DOI: 10.11817/j.issn.1672-7207.2015.10.010

大铸锭铝熔体中超声振动系统空化区域分析及实验研究

董方,李晓谦,张敏

(中南大学 机电工程学院,高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:根据比值校正法利用激光测距仪对超声系统辐射杆振动进行测试,其结果进行幅值谱校正后得到辐射杆位移幅值分布,分别对超声变幅杆浸入铝溶液及水中不同深度进行空蚀分布实验,运用有限元法对水及铝熔体中空化区域进行模拟。研究结果表明:振动系统在谐振点以下电流更加稳定,声流效应不易产生突变;超声振动系统辐射杆以纵向振动为主,声压幅值在铝熔体中辐射杆端面法线上单调递减;侧面横向振动的最大振动幅值约为端面纵振幅1/2,位置约为端面以上15~55 mm处;空化区域仿真结果与实验结果基本吻合。

关键词:超声辐射杆;纵横振动;空化区域

中图分类号:TG249.9;TB559 文献标志码:A 文章编号:1672-7207(2015)10-3625-06

Regional and experimental analysis of large ingots ultrasonic vibration cavitation system molten aluminum

DONG Fang, LI Xiaoqian, ZHANG Min

(State Key Laboratory of High Performance Complex Manufacturing,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Vibration test was done for a piezoelectric ultrasonic transducer for casting by laser range finder, the displacement amplitude distribution of end and cylindrical surface was obtained through amplitude spectrum correction for the vibration series based on interpolation method, and cavitation erosion test with different depths of the ultrasonic horn was immersed in the solution of aluminum and water. Finite element methods was used to carry on the numerical simulation cavitation. The results show that the current in the resonant points below the vibration system is more stable, and it is not easy for acoustic streaming effect. The experiments of ultrasonic casting of aluminium alloy were carried out when the depth of ultrasonic vibration was applied on melt. The max amplitude of transverse vibration reaches 1/2 of the longitudinal vibration amplitude and the peak of transverse vibration appears above the end surface 15-55 mm. When the depth of vibration increases, the cavitation area was reduced. Cavitation simulation results are in good agreement with the experimental results.

Key words: ultrasound radiation; longitudinal and transverse vibration; cavitation region

超声空化对铝合金凝固过程有细化晶粒[1-6]、熔体净化[7]、弱化合金元素富集并改善溶质元素偏析[8]、增大合金元素固溶度且改变二次相分布等诸多优点[9],但目前关于超声空化处理熔体技术大基于定性研究,定量分析的研究报道甚少,深入了解超声波在铝熔体中的空化分布场是优化超声铸造各种物理参数及电源参数匹配的关键。在金属熔体中,由于高温及内部不可视因而无法定量测量空化强度和空化范围,本文作者试图通过超声振动系统幅频特性在空气中的测试及仿真模拟水中空化场,进而定量推测超声波在7085铝熔体中产生的空化区域,对超声铸造工艺参数匹配有指导意义。

1 超声空化效应及空化分布

1.1 超声空化机理

超声空化是指高能超声波在液体介质内传递,熔体内微小气泡核在声压的稀疏相和压缩相交替的过程中,其体积经历膨胀、压缩、连续振动并高速崩溃的一系列动力学过程[10-13]。空化泡溃灭瞬间,在极有限的体积内产生了巨大的温度和压力梯度因而产生诸多物理、化学效应,如微射流、冲击波等。据此原理,超声铸造会在铝熔体内也会产生此现象从而作用和改变铝熔体凝固的条件过程。

1.2 空化区域分布

超声空化可以使溶液在铸锭内充分流动,避免合金在大铸锭范围内分布不均,降低宏观偏析;使铸锭内横截面温度梯度大幅降低从相变应力不容易集中在同一位置,避免宏观疏松;促进结晶组织细化[14]。超声在熔体中产生的高声压与高声强是影响铝合金凝固进程的主要因素,超生对铝熔体空化区域的精确确定,有利于超声电源参数及超声铸造各种物理参数合理匹配。

