文章编号: 1004-0609(2005)12-1910-07

TA15钛合金接头活性剂补焊的组织特征

刘黎明1, 杜 鑫1, 张兆栋1, 王 敏2, 李 锋2

(1. 大连理工大学 三束材料表面改性国家重点实验室, 大连 116024;

2. 沈阳飞机制造有限公司 制造工程部, 沈阳 110034)

摘 要: 采用现代测试手段分析TA15钛合金活性剂补焊接头微观组织特征, 探讨钛合金焊缝采用活性剂多次补焊的可行性。 结果表明: 涂有活性剂补焊接头各区域结合良好, 热影响区域小且与焊缝区过渡平缓, 没有出现明显分界; 涂活性剂焊缝区晶内组织并未因补焊次数的增加而粗大; 焊缝接头主要元素Ti、 Al、 Mo、 V和Zr均分布均匀, 没有因采用活性剂而出现烧损和偏聚的现象; 室温下补焊焊缝组织由α-Ti组成; 涂活性剂焊缝各补焊区硬度值接近, 略低于正常焊缝区硬度。 采用活性剂对钛合金可以进行多次补焊并能够获得高质量焊缝。

关键词: TA15钛合金; 钨极氩弧焊; 活性剂; 补焊; 组织特征 中图分类号: TG403

文献标识码: A

Microstructure analysis of ctivated repair welding joint of TA15 titanium alloy

LIU Li-ming1, DU Xin1, ZHANG Zhao-dong1, WANG Min2, LI Feng2

(1. State Key Laboratory of Material Surface Modification by Laser,

Ion and Beams, Dalian University of Technology, Dalian 116024, China;

2. Department of Manufacturing Engineering,

Shenyang Aircraft Corporation, Shenyang 110034, China)

Abstract: The microstructure characteristics of TA15 titanium alloy joint multiple repaired with activated flux were analyzed by modern testing means. The results show that the interfaces of each repair zone welded with flux are joined well, the HAZ is narrow and the area from HAZ to bead transits smoothly. The microstructure of welding intracrystalline repair welded with flux does not grow up with increasing time. The major elements Ti, Al, Mo, V and Zr within the weld are distributed symmetrically, and the melting loss and segregation do not appear. In the room temperature repair joint structure is composed of α-Ti. Meanwhile the micro-rigidities of each repair zone are parallel, and are a bit lower than initial weld zones. The repair welding of TA15 titanium alloy with flux is a mending method which can obtain high quality repairing bead.

Key words: TA15 Ti alloy; gas tungsten arc welding; flux; repair welding; structure character

钛合金具有比强度大, 密度小、 耐高温等优点, 被广泛的应用于航天、 航空等领域, 特别是钛合金作为飞机结构件而被大量使用, 使飞机结构效率大幅度提高[1-5]。 飞机结构件之间需要采用焊接的方法连接起来, 但是钛合金焊接过程中焊接接头经常出现气孔、 夹杂、 裂纹、 未焊透等缺陷[1, 6], 以及在服役过程中焊接接头易于磨损, 这就使结构件的使用寿命减短, 同时也对飞机的飞行安全构成严重威胁。 由于飞机结构件成本非常高, 换掉带有缺陷的结构件将造成很大经济损失, 为此, 对结构件有缺陷焊缝采用补焊方法进行修复, 从而延长结构件使用寿命, 降低成本。

目前, 国内外焊接界的学者对一些金属材料(尤其是钢类)焊缝补焊接头已经进行了研究, 其主要侧重在补焊接头的力学性能等方面[7-12], 对钛合金焊缝进行多次补焊后的接头组织研究尚未见报道。 由于活性剂除了具有增加熔深的作用外, 还可以大幅度地消减焊缝产生的气孔、 提高焊接效率, 同时也会对焊缝成形、 性能和组织产生影响[13-16], 更重要的是采用活性剂进行补焊不需对缺陷部位进行钻孔清除。 本文作者对钛合金活性焊剂多次补焊接头组织特征进行研究, 探索钛合金活性焊剂多次补焊的可行性, 这对优质、 多次修复钛合金结构件具有理论指导意义。

