合理垂直烧结速度的研究

许 斌,常亮亮,姜 涛,郭宇峰,李光辉,杨永斌

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘 要:通过考查气流速度的变化研究垂直烧结速度随烧结过程的变化规律。结果表明:垂直烧结速度并非固定不变,而是随着烧结过程的逐步进行发生显著变化;点火保温后,随烧结物理化学反应的进行,燃烧带逐渐形成并变宽且产生过湿现象,导致料层的透气性显著变差,烧结速度显著下降,直至约25 min后过湿层完全消失,透气性变好,烧结速度迅速上升。根据垂直烧结速度变化规律,通过改变负压烧结,进行烧结速度优化实验,结果表明:在保持转鼓强度及成品率基本不变的情况下,将垂直烧结速度由20.08 mm/min提高到21.82 mm/min,利用系数由1.401 t/(m2?h)提高到1.587 t/(m2?h)。

关键词:烧结;垂直烧结速度;优化

中图分类号:TF046 文献标识码:A 文章编号:1672-7207(2007)02-0245-06

Research of rational vertical sintering speed

XU Bin, CHANG Liang-liang, JIANG Tao, GUO Yu-feng, LI Guang-hui, YANG Yong-bin

(School of Resources Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract:The variation rule of the vertical sintering speed with proceeding of sinter was investigated by studying the air speed. The results show that the vertical sintering speed changes notably with the proceeding of sintering process. After ignition and thermal retardation the bed permeability deteriorates and the sintering speed decreases notably because of the progress of physical chemistry reaction, formation and broaden of combustion zone, and formation of overwet zone. In about 25 min, the over wet zone vanishes, so the bed permeability meliorates and the speed arises rapidly. According to the variation rule of the vertical sintering speed, the sintering speed optimization experiment was carried out. Because of the rationalized distribution of vertical sintering speed with sintering process by changing the pressure. The vertical sintering speed increases from 20.08 to 21.82 mm/min, and the productivity rate increases from 1.401 to 1.587 t/(m2?h) keep the yield and tumble index keeping unchanged.

Key words:sintering; vertical sintering speed; optimization

垂直烧结速度即为燃烧带中温度最高点往下迁移的速度,在燃烧带中,会发生混合料软化、熔融及液相形成等一系列物理化学变化,故此带对烧结过程产量及质量影响很大。燃烧带在料层中的位置随着烧结过程的进行沿着气流方向波浪式地下移,其下移速度与抽风量有着密切关系。一般而言,在烧结过程中燃烧带下移速度加快,烧结过程加快,生产率提高,但如果速度过快,料层中高温保持时间缩短,液相形成不充分,对烧结过程会产生负面影响。对特定物料而言,存在一定的适宜烧结速度。料层中高温保持时间缩短是恶化烧结过程的一个重要因素,如能对烧结料面沿台车前进方向进行“速度分配”,以保证在烧结过程的不同阶段垂直烧结速度在一个适宜的范围,进而确保各个烧结段中料层有足够的高温保持时间,将能提高烧结的产量和质量,特别是对提高烧结生产率起到重要的作用[1-5]。

气体速度是影响垂直烧结速度的一个重要因素,在原料及气流介质一定的条件下,加快气流速度,可加速传热,还可增加风量即增加含氧量,促进燃烧,进而提高垂直烧结速度。因此,在一定的风速范围内,气流速度能够反映垂直烧结速度的变化规律[6-9]。

1 实 验

本研究所使用的原料、燃料(焦粉)、熔剂由宝钢股份有限公司提供。实验流程如下:

1.1 配料、混匀及制粒

烧结采用质量配料法配料,人工混合3次,加水后混合3次,混匀后,在直径×高为600 mm×1 400 mm的圆筒混合机内制粒,圆筒混合机转速15 r/min,制粒3 min,制粒完毕后,测取样品的水分、粒度组成和堆密度。

1.2 布料

采用10~15 mm烧结矿作铺底料,铺底料质量为1 kg,铺底料厚度为20~25 mm,经制粒后的混合料装入有铺底料的烧结杯内至一定高度,布料后压料20 mm。

1.3 点火及保温

采用液化气点火及保温,点火时间为1 min,点火温度为(1 150±50) ℃,点火负压为5 000 Pa,保温时间为2 min,保温温度为(950±50) ℃,保温负压 为5 000 Pa。