2 实验

2.1 辐射杆振幅测量

激光测距仪振动测试装置连接示意图见图1。隔振平台搭建,开启激光探头,调试焦距对准,启动超声波电源。将驱动频率设为自动跟踪状态,待振动系统平稳谐振后进行数据采集。其中采样频率为392 kHz;数据采样点数为131 072,每个点测量3次。幅频特性测试与振幅分布测试按如下步骤进行:

1) 幅频特性:在超声振动系统谐振点左右调节电源驱动频率,每50 Hz进行一次振动数据采集。

2) 端面与侧面振幅:辐射杆端面沿边缘均布12个测量点,中心测量点为圆心;侧面沿长度方向布置22个测量点,第1个点距端面1 mm,其余点依次间隔5 mm。上述数据均在谐振状态下采集。

图1 振幅测量装置

Fig. 1 Device of amplitude measurement

2.2 蒸馏水中铝箔空化腐蚀实验

实验材料采用0.05 mm纯铝铝箔,其质软易变形,且变形后不反弹便于对超声空化腐蚀进行快速、直观目测,液体介质选择无色透明的蒸馏水。将铝箔固定于钛合金厚箔之上后放置于烧杯内并加入适量蒸馏水,超声辐射杆浸入液面10 mm用支撑架固定,见图2。开启超声波发生器,激振电压为300 V,频率范围为17~22 kHz,设为自动搜索跟踪模式,调节激振频率至谐振状态后施振15 s,结束后取出铝箔烘干。依上述流程再对超声辐射杆浸入液面40 mm与70 mm进行实验。

图2 铝箔空蚀实验装置

Fig. 2 Aluminum foil cavitation test apparatus

2.3 铝熔体中辐射杆空化腐蚀实验

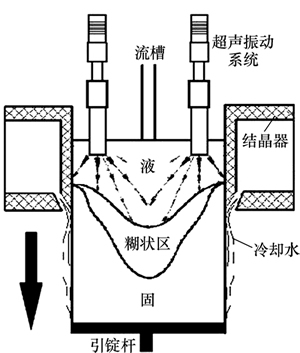

半连续铸造7085铝合金材料,浇注温度为720 ℃,引锭速度为2.4 mm/min,结晶器及喷淋水压为0.1 MPa。铸造过程中分别将超声辐射杆浸入铝溶液40 mm与70 mm,开启超声波发生器,激振电压为300 V,频率范围为17~22 kHz,铸造结束后取出超声辐射杆,见图3。

图3 超声半连铸示意图

Fig. 3 Schematic diagram of ultrasonic semi-continuous casting

3 实验结果与分析

3.1 超声振动系统的幅频特性

当超声波电压为300 V,经测试得知空气中该超声振动系统在17~22 kHz内只有一个谐振点,谐振频率为20 168 Hz。在该谐振点附近采集振动信号,信号频谱分析后得超声振动系统电流与端面圆心处振动幅值随频率变化规律,如图4所示。从图4可知:电流与振幅在谐振点左右两侧均为非对称分布。将实验测试频率段进一步分为谐振点以下及以上2个区间,2个区间内输出振幅与电流的关系如图5所示。

在谐振点上下区间,输出振幅与电流呈线性关系,但2个区间振幅输出特性有所差异。谐振点以上,输出振幅存在突变,之后随电流稳定下降。当电流相等时,谐振点下区间振幅要明显高于上区间振幅,这意味着振动系统在谐振点以下输出性能要明显优于谐振点以上输出性能。该结论与本课题组长期实验经验相符,在超声铸造试验中,往往发现频率一旦高于谐振点,则声流现象急剧减弱甚至消失。而从谐振点频率往下调节,则电流变化较为平缓,声流效应不会产生突变。

