文章编号:1004-0609(2008)11-1964-07

Bc路径等径角挤压7090/SiCp的显微组织及性能

孙有平,严红革,陈振华,陈 刚

(湖南大学 材料科学与工程学院,长沙 410082)

摘 要:采用Bc路径对超高强铝合金基复合材料7090/SiCp进行等径角挤压加工。采用金相显微镜、力学性能测试及扫描电镜,分析该复合材料的显微组织和力学性能。结果表明:经过4个道次的等径角挤压加工,该复合材料的晶粒逐渐被细化,第三道次后晶粒尺寸达到1 μm以下;继续进行等径角挤压时,晶粒未发生明显变化。室温拉伸结果显示:晶粒的抗拉强度逐渐增大,在第三道次下道次间抗拉强度的增加幅度最大,达到14.3%,此时其抗拉强度及伸长率分别为338.57 MPa及15%;SiC颗粒在大的剪切力作用下被破碎细化,在基体中的分布也更加均匀。

关键词:铝基复合材料;SiC;等径角挤压;显微组织;力学性能

中图分类号:TG146.2 文献标识码:A

Microstructure and properties of Bc route ECAP of 7090/SiCp composite

SUN You-ping, YAN Hong-ge, CHEN Zhen-hua, CHEN Gang

(College of Materials and Engineering, Hunan University, Changsha 410082, China)

Abstract: The structures and properties of 7090/SiCp Al matrix composites were studied by severe plastic deformation through Bc route equal channel angular pressing (ECAP). Equal channel angular pressing was performed on an ultra-high strength 7090/SiCp aluminum alloy matrix composite. By optical microscopy, mechanical tensile test and scanning electron microscopy, the microstructures and mechanical properties of 7090/SiCp composite were discussed. The results show that the size of the composites is fined gradually, and the finest grains are obtained of less than 1 μm after 3 passes of ECAP. However the grains do not change after the 4th pass of ECAP. The tensile strength increases gradually with the addition of pass at room temperature, and the increasing degree between two passes achieves the maximum at the third pass, is 14.3%, and the ultimate tensile strength and elongation are 338.57 MPa and 15%, respectively. SiC particles are broken under high shearing stress, and the particle distribution in the matrix alloy is homogeneous.

Key words: aluminum matrix composite; SiC; equal channel angular processing; microstructure; mechanical properties

等径弯曲通道挤压,即等径角挤压(Equal-channel angular pressing,ECAP)是目前材料科学界普遍关注的一个新兴研究领域,是20世纪70年代由前苏联科学家SEGAL等[1]提出的一种独特的制备高性能、超细晶金属材料的加工方法,可以有效地细化材料的晶粒,制备出大块纳米晶或超细晶材料[2?8]。ECAP加工时材料在大的挤压力作用下通过一个以一定角度相互交叉的挤压通道,利用通道转角处产生的一定量均匀纯剪切变形,使材料原有组织结构得到一定的改变,材料的晶粒得到细化、呈取向性分布,从而使材料的物理性能、力学性能、抗腐蚀等性能出现新的变化。这一技术是制备超细晶金属材料的一种新方法,具有良好的应用价值与前景[9?11]。

过去等径角挤压技术主要用于对镁合金及铜合金

进行塑性变形以达到细化晶粒的目的,近年来国内外一些学者开始采用等径角挤压技术来对铝合金及其复合材料的显微组织及力学性能的影响进行了一些的研究[12?13]。目前对喷射沉积技术制备的7090/SiCp铝基复合材料进行等径角挤压加工的报道尚未见文献报道。因此,本文作者拟采用Bc路径等径角挤压工艺对多层喷射沉积法制备的7090/SiCp铝基复合材料进行塑性变形加工,并研究材料经过挤压加工后材料的显微组织与力学性能变化。

