固相合成AZ91D镁合金的组织和性能

吉泽升1, 陈晓瑜1, 胡茂良1, S. Sumio2, 杨续跃3

(1.哈尔滨理工大学 材料科学与工程学院, 哈尔滨 150080;

2. 东京大学 生产技术研究所, 东京 153-8505;

3.日本国立电气通信大学 机械工程系, 东京 182-8585)

摘 要: 利用固相合成方法在挤压比为11∶1的条件下, 将AZ91D镁合金屑分别在573、 623、 673和723K时制备成试样, 对试样进行微观组织观察和力学性能测试。 结果表明: 在573~673K时, AZ91D镁合金的抗拉强度和延伸率随合成温度的升高而增大, 高于673K时其抗拉强度和延伸率随合成温度的升高而降低, 在合成温度为673K时, 其抗拉强度最高, 达到384.4MPa; 在热挤出过程中氧化层被均匀弥散在组织中且发生动态再结晶, 使固相合成AZ91D镁合金的力学性能与铸态和用铸锭热挤出制备的镁合金相比明显提高, 在合成温度为673K时, 其延伸率为5.8%, 比铸态增加152%; AZ91D镁合金屑在挤出过程中不能完全结合且出现较多的微裂纹, 使其延伸率与铸锭热挤出制备的AZ91D镁合金相比低44%。

关键词: AZ91D镁合金; 固相合成; 热挤出; 力学性能 中图分类号: TG146.2; TG376.2

文献标识码: A

Microstructure and properties of AZ91D magnesium alloy by solid-state recycling

JI Ze-sheng1, CHEN Xiao-yu1, HU Mao-liang1, S. Sumio2, YANG Xu-yue3

(1. School of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150080, China;

2. Institute of Industrial Science, University of Tokyo, Tokyo 153-8505, Japan;

3. Mechanical Department, University of Electro-Communications, Tokyo 182-8585, Japan)

Abstract: AZ91D magnesium alloy was prepared by hot extrusion of machined chips at 573, 623, 673 and 723K with an extrusion ratio of 11∶1, subsequently its microstructure and mechanical properties were investigated. The results indicate that the ultimate tensile strength and elongation of AZ91D magnesium alloys increase with the elevation of preparation temperature at 573-673K, and decrease with the elevation of preparation temperature above 673K, and its ultimate tensile strength is the best at 673K and can reach 384.4MPa. Compared with the as-cast specimens and the extruded specimens from cast ingot, the mechanical properties of the AZ91D magnesium alloy improve evidently because the oxide layers are dispersed in the structure and the dynamic recrystallization happens in the extrusion process. When the preparation temperature is 673K, the elongation is 5.8%, and it is 152% higher than that of the as-cast specimens. The AZ91D magnesium alloy machined chips cant be connected completely and a lot of cracks appear during the extrusion process. Compared with the extruded specimens from cast ingot at 673K, the elongation is 44% lower.

Key words: AZ91D magnesium alloy; solid-state recycling; hot extrusion; mechanical properties

镁合金作为轻质结构材料由于具有密度小、 比强度和比刚度高、 导热和导电性能好、 切削加工性能好、 优良的阻尼性和电磁屏蔽性等优点, 在航空航天、 汽车、 电子、 通讯等方面获得了广泛的应用。 尽管如此, 由于受材料制备、 加工技术、 抗腐蚀性能以及价格等因素的制约, 镁合金尤其变形镁合金的应用远远落后于钢铁和铝合金。 21世纪的能源和环保问题日益突出, 镁合金作为轻质和可回收的材料备受重视。 近年来, 随着镁合金制品的日益增多, 在其生产过程中造成的浪费也大量增多, 特别是镁合金压铸生产, 其中只有50%的金属投料最终成为铸件, 其余均为工艺废料[1]。 因此镁合金的回收将是镁产业的一个重要研究课题。