图4 电流与振幅随频率的变化

Fig. 4 Variation of current and amplitude with frequency

图5 谐振点两侧输出振幅与电流关系

Fig. 5 Relationship between output amplitude and current in resonant point on both sides

3.2 辐射杆纵横振幅分布

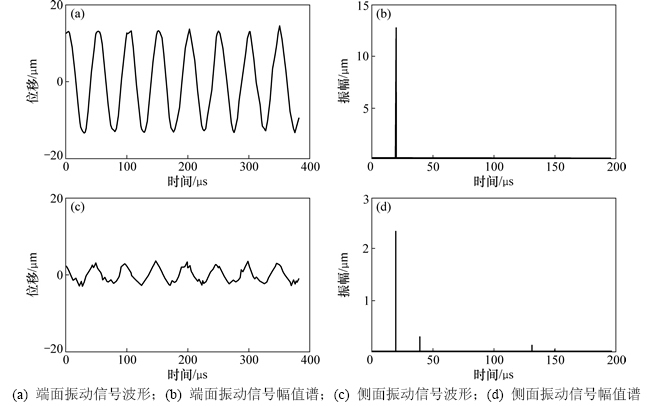

图6所示为端面与侧面振动信号波形与幅值谱,其波形为规则正弦曲线,横向振动有明显噪音,由图6可知:端面纵向振动幅值明显高于侧面横向振动幅值,说明系统振动以纵向振动为主。

辐射杆端面上各测量点振动幅值均在10 μm以上,以圆心处振动幅值最大,边部幅度平缓减弱;辐射杆侧面径向振动位移幅值沿长度方向上分布不均,主要峰值位置约为端面以上40 mm处,最大值为5.382 μm,达到纵向振动幅值的1/2,这表明辐射杆存在较强纵横耦合。根据超声振动系统设计理论,当振动体横向尺寸大于1/4波长时,横向振动不能忽略,因此超声振动体的设计不能按照一维振动设计理论进行设计。

3.3 超声在水中的空化区域及腐蚀特性

图7所示为在300 V电压激励下水中不同施振深度空蚀宏观分布。由图7可知:空化区域主要出现在辐射杆端面正下方,声压幅值从中心向边部递减。在施振深度为10 mm时,端面以下仅出现一个空化区域,距离端面越远声压幅值越小,空蚀孔数目逐渐减少且分布越为稀疏,见图7(a)。在施振深度为40 mm时,端面下方出现3个分离的空化区域,侧面各出现一个空化区。其中正下方区域最为明显且空蚀孔分布最为密集,经测量,端面下方最远空蚀区域距端面约为150 mm,该距离约为超声在水中波长的2倍;辐射杆侧面空蚀区域空蚀坑分布稀疏,范围较小,空化强度较弱,见图7(c)。在施振深度为70 mm时,端面下方出现3个分离的空化区域分别距离端面55,100与160 mm;对于侧面空蚀区较40 mm时偏大,见图7(e)。

图6 端面与侧面振动信号波形与幅值谱

Fig. 6 End and side vibration signal waveform and amplitude spectrum

图7 水中空蚀范围及超声空化分布

Fig. 7 Water cavitation ultrasonic cavitation range and distribution

基于ANSYS建立超声铸造振动系统有限元模型,对前面振动测试结果进行讨论并对超声振动系统在流体介质中声压场进行有限元计算。当介质中声压幅值高于空化阈值时将才会产生声空化,对近场声压幅值高于0.9 MPa[15]区域进行标示,结果见图7(b),(d)和(f)。

水中空化场端面实测相对仿真偏小,这是由于没有考虑在声压幅值有限元计算过程中超声传递及端面透射过程中的耗损所致。辐射杆侧面空蚀区要比仿真范围偏大,主要原因是辐射杆横向振动幅值要大于有限元计算结果,这一点在前面测试结果中已得到验证。因此,在较强的纵横耦合振动下辐射杆侧面空蚀区域则较为明显。总体上空化场实测区域与仿真结果趋于一致,这表明声压场有限元仿真较为准确。

