文章编号:1004-0609(2016)02-0310-07

预热对激光沉积修复TA15钛合金形貌尺寸和组织的影响

卞宏友1,雷 洋1,李 英2,杨 光1,钦兰云1,王 维1

(1. 沈阳航空航天大学 航空制造工艺数字化国防重点学科实验室,沈阳 110136;

2. 中航工业沈阳黎明航空发动机(集团)有限公司 焊接研究所,沈阳 110043)

摘 要:采用感应加热装置实现激光沉积修复基材的预热,完成基材预热下的激光沉积修复试验,研究不同基材预热温度对试样形貌尺寸、显微组织及硬度的影响规律。结果表明:基材预热后的沉积试样表面更加平整,试样熔宽和熔高有所增大;随着预热温度的升高,沉积试样底部的柱状晶越粗壮、尺寸越短,顶部的枝晶数量越少,显微组织中片层α组织越粗大;且沉积试样显微硬度轻微降低。基材预热可明显改善沉积质量。

关键词:TA15钛合金;激光沉积修复;预热;形貌尺寸;显微组织;显微硬度

中图分类号:TG456.7;TG155.2;TG113 文献标志码:A

激光沉积修复技术(Laser deposition repair,LDR)是基于层层叠加制造原理,以激光为热源,对同轴输送的金属粉末材料按照规划的扫描路径实现逐层熔化沉积的技术。它具有热影响区小、自动化程度高、工艺重复性好以及可实现缺损部位近净成形修复等优点,在钛合金等贵重金属零件快速修复方面具有明显的技术优势和巨大的应用前景[1-4]。

激光沉积过程中热传递遍历逐点、逐道、逐层堆积加工的始末。沉积过程的温度场分布对于沉积工件的形貌尺寸、显微组织有直接的影响,进而影响沉积工件的力学性能。同时沉积过程中所具有的能量集中输入、快速加热冷却等特点,使得沉积工件内部以及工件与基材间存在着巨大的温度梯度,进而产生热应力,当热应力达到材料极限时,工件将产生裂纹甚至发生断裂。基材预热是解决这一问题的有效途径之一,对基材预热可有效降低沉积过程中试样与基材的温度梯度,使沉积过程温度场分布更加均匀稳定[5-6]。

与传统的火焰加热、电阻加热等预热方式相比,感应加热的热源和受热物体不直接接触,具有非接触加热、输入热量易于控制、加热效率高、感应加热器可根据加热工件形状及位置进行仿形设计,实现局部加热等优点[7]。FARAHMAND等[8]研究发现,激光熔覆与感应加热复合不仅提高了熔覆层的均匀性及光滑度,而且显微组织得到改善;黄永俊[9]研究发现感应加热可以提高激光熔覆的沉积效率,形成与基体呈良好冶金结合的无裂纹熔覆层;林涛等[10]针对感应加热消除不锈钢管焊接应力进行模拟,指出感应加热易于操作和控制,消除残余应力效果更明显。

本文作者采用感应加热装置对激光沉积修复基材进行预热,研究不同基材预热温度对修复试样形貌尺寸、显微组织及硬度的影响规律。

1 实验

激光沉积修复TA15钛合金试样是在沈阳航空航天大学构建的LDM-800系统上完成,该系统由6 kW光纤激光器、悬臂式三轴平移运动系统、集成冷却和保护气系统的同轴熔覆头、双桶送粉器、气体循环净化系统以及氩气保护箱等组成。

预热采用的感应加热装置包括:通过调节电流(最大输入电流为37 A)来控制加热温度及加热速度的高频(30 kHz)感应加热设备;可根据试样修复部位的实际形状进行仿形设计制造的感应加热器;对试样加热温度进行实时监测的红外热像仪(测温范围:200~1500 ℃,最大采样帧频为50 Hz)。

试验采用厚度为5 mm的TA15钛合金基材。试验前用砂纸打磨掉表面的氧化皮,并用丙酮和酒精清洗干净并烘干。选用粉末粒度分布为44~149 μm的球形粉末TA15作为沉积材料,粉末化学成分见表1,粉末采用真空烘干处理。