1 实验

1.1 材料

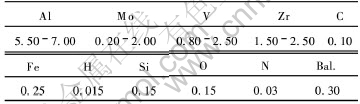

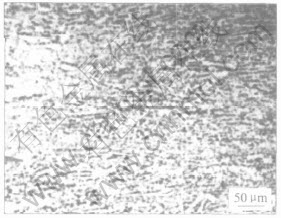

实验选用厚度为2.5mm国产TA15钛合金板材, 其化学成分见表1, 母材组织为轧制纤维状组织, 其显微组织如图1所示。 采用氩弧焊填丝焊, 活性剂为自制混合活性剂, 其主要成分为CaF2, 选用纯度为99.99%的高纯氩做保护气体, 并对被焊试件采用三重气体保护: 喷嘴、 背面和拖罩。

表1 母材TA15的化学成分

Table 1 Chemical composition of base metal(TA15)(mass fraction, %)

图1 母材的微观组织

Fig.1 Microstructure of base metal

1.2 实验方法

首先, 将粉末状活性剂用无水乙醇混合成悬浊液, 用扁平毛刷将悬浊液均匀涂敷在试件表面, 并擦除待焊表面外的所有残余试剂, 然后将试件放入烘干箱中, 使无水乙醇完全挥发。 采用TIG焊方法, 焊接电流170A, 焊接速度500mm/min, 首先对涂有活性剂的TA15钛合金板材进行正常焊接, 获得钛合金A-TIG焊对接接头, 对正常焊缝假定存在缺陷部位再涂敷活性剂, 然后直接进行一次填丝补焊, 再对一次补焊焊缝涂活性剂进行二次补焊, 重复上述操作, 最终获得三次活性补焊试样, 三次补焊焊接电流均为120A。

制备未涂活性剂三次补焊试样, 首先采用焊接电流230A, 焊接速度500mm/min进行正常焊接, 对正常焊缝假定存在缺陷部位钻孔清除, 进行一次填丝补焊, 再对一次补焊焊缝局部钻孔清除进行二次填丝补焊, 重复上述操作, 最终获得未涂活性剂的三次补焊试样, 三次补焊焊接电流均为160A。

焊后采用光学显微镜、 电子探针和X射线衍射)等分析测试手段对接头进行微观组织观察、 微区成分和相组成分析实验。

2 结果与分析

2.1 焊接接头的组织分析

为分析活性剂对多次补焊的影响, 选取焊接接头为三次活性剂补焊接头。 沿垂直于焊缝方向取样, 将制备好的金相试样用含HF、 HNO3混合溶液腐蚀, 在光学显微镜下观察焊接接头的组织。