3.4 超声在铝熔体中的空化范围

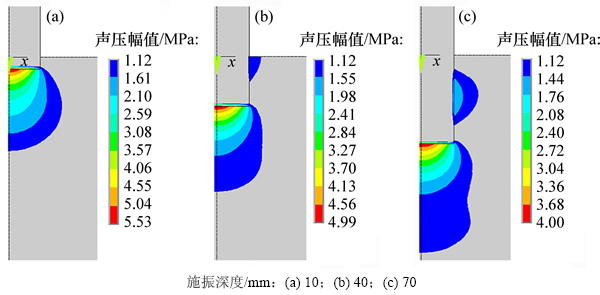

由于铝熔体密度及超声传播速率与水不同,故超声振动系统在熔体区域内空化场分布将与水中有所不同。依据上述分析方法,将流体材料属性改为铝熔体,对声压幅值高于1.12 MPa[16]区域进行标示,结果如图8所示。

图8 铝熔体中超声空化范围

Fig. 8 Aluminum melt range of ultrasonic cavitation

对于铝熔体超声铸造中高温及不可视的局限性,现通过熔体内空化会对辐射杆产生空蚀作用,推测铝熔体内空化区域。图10所示为由半连续铸造结晶器内的辐射杆空蚀,在浸入70 mm的工具头表面,端面空蚀程度较为严重且全面覆盖,而侧面空蚀区域仅在距端面15~55 mm范围出现,其空蚀强度、区域与铝熔体中空化区域仿真结果相符,印证了仿真结果的可靠性。

同时,从图8(b)和9(b)可以看出:辐射杆浸入40 mm时侧面空化效应会对铝溶液表面有强烈的干扰搅动,铸造过程中会将大量的氧化物夹杂带入到铸造熔体中,造成气孔、疏松等缺陷。因此,铸造过程中要合理避开横向振动对液面干扰。

图9 辐射杆空蚀前后对比

Fig. 9 Comparison of cavitation radiation before and after rod

4 结论

1) 振动系统在谐振点以下电流更加稳定,声流效应不易产生突变。

2) 超声振动系统辐射杆以纵向振动为主,侧面横向振动的最大振动幅值约为端面纵振幅值1/2,位置约为端面以上15~55 mm的范围。

3) 水中超声振动系统产生的空化区域主要为辐射杆端面正下方,距端面越远,空化强度越低,空化区域越小。随着施振深度增加,辐射杆侧面会出现小范围空化区域。

4) 铝熔体中辐射杆端面中心部空化程度高于边部空化程度。随着施振深度增加,超声辐射杆端面与侧面均出现显著的空化腐蚀形貌。

参考文献:

[1] 崔莹, 李晓谦.超声对7050铝合金显微组织及溶质固溶度的影响[J]. 中南大学学报(自然科学版), 2012, 43(9): 54-58.

CUI Ying, LI Xiaoqian. Effects of ultrasonic on microstructures and solid solubility of main solute elements in aluminium alloy 7050[J].Journal of Central South University (Science and Technology), 2012, 43(9): 54-58.

[2] 李晓谦, 林森, 蒋日鹏. 超声波对 AlTiC 细化剂的活化机理研究[J]. 华中科技大学学报(自然科学版), 2013, 41(6): 11-15.

LI Xiaoqian, LIN Shen, JIANG Ripeng. Effect of high intensitive ultrasound on AlTiC refiner[J]. Journal of Huazhong University of Science and Technology (Nature Science Edition), 2013, 41(6): 11-15.

[3] Eskin G I. Broad prospects for commercial application of the ultrasonic (cavitation) melt treatment of light alloys[J]. Ultrasonics Sonochemistry, 2001, 8(3): 319-325.

[4] Komarov S V, Kuwabara M, Abramov O V. High power ultrasonics in pyrometallurgy: Current status and recent development[J]. ISIJ international, 2005, 45(12): 1765-1782.

