DOI: 10.11817/j.issn.1672-7207.2016.06.041

速度环量对大型轴流泵站水力性能的影响

燕浩,刘梅清,赵文胜,林鹏,吴远为

(武汉大学 动力与机械学院,湖北 武汉,430072)

摘要:为了研究大型轴流泵装置内部由空化引起的有旋流动对机组水力性能的影响,基于SST(shear-stress transport)k-ω湍流模型,应用Rayleigh-Plesset模型对泵站内部空化进行描述,并用速度环量分别对非空化和空化2种状态的有旋流动进行计算,结合模型泵试验研究等方法对泵内有旋流动进行分析。比较2种工作状态下流体流动偏移角(γ),研究速度环量对水力性能影响的规律。研究结果表明:在设计工况下,扬程相对误差为3.58%,效率相对误差为3.31%,验证了湍流模型的适用性,并得到泵站装置临界空化压力(Pc)和断裂空化压力(Pf);在设计工况下,空化会增大流体流动偏移角,增大速度环量,增加内部流道水力损失;在偏离设计工况下,会增大流体流动偏移角(γ)。其中,在小流量系数条件下较大,此时空化进一步增大流动偏移角(γ),并增加由此引起的速度环量变化量以及进出口流道内部损失,使大型轴流泵站性能下降。

关键词:大型轴流泵装置;速度环量;空化;计算流体力学;水力性能

中图分类号:TH311 文献标志码:A 文章编号:1672-7207(2016)06-2125-08

Influence of velocity circulation on hydraulic performance of large axial-flow pumps station

YAN Hao, LIU Meiqing, ZHAO Wensheng, LIN Peng, WU Yuanwei

(School of Power and Mechanical Engineering, Wuhan University, Wuhan 430072, China)

Abstract: To study the effect of inner rotational flow on hydraulic performance of large axial-flow pumps caused by cavitation, based on SST (shear-stress transport) k-ω turbulence model, the pumps internal cavitation was described by applying Rayleigh-Plesset model. The rotational flows of pumps under cavitation and non-cavitation condition were calculated by velocity circulation theory, combined with the model pump experimental study. The flow deviation angle (γ) of two different working conditions was compared, and the effect of velocity circulation on the hydraulic performance was discussed. The results show that under the optimal conditions, the head error is 3.58% while the efficiency error is 3.31%, which indicates the correctness of SST k-ω turbulence model, and the critical cavitation pressure (Pc) and fracture cavitation pressure (Pf) are also obtained. Under off design conditions, the cavitation increases the flow deviation angles, the velocity circulation and internal passage hydraulic loss. Under off design conditions, the γ values become large, especially larger at small flow coefficient, the cavitation further increases the flow deviation angles (γ), the velocity circulation and internal passage hydraulic loss, reducing the hydraulic performance of large axial-flow pumps.

Key words: large axial-flow pumps station; velocity circulation; cavitation; computational fluid dynamics; hydraulic performance

大型轴流泵装置内部流动为有旋流动时,泵内速度环量会使机组发生振动、噪音,影响其安全稳定运行,使内部流体发生变化,出现脱流、二次回流等不利流动,严重时会使机组性能迅速下降,甚至会使机组无法正常工作。目前,国内外学者对泵及泵装置进行了大量研究,包括对其水力特性预测[1-2]以及效率换算方法研究[3-4]等,并取得一定研究成果。随着电子科技发展,数值模拟技术(CFD)已应用于水力机械领域[5-7],使通过流场分析揭示大型泵站内部有旋流动规律成为可能。国内外学者采用CFD技术对立式轴流泵站[8]、斜轴伸泵装置[9]、大型低扬程泵装置[10]、各种贯流泵装置[11-14]及双向泵站装置[15-17]等内部流场进行了研究,并经试验验证,能够准确地对泵站装置水力特性进行预测;近年来,一些学者采用SST k-ω湍流模型对轴流泵内部空化特性进行预测[18-20],成功捕捉到空化区域,并用PIV技术进行了试验验证,得到轴流泵发生空化时会使泵的应能下降,进、出口速度环量发生变化,内部流态会发生变化。但上述研究成果均没有对现场泵站作为一个整体研究空化引起水力性能的变化。本文作者基于SST k-ω湍流模型对现场大型轴流泵装置(包括肘形进水流道、叶轮、导叶和虹吸式出水流道)进行数值模拟,分析不同工作状态下各截面处速度环量,研究空化促使速度环量变化以及对泵装置水力性能的影响,阐述空化和非空化状态下速度环量变化以及对大型轴流泵装置水力性能影响机理。

