Trans. Nonferrous Met. Soc. China 22(2012) 2633-2637

Microstructure and defect of titanium alloy electron beam deep penetration welded joint

ZHANG Bing-gang1, SHI Ming-xiao2, CHEN Guo-qing1, FENG Ji-cai1

1. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China

2. School of Materials Science and Engineering, Lanzhou University of Technology, Lanzhou 730050, China

Received 14 September 2011; accepted 6 November 2011

Abstract: The microstructure, phase composition and cold shut defect of thick titanium alloy electron beam welded joint were studied. The results showed that the microstructure of weld zone was composed of α′ phase; the heat affected zone was divided into fine-grained zone and coarse-grained zone, the microstructure of fine-grained zone was primary α phase + β phase + equiaxed α phase, and the microstructure of coarse-grained zone was primary α phase + acicular α′ phase; the microstructure of base metal zone basically consisted of primary α phase, and a small amount of residual β phase sprinkled. The forming reason of cold shut was analyzed, and the precaution of cold shut was proposed.

Key words: TA15 titanium alloy; electron beam welding; microstructure; phase composition; cold shut defect; weld zone; heat affected zone

1 Introduction

Titanium alloys had been widely applied in aerospace field with high specific strength, strong corrosion resistance, good thermostability and weldability [1], and the large thick titanium alloys were already used as important bearing components in large aircraft manufacturing [2].

The electron beam welding has such advantages as small welding deformation, high efficiency, good procedure repeatability and reproducibility, thus it has already become the preferred welding method of titanium alloys [3-5]. Currently, the electron beam welding of large thick titanium alloys has prominent problems in engineering applications, which mainly manifested on the control of penetration and appearance of weld, welding residual stress and deformation, uniformity of weld composition and property [6-9]. Recently, HU et al [10] have studied the temperature field and stress field of 12 mm-thick TC4 titanium alloy electron beam welded joint. Further recently, the effect of heat treatment on the mechanical property of thick TC4 titanium alloy electron beam welded joint has been reported [11-13]. However, research reports on thick TA15 titanium alloy electron beam welding are rare [14-16]. Therefore, the research on thick TA15 titanium alloy electron beam welding has important theoretical and engineering application value.

In this study, electron beam welding experiment was carried out on the 20 mm-thick titanium plate, the microstructure, phase composition and cold shut defect of welded joints were analyzed, and the precaution of cold shut was proposed.

2 Experimental

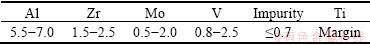

The material used in the experiments was near α-type TA15 titanium alloy, of which chemical compositions are listed in Table 1.

Table 1 Chemical compositions of TA15 titanium alloy (mass fraction, %)

The base metal specimens were rectangular, with 100 mm in length, 50 mm in width and 20 mm in thickness. The base metal specimens were burnished using SiC sand paper before welding, and then were cleaned with acetone and alcohol. The experimental equipment was MEDARD45 vacuum electron beam welding machine which was produced by TECHMET company of French, with a maximum accelerating voltage of 60 kV, and a maximum power of 6 kW. The cathode diameter used in the experiment was 2.0 mm. The plate of TA15 titanium alloy was mounted by a self-made clamp, and then the welding process was implemented under vacuum condition. The microstructure and cold shut were observed by a PMG3 OLYMPUS optical microscope after welding. The phase composition was analyzed by a D/max-rb rotating anode X-ray diffractometer combined with a metallographic observation. The formation mechanism of cold shut was studied, and the precaution of cold shut was proposed. The welding parameters were as follows, welding rate of 6 mm/s, accelerating voltage of 55 kV, and working distance of 175 mm, and beam current values were 20, 30, 40, 50, 55, 60 and 65 mA respectively.