镁合金的回收方法分为液态回收和固相回收, 其中液态回收一般可通过蒸馏法和熔炼法得到。 固态回收法一般将镁合金废料在保护气氛下球磨粉碎, 也可以通过切割加工变成碎屑, 这些碎屑可以通过触变成型(注射成型)加工成各种零件[2]。 Kondoh[3]等则通过反复塑性加工制备了镁基复合材料。 另外一种则是通过大挤压比挤压出各种型材, 目前, 其研究的合金体系主要是AZ91[4-6]和AZ31[7-8]。 LIU等[9]则通过此法制备了AZ80镁合金, 结果发现, 镁合金经碎屑热挤出制备成型后, 无论是抗拉强度、 屈服强度还是伸长率均优于铸造材料。 本文作者则进一步探讨固相合成镁合金的组织和性能并分析其缺陷, 这对扩展该方法在循环镁合金领域的应用具有重大意义。

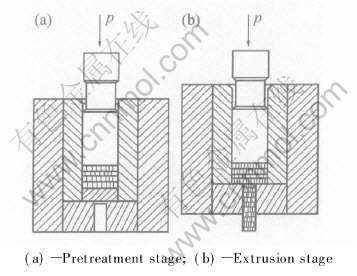

1 实验

选择目前商业使用较多且抗腐蚀能力较强的AZ91D铸造镁合金作为原材料, 切削成长和宽均为2~4mm, 厚1~2mm的碎屑(图1(a))。 首先是预处理阶段, 即将碎屑放入模具中并在室温下用WE-60液压万能实验机进行挤压, 得到直径40mm, 厚23mm的坯锭(图1(b))。 第二阶段为热挤出阶段, 挤出温度分别为573、 623、 673和723K, 模具挤压比为11∶1, 加载速度为0.08mm/s, 整个过程如图2所示。 其中673K温度下所得试样如图1(c)所示。 观察在不同温度下所获得的镁合金试样的微观组织并测试其力学性能。

将各挤出棒材沿挤出方向分别截取拉伸及金相试样。 拉伸试样按国标GB6397—86制得, 试样有效截面直径为5mm, 拉伸方向与挤压方向平行; 金相试样则沿纵向和横向截取。

图1 制备过程所得实物图

Fig.1 Obtained object photos of preparation process

在WDW-200 型微机控制电子万能实验机上进行室温拉伸实验, 分别用OLYMPUS-GX71光学显微镜和FEI-SIRION热场发射扫描电镜, 观察显微组织和拉伸断口组织。

2 结果及分析

2.1 材料的力学性能

用不同方法制备的AZ91D镁合金的力学性能如表1所示。 与铸态和用铸锭热挤压制备棒材的力学性能相比, 碎屑挤出抗拉强度最高, 延伸率虽低于铸锭热挤出材, 但仍高于铸造材。 由此可见碎屑挤出具有优良的力学性能。 图3所示为抗拉强度和延伸率随挤压温度的变化规律曲线, 在573~673K之间固相合成的AZ91D镁合金随挤压温度的升高抗拉强度和延伸率均增大, 当挤压温度达到673K时抗拉强度和延伸率分别达到384.4MPa和5.8%, 之后则随挤压温度的升高而降低, 当挤压温度达到723K时, AZ91D镁合金抗拉强度降到305.5MPa, 但仍比铸态抗拉强度高23%。

图2 制备过程示意图

Fig.2 Schematic diagram of preparation process

图3 抗拉强度和延伸率随挤压温度的变化曲线

Fig.3 Change curves of tensile strength and elongation with extrusion temperature

表1 不同方法制备的AZ91D镁合金的力学性能

Table 1 Mechanical properties of AZ91D magnesium alloys prepared by different methods