1 基本参数和理论分析

1.1 基本参数

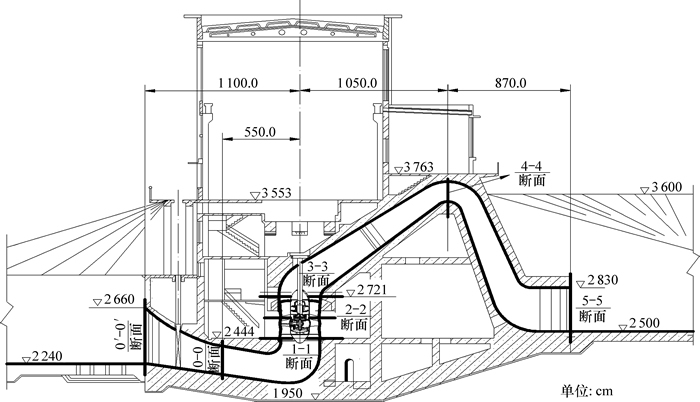

选取幸福泵站作为研究对象,泵站纵剖面图如图1所示,其水力部件包括肘形进水流道、叶轮、导叶和虹吸式出水流道4部分。其中,泵站中立式轴流泵设计参数为:流量Q=21.28 m3/s,扬程H=5.30 m,转速n=150 r/min,比转数ns=778。主要几何参数:叶轮直径D2=2 800 mm,叶轮轮毂圆直径Dh=1 520 mm,叶片数为4个,导叶为圆弧形结构,导叶片数为6个,导叶与叶轮之间的距离δ=360 mm。

1.2 理论分析

1.2.1 叶轮进出口速度环量

由泵内进出口速度三角形得:

(1)

(1)

(2)

(2)

式中:u为叶轮圆周速度,m/s;vm为轴面流速,m/s;β2为出口安放角,(°);γi为偏离角,(°);i=0,1,2,3和4,0代表泵进口,1代表叶轮进口,2代表叶轮出口,3代表导叶出口,4代表泵出口。

因此,叶轮进出口速度环量方程为

(3)

(3)

图1 泵站纵剖面图

Fig. 1 Profile of pump station

式中:R为截面水力半径,mm。

轴流泵叶轮内部能量方程:

(4)

(4)

式中:ω为旋转角速度,rad/s。

1.2.2 流道内速度环量

当流道内流体为有旋流动时,表现为流速流线与流道几何中心线有一定角度,流道速度有圆周方向分量存在,即Γi≠0,流体并呈螺旋前进。流道内流体速度环量为

(5)

(5)

图2 叶片内速度三角形

Fig. 2 Velocity triangle of impellers

2 数值模拟

2.1 模拟方法

三维湍流数值模拟的控制方程包括基于两相流混合模型的空化模型、雷诺时均(RANS)纳维-斯托克斯(N-S)方程以及更适合流体分离的SST k-ω湍流模 型[21]。控制方程离散采用控制体积法,方程扩散项为中心差分格式,对流项为二阶迎风格式。方程求解采用分离半隐式压力耦合算法。对空化气泡的描述采用以Rayleigh-Plesset为基础的Zwart方程,分析空泡产生和溃灭与流体之间发生质量传递过程。进口条件为压力进口,出口为质量流量出口,计算收敛标准设为1×10-4,输送介质选为25 ℃的水,计算类型为稳态。

近壁面处采用壁面函数法进行计算,近壁面处的切向速度是与壁面剪切应力τw成对数关系,表达式为

(6)

(6)

式中:y+=ρΔyuτ/μ;uτ=(τw/ρ)1/2;u+为近壁速度,m/s;uτ为摩擦速度,m/s;Ut为距离壁面Δy处的壁面的切向速度,m/s;y+为壁面的距离(量纲一的量);κ为Karman常数;C为壁面粗糙度相关的对数层常数。