1 实验

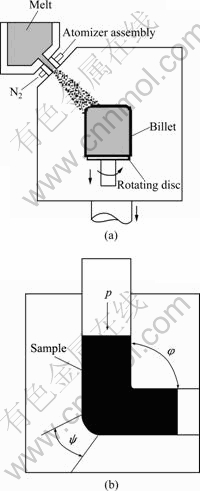

实验用7090/SiCp复合材料采用自主发明设计的多层喷射共沉积设备制得,其工作原理见图1(a),该材料基体合金的化学组成见表1,其中SiC颗粒的体积分数约为15%,其名义尺寸为10 μm,雾化气体为氮气,斜喷角为30?。沉积制备的复合材料坯经机加工后的尺寸为d=160 mm,将其在卧式挤压机上热挤压成d=25 mm的棒材,挤压比为10?1,热挤压温度为420 ℃。进行等径角挤压的复合材料棒材的尺寸为直径d=19 mm,长145 mm。为本次实验所使用的等径角挤压模的模孔为圆形,直径为20 mm,其工作原理见图1(b)所示。模具由两个具有相同横截面的通道相贯成L形, =90?,

=90?, =30?。挤压时,与通道形状一致且润滑良好的试样放入其中一个通道,在压力作用下,试样从另一个通道中挤出,在两通道相交产生近似理想的纯剪切塑性变形。试样保温温度为400 ℃,保温时间为20 min,模具加热温度为350 ℃。

=30?。挤压时,与通道形状一致且润滑良好的试样放入其中一个通道,在压力作用下,试样从另一个通道中挤出,在两通道相交产生近似理想的纯剪切塑性变形。试样保温温度为400 ℃,保温时间为20 min,模具加热温度为350 ℃。

图1 多层喷射沉积与等径角挤压原理示意图

Fig.1 Schematic diagram of principle of multi-layer spray- deposition(a) and ECAP(b)

表1 实验基体合金的化学成分

Table 1 Chemical composition of matrix alloy (mass fraction, %)

本实验主要对Bc路径4个道次等径角挤压后的7090/SiCpAl基复合材料的显微组织与室温力学性能进行了研究。采用MM?6型金相显微镜,JSM?5610型扫描电子显微镜,WDW?E200型微机控制电子万能试验机等检测设备对材料进行显微组织及室温力学性能的检测,并对检测结果进行分析与讨论。

2 结果与讨论

2.1 复合材料的显微组织

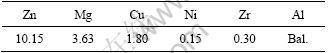

图2所示为复合材料初始挤压态,1次及4次等径角挤压的显微照片。从图2可以看出,经多层喷射沉积制备的复合材料经过热挤压加工后其显微组织非常细小,大约为3 μm左右,经过一个道次的等径角挤压后(见图2(b)),晶粒被进一步地破碎细化,其中较大的晶粒尺寸在2.5 μm左右,大多数晶粒尺寸在1 μm左右;继续进行等径角挤压时,晶粒被进一步均匀破碎,经过4次等径角挤压后,大尺寸晶粒全部被破碎,晶粒组织细小均匀,尺寸小于1 μm。

图2 挤压态及不同道次等径角挤压试样显微组织

Fig.2 Microstructures of as-extruded and after different passes of ECAP: (a) As-extruded; (b) 1 pass of ECAP; (c) 4 passes of ECAP

