data manual[M]. Beijing: Metallurgical Industry Press, 2002.

[14] PEI H B, XU B Q, LI Y F. Study on the thermal decomposition behavior of magnetite in carbothermic reduction extraction process for magnesium in vacuum[J]. Light Metals, 2010: 46-50.

[15] EASTON M A, SCHIFFL A, YAO J Y, KAUFMAN N H. Grain refinement of Mg-Al(-Mn) alloys by SiC additions[J]. Scripta Materialia, 2006(55): 379-382.

[16] LU L, DAHLE A K, STJOHN D H. Heterogeneous nucleation of Mg-Al alloys[J]. Scripta Materialia, 2006, 54: 2197-2201.

[17] GASKELL D R. Introduction to the thermodynamics of materials[M]. Washington, DC: Taylor and Francis, 1995.

[18] LEE J C, BYUN J Y, PARK S B, LEE H I. Prediction of Si contents to suppers the formation of Al4C3 in the SiCp/Al composite [J]. Acta Materialia, 1998, 46(5): 1771-1780.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51264032,51361022);教育部留学回国人员科研启动基金资助项目(第44批)

收稿日期:2014-09-01;修订日期:2015-01-05

通信作者:李 克,教授;电话:18970029945;E-mail: like.1@126.com