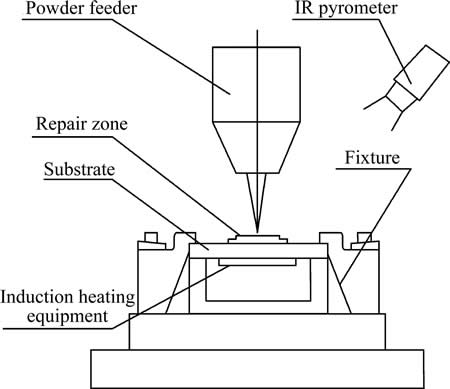

激光沉积修复过程中,感应加热装置将基材加热到预定温度并保持温度恒定,然后进行修复试验。预热下激光沉积修复示意图如图1所示。试验工艺参数如表2所列。

采用Olympus GX51型光学金相显微镜对试样金相进行显微组织观察分析;采用HXZ-1000型显微硬度计测试显微硬度,载荷为9.8 N,保载时间为12 s。

图1 预热下激光沉积修复示意图

Fig. 1 Schematic diagram of laser deposition repair under induction heating

2 结果与分析

2.1 形貌分析

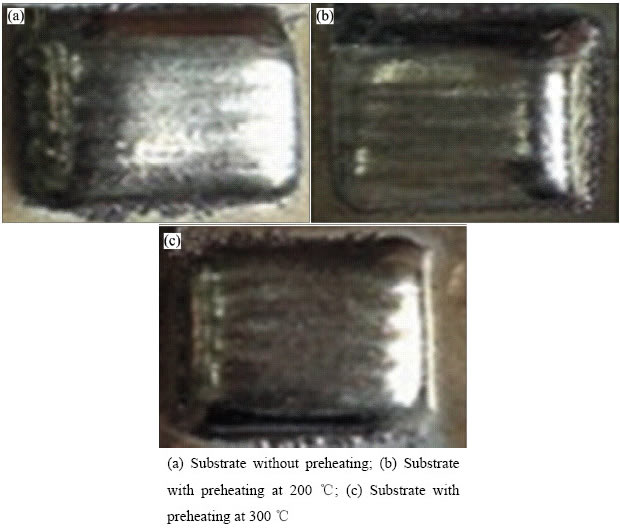

图2和3所示分别为不同预热温度下单道单层(各图中下面的沉积道)、单道六层(各图中上面的沉积道)、多道七层的沉积试样形貌,沉积试样表面没有裂纹和气孔等缺陷。预热单道试样时发生不同程度的氧化现象,预热温度越高,氧化越严重。对于多道七层沉积试样,基材未预热时的沉积试样表面沟壑分明,基材预热的沉积试样表面变得较为平整,颗粒状物质减少,同时宽度大小整体上趋向均匀。主要原因是基材预热使基材吸收激光的能量增加,熔池增大,提高了沉积率,而且表面质量得到一定的改善[11]。沉积试样表面的氧化层厚度仅有几个微米,下一层沉积时会把上一沉积层顶部重熔,氧化层自然熔失,最后一层的氧化层,通过后续机械加工即可去除,不会影响试样性能。

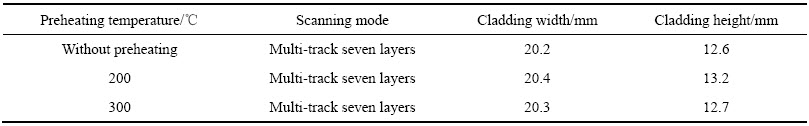

2.2 尺寸分析

表3和4所列为分别是不同预热温度下单道单层和单道六层以及多道七层熔宽、熔高的平均尺寸。由表3和4中数据分析可知,基材预热后,沉积试样的熔覆宽度和熔覆高度(分别简称熔宽、熔高)有所增大。因为金属材料对激光的吸收系数(At)随着基材预热温度(t)的升高而提高,其变化规律如式(1)所示:

表1 TA15钛合金的化学成分

Table 1 Chemical composition of TA15 titanium alloy (mass fraction, %)