2.2 网格划分

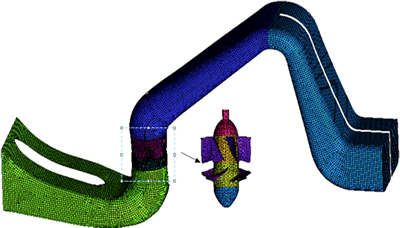

由于该轴流泵模型和装置结构尺寸较大,在进行网格划分时,网格数量和质量直接决定数值计算结果正确性,其中,近壁区黏性底层距离y+影响数值计算网格划分数量和黏性底层的捕捉情况,从而对计算结果具有较大影响。采用ICEM分别对各水力部件进行网格划分,对y+进行适当调整,选用自适性很强的四面体和三角锥混合型网格,分别对影响水力性能关键性部件(叶片和导叶)的近壁面黏性底层满足y+≤5要求,其他过流部件满足SST湍流模型对近壁黏性底层满足y+<50的要求。对大型轴流泵装置进行网格无关性验证,当网格总数在1 494.8万左右时泵效率变化约为0.5%。因此,该泵装置网格总数宜为1 494.8万左右。图3所示为大型轴流泵装置网格图。

图3 大型轴流泵装置网格图

Fig. 3 Mesh of large-scale axial flow pumping unit

3 结果分析

3.1 空化性能预测

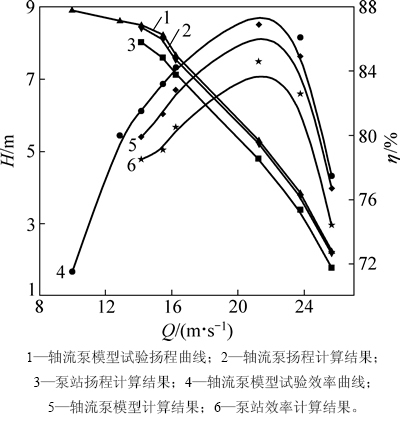

选取7个计算工况点对大型轴流泵模型和泵站装置进行数值模拟,并与模型泵试验进行对比,结果如图4所示。针对模型泵,从图4可以看到:数值模拟结果能够与试验外特性曲线较好地吻合。在设计工况下,计算扬程为5.11 m,与试验结果的相对误差为3.58%,效率相对误差为3.31%,SST k-ω湍流模型计算结果完全满足工程应用要求[22]。在此基础上对大型轴流泵装置水力性能进行预测。由图4可知:轴流泵扬程整体比模型泵扬程低,在设计工况时,计算扬程为4.71 m,与模型泵扬程相比减小了7.83%。由于泵站装置内的局部损失:包括渐缩管损失,弯管损失、渐扩管损失以及流体的分离和汇合时而所产生的损失等因素,均会使泵扬程降低,这与实际情况相符。

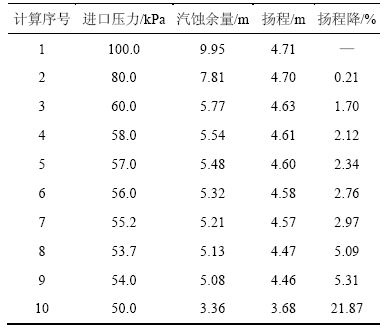

表1所示为大型轴流泵站装置空化外特性曲线的预测结果。通过改变泵进口压力使其发生空化,与设计工况点扬程相比,当扬程下降3.00%时,该点为空化临界点,当扬程下降5.00%时为临界断裂空化点[23]。在装置进口压力为55.20 kPa时,扬程下降了2.97%;当进口压力为53.70 kPa时,扬程下降5.09%,该泵站已发生断裂空化;当进口压力继续降低时,扬程迅速下降,将发生严重空化现象,甚至使泵站不能正常工作。因此,泵临界空化压力(Pc)为55.20 kPa,断裂空化压力(Pf)为53.70 kPa。

图4 试验与模拟外特性曲线比较

Fig. 4 Comparison between experimental and numerical performance curves

表1 大型轴流泵装置空化性能预测

Table 1 Cavitation performance prediction of large axial flow pumps

3.2 流道内部速度场分析

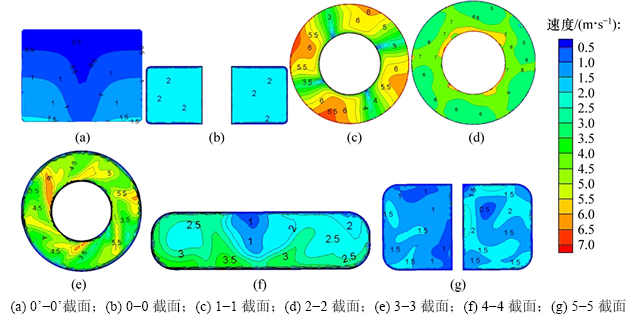

图5和图6所示分别为大型轴流泵装置在非空化和空化2种状态下流道内部速度场分布情况,其中,在设计流量下,进口压力分别为100 kPa(非空化)和断裂空化压力(Pf)各截面位置,如图1所示。