1.4 烧结

烧结实验采用直径为150 mm的烧结杯,料层高度为640 mm,根据垂直烧结速度随烧结过程的变化规律变负压烧结。从点火至烧结废气温度达到最高值所需时间即为烧结时间。到达烧结终点时,抽风负压降低至5 000 Pa,冷却3 min后卸料。然后进行落下强度检测、筛分分级及转鼓强度检测等。转鼓实验采用1/2 ISO 转鼓。

实验中气流流量的测定方法如下:烧结点火保温后,将风速测定仪置于烧结杯顶部,随着烧结过程的进行,每隔30 s记录1次风速仪上显示的气流瞬时流量,在实际操作中,在烧结杯与之间填充一圈石棉绳以防止漏风,保证测量结果的准确性。

2 结果及讨论

2.1 基准实验

2.1.1 焦粉含量对烧结矿产质量的影响

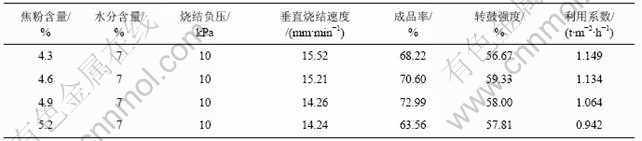

固定水分含量为7.0%,研究焦粉含量对烧结矿产质量指标的影响,结果见表1。

表1 焦粉含量对烧结矿产量和质量的影响

Table 1 Effect of coke powder content on yield and quality of sinter

实验结果显示,垂直烧结速度、利用系数随着焦粉含量的增加而减小,而成品率和转鼓强度则成抛物线形式,出现极大值。这是因为在固定水分含量为7.0%时,有一适宜的燃料用量以保证烧结矿具有足够的强度和良好的还原性,焦粉含量增加,会使烧结矿过熔,且在烧结料层下部形成大孔薄壁结构,致使转鼓强度和成品率降低[10]。

根据实验结果,综合考虑垂直烧结速度、成品率、转鼓强度、利用系数等烧结产质量指标,本试验研究焦粉含量选取4.6%为宜。

2.1.2 水分含量对烧结矿产质量的影响

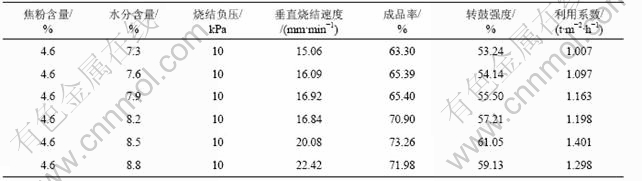

在焦粉含量为4.6%的条件下,研究水分含量对烧结矿产质量指标的影响。

实验结果(见表2)表明:随着水分用量的增加,烧结速度、利用系数、成品率及转鼓强度均随之增加。当水分含量达到8.5%,此时烧结产质量各指标达到最优:烧结速度为20.08 mm/min,利用系数为1.401 t/(m2?h),转鼓强度为61.05%,成品率为73.26%,利用系数为1.401。水分含量继续增大,各产质量指标均有下降的趋势。分析其原因可能是,水分含量过大将导致速度过快,在烧结过程物化反应不充分,影响烧结矿转鼓强度及成品率,且水分增加,烧结过程所需热量增大,会导致固体燃耗增加[11]。因此本研究水分含量选取8.5%。

表2 水分含量对烧结矿产量和质量的影响

Table 2 Effect of water content on yield and quality of sinter

基准实验结果显示,本研究所用原料在实验室烧结条件下,最佳烧结焦粉含量为4.6%,水分含量为8.5%。此时垂直烧结速度为20.08 mm/min,成品率为73.26%,转鼓强度为61.05%,利用系数为1.401 t/(m2·h)。

2.2 合理垂直烧结速度烧结实验

通常所谓的“垂直烧结速度”是用烧结料高除以烧结时间所得的1个平均速度,然而,由于烧结过程的各个带对烧结料层透气性的影响存在显著差异,随着烧结过程的进行垂直烧结速度并非均一,而是一个不断变化的量[12-13]。由于烧结过程在黑箱操作下进行的,在实验室条件下只能通过调节烧结负压的方式来改变风量(风速),进而优化垂直烧结速度,使其能够随烧结过程合理分布[14-15]。