2.2 微观组织

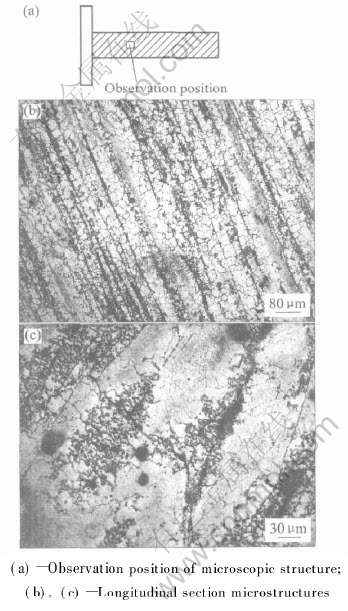

图4所示为显微组织的观察部位示意图。 图5所示为不同温度下所得的固相合成镁合金的微观组织, 图5(a)所示为623K时所得到的显微组织。 从

图4 显微组织的观察部位

Fig.4 Observation position of microscopic structure

图5 不同温度下挤出试样的微观组织

Fig.5 Microstructures of specimens extruded at different temperatures

图中可以明显地看到部分再结晶组织, 由此认为在挤出过程中发生了动态再结晶。 动态再结晶通常开始于旧晶界处, 新的晶粒又在正在长大的的再结晶边界形核长大, 这样就形成了再结晶的增厚带[11]。 变形程度较低时, 与原始晶粒相比, 再结晶晶粒直径较小, 就形成了图5(a)所示的“项链”结构[12], 显微组织呈现出变形的大晶粒和动态再结晶的小晶粒共存的现象。 从图5(b)可知, 当温度为673K时的晶粒尺寸较623K时均匀, 这是随着温度升高, 再结晶晶粒不断长大的结果。 而在723K时, 如图5(c)所示, 再结晶晶粒变得更大, 基本为完全的再结晶组织。

微观组织随温度的变化是挤压材力学性能随温度变化的主要原因。 当温度低于673K时, 虽然由于动态再结晶使晶粒得到细化, 但是组织还是以变形大晶粒为主, 整个组织晶粒大小分布不均匀, 这会影响到材料的力学性能。 当温度达到673K时, 组织中原有的粗大晶粒数量逐渐减少, 在大晶粒周围出现了越来越多的细小等轴晶。 细小的再结晶晶粒逐步取代原始大晶粒, 组织趋于稳定状态, 整个材料晶粒尺寸均匀细小, 此时材料表现出良好的力学性能和变形特性。 在723K时, 由于温度升高, 再结晶形核速率小于晶粒长大速率, 再结晶晶粒开始互相蚕食而逐渐长大, 整个组织呈现粗化趋势, 导致了材料的性能明显下降。

2.3 讨论

镁是密排六方结构, 室温下变形主要通过{0001}〈112[TX-]0〉滑移系进行, 而在锥面{101[TX-]2}〈101[TX-]1〉滑移系只发生适量的压缩孪生变形。 α-Mg 相只有3个几何滑移系和2个独立的滑移系, 不能提供协调任意方式形变所需的5 个独立滑移系。 研究表明[13], 在温度高于473K时, 镁及其合金第Ⅰ类角锥面{1011}上的滑移系可以开动, 498K以上第Ⅱ类角锥面{1012}上的滑移系也可以开动。 在573K时挤出可以激活棱柱面{101[TX-]1}〈112[TX-]0〉滑移系, 开动第Ⅱ类角锥面滑移系, 使AZ91D 镁合金实现塑性形变, 并获得高屈强比的挤出棒材。 需考虑的温度因素还有: 温度太低, AZ91D碎屑不能完全结合; 达不到动态再结晶所需温度时, 不能使晶粒细化; 温度太高镁合金易氧化[14]。

在挤出过程中作用于坯锭上的外力有变形力、 挤压筒壁的正压力和摩擦力等。 在这种情况下变形金属处于体应力状态下而具有很高的塑性, 也就是说由于主法向压应力的作用使脆性断裂难以发生。 金属内出现不大的副拉应力, 其大小取决于主法向应力的数值。 在主法向应力数值很大、 三向不等值压缩情况下, 变形金属将有最好的塑性。