从图5可以看到:在泵装置进口受到整流墩影响,流速呈对称分布;流体流到2-2截面处时速度分布均匀,流线较好;随着流体继续流动,受到肘形进水流道和叶轮旋转的影响,在叶轮进口处速度均匀性较差,且有明显速度梯度,叶轮出口呈有旋流动;流体进过导叶整流作用后导叶出口处速度梯度有明显改善,但仍有明显有旋流动;流体流经虹吸式出水流道速度梯度进一步降低,速度分布得到一定改善,漩涡区域得到明显改善。

图6所示为空化状态下大型轴流泵内速度分布情况。比较图6与图5可以发现:在空化状态下,大型轴流泵内速度分布明显变差,空化不仅会使流道内速度分布规律性变差,而且会增大流道内漩涡流动区域;肘形进水流道内漩涡区域明显增大,在虹吸式出水流道内也有类似的情况发生。

3.3 瞬时流动偏离角γj分布

定义各单元速度瞬时偏移角γj为

(6)

(6)

式中:uaj为水泵进口断面各单元轴向速度,m/s;utj为水泵进口断面各单元横向速度,m/s。

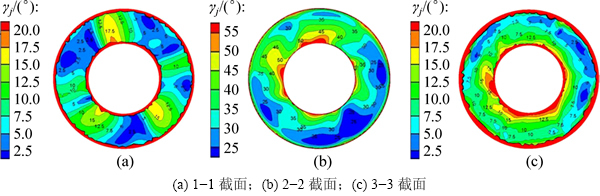

图7所示为非空化状态下各截面处瞬时流动偏移角γj分布情况。从图7可以看到:流体经过肘形进水流道后,在1-1截面处各单元瞬时速度偏移角γj未呈对称分布,受到叶轮旋转的影响,靠近叶轮进口边流动偏移角γj较大,约为17.5°,远离叶轮进口边流体的γj较小约为5°;流体进过叶轮获得能量后,2-2截面流体偏移角从轮毂到轮缘呈逐渐增大趋势,这与叶片安放角变化趋势相同;当流体经过导叶整流后,流体并没有沿竖直方向流动,而是与轴面流线呈一定偏移角γj,说明导叶出口有速度环量存在。

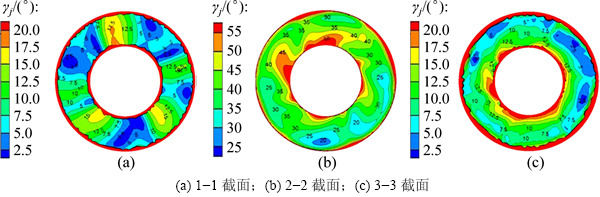

图8所示为空化状态下各截面处瞬时流动偏移角γj分布情况。比较图7和图8可以发现:空化状态下流体流动偏移角γj与非空化状态下的γj具有相似的变化规律。但是空化状态下γj大于非空化状态下γj,表明空化将会增大流体流动偏移角。

图5 非空化状态各截面速度场分布

Fig. 5 Velocity distribution in non-cavitation status

图6 空化状态各截面速度场分布

Fig. 6 Velocity distribution in cavitation status

图7 非空化状态各截面偏移角γj分布

Fig. 7 Instantaneous flow deviation angle distribution in non-cavitation status

图8 空化状态各截面偏移角γj分布

Fig. 8 Instantaneous flow deviation angle distribution in cavitation status

3.4 空化引起速度环量变化

为了计算各个截面流体速度平均偏移角γ,将各截面瞬时偏移角γj数据导出,进行加权平均求解,其计算公式如下:

(7)

(7)