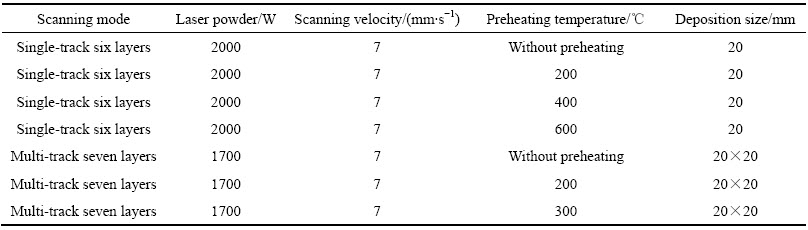

表2 激光沉积修复试验工艺参数

Table 2 Process parameters of laser deposition repair experiment

图2 不同预热温度下单道沉积试样的形貌

Fig. 2 Single-track deposition morphologies of samples at different preheating temperatures

图3 不同预热温度下多道沉积试样的形貌

Fig. 3 Multi-track deposition morphologies of samples at different preheating temperatures

(1)

(1)

式中: 是一个常数[12];一般情况下,A1000 ℃≤ 5A20 ℃,多数金属的吸收系数At≈1×105~1×106 cm-1。因此,在工艺参数一定的条件下,预热使得基材吸收激光的

是一个常数[12];一般情况下,A1000 ℃≤ 5A20 ℃,多数金属的吸收系数At≈1×105~1×106 cm-1。因此,在工艺参数一定的条件下,预热使得基材吸收激光的

能力增强,熔池尺寸会有一定增加,熔宽、熔高有所增大,有利于提高沉积效率。

将单道单层沉积尺寸与单道六层的平均尺寸进行对比,分析发现六层沉积的宽度比单层沉积的宽度大,

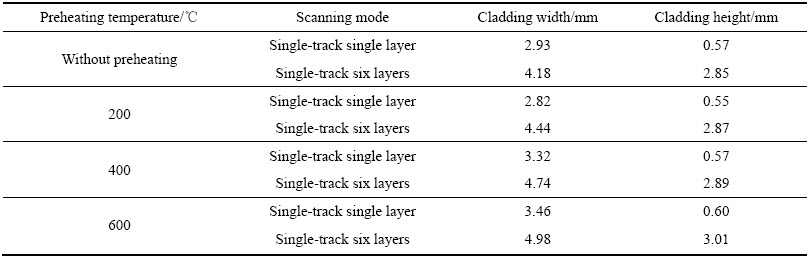

表3 单层沉积与单道六层的熔宽熔高

Table 3 Cladding width and cladding height of single layer and six layers

表4 多道七层的熔宽熔高

Table 4 Cladding width and cladding height of multi-track seven layers

而六层沉积平均高度要比单层沉积的高度小,六层平均高度约为0.48 mm,小于任一个单层高度。因为随着沉积层数的增加,热量不断累积,材料内部的温度逐渐升高,最初几层时,熔池距离基材较近,散热较快,熔池快速冷却并凝固;而随着沉积层数的增加,热量累积使基材温度逐渐提高,所以熔池的尺寸越来越大,吞噬金属粉末数量的能力增强,沉积宽度增加。因此,在相同工艺条件下,与单层沉积宽度相比,多层沉积宽度更大。

预热后多道七层的熔宽变化较小,熔高变化相对更明显,基材预热200 ℃下,熔高增加0.6 mm,变化量约为未预热时的4.8%;熔宽增加0.2 mm,变化量约为未预热时的1.0%,表明了基材预热后,沉积效率相应提高。

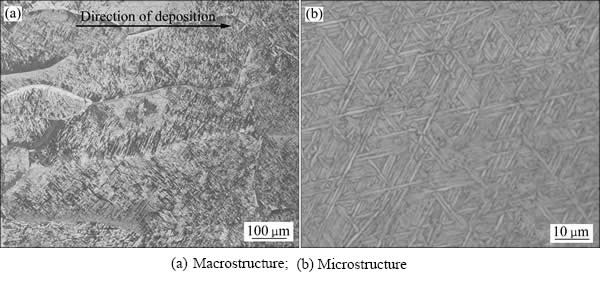

2.3 组织分析

采用线切割将试样的1/4部位切成块,经打磨、抛光,并采用Kroll腐蚀剂及体积比为1:6:7的HF-HNO3-H2O溶液化学腐蚀后制成金相试样。图4~6所示分别为基材未预热、200 ℃、300 ℃预热下激光沉积修复TA15的OM像。