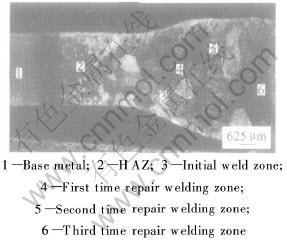

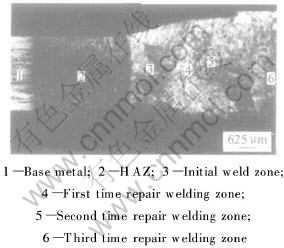

图2和3所示分别为涂有活性剂和未涂活性剂的三次补焊焊接接头宏观组织。 焊接接头均由母材、 热影响区、 正常焊接区、 一次补焊区、 二次补焊区和三次补焊区组成。 采用未涂活性剂补焊时需先将缺陷部分钻孔清理然后再进行填丝补焊, 因此未涂活性剂补焊接头中正常焊缝区与补焊区、 补焊区与补焊区之间分界比较清晰, 如图3所示。 另外, 未涂活性剂补焊接头的热影响区与焊缝区分界也很明显, 且热影响区范围较宽, 宽度为3.8mm。 涂有活性剂补焊时由于不需钻孔就可以直接进行填丝补焊, 所以涂有活性剂补焊接头中正常焊缝区与补焊区、 补焊区与补焊区之间没有明显分界, 如图2所示。 同时, 涂有活性剂补焊接头焊缝与母材结合状态良好, 热影响区向焊缝过渡均匀, 热影响区的范围也较窄, 宽度为2.9mm, 较未涂活性剂范围减小23%; 在补焊接头晶粒尺寸方面涂有活性剂补焊接头则较未涂活性剂补焊接头略有不足, 涂有活性剂接头晶粒尺寸略大于未涂活性剂的。 一般来说, 热影响区是焊接接头较为薄弱的环节, 而由于多次补焊的缘故, 热影响区反复受到焊接电弧热作用, 使这种危险程度大大增加, 而涂活性剂后, 由于焊接电弧收缩, 使电弧对母材热作用范围缩小, 从而使热影响区域变窄, 这在很大程度上降低了这一薄弱环节的危险性, 但同时由于电弧的收缩, 能量集中, 补焊方式又是采用局部点补焊, 使焊接电弧能量较未涂时更加集中, 致使涂有活性剂补焊接头晶粒较未涂活性剂补焊接头晶粒略微粗大。 对于补焊来讲, 与未涂活性剂相比, 补焊区与焊缝区之间熔合状态也是至关重要的, 而涂活性剂使补焊接头补焊区与焊缝区熔合更加良好、 更加均匀; 这些同时也弥补了涂活性剂接头焊缝区晶粒尺寸略大的不足。

图2 涂有活性剂接头的宏观组织

Fig.2 Macrophotograph of joint welded with flux

图3 未涂活性剂接头的宏观组织

Fig.3 Macrophotograph of joint welded without flux

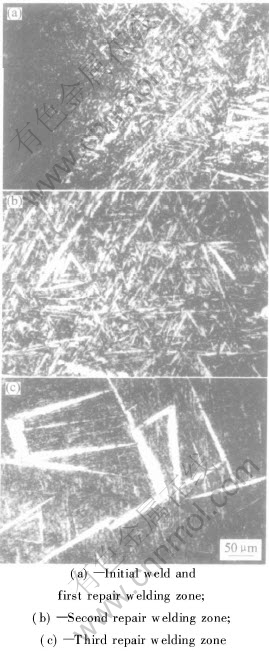

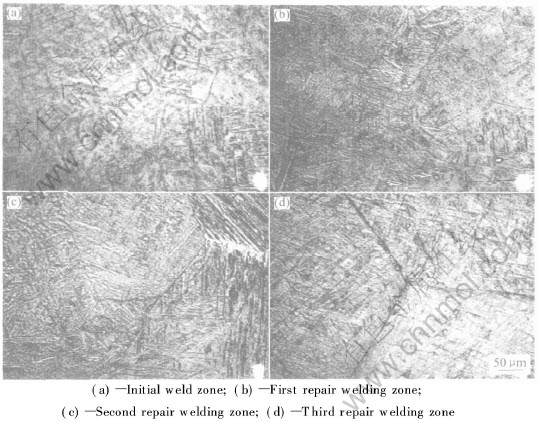

图4和图5分别为未涂活性剂和涂活性剂的三次补焊焊缝区微观组织照片, 图4(a)、 (b)、 (c)所示分别为正常焊接区及一次补焊区、 二次补焊区、 三次补焊区的微观组织, 图5(a)、 (b)、 (c)、 (d)所示分别为正常焊接区、 一次补焊区、 二次补焊区、 三次补焊区的微观组织。 从图4中可以看出, 对于未涂活性剂的钛合金补焊接头各个区域均出现针状α相, 因为高次补焊是在低次补焊或正常焊接区的基础上重新熔化凝固形成, 由于组织遗传性的影响, 在新的补焊熔池凝固过程中, 新补焊区组织沿上次补焊组织形式析出所需能量最低, 因此高次补焊区组织便按低次补焊或正常焊接区组织形式出现, 由于新的热输入量的影响, 进而使高次补焊区组织长大, 这就造成高次补焊区组织均比低次补焊区更为粗大, 其内部的针状α相增多并长大, 图4(c)中尤为明显。 而涂活性剂后, 由于活性剂的存在为晶内α相的形成提供了大量的形核质点, 降低了形核能, 从而使大量α相析出并长大, 在长大过程中α相之间交互相遇, 互相阻碍长大路径, 使α相不能进一步长大, 从而使晶粒内部组织均匀细化, 如图5所示。 对比图4未涂活性剂的焊缝晶内微观组织, 涂有活性剂的焊缝各区组织较未涂焊缝的组织有较为明显的细化现象, 尤其是二次补焊区和三次补焊区最为明显; 图5中, 涂有活性剂的正常焊接区及各补焊区的显微组织均为较细层片状交汇的网篮状组织, 并没有出现随补焊次数的增加组织长大的现象, 更没有出现粗大的α相。 网篮状组织由具有粗大β晶粒和细小α群体的组织构成, 是不同的片相遇时停止长大。 而网篮组织是钛合金各种组织中最为理想的一种, 在常规拉伸性能、 疲劳强度和断裂韧性等方面都具有良好性能, 它保证了补焊接头具有各种使用性能的配合[17]。