从表1可知, 与铸态相比经过挤出后所得到的合金的强度和塑性指标都有所提高, 主要原因是在挤出过程中发生的动态再结晶使晶粒得到细化; 同时由于镁合金易氧化, 所以在车削成屑过程中会引起镁合金的表面氧化, 氧化层会阻止在挤出过程中碎屑的结合, 但由于热挤出能够提供大的剪切应力而将该氧化层打破, 所以仍能达到充分的冶金结合。 LIU等[9]发现打破的氧化层在挤出过程中变细并形成了外加的第二相被均匀弥散在镁合金中。 再结晶时, 第二相处于晶界上, 阻碍晶界或亚晶界的迁移, 降低了晶界和亚晶界的迁移速度; 另外, 在外加的弥散第二相周围, 挤压时明显产生畸变, 畸变区域具有高的位错密度和相对大的晶界取向差, 畸变区域成为再结晶的核心, 增大了形核率[15]。

图6 673K温度下挤出试样的取样位置和纵截面微观结构

Fig.6 Observation position and microstructures of specimen extruded at 673K

从表1可知, 固相合成得到的镁合金的力学性能比其它2种方法获得的镁合金的抗拉强度都高, 但发现其延伸率虽比普通铸态的高, 却比用铸锭热挤出所获得的镁合金低。 从图6(b)所示的碎屑热挤出所获得的微观组织可以发现清晰的变形流线和少量未发生再结晶而被拉长的纤维组织。 同时从图6(c)还可在晶粒内部和沿晶界处有明显的微裂纹, 在晶粒内的裂纹表征挤压使晶粒拉长以致断裂成微小的颗粒, 从而获得细小的晶粒; 沿晶界处的裂纹则表征碎屑没有完全结合, 这一现象与Doo-Myun[16]的研究结果相符, 即在挤压比低于15∶1的条件下, 所获得的AZ91D镁合金碎屑不能完全结合。 另外, 在晶粒内部和晶界之间还有微孔的出现, Chio等[7]分析AZ31发现, 固相合成所获得的组织微孔体积比铸锭挤出态大, 数量也相对较多。 微孔在晶界处的形成是由于晶界滑移引起的应力集中。 Watanbe等[17]研究发现在超塑性镁合金中晶粒内部的位错运动起到了很重要的作用。 晶粒内部的微孔形核是由于位错引起的应力集中或在高应变条件下在碎屑挤出过程中第二相与基体塑性变形不协调而产生的。 固相合成与铸锭热挤出相比, 一个突出特点就是其制备的材料当中均匀分布了很多的氧化弥散相, 这些氧化弥散相容易导致固相合成制备的材料组织中微孔的形核。 这些晶界处的微裂纹和组织内的微孔降低了组织延伸率。

4 结论

1) 由固相合成的方法在挤压比为11∶1的条件下制备的AZ91D镁合金有较高的力学性能。 在挤压温度为673K时, 其抗拉强度高于用铸锭热挤出制备的AZ91D镁合金23%, 而延伸率比铸锭热挤出所得到镁合金低44%。

2) 在挤压温度低于673K时固相合成的AZ91D镁合金, 抗拉强度和延伸率随挤压温度升高而增大; 673K以上固相合成的AZ91D镁合金抗拉强度和延伸率则随成型温度升高而降低。

3) 在挤出的过程中发生了动态再结晶, 且随着挤压温度的升高晶粒变大。 在挤压温度低于673K时, 再结晶的细小晶粒长大不明显, 导致晶粒大小不均匀, 影响了材料的性能。

4) 在挤压比为11∶1的条件下用固相合成方法制备的AZ91D镁合金屑没有完全结合, 同时还发现组织内有很多微孔, 使延伸率低于用铸锭热挤出制备的镁合金。

REFERENCES

[1]陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 372.

CHEN Zhen-hua. Deform Magnesium Alloy[M]. Beijing: Chemical Industry Press, 2005: 372.

[2]季为民. 应用半固态射压成型镁合金零件特点及设计要点[J]. 工程建设与设计, 2004, 10: 46-47.

JI Wei-min. Characteristic and design point of accessory of appliance semisolid thixomolding magnesium alloy[J]. Construction & Design for Project, 2004, 10: 46-47.