由图4~6所示,基材预热后试样宏观组织没有明显变化,都是由贯穿多个沉积层的粗大β初生柱状晶所组成。其形成原因是在激光熔池冷却过程中,熔池中绝大部分热量以热传导的方式通过基材沿垂直向下

图4 基材未预热下激光沉积修复TA15的OM像

Fig. 4 OM images of laser deposition repair TA15 titanium alloy under substrate without preheating

图5 基材预热200 ℃下激光沉积修复TA15的OM像

Fig. 5 OM images of laser deposition repair TA15 titanium alloy under substrate with preheating at 200 ℃

图6 基材预热300 ℃下激光沉积修复TA15的OM像

Fig. 6 OM images of laser deposition repair TA15 titanium alloy under substrate with preheating at 300 ℃

的方向散失,晶体逆着热流向上定向生长并形成柱状晶。但由于从激光熔池底部到顶部,温度梯度逐渐降低,凝固速度减小,温度梯度的方向由底部垂直扫描方向逐渐转变为顶部的接近平行扫描方向,使得在熔池顶部出现柱状晶到等轴晶的转变[13]。

在沉积试样组织中,可清楚地看到平行于激光扫描方向的沉积层间层带,层带现象主要是前一沉积层所析出的α板条在后一沉积层沉积时,前一沉积层顶部的熔池热影响区的α板条受热粗化造成的[14]。从图4~6中可以看出基材预热温度越高,沉积试样底部的柱状晶形态越粗大,尺寸越短;而顶部的柱状枝晶数量越少。

沉积试样显微组织无明显变化,均为由片状初生α相和片状α相间薄片β相所组成的网篮组织,但是可以明显看出,基材预热下沉积的TA15钛合金试样,其网篮组织中的片状α和β相的长宽比相对较大,片层α组织随着预热温度的升高而发生粗化。主要原因是在无预热的条件下熔池的冷却速率较快,而基材预热后沉积试样与基材温度梯度变小,熔池冷却时间也相应延长;另外激光沉积修复过程中处于热影响区位置的基材受到下一沉积层的加热作用,相当于进行退火处理,导致α组织生长更加充分而变得粗大。

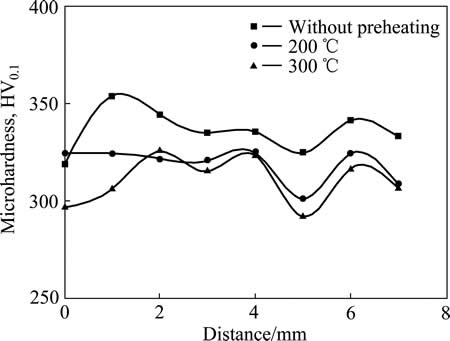

2.4 硬度分析

图7所示为基材在未预热,预热200 ℃、300 ℃沉积试样显微硬度变化曲线。第一测试点的位置位于沉积层与基材结合界面1 mm 处,以后各点分别以 0.1 mm 的增量沿垂直于结合界面向沉积生长的方向取点测试。可以看出,沉积试样显微硬度值变化不大,随着预热温度的升高,沉积试样显微硬度呈现轻微的下降趋势,但是平均硬度整体上很接近,最大硬度差为25 HV0.1。这是因为基材预热温度越高,造成输入的热量增多,激光沉积修复完成之后,冷却速率变慢,而高的硬度值需要高的冷却速率[15],所以基材预热温度越高,显微硬度值越低。

图7 不同温度下预热基材显微硬度变化曲线

Fig. 7 Microhardness curves of substrate with preheating at temperatures

3 结论

1) 基材预热后的沉积试样表面更加平整,试样的熔宽和熔高有所增大。

2) 基材预热后的沉积试样宏观组织没有明显变化,都是由贯穿多个沉积层的粗大β初生柱状晶组成;显微组织为典型的网篮状组织,随着基材预热温度升高,其组织中的片状α和β相的长宽比相对较大,且片层α组织变得粗大。

3) 基材预热温度升高,沉积试样显微硬度呈现轻微下降趋势。

REFERENCES

[1] 王华明, 张述泉, 王向明. 大型钛合金结构件激光直接制造的进展与挑战[J]. 中国激光, 2009, 36(12): 3204-3209.