图4 未涂活性剂焊缝区的微观组织

Fig.4 Microstructures of joint welded without flux

图5 涂有活性剂焊缝区的微观组织

Fig.5 Microstructures of joint welded with flux

涂活性剂补焊接头宏观及微观组织分析结果证明了采用活性剂对钛合金进行补焊是可行的, 并可以获得具有理想组织的补焊接头。

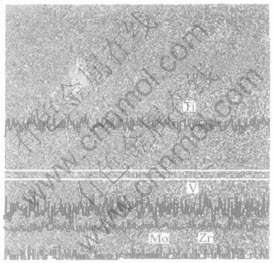

2.2 焊缝区的元素分析

为了分析活性剂钛合金补焊接头元素分布, 使用电子探针对三次补焊焊缝区进行线分析测试, 如图6和7所示, 分别为活性剂补焊后焊缝中心区晶内和晶间的元素分析结果。 可以看出, 无论是在晶内或晶间, Ti、 Al、 Mo、 V和Zr这5种主要元素的线分布都较均匀, 没有出现明显的元素偏聚现象, 这说明同时采用活性剂及补焊并没有使焊缝中主要合金元素Ti、 Al、 Mo、 V、 Zr产生烧损和偏聚。 这一结果进一步表明了钛合金活性剂补焊是可行的。

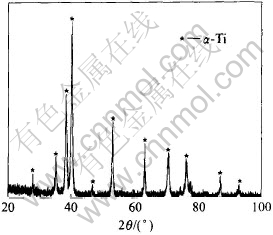

2.3 补焊区相的组成及接头的硬度分析

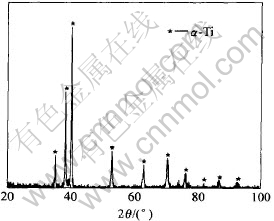

为分析焊缝区的相组成, 检验采用活性剂补焊是否会造成其补焊焊缝相组成与未涂活性剂补焊焊缝相组成存在差异, 为此, 对涂与未涂两种补焊接头均用X射线衍射仪进行了分析, 衍射结果如图8和9所示, 每个衍射峰对应均为α相, 因此两种补焊接头焊缝区相组成均主要由α相构成, 说明涂有活性剂补焊焊缝相组成与未涂活性剂补焊焊缝相组成不存在明显差别。 因为TA15为近α合金, 而所采用的正常焊接的焊丝和补焊焊丝均为α相的合金, 由于焊接时焊缝处的材料成分主要决定于焊丝的成分, 所以在焊缝处的X射线衍射结果为α相。