3 Results and discussion

3.1 Macromorphology of welded joint

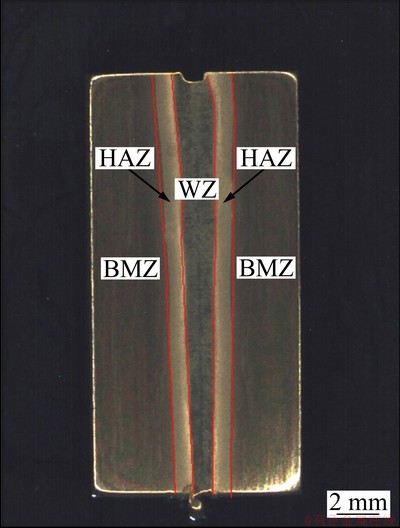

The macromorphology of the welded joint is shown in Fig. 1. The welded joint can be divided into the weld zone (WZ), heat affected zone (HAZ) and base metal zone (BMZ). The weld zone is narrow and slender, the fusion lines that lie both sides of the weld are almost parallel, and the heat affected zone is very narrow. The welded joint shows the typical characteristic of high aspect ratio, which embodied the feature of high energy density of electron beam welding.

Fig. 1 Macromorphology of welded joint

3.2 Microstructure of welded joint

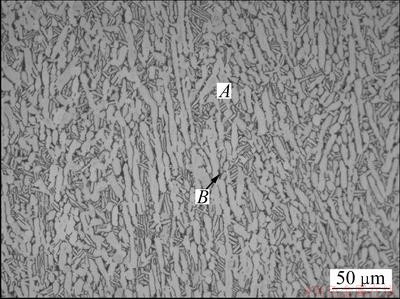

3.2.1 Microstructure of base metal zone

The microstructure of the base metal zone was studied by optical metallographic observation, as shown in Fig. 2. It can be seen from Fig. 2 that the microstructure of base metal zone consists of two phases. The A phase is long strip and block primary α phase, and a small amount of β phase dispersed. The surface of base metal zone was analyzed by XRD. The result is shown in Fig. 3. It can be seen from Fig. 3 that the microstructure of base metal zone consists of α phase and β phase, the amount of β phase is very small, and the α phase is major. The combination of diffraction result and metallographic observation shows that A phase is α phase, and B phase is β phase. This is mainly because the base metal zone is far away from heat source, so there is no so there is no so there is phase transition in the welding process. The original microstructure was retained, which was long strip and block primary α phase + a small amount of residual β phase.

Fig. 2 Microstructure of base metal zone

Fig. 3 XRD pattern of base metal surface

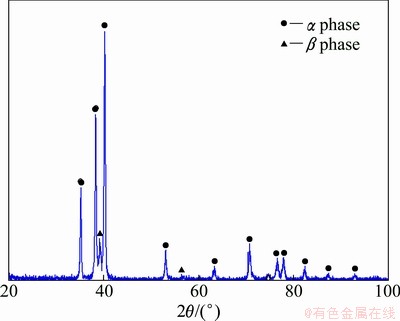

3.2.2 Microstructure of weld zone

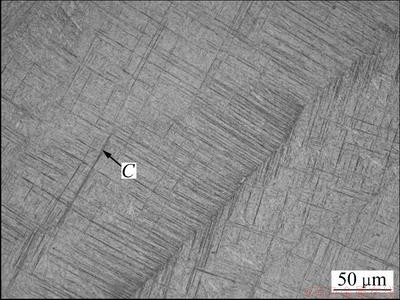

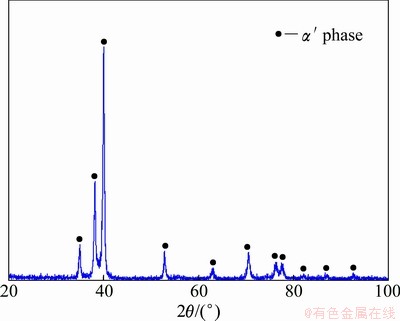

The microstructure of weld zone is shown in Fig. 4. It can be seen from Fig. 4 that the microstructure of weld zone mainly consists of acicular C phase that is dispersed. The surface of weld zone was analyzed by XRD. The result is shown in Fig. 5. It can be seen from Fig. 5 that the microstructure of weld zone consists of martensite α′ phase. The combination of diffraction result and metallographic observation shows that C phase is α′ phase. This is because the cooling rate of electron beam welded joint was fast, the liquid metal in the weld first crystallized to form β phase, the β phase was too late to transform into α phase as the temperature of joint sustained decreased rapidly, and only transformed into supersaturated α′ phase. Therefore, the weld zone formed a great deal of dispersed acicular martensite α′ phase.