式中:m为水泵进口断面剖分单元数。

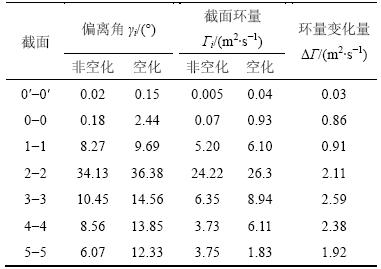

表2 各截面速度环量变化

Table 2 Velocity circulation variation in different cross sections

从表2可以得到:在肘形进水流道内平均流动偏移角γ从泵站装置进口到叶轮进口截面变化过程中,呈先逐渐增大趋势,这种变化受叶轮旋转的影响,流体越远离叶轮,受到叶轮旋转的影响就越小,γ就越小;在叶轮出口截面处γ最大,这是由于叶片出口安放角的影响,使流体沿着叶片流动,使偏离轴面流线较大,将叶轮出口轴面偏移角与叶片安放角求差时,为流体流动偏移角;受到导叶整流作用,在导叶出口截面处γ有一定程度减小;在虹吸式出水流道内,受流体扩散、整流以及远离旋转叶轮的影响,导叶出口截面到泵站出口截面变化过程中,γ逐渐变小。通过比较可以发现:空化状态下γ变化规律与非空化状态下的相同,但是空化在一定程度上增大流体流动偏离轴面流线程度。将2种工作状态下的γ角代入式(5)可以得到各截面平均速度环量,即可得到由空化引起的速度环量变化。比较2种工作状态下速度环量可以发现:在肘形进水流道内,在1-1截面处,由空化引起的速度环量变化量最大,为0.91 m2/s。在虹吸式出水流道内,在3-3截面处速度环量变化量最大,为 2.59 m2/s。

3.5 速度环量变化对水力性能的影响

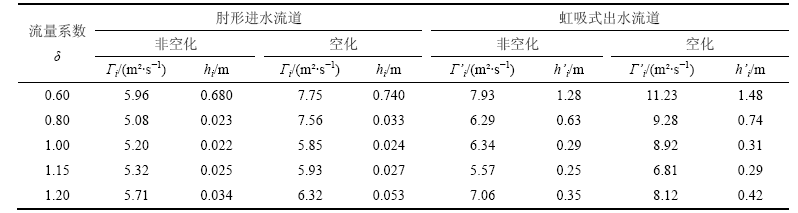

为了能够全面计算空化引起的速度环量变化对大型轴流泵水力性能的影响,在不同流量系数δ(运行流量与设计流量的比值Q/Qt)下对非空化和空化2种工作状态下泵站水力性能进行比较,结果如表3所示。

从表3可以得到:流量系数从小到大变化过程中,速度环量呈先减小后增大的趋势,但仅在小范围内变化,泵站内部水力损失具有相同变化规律。在流量系数为1时,内部损失最小。通过比较非空化和空化状态下速度环量可知:在肘形进水流道内,由空化引起的速度环量在流量系数为0.6时为1.79 m2/s,远大于流量系数为1.2时的速度环量;在虹吸式出水流道内具有类似变化规律,当δ=0.6时,由空化引起的速度环量变化量最大为3.30 m2/s,在δ=1.2时,速度环量变化量最小为1.06 m2/s。通过比较由空化引起的能量损失可以得到:变化趋势与空化引起的速度环量变化量相同,但并不成线性变化,即空化增加速度环量变化量,增加能量损失;随着流量系数的变化,泵站进、出口流道内部能量损失均在小流量工况下最大,在大流量工况下最小。

综上所述,在设计工况下,空化会增大流体流动偏移角,并增大速度沿圆周方向上的分量,即增大速度环量,改变大型轴流泵装置内部流体流动规律,增大内部漩涡区域,进而增加内部流道水力损失。当泵偏离设计工况工作时,均会增大流体流动偏移角,其中,在小流量系数条件下,偏移角较大。空化会进一步增大流动偏移角,并增加由此引起的速度环量变化量和流道内部损失,使大型轴流泵装置性能下降,空化严重时,机组甚至不能正常工作。

表3 速度环量变化对泵装置水力性能的影响

Table 3 Influence on hydraulic performance of pumping stations by velocity circulation change

4 结论

1) 通过理论分析推导出由流体流动偏离角引起的速度环量关系式,结合数值模拟技术研究非空化和空化状态下速度环量变化规律,揭示空化和非空化2种状态下速度环量变化对大型轴流泵装置水力性能的影响。

2) 结合数值模拟和模型泵试验方法,得到数值模拟结果与试验外特性曲线能够较好地吻合,并对泵装置性能和空化特性进行预测,得到泵装置临界空化压力(Pc)为55.20 kPa,断裂空化压力(Pf)为53.70 kPa。

3) 通过计算得到空化会增大流动偏移角,增大速度环量,并增大泵站内部流道能量损失;随着流量系数变化过程中,空化引起的速度环量和泵站进、出口流道内部损失均在小流量系数条件下达到最大值,在大流量系数工作时最小。

参考文献:

[1] 李彦军, 黄良勇, 袁寿其, 等. 大型泵与泵装置效率特性预测理论分析[J]. 农业机械学报, 2009, 40(1): 45-52.