[5] 陈思忠. 我国功率超声技术近况与应用进展[J]. 声学技术, 2009, 21(2): 46-49.

CHEN Sizhong. The present situation and its application developing trend of high power ultrasonic technique in China[J]. Technical Acoustics, 2009, 21(2): 46-49.

[6] 马立群, 舒光冀, 陈锋. 金属熔体在超声场中凝固的研究[J]. 材料科学与工程, 1995, 13(4): 2-7.

MA Liqun, SHU Guangji, CHEN Feng. Research on solidification of metal melt under ultrasonic field[J]. Materials Science & Engineering, 1995, 13(4): 2-7.

[7] 李晓谦, 陈铭, 赵世琏. 功率超声对7050铝合金除气净化作用的试验研究[J]. 机械工程学报, 2010, 46(18): 41-45.

LI Xiaoqian, CHEN Ming, ZHAO Shilian. Experimental research on the effect of power ultrasonic on the degassing process of 7050 aluminum melts[J]. Journal of Mechanical Engineering, 2010, 46(18): 41-45.

[8] 黎正华, 李晓谦, 胡仕成. 超声对7050铝合金显微组织及溶质固溶度的影响[J]. 中南大学学报(自然科学版), 2011, 42(9): 2669-2675.

LI Zhenghua, LI Xiaoqian, HU Shicheng. Effect of 7050 aluminum alloy melt treated by ultrasonic on macrosegregation in ingot[J]. Journal of Central South University (Science and Technology), 2011, 42(9): 2669-2675.

[9] 余琨, 薛新颖, 毛大恒. 超声铸造对AZ31镁合金铸锭及热轧板材组织与性能的影响[J]. 中南大学学报(自然科学版), 2011, 42(7): 1918-1922.

YU Kun, XUE Xinying, MAO Daheng. Effects of ultrasonic vibration on microstructure and properties of as-cast and hot rolled AZ31 magnesium alloy[J]. Journal of Central South University (Science and Technology), 2011, 42(7): 1918-1922.

[10] Eskin G I. Effect of ultrasonic treatment of the melt on the microstructure evolution during solidification of aluminum alloy ingots[J]. Zeitschrift fuer Metallkunde, 2002, 93(6): 502-507.

[11] Park J C, Han M S, Kim S J. Investigation on the cavitation damage behavior with temperature and cavitation time in seawater[J]. Surface and Interface Analysis, 2012, 44(11/12): 1407-1410.

[12] Komarov S, Oda K, Ishiwata Y, et al. Characterization of acoustic cavitation in water and molten aluminum alloy[J]. Ultrasonics Sonochemistry, 2013, 20(2): 754-761.

[13] Abramov O V. Action of high intensity ultrasound on solidifying metal[J]. Ultrasonics, 1987, 25(2): 73-82.

[14] LIU Xinbao, Osawa Y, Takamori S. Microstructure and mechanical properties of AZ91 alloy produced with ultrasonic vibration[J]. Materials Science and Engineering A, 2008, 487(1): 120-123.

[15] 周光平, 梁明军, 王家宜. 大尺寸超声振动体的研究[J]. 声学技术, 2004, 23(3): 183-192.

ZHOU Guangping, LIANG Mingjun, WANG Jiaxuan. Study on large sized ultrasonic vibrators[J]. Technical Acoustics, 2004, 23(3): 183-192.

[16] Eskin G I. Ultrasonic treatment of light alloy melts[M]. Amsterdam: Gordon & Breach, 1998: 41-51.

(编辑 陈爱华)

收稿日期:2015-01-13;修回日期:2015-04-20

基金项目(Foundation item):国家重点基础研究发展规划(973 计划)项目(2010CB731706,2012CB619504)(Projects (2010CB731706, 2012CB619504) supported by the National Key Basic Research Development Program of China (973 Program))

通信作者:董方,博士研究生,工程师,从事铝合金凝固过程控制研究; E-mail:dongfang0408@163.com