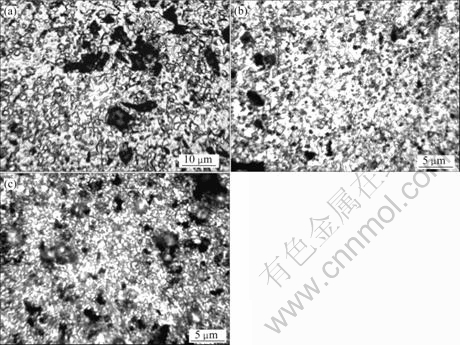

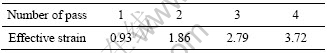

图3所示为7090/SiCp铝基复合材料中的SiC颗粒经过热挤压加工及等径角挤压加工后的宏观形貌。从图中可以看出,由于使用的原始SiC颗粒为带有棱角的不规则形状,而该复合材料在热挤压加工过程中因为挤压比较小,不能使SiC颗粒很好地得到破碎,因此,仍然呈现出棱角分明的条状及近圆形(见图3(a))。研究表明,SiC颗粒的棱角区域极易产生应力集中,在拉伸过程中会在这些位置产生裂纹,当裂纹扩展并连接在一起时会使材料发生断裂。同时在喷射沉积过程中由于加粉操作的原因,会对SiC颗粒的分布产生一定的影响,在复合材料的某些区域会发生SiC颗粒团聚的现象,从图3(a)中可以看出,在挤压态复合材料中仍有SiC团聚的现象存在。

图3 7090/SiCp复合材料中SiC的形貌

Fig.3 Morphologies of SiC particles in 7090/SiCp composite: (a) As-extruded; (b) 1 pass of ECAP; (c) 2 passes of ECAP; (d) 3 pass of ECAP; (e) 4 passes of ECAP

观察等径角挤压后的SiC颗粒的形貌可以看出,由于在等径角挤压过程中无论是对基体合金还是对SiC颗粒都会产生极大的剪切力,在这种剪切力的作用下,基体合金的晶粒及SiC颗粒将被破碎细化。观察图3(b)可以看出,经过1个道次的等径角挤压加工SiC颗粒就可以得到很好的破碎效果,其破碎细化幅度最大,绝大部分的SiC颗粒尺寸在2 ?m以下,在一定程度上改善了带有尖锐棱角的形貌特征。在剪切力的作用下,SiC颗粒会在基体合金中发生流动,使原来团聚在一起的及破碎的SiC逐渐弥散分布在基体合金中(见图3(b)、(c)、(d)、(e))。继续进行等径角挤压加工,SiC颗粒会被继续细化,但是细化效果逐渐变小。但是,等径角挤压技术并不能将大尺寸的SiC全部破碎成细小的颗粒,在每一道次的SiC分布状态图中都可以发现一定量尚未破碎的较大尺寸的SiC颗粒。

2.2 复合材料的力学性能

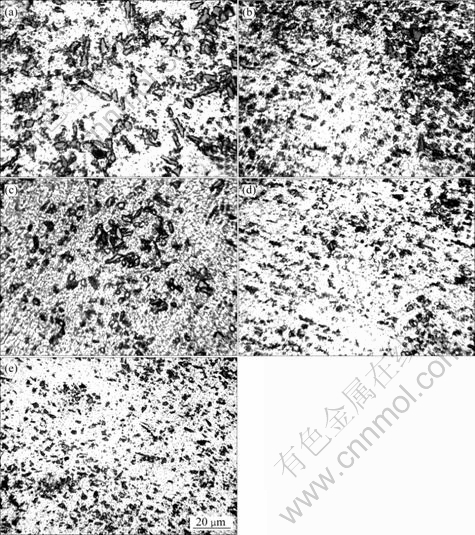

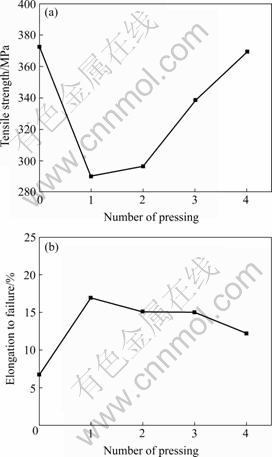

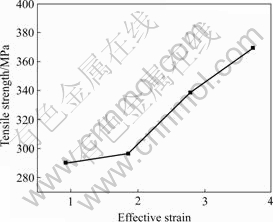

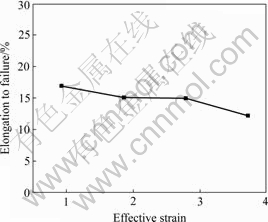

图4(a)和(b)所示分别为该复合材料挤压态及经过1~4个道次的等径角挤压加工后的室温抗拉强度及断裂伸长率随等径角挤压道次的变化。从图中可以看出,挤压态试样的抗拉强度为372.30 MPa,伸长率为6.77%。经过1个道次的等径角挤压后,该复合材料的抗拉强度下降为290.38 MPa,下降幅度为22%,但伸长率增加到16.9%,增加幅度为149.63%;随着挤压道次的增加,该复合材料的抗拉强度持续上升,第四道次的抗拉强度为369.33 MPa,但是从第二道次开始,该复合材料的伸长率逐渐减小,在第四道次时,其伸长率减为12.2%。