LI Yanjun, HUANG Liangyong, YUAN Shouqi, et al. Theoretical analysis of efficiency characteristic prediction on large pump and pump installation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(1): 45-52.

[2] 严登丰. 泵与泵装置特性预测[J]. 排灌机械工程学报, 2012, 30(3): 315-328.

YAN Dengfeng. Performance prediction for pump and pumping system[J]. Journal of Drainage and Irrigation Machinery Engineering, 2012, 30(3): 315-328.

[3] 陈松山, 严登丰, 葛强, 等. 泵及泵装置效率换算方法[J]. 农业机械学报, 2006, 37(11): 53-57.

CHEN Songshan, YAN Dengfeng, GE Qiang, et al. Research on conversion method of pump and pump set efficiency between hydraulic model and prototype[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(11): 53-57.

[4] 陆伟刚, 严登丰, 甄峰. 水泵及泵装置效率换算方法[J]. 排灌机械工程学报, 2012, 30(6): 677-684.

LU Weigang, YAN Dengfeng, ZHEN Feng. Efficiency scaling method for pumps and their systems[J]. Journal of Drainage and Irrigation Machinery Engineering, 2012, 30(6): 677-684.

[5] WANG Zhengwei, PENG Guangjie, ZHOU Lingjiu, et al. Hydraulic performance of a large slanted axial-flow pump[J]. Engineering Computations, 2010, 27(2): 243-256.

[6] ZHANG Rui, CHEN Hongxun. Numerical analysis of cavitation within slanted axial-flow pump[J]. Journal of Hydrodynamics, 2013, 25(5): 663-672.

[7] 张仁田, 岳修斌, 朱红耕, 等. 基于CFD的泵装置性能预测方法比较[J]. 农业机械学报, 2011, 42(3): 85-90.

ZHANG Rentian, YUE Xiubin, ZHU Honggeng, et al. Comparison on performance prediction methodologies of low-head pump systems based on CFD[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(3): 85-90.

[8] 成立, 刘超, 汤方平, 等. 基于 RNG 紊流模型的立式轴流泵站三维流动数值模拟及性能预测[J]. 机械工程学报, 2009, 45(3): 252-257.

CHENG Li, LIU Chao, TANG Fangping, et al. 3D numerical simulation and performance predication of vertical axial flow pumping station by RNG turbulent model[J]. Journal of Mechanical Engineering, 2009, 45(3): 252-257.

[9] 杨帆, 刘超, 汤方平, 等. 斜轴伸泵装置水动力数值计算与模型试验[J]. 机械工程学报, 2012, 48(18): 152-160.

YANG Fan, LIU Chao, TANG Fangping, et al. Numerical simulation on the hydraulic performance and model test of slanted axial pumping system[J]. Journal of Mechanical Engineering, 2012, 48(18): 152-160.

[10] 李彦军, 颜红勤, 葛强, 等. 大型低扬程泵装置优化设计与试验[J]. 农业工程学报, 2010, 26(9): 144-150.

LI Yanjun, YAN Hongqin, GE Qiang, et al. Optimum hydraulic design and model test of large-scale low-lift pump devices[J]. Transactions of the Chinese Society of Agricultural Engineering, 2010, 26(9): 144-150.

[11] 徐磊, 陆林广, 陈伟, 等. 南水北调工程邳州站竖井贯流泵装置进出水流态分析[J]. 农业工程学报, 2012, 28(6): 50-56.

XU Lei, LU Linguang, CHEN Wei, et al. low pattern analysis on inlet and outlet conduit of shaft tubular pump system of Pizhou pumping station in South-to-North Water Diversion Project[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(6): 50-56.

[12] 陆林广, 陈坚, 梁金栋, 等. 灯泡贯流泵装置的优化水力设计[J]. 水利学报, 2008, 39(3): 354-359.

LU Linguang, CHEN Jian, LIANG Jindong, et al. Optimal hydraulic design of bulb tubular pump system[J]. Journal of Hydraulic Engineering, 2008, 39(3): 354-359.

[13] 刘君, 郑源, 周大庆, 等. 前、后置竖井贯流泵装置基本流态分析[J]. 农业机械学报, 2010, 41: 32-38.