2.2.1 垂直烧结速度随烧结过程的变化规律

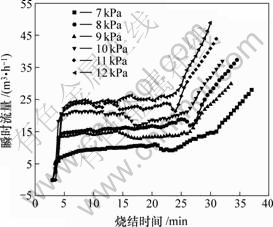

基准实验结果显示,本实验所用原料最佳焦粉含量为4.6%,水分为8.5%。在此条件下,研究了不同烧结负压下垂直烧结速度的变化规律。

实验过程中用流量表对烧结过程的瞬时流量进行了测定(见图1),用瞬时流量除以烧结杯的横截面积即为烧结瞬时流速。由于烧结杯的横截面积一定,因此,瞬时流量的变化规律也基本上反映了垂直烧结速度随烧结过程的进行的变化规律。实验结果表明:

a. 随着负压的提高,气体瞬时流量增大,垂直烧结速度加快;通过调节负压可以改变烧结过程各时间段或各个带的烧结速度;

b. 随着烧结过程的进行,垂直烧结速度变化较大;

c. 点火保温后,在抽风作用下,料层压紧并产生过湿现象,料层阻力升高,导致烧结速度下降,同时燃烧带熔融物的形成以及干燥预热带球粒的破裂进一步增大了料层阻力,导致透气性恶化,烧结速度显著下降;随着烧结矿的形成及烧结矿带的增厚、过湿带的消失,料层阻力逐渐下降,透气性变好,烧结速度明显改善。从图1中可以明显看出,垂直烧结速度随着烧结过程的进行先下降后上升的过程,即点火保温后至过湿层消失前的烧结速度降低,而过湿层消失后(约25 min)烧结速度显著提高,瞬时流量的跨度多达20 m3/h。

因此,随着烧结过程的逐步进行垂直烧结速度有显著的变化。究其原因是因为烧结过程主要可分为原始料带、预热干燥带、燃烧带、水分冷凝带及烧结矿带5个带,各带的阻力各不相同,对烧结料层透气性影响的差异很大。燃烧带、过湿带的阻力最大,透气性最差;其次是原始料带、干燥带;阻力最小,透气性最好的是烧结矿带。由于烧结过程各带的阻力的差异及随烧结过程的进行5个带的相对宽度不断变化,因而烧结料层透气性显著变化,导致垂直烧结速度随烧结过程变化显著。

图1 不同负压条件下烧结过程的瞬时流量变化

Fig.1 Variation of instantaneous flux of sintering process at different negative pressures

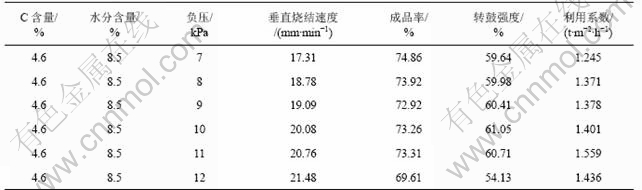

由表3可知,随着烧结负压的提高垂直烧结速度逐渐增加;转鼓强度、成品率及利用系数逐渐增加后在12 kPa又开始降低。这可能是由于烧结过程中需要一定的风量以保证烧结过程的顺利进行及确保烧结矿具有一定的强度,但负压过高会导致烧结速度过快,各种物理化学反应不能充分进行,使烧结矿欠烧,因此烧结矿强度降低,质量下降。

表3 负压对烧结矿产量和质量的影响

Table 3 Effect of negative pressure on yield and quality of sinter

2.2.2 垂直烧结速度优化研究

为了使垂直烧结速度随烧结过程的分布更加合理化,进行烧结速度优化实验,以达到匀速烧结目的,强化烧结过程。优化方法是在透气性差的阶段采用较高抽风负压,而在过湿层消失后透气性较好阶段采用低负压烧结。