Fig. 4 Microstructure of weld zone

Fig. 5 XRD pattern of weld surface

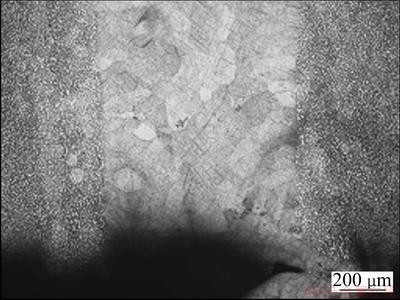

3.2.3 Microstructure of heat affected zone

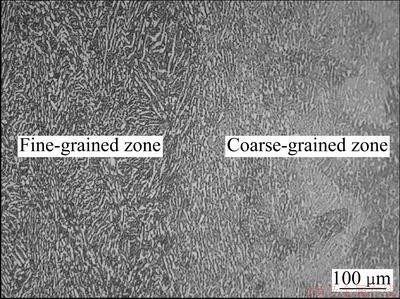

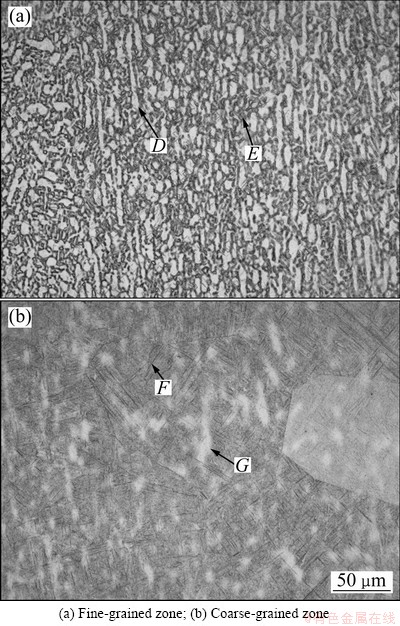

The microstructure of the heat affected zone was between the microstructure of base metal zone and the microstructure of weld zone. The microstructure of the heat affected zone was studied by optical metallographic observation. The microstructure is shown in Fig. 6. It can be seen from Fig. 6 that the heat affected zone was divided into fine-grained zone which was near the base metal zone and coarse-grained zone which was near the weld zone. These two zones were locally amplified as shown in Figs. 7(a) and (b). It can be seen from Fig. 7(a) that the microstructure of fine-grained zone consists of two phases, which are D phase and E phase, respectively. The D phase is primary α phase and the E phase is β phase according to the previous analysis to the microstructure of base metal zone. It can also be found in the fine-grained zone that the amount of primary α phase reduces compared with the base metal zone, the amount of β phase increases significantly, and there is fine equiaxed α phase to precipitate from β phase matrix. This shows that the transformation of α phase to β phase occurred in the zone in the welding process. This is mainly due to the heating of heat source so that the zone reaches the phase transition temperature. But because the fine-grained zone was far away from the heat source, so the temperature was low and the phase transition was not complete. There is still a great deal of primary α phase to retained. In the subsequent cooling process, the fine α equiaxed grains precipitated from the β phase matrix. So the microstructure of fine-grained zone was primary α phase + β phase + equiaxed α phase. It can be seen from Fig. 7(b) that the microstructure of coarse-grained zone also consists of two phases, which are F phase and G phase, respectively. The F phase is α′ phase and the G phase is primary α phase according to the previous analysis on the microstructure of base metal zone and weld zone. It can also be seen in the coarse-grained zone that the amount of primary α phase significantly reduces, and apparent coarsening happens in the grains. This shows that in the zone the transformation of α phase to β phase occurred in the welding process. This is mainly due to the heating of heat source so that the zone reaches the phase transition temperature. And because the coarse-grained zone was near the heat source, the temperature was high and phase transition was complete. So there was less primary α phase to be retained. But under the action of high temperature, the phenomenon of grain growth is serious. However, in the subsequent cooling process, the β phase was too late to transform into equilibrium α phase through atomic diffusion because of the fast cooling rate, it only transformed into acicular martensite α′ phase by the way of shear, and the mode to achieve shear relied on the atoms in β phase regularly short-range migrated. Therefore, the microstructure of coarse-grained zone was primary α phase + α′ phase.