图6 涂活性剂焊缝晶内元素线分布

Fig.6 Elemental line scanning distribution

of intracrystalline alloy in activited welding bead

图7 涂活性剂焊缝晶间元素线分布

Fig.7 Elemental line scanning distribution of

intercrystalline alloy in activited welding bead

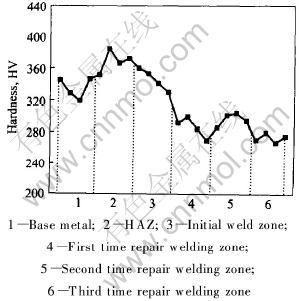

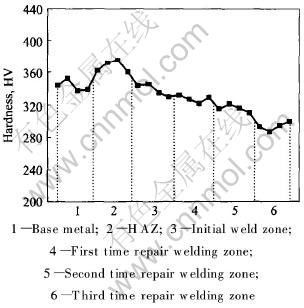

如图10所示, 母材硬度值在HV 320~350之间; 热影响区在各区域的硬度值最高, 在HV 360上下浮动; 正常焊缝区硬度略高于母材, 为HV 330~360; 而一次、 二次、 三次补焊区硬度明显低于正常焊缝区, 三补焊区硬度接近, 均在HV 270~310之间。 对比未涂活性剂补焊接头硬度图11, 涂有活性剂与未涂活性剂接头的热影响区及正常焊接区硬度接近, 而涂有活性剂接头的补焊区硬度则低于未涂活性剂的, 这是由于涂有活性剂接头补焊区晶粒尺寸略大于未涂活性剂接头补焊区晶粒尺寸。 涂活性剂补焊接头和未涂活性剂补焊接头的硬度从正常焊接区到三次补焊区均是呈下降趋势的, 这是因为两种补焊接头的晶粒尺度从正常焊接区到三次补焊区是增大的, 而晶粒内部组织也同样增大, 只是涂活性剂补焊接头晶粒内部组织增大并不十分明显。

图8 涂活性剂补焊接头的X射线衍射谱

Fig.8 XRD pattern of joint repaired with flux

图9 未涂活性剂补焊接头的X射线衍射谱

Fig.9 XRD pattern of joint repaired without flux

图10 涂有活性剂焊接接头的硬度

Fig.10 Hardness of joint repaired with flux

图11 未涂活性剂焊接接头的硬度

Fig.11 Hardness of joint repaired without flux

3 结论

1) 涂有活性剂补焊试样的接头结合状态良好, 热影响区范围较未涂活性剂热影响区范围减小23%; 涂活性剂接头补焊区晶粒尺寸略大于未涂活性剂的晶粒尺寸, 但涂有活性剂的补焊焊缝晶内组织并未因补焊次数的增加而增大, 且较未涂活性剂的组织明显细化, 均为较细层片状交汇的网篮状组织, 未出现针状或锯齿状α-Ti。

2) 涂有活性剂焊缝中主要元素Ti、 Al、 Mo、 V、 Zr分布较均匀, 并没有因采用活性剂补焊而使焊缝中主要合金元素产生烧损和偏聚; 活性补焊焊缝相组成为α相。

3) 涂有活性剂补焊接头的正常焊缝区硬度略低于热影响区, 与母材硬度接近, 而补焊区硬度则明显低于正常焊缝区; 涂活性剂补焊区硬度低于未涂活性剂补焊区硬度。

REFERENCES

[1]中国机械工程学会焊接学会. 焊接手册(2)[M]. 北京: 机械工业出版社, 2001. 580-581.

Chinese mechanical engineering society welding society. Welding Handbook(2)[M]. Beijing: China Machine Industry Press, 2001. 580-581.

[2]董宝明, 郭德伦, 张田仓. 钛合金焊接结构在先进飞机中的应用及发展[J]. 航空材料学报, 2003, 23(增刊): 239-243.

DONG Bao-ming, GUO De-lun, ZHANG Tian-cang. Application and development of titanium alloy weldstructure on advanced aircraft[J]. Journal of Aeronautical Materials, 2003, 23(S): 239-243.

[3]Boyer R. R. An overview on the use of titanium in the aerospace industry[J]. Mater Sci Eng A, 1996, A213: 103-114.

[4]宁兴龙. 俄罗斯航空用钛合金[J]. 钛工业进展, 1999, 4: 19-25.

NING Xing-long. Titanium alloy used in Russian aviation[J]. Titanium Industry Progress, 1999, 4: 19-25.

[5]李梁, 孙健科, 孟祥军. 钛合金的应用现状及发展前景[J]. 钛工业进展, 2004, 21(5): 19-24.

LI Liang, SUN Jian-ke, MENG Xiang-jun. Application state and prospects for titanium alloys[J]. Titanium Industry Progress, 2004, 21(5): 19-24.