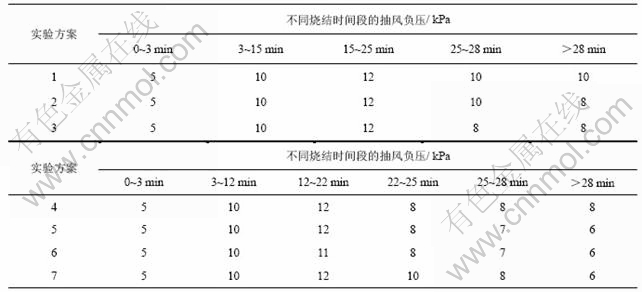

根据图1所示的垂直烧结速度变化规律,制定了烧结速度优化方案,通过调节负压来达到烧结速度的优化,如表4所示。点火保温段(0~3 min)烧结负压为5 kPa;从点火保温结束将烧结负压调为常规烧结下的10 kPa;由于随着烧结反应的进行,透气性恶化,烧结速度降低,因此在过湿层消失(约25 min)前的一段时间内,为了有效提高烧结度,将负压提高到12 kPa;过湿层消失至到达烧结终点这一时段,由于烧结速度有显著增大,因此在此段将负压降至10 kPa甚至更低。在上述负压调节方式基础上结合时间段的合理划分,确定了7组烧结速度优化方案。实验结果如图2及表5所示。实验结果表明:

表4 烧结速度优化方案

Table 4 Optimization project of sintering speed

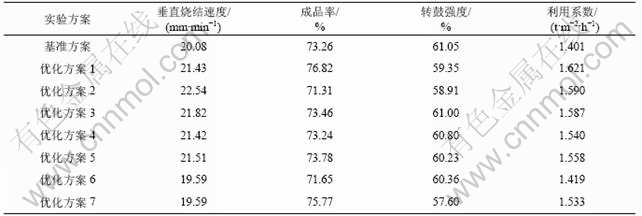

表5 不同烧结速度优化方案对烧结矿产量和质量的影响

Table 5 Effect of sintering speed optimization project on yield and quality of sinter

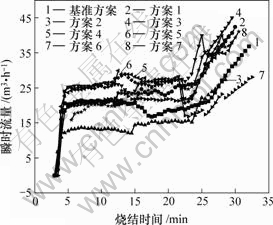

图2 不同烧结速度下优化方案下烧结过程的瞬时流量变化

Fig.2 Variation of instantaneous flux in sintering process of different sintering speed optimization projects

a. 与图1相比,优化后流量(速度)曲线更加平稳,垂直烧结速度的分布更为合理;

b. 过湿层完全消失后(料层主要为烧结矿带)烧结速度显著加快的现象趋缓,瞬时流量的跨度仅有5~10 m3/h;

c. 图2中曲线在12 min(15 min)及22 min(25 min)的突变是由人为的调节负压操作造成的而不是烧结过程本身的速度规律;

d. 从成品烧结矿的产、质量指标可以看出,与常规烧结相比,经过优化试验后,在满足烧结矿成品率及转鼓强度的基础上利用系数均有显著提高,优化方案3的效果最好,在转鼓强度及成品率基本相同的条件下,垂直烧结速度由20.08提高到21.82 mm/min,提高了8.7%;利用系数由1.401提高到1.587 t/(m2?h),提高了13.3%。

3 结 论

a. 基准实验结果显示,本研究所用原料在实验室烧结条件下,最佳烧结焦粉含量为4.6%,水分含量为8.5%。此时垂直烧结速度为20.08 mm/min,成品率为73.26%,转鼓强度为61.05%,利用系数为1.401 t/(m2·h)。

b. 随着烧结过程的进行,垂直烧结速度变化较大。火保温,在抽风作用下,料层压紧并产生过湿现象,料层阻力升高,导致烧结速度下降,同时,燃烧带熔融物的形成以及干燥预热带球粒的破裂进一步增大了料层阻力,导致透气性恶化,致使烧结速度显著下降;随着烧结矿的形成及烧结矿带的增厚、过湿带的消失,料层阻力逐渐下降,透气性变好,烧结速度明显提高。

c. 经过优化烧结速度后,在烧结矿成品率及转鼓强度基本不变的基础上利用系数均有显著提高。比较几个烧结速度优化方案,方案3的效果最好,在转鼓强度及成品率基本相同的条件下,垂直烧结速度由20.08提高到21.82 mm/min,利用系数由1.401提高到1.587 t/(m2?h)。

参考文献:

[1] 唐先觉. 我国烧结工业现状及面临的问题[J]. 烧结球团, 1995, 20(6): 1-6.