Fig. 6 Microstructure of heat affected zone

3.3 Analysis of welding defect

There is cold shut defect in the incomplete penetration weld root, as shown in Fig. 8, but in the complete penetration weld there is no cold shut, as shown in Fig. 9.

The cold shut was a specific defect of electron beam welding. Electron beam welding is a dynamic process.

Fig. 7 Microstructure of different regions in heat affected zone

Fig. 8 Cold shut in incomplete penetration weld root

Fig. 9 Complete penetration weld root

Under Under the joint action electron beam pressure, metal vapor reaction, molten metal surface tension and hydrostatic pressure, collision and fusion of multi-strand streams in the molten pool existed. On the keyhole tip of incomplete penetration molten pool, the high temperature metal vapor is not easy to leak because the keyhole tip was tip was far away from the molten pool surface, the high temperature metal vapor generated a great impediment to the flow and fusion of liquid metal. At the same time because of small heat input and fast cooling rate of electron beam welding, the streams had solidified before they could overcome the impediment of high temperature metal vapor, therefore in the weld root the penetrating gap occurred, which had a smooth edge called cold shut. However, for complete penetration welds, because the high temperature metal vapor inside the keyhole will leak through the weld root, which has no effect on the fusion of streams, the weld root does not have cold shut.

The above analysis shows that the formation of cold shut is mainly due to the fact that the high temperature metal vapor can not leak weld smoothly, which hinders the fusion of streams. In order to avoid cold shut, the conditions must be created to make the high temperature metal vapor leak the weld smoothly.

The experimental result shows that the cold shut mainly occurred in incomplete penetration welds, yet the complete penetration welds did not have this defect. Therefore, if conditions are allowed, the welds of titanium alloy electron beam welding should try to be penetrated.

4 Conclusions

1) The microstructure of weld zone is martensite α′ phase; the heat affected zone consists of fine-grained zone and coarse-grained zone, the microstructure of fine-grained zone was primary α phase + β phase + equiaxed α phase, and the microstructure of coarse-grained zone was primary α phase + α′ phase. The microstructure of base metal zone basically consists of long strip and block primary α phase, and a small amount of residual β phase sprinkled.

2) The formation reason of cold shut was mainly due to the fact that the high temperature metal vapor could not leak weld smoothly, which obstructed flow and fusion of the liquid metal, the liquid metal could not be fully integrated before solidification under the condition of rapid cooling, therefore, in the weld root the penetrating gap formed, which had a smooth edge called cold shut.

3) For avoiding cold shut, the weld of titanium alloy electron beam welding should try to be penetrated if the conditions were permissible.

References

[1] LI Liang, SUN Jian-ke, MENG Xiang-jun. Application state and prospects for titanium alloys [J]. Titanium Industry Progress, 2004, 21(5): 19-24. (in Chinese)

[2] LUO Guo-zhen. Research and development review for titanium [J]. Rare Metal Materials and Engineering, 1993, 22(5): 19-28. (in Chinese)

[3] LI Xing-yuan, SHA Ai-xue, ZHANG Wang-feng, CHU Jun-peng, MA Ji-min. TA15 titanium alloy and its applying prospects on airframe [J]. Titanium Industry Progress, 2003, 20(4): 90-94. (in Chinese)

[4] WEN Hua-li. New trend of titanium production technology and use development in the world [J]. Light Metals, 1997(8): 4-7. (in Chinese)

[5] ZHANG Bing-gang, WANG Ting, CHEN Guo-qing, LIU Cheng-lai, LIU Yu-long. Electron beam welding of TC21 titanium alloy with large thickness [J]. Transactions of the China Welding Institution, 2009, 30(11): 5-8. (in Chinese)

[6] DU Xin, LIU Li-ming, SONG Guang, WANG Min, YANG Lei. Analysis on repair welding microstructure feature of TAl5 welded joint [J]. Transactions of the China Welding Institution, 2005, 26(2): 45-48. (in Chinese)

[7] XU Wen-chen, SHAN De-bin, WANG Zhen-long, YANG Guo-ping,  Yan, KANG Da-cheng. Effect of spinning deformation on microstructure evolution and mechanical property of TA15 titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1205-1211.