[6]American Welding Society. Welding Handbook: Metals and Their Weldability[M]. Miami, Fla: American Welding Society, 1976. 576-577.

[7]Allen D J. Weld repair of steam drum downcomer nozzle cracking in coal-fired power plant[J]. Weld and Metal Fabrication, 1995, 63(6): 225-228.

[8]丁辉, 杨兵, 李晓红, 等. 电站厚壁结构模拟多次修复后残余应力变化的研究[J]. 武汉大学学报, 2001, 34(3): 81-85.

DING Hui, YANG Bing, LI Xiao-hong, et al. Research on residual stress after simulating repetitious repairing of thick wall structure in power plants[J]. Engineering Journal of Wuhan University, 2001, 34(3): 81-85.

[9]李冬霞, 李阳, 贾宝春. 多次补焊工艺及其对高强钢焊接接头力学性能的影响[J]. 中原工学院学报, 2004, 15(2): 24-25.

LI Dong-xia, LI Yang, JIA Bao-chun. The effect of technology of multiple repairing weld on mechanical property of high strength steel weld bead[J]. Journal of Zhongyuan Institute of Technology, 2004, 15(2): 24-25.

[10]刘海涛, 柳春图, 黎之奇, 等. 海洋平台用高强度钢多次补焊的疲劳分析[J]. 机械强度, 2002, 24(3): 433-435.

LIU Hai-tao, LIU Chun-tu, LI Zhi-qi, et al. Fatigue analysis of multiple repairing welding on high strength offshore structure steel[J]. Journal of Mechanical Strength, 2002, 24(3): 433-435.

[11]Bhaduri A K, Gill T P S, Albert S K, et al. Repair welding of cracked steam turbine blades using austenitic and martensitic stainless-steel consumables[J]. Nuclear Engineering and Design, 2001, 206(2): 249-259.

[12]Krishnakumar S, WU Wei-dong. Effect of welding and weld repair on crack propagation behaviour in aluminium alloy 5083 plates[J]. Materials and Design, 2002, 23(2): 201-208.

[13]刘凤尧, 林三宝, 杨春利, 等. TIG焊活性剂对焊缝成形的影响[J]. 焊接学报, 2002, 23(1): 1-3.

LIU Feng-yao, LIN San-bao, YANG Chun-li, et al. Effect of activating fluxes on TIG weld formation[J]. Transactions of the China Welding Institution, 2002, 23(1): 1-3.

[14]林三宝, 杨春利, 刘凤尧, 等. 不锈钢TIG焊活性剂对焊缝性能的影响[J]. 哈尔滨工业大学学报, 2002, 34(3): 308-311.

LIN San-bao, YANG Chun-li, LIU Feng-yao, et al. Effect of activating fluxes on weld properties during TIG welding of stainless steel[J]. Journal of Harbin Institute of Technology, 2002, 34(3): 308-311.

[15]LIU Feng-yao, YANG Chun-li, LIN San-bao, et al. Effect of weld microstructure on weld properties in A-TIG welding of titanium alloy[J]. Trans. Nonferrous Met Soc China, 2003, 13(4): 876-880.

[16]张兆栋, 刘黎明, 沈勇, 等. 镁合金的活性电弧焊接[J]. 中国有色金属学报, 2005, 15(6): 912-916.

ZHANG Zhao-dong, LIU Li-ming, SHEN Yong, et al. Activating flux for arc welding of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 912-916.

[17]Bophcoba E A. 钛合金金相学[M]. 陈石卿, 译. 北京: 国防工业出版社, 1980.

Bophcoba E A. Titanium Alloy Metallography[M]. CHEN Shi-qing, transl. Beijing: National Defence Industry Press, 1980.

基金项目: 教育部新世纪优秀人才支持计划资助项目(NCET-04-0271)

收稿日期: 2005-02-28; 修订日期: 2005-09-26

作者简介: 刘黎明(1967-), 男, 教授, 博士

通讯作者: 刘黎明, 教授; 电话: 0411-84707817; E-mail: Liulm@dlut.edu.cn

(编辑陈爱华)