LIU Jun, ZHENG Yuan, ZHOU Daqing, et al. Analysis of basic flow pattern in shaft front-positioned and shaft rear-positioned tubular pump systems[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41: 32-38.

[14] 杨帆, 刘超, 汤方平, 等. S 形下卧式轴伸贯流泵装置的振动特性分析[J]. 农业工程学报, 2013, 29(16): 74-83.

YANG Fan, LIU Chao, TANG Fangping, et al. Analysis on vibration characteristics of S-shaped shaft-extension tubular pumping system[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(16): 74-83.

[15] 成立, 刘超, 汤方平, 等. 对称翼型转轮双向泵装置紊流数值模拟与性能预测[J]. 农业机械学报, 2004, 35(5): 78-81.

CHENG Li, LIU Chao, TANG Fangping, et al. Numerical simulation and performance prediction of reversible pump with symmetric aerofoil[J]. Transactions of the Chinese Society for Agricultural Machinery, 2004, 35(5): 78-81.

[16] 杨帆, 刘超, 汤方平, 等. 灌排双向立式泵装置内部水流压力脉动特性[J]. 排灌机械工程学报, 2011, 29(4): 316-324.

YANG Fan, LIU Chao, TANG Fangping, et al. Analysis on pressure fluctuation of interior flow in reversible pumping system for irrigation and drainage[J]. Journal of Drainage and Irrigation Machinery Engineering, 2011, 29(4): 316-324.

[17] 杨帆, 金燕, 刘超, 等. 双向潜水贯流泵装置性能试验与数值分析[J]. 农业工程学报, 2012, 28(16): 60-67.

YANG Fan, JIN Yan, LIU Chao, et al. Numerical analysis and performance test on diving tubular pumping system with symmetric aerofoil blade[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(16): 60-67.

[18] 张德胜, 吴苏青, 施卫东, 等. 轴流泵小流量工况条件下叶顶泄漏空化特性[J]. 农业工程学报, 2013, 29(22): 68-76.

ZHANG Desheng, WU Suqing, SHI Weidong, et al. Characteristics of tip leakage vortex cavitation in axial flow pump at small flow rate condition[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(22): 68-75.

[19] 施卫东, 吴苏青, 张德胜, 等. 叶片数对高比转数轴流泵空化特性的影响[J]. 农业机械学报, 2013, 44(11): 72-77.

SHI Weidong, WU Suqing, ZHANG Desheng, et al. Effects of number of blades on cavitation of high specific speed axial flow pump[J]. Journal of Agricultural Machinery, 2013, 44(11): 72-77.

[20] ZHANG Rui, CHEN Hongxun. Numerical analysis of cavitation within slanted axial-flow pump[J]. Journal of Hydrodynamics, 2013, 25(5): 663-672.

[21] 张德胜, 吴苏青, 施卫东, 等. 不同湍流模型在轴流泵叶顶泄漏涡模拟中的应用与验证[J]. 农业工程学报, 2013, 29(13): 46-53.

ZHANG Desheng, WU Suqing, SHI Weidong, et al. Application and experiment of different turbulence models for simulating tip leakage vortex in axial flow pump[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(13): 46-53.

[22] 施卫东, 李通通, 张德胜, 等. 轴流泵叶轮区域空化特性数值模拟[J]. 农业工程学报, 2012, 28(13): 88-96.

SHI Weidong, LI Tongtong, ZHANG Desheng, et al. Numerical simulation on cavitating characteristic in impeller of axial-flow pump[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(13): 88-96.

[23] 潘中永, 袁寿其. 泵空化基础[M]. 镇江: 江苏大学出版社, 2013: 20-40.

PAN Zhongyong, YUAN Shouqi. Fundamentals of cavitation in pumps[M]. Zhenjiang: Jiangsu University Press, 2013: 20-40.

(编辑 赵俊)

收稿日期:2015-06-04;修回日期:2015-09-07

基金项目(Foundation item):国家自然科学基金资助项目(50879062,51179135,51409197);湖北省水利重点科研课题(HBSLKJHT201307)(Projects (50879062, 51179135, 51409197) supported by the National Natural Science Foundation of China; Project(HBSLKJHT201307) supported by the Hubei Provincial Water Resources Research Program)

通信作者:刘梅清,教授,博士生导师,从事流体机械及工程方面研究;E-mail:yanying0708@126.com