WANG Hua-ming, ZHANG Shu-quan, WANG Xiang-ming. Progress and challenges of laser direct manufacturing of large titanium structural components[J]. Chinese Journal of Lasers, 2009, 36(12): 3204-3209.

[2] 黄卫东, 林 鑫. 激光立体成形高性能金属零件研究进展[J]. 中国材料进展, 2010, 29(6): 12-27.

HUANG Wei-dong, LIN Xin. Research progress in laser solid forming of high performance metallic component[J]. Materials China, 2010, 29(6): 12-27.

[3] 席明哲, 张永忠, 石力开, 程 晶. 激光快速成型致密金属零件的研究[J]. 北京科技大学学报, 2002, 24(4): 441-444.

XI Ming-zhe, ZHANG Yong-zhong, SHI Li-kai, CHENG Jing. Investigation on the fully dense metal part by laser rapid prototyping[J]. Journal of University of Science and Technology Beijing, 2002, 24(4): 441-444.

[4] 苏海洋, 尉凯晨, 郭 伟, 马菱薇, 于瑞龙, 张 冰, 张 军, 刘 林, 傅恒志. 激光快速成形技术新进展及其在高性能材料加工中的应用[J]. 中国有色金属学报, 2013, 23(6): 1567-1574.

SU Hai-yang, WEI Kai-chen, GUO Wei, MA Ling-wei, YU Rui-long, ZHANG Bing, ZHANG Jun, LIU Lin, FU Heng-zhi. New development of laser rapid forming and its application in high performance materials processing[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1567-1574.

[5] 苏荣华, 刘伟军, 龙日升. 不同基板预热温度对激光金属沉积成形过程温度场的影响[J]. 工程设计学报, 2009, 16(1): 44-49.

SU Rong-hua, LIU Wei-jun, LONG Ri-sheng. Effects of different substrate preheating temperature on temperature field during laser metal deposition shaping[J]. Journal of Engineering Design, 2009, 16(1): 44-49.

[6] 龙日升, 刘伟军, 邢 飞, 王华兵, 卞宏友. 基板预热对激光金属沉积成形过程热应力的影响[J]. 机械工程学报, 2009, 45(10): 241-247.

LONG Ri-sheng, LIU Wei-jun, XING Fei, WANG Hua-bing, BIAN Hong-you. Effects of substrate preheating on thermal stress during laser metal deposition shaping[J]. Journal of Mechanical Engineering, 2009, 45(10): 241-247.

[7] 卞宏友, 韩双隆, 李 英, 杨 光, 钦兰云, 王 维, 赵翔鹏. 感应加热参数对激光沉积修复基板温度场的影响[J]. 激光与光电子学进展, 2014, 51: 111403-1-7.

BIAN Hong-you, HAN Shuang-long, LI Ying, YANG Guang, QIN Lan-yun, WANG Wei, ZHAO Xiang-peng. Effect of different induction heating parameters on the substrate temperature field during laser deposition repair[J]. Laser& Optoelectronics Progress, 2014, 51: 111403-1-7.

[8] FARAHMAND P, LIU S, ZHANG Z, KOVACEVIC R. Laser cladding assisted by induction heating of Ni-WC composite enhanced by nano-WC and La2O3[J]. Ceramics International, 2014, 40(10): 15421-15438.

[9] 黄永俊. 激光-感应复合熔覆工艺及机理研究[D]. 武汉: 华中科技大学, 2009.

HUANG Yong-jun. Study on technology and mechanism of laser-induction hybrid cladding[D]. Wuhan: Huazhong University of Science & Technology, 2009.

[10] 林 涛, 陈怀宁, 刘 英. 感应加热消除不锈钢管焊接应力数值模拟[J]. 压力容器, 2009, 26(5): 38-43.