Yan, KANG Da-cheng. Effect of spinning deformation on microstructure evolution and mechanical property of TA15 titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1205-1211.

[8] LI S K, XIONG B Q, HUI S X. Effects of cooling rate on the fracture properties of TA15 ELI alloy plates [J]. Rare Metals, 2007, 26(1): 33-38.

[9] SARESH N, GOPALAKRISHNA P M, MATHEW J. Investigations into the effects of electron beam welding on thick Ti-6Al-4V titanium alloy [J]. Journal of Materials Processing Technology, 2007, 192-193: 83-88.

[10] HU Mei-juan, LIU Jin-he. Numerical simulation for electron beam welding of 12 mm-thickness titanium alloy plate [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1622-1626. (in Chinese)

[11] ZHAO Z L, GUO H Z, CHEN L, YAO Z K. Superplastic behaviour and microstructure evolution of a fine-grained TA15 titanium alloy [J]. Rare Metals, 2009, 28(5): 523-527.

[12] GALATOLO R, LANCIOTTI A. Fatigue crack propagation in residual stress fields of welded plates [J]. International Journal of Fatigue, 1997, 19(1): 43-49.

[13] BARREDA J L,  F, AZPIROZ X, IRISARRI A M, VARONA J M. Electron beam welded high thickness Ti6Al4V plates using filler material of similar and different composition to the base plate [J]. Vacuum, 2001, 62: 143-150.

F, AZPIROZ X, IRISARRI A M, VARONA J M. Electron beam welded high thickness Ti6Al4V plates using filler material of similar and different composition to the base plate [J]. Vacuum, 2001, 62: 143-150.

[14] ZHU Jing-chuan, WANG Yang, LIU Yong, LAI Zhong-hong, ZHAN Jia-jun. Influence of deformation parameters on microstructure and mechanical properties of TA15 titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(s1): 490-494.

[15] LI Xing-zhi, HU Shu-bing, XIAO Jian-zhong, WANG Ya-jun, LI Qing-hua, JI Long-bo. Study on fatigue crack propagation in different zones of TAl5 electron beam welded joint [J]. Journal of Aeronautical Materials, 2010, 30(1): 52-56. (in Chinese)

[16] GUO Zhi-jun, WANG Jian, WANG Hong-wu. Effects of deformation parameters on microstructures and mechanical properties of TA15 alloy plate [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(s1): 40-42. (in Chinese).

钛合金电子束深熔焊接头的组织及缺陷

张秉刚1,石铭霄2,陈国庆1,冯吉才1

1. 哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001;

2. 兰州理工大学 材料科学与工程学院,兰州 730050

摘 要:对大厚度钛合金电子束焊接接头的显微组织、相组成和冷隔缺陷进行研究。结果表明,焊缝区组织为马氏体α′相;热影响区由细晶区和粗晶区两部分组成,细晶区组织为初生α相+β相+等轴α相,粗晶区组织为少量的初生α相+针状α′相;母材区组织基本上都是长条状和块状的初生α相,其间分布着少量残余β相。对冷隔的形成原因进行了分析,并提出了预防措施。

关键词:TA15钛合金;电子束焊;显微组织;相成分;冷隔缺陷;焊缝区;热影响区

(Edited by YANG Hua)

Foundation item: Project (2010CB731704) supported by the National Basic Research Program of China

Corresponding author: SHI Ming-xiao; Tel: +86-15114682208; Fax: +86-451-86412911; E-mail: hero-4587@163.com

DOI: 10.1016/S1003-6326(11)61510-0