TANG Xian-jue. Problems on the domestic sintering industrial status[J]. Sintering and Pelletizing, 1995, 20(6): 1-6.

[2] 付菊英, 姜 涛, 朱德庆. 烧结球团学[M]. 长沙:中南工业大学出版社,1996: 2.

FU Ju-ying, JIANG Tao, ZHU De-qing. Sintering and pelletizing[M]. Changsha: Central South University of Technology Press, 1996: 2.

[3] 唐贤容. 烧结理论与工艺[M]. 长沙:中南工业大学出版社,1992: 10.

TANG Xian-rong. Sintering theory and technology[M]. Changsha: Central South University of Technology Press, 1992: 10.

[4] Kanjilal P P, Rose E. Aplication of adaptive prediction and control methods for improved operation of the sintering process [J]. Ironmaking and Steelmaking, 1986, 13(6): 289-293.

[5] 习乃文. 烧结技术[M]. 昆明: 云南人民出版社, 1993: 5.

XI Nai-wen. Sintering technology[M]. Kunming: Yunnan People’s Press, 1993: 5.

[6] 边美柱,何晓义,侯贵生. 固体燃料在烧结料中的燃烧分析及降耗措施[J]. 包钢科技,2002,28(3):19-22.

BIAN Mei-zhu, HE Xiao-yi, HOU Gui-sheng. Combustion analysis and reducing combustion of solid fuels in sinter mix[J]. Science & Technology of Baotou Steel (Group) Corporation, 2002, 28(3): 19-22.

[7] 黄希祜. 钢铁冶金原理[M]. 北京:冶金工业出版社, 1986.

HUANG Xi-hu. Ferrous metallurgy principle[M]. Beijing: Metallurgical Industry Press, 1986.

[8] 周文涛, 吴文达. 提高料层燃料燃烧效率的途径[J]. 鞍钢技术, 1998(1): 7-15.

ZHOU Wen-tao, WU Wen-da. Path to increase fuel’s combustion efficiency in bed [J]. Technology of Anshan Steel (Group) Corporation, 1998(1): 7-15.

[9] 蔡汝卓. 关于烧结料层透气性与料层性状的关系[J]. 烧结球团, 1985, 10(4): 17-26.

CAI Ru-zhuo. Relationship of bed permeability and character in sinter[J]. Sintering and Pelletizing, 1985, 10(4): 17-26.

[10] 傅崇说. 有色冶金原理[M]. 北京: 冶金工业出版社, 1984: 11.

FU Chong-yue. Nonferrous metallurgy principle[M]. Beijing: Metallurgical Industry Press, 1984: 11.

[11] Toda H, Kato K. Theoretical investigation of sintering process[J]. Ironmaking and Steelmaking, 1991, 18(2): 89-95.

[12] Kawaguchi T, Saino M. Development and application of an integrated simulation model for iron ore[J]. Sintering Ironmaking Proceedings, 1987, 46: 99-106.

[13] 崔玉元. 烧结固体燃料燃烧动力学特征及包钢降耗途径[J]. 包钢科技,2000, 26(4): 4-8.

CUI Yu-yuan. Burning dynamic features of solid fuel sintering and measures for reducing consumption[J]. Science & Technology of Baotou Steel (Group) Corporation, 2000, 26(4): 4-8.

[14] 黎建明,王敏杰. “均压”烧结新技术的评述与展望[J]. 钢铁钒钛, 1995, 16(3): 10-15.

LI Jian-ming, WANG Min-jie. Discussion and prospect on the new techniques of indentical load sintering [J]. Iron Steel Vanadium Titanium, 1995, 16(3): 10-15.

[15] 张同山. 均质烧结技术的发展与配套设计[J]. 烧结球团, 2001, 26(2): 1-5.

ZHANG Tong-shan. Development and project design of uniform sintering process[J]. Sintering and Pelletizing, 2001, 26(2): 1-5.

收稿日期:2006-09-12

基金项目:教育部新世纪优秀人才支持计划资助项目(NCET-04-0748)

作者简介:许 斌(1962-),女,陕西西安人,副教授,从事烧结球团及复杂矿综合利用研究

通讯作者:许 斌,女,博士研究生;电话:0731-8710225(O);E-mail:xubin@mail.csu.edu.cn