LIN Tao, CHEN Huai-ning, LIU Ying. Simulation of relieving welding residual stresses in the girth-weld stainless steel tube by induction heating method[J]. Pressure Vessel Technology, 2009, 26(5): 38-43.

[11] 周圣丰, 曾晓雁, 胡乾午, 黄永俊. 激光-感应复合熔覆Ni基WC复合层的工艺研究[J]. 激光技术, 2009, 33(2): 124-126.

ZHOU Sheng-feng, ZENG Xiao-yan, HU Qian-wu, HUANG Yong-jun. Process study of Ni-based WC composite coatings by means of laser-induction hybrid cladding[J]. Laser Technology, 2009, 33(2): 124-126.

[12] 张永康, 周建忠, 叶云霞. 激光加工技术[M]. 北京: 化学工业出版社, 2004: 51-53.

ZHANG Yong-kang, ZHOU Jian-zhong, YE Yun-xia. Laser processing technology[M]. Beijing: Chemical Industry Press, 2004: 51-53.

[13] 张小红, 林 鑫, 陈 静, 黄卫东. 热处理对激光立体成形TA15合金组织及力学性能的影响[J]. 稀有金属材料与工程, 2011, 40(1): 142-147.

ZHANG Xiao-hong, LIN Xin, CHEN Jing, HUANG Wei-dong. Effects of heat treatment on the microstructures and mechanical properties of TA15 titanium alloys by laser solid forming[J]. Rare Metal Materials and Engineering, 2011, 40(1): 142-147.

[14] QIAN Ting-ting, LIU Dong, TIAN Xiang-jun, LIU Chang-meng, WANG Hua-ming. Microstructure of TA2/TA15 graded structural material by laser additive manufacturing process[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2729-2736.

[15] 孔 源. 激光快速成形方法制备金属零件关键技术研究[D]. 沈阳: 中国科学院沈阳自动化研究所, 2012: 87.

KONG Yuan. Research on the key technology of produce metal parts by laser rapid prototyping method[D]. Shenyang: Shenyang Institute of Automation, Chinese Academy of Sciences, 2012: 87.

Effects of preheating on morphology size and microstructure of laser deposition repair TA15 titanium alloy

BIAN Hong-you1, LEI Yang1, LI Ying2, YANG Guang1, QIN Lan-yun1, WANG Wei1

(1. Shenyang Aerospace University, Key Laboratory of Fundamental Science for National Defence of Aeronautical Digital Manufacturing Process, Shenyang 110136, China;

2. Welding Laboratory, AVIC Shenyang Liming Aero-Engine (Group) Corporation Ltd., Shenyang 110043, China)

Abstract: Laser deposition repair (LDR) experiments under substrate with preheating were completed assisted by induction heating equipment. The morphology sizes and microstructures of LDR TA15 titanium alloy with different preheating temperatures were characterized, and the microhardness of the deposition layers was tested. The results show that after the substrate is preheated, the deposition layer surface is smoother, cladding width and cladding height are increased. With increasing preheating temperature, macrostructure of the columnar crystal is thicker and shorter at the bottom, the amount of dendritic crystal at the top is reduced, microstructure of lamella α becomes thicker, furthermore, the microhardness is slightly reduced. The substrate with preheating can obviously improve the deposition layer quality.

Key words: TA15 titanium alloy; laser deposition repair; preheating; morphology size; microstructure; microhardness

Foundation item: Projects(51375316, 51305280) supported by the National Natural Science Foundation of China; Project(201202173) supported by the Natural Science Foundation of Liaoning Province, China; Project(2014ZE54028) supported by Aeronautical Science Foundation of China; Project(L2014054) supported by Scientific Research of Higher Education of Liaoning Province, China

Received date: 2015-06-09; Accepted date: 2015-11-20

Corresponding author: BIAN Hong-you; Tel: +86-18040036511; E-mail: bianhongyou@sau.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51375316,51305280);辽宁省自然科学基金资助项目(201202173);航空科学基金资助项目(2014ZE54028);辽宁省高等学校科学研究(L2014054)

收稿日期:2015-06-09;修订日期:2015-11-20

通信作者:卞宏友,副教授,博士;电话:18040036511;E-mail: bianhongyou@sau.edu.cn