[3]Kondoh K, Luangvaranunt T, Izawa T. Morpholo-Gyfree processing of magnesium alloys[J]. Materials Transactions, 2001, 42(7): 1254-1257.

[4]Mabuchi M, Kubota K, Higashi K. New recycling process by extrusion for machined chips of AZ91 magnesium and mechanical properties of extruded bars [J]. Materials Transactions, JIM, 1995, 36(10): 1249-1254.

[5]Kondoh K, Luangvaranunt T, Aizawa T. Solid-ate recycling of AZ91D magnesium alloy chips[J] . Journal of Japan Institute of Light Metals, 2001, 51(10): 516-520.

[6]Mabuchi M, Kubota K, Higashi K. Mechanical properties of AZ91 magnesium alloy processed from its machined chips[J] . J Japan Soc Powder and Powder Metallurgy, 1993, 40: 397-400.

[7]Chino Y, Kishihara R, Shimojima K, et al. Superplasticity and cavitation of recycled AZ31 magnesium alloy fabricated by solid recycling process[J]. Materials Transactions, 2002, 43(10): 2437-2442.

[8]Chino Y, Kobata M, Shimojima K, et al. Blow forming of Mg alloy recycled by solid-state recycling[J]. Materials Transactions, 2004, 45(2): 361-364.

[9]LIU Ying, LI Yuan-yuan, ZHANG Da-tong, et al. Microstructure and properties of AZ80 magnesium alloy prepared by hot extrusion from recycled machined chips[J]. Trans Nonferrous Met Soc China, 2002, 12(5): 882-885.

[10]徐春杰, 张忠明, 郭学锋, 等. 热挤压AZ91D 镁合金的组织与力学性能[J]. 西安理工大学学报, 2005, 21(4): 356-360.

XU Chun-jie, ZHANG Zhong-ming, GUO Xue-feng, et al. Microstructure and mechanical properties of extruded AZ91D alloy[J]. Journal of Xian University of Technology, 2005, 21(4): 356-360.

[11]Cahn R W. 材料科学与技术丛书(第15卷)[M]. 雷廷权, 等译. 北京: 科学出版社, 1999: 408-414.

Cahn R W. Processing of Metal and Alloys(Vol.15)[M]. LEI Ting-quan, et al, transl. Beijing: Science Press, 1999: 408-414.

[12]郭强, 严红革, 陈振华, 等. AZ31镁合金高温热压缩变形特性[J]. 中国有色金属学报, 2005, 15(6): 900-906.

GUO Qiang, YAN Hong-ge, CHEN Zhen-hua, et al. Hot compression deformation behavior of AZ31 magnesium alloy at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 900-906.

[13]Polmear I J. Magnesium alloys and applications[J]. Mater Sci & Tech, 1994, 10: 1214-1218.

[14]Nakanishi M, Mabuchi M, Saito N, et al. Tensile properties of the ZK60 magnesium alloy produced by hot extrusion of machined chip[J]. Journal of Materials Science Letters, 1998, 17: 2003-2005.

[15]Doherty R D, Hughes D A, Humphreys F J, et al. Current issues in recrystallization: a review[J]. Mater Sci Eng A, 1997, A238(2): 238-275.

[16]Doo-Myun L, Joon-Seo L, Chi-Hwan L.The microstructure and mechanical properties of extruded machined chips for AZ91D magnesium alloy[J]. Light Metals, 1995, 45(7): 391-396.

[17]Watanabe H, Mukai T, Kohzu M, et al. Effect of temperature and grain size on the dominant diffusion process for superplastic flow in an AZ61 magnesium alloy[J]. Acta Mater, 1999, 47(14): 3753-3758.

(编辑李向群)

基金项目: 黑龙江省教育厅海外学人科研资助项目(1151hz002)

收稿日期: 2006-04-29; 修订日期: 2006-09-15

通讯作者: 吉泽升, 教授; 电话: 0451-86674840, 13804517924; E-mail: jzes@sohu.com