图4 等径角挤压试样力学性能的变化

Fig.4 Variation of mechanical properties of ECAP samples: (a) Tensile strength; (b) Elongation

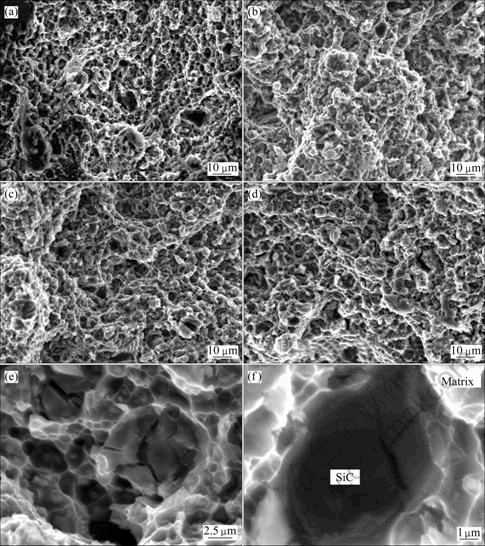

图5所示为复合材料经1~4道次等径角挤压后的室温拉伸断口。从图中可以看出,SiC颗粒增强7090Al基复合材料的拉伸断口呈韧窝特征,材料主要沿晶界发生断裂,属于典型的韧性断裂,且各个道次等径角挤压后的拉伸断口形貌特征比较相似(见图5(a)、(b)、(c)和(d))。由于等径角挤压过程中大的剪切力的作用,SiC颗粒被破碎成小颗粒,图5(e)、(f)所示为SiC颗粒断裂后形成的裂纹,拉伸过程中,在拉伸应力的作用下,基体与SiC颗粒界面上局部结合力较弱的区域开始萌生裂纹,形成裂纹源。拉伸应力增大时,裂纹会不同程度地发生扩展,裂纹扩展的方向与拉伸应力的方向垂直。

图5 等径角挤压试样的室温拉伸断口形貌

Fig.5 Tensile fracture surface morphologies of ECAP: (a) 1 pass of ECAP; (b) 2 passes of ECAP; (c) 3 passes of ECAP; (d) 4 passes of ECAP; (e), (f) Cracks and interfaces of SiC/matrix

在SiC颗粒破碎的过程中,颗粒断裂时形成的裂纹还会向基体合金扩展,从而使基体合金中产生微裂纹,这些微裂纹在拉伸过程中将成为裂纹源,在拉伸应力的作用下不断扩张,最后导致材料断裂。但是同时SiC颗粒还会起到阻碍基体合金中的裂纹扩展的作用,拉伸时当基体合金中的裂纹扩展至SiC附近时,将中止扩展或改变运动的方向(见图5(e)和(f))。

2.3 等效应变的影响

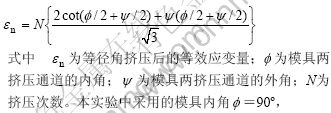

在试样与模壁润滑的情况下,试样通过模具每次的应变量为一定值。IWAHASHI等[10]根据相关理论计算出它们之间的关系如下:

模具外角 =30?。此时相邻道次间剪切平面的夹角

=30?。此时相邻道次间剪切平面的夹角 的为60°,相邻道次间的等效应变差为0.93,这是细化晶粒最好的方式[14]。

的为60°,相邻道次间的等效应变差为0.93,这是细化晶粒最好的方式[14]。

表2所列为本次等径角挤压过程中多次挤压后的累积应变量的大小。

表2 多次挤压后的等效应变量

Table 2 Amount of effective strain after several ECAP pressing

图6所示为7090/SiCp复合材料等径角挤压后的室温抗拉强度随等效应变的变化。从图中可以看出,随着等效应变值的增大,室温抗拉强度逐渐增大,并且在等效应变为2.79时,相邻两道次间的室温抗拉强度的增加幅度最大,为14.3%,进行第四道次的加工后,等效应变为3.72,材料的抗拉强度继续增加,为369.33 MPa,但是相邻道次间的强度增大幅度为9.1%。

图6 7090/SiCp复合材料拉伸强度随等效应变的变化

Fig.6 Variation of tensile strength with effective strain for 7090/SiCp composites

图7所示为该复合材料等径角挤压后的伸长率随等效应变的变化。从图中可以看出,当等效应变值为0时,该复合材料的伸长率为6.77%,经过一个道次的等径角挤压加工后,即等效应变值为0.93时,该复合材料具有最大的伸长率,为16.9%;随着等效应变值的增大,伸长率逐渐减小。

图7 7090/SiCp复合材料伸长率随等效应变的变化

Fig.7 Variation of elongation with effective strain for 7090/SiCp composites

有研究表明[15?16],模具内角为90°时,单次剪切应变量较大,此时晶粒细化的速度和程度越高,细化效果越明显,材料的力学性能也越好。

在本实验中,开始进行等径角挤压加工时,累积应变量较小,试样的变形程度不大,同时因剪切变形而产生的位错密度及材料内积聚的内能也相对较小,这一阶段位错增殖的速度大于湮灭的速度,回复作用不明显。随着位错密度的不断增大,晶粒细化作用开始逐渐明显,随着累积应变量的不断增加,位错的增殖和湮灭速度达到了动态平衡,回复作用变得逐渐明显,晶粒细化程度达到最大。

所以,在对7090/SiCp复合材料进行等径角挤压实验中,当累积应变量为2.79时,材料的强度得到最大程度的提高,晶粒尺寸最小。在累积应变量达到3.72时,该复合材料的晶粒细化作用减小,此时试样的强度和伸长率的变化减小。

3 结论

1) 热挤压态7090/SiCp复合材料的晶粒尺寸大约在3 ?m左右,等径角挤压可以有效地细化基体合金显微组织,经过4个道次的等径角挤压晶粒尺寸均小于1 μm,且组织分布均匀。

2) 热挤压态复合材料中SiC颗粒分布比较均匀,但仍存在一定团聚现象,SiC颗粒的形状不规则,为带有尖锐棱角的多边形;经过等径角挤压后,SiC颗粒可以在大的剪切力的作用下被破碎细而细化,经过一个道次的等径角挤压加工,SiC颗粒就可以得到很好的破碎效果,其破碎细化幅度最大,绝大部分的SiC颗粒尺寸在2 ?m以下。在剪切力的作用下,SiC颗粒会在基体合金中发生流动,使原来团聚在一起的及破碎的SiC逐渐弥散分布在基体合金中。

3) 等径角挤压后,7090SiCp复合材料表现为典型的延性断裂,拉伸断口上存在大量的韧窝。等径角挤压的剪切作用使SiC颗粒断裂时形成的裂纹会向基体合金扩展,在拉伸应力的作用下,这些裂纹将扩大并导致复合材料断裂。同时基体与SiC之间局部结合较弱的区域在拉伸时会脱粘,形成裂纹源。但是SiC颗粒也会阻止基体合金中裂纹的扩展。

REFERENCES

[1] SEGAL V M. Materials processing by simple shear[J]. Mater Sci Eng A, 1995, 197: 157?159.

[2] VALIEV R Z. Structure and mechanical properties of ultrafine grained metals[J]. Mater Sci Eng A, 1997, 234/236: 59?63.

[3] SEGAL V M, GOFORTH R E, HARTWIG K T. Apparatus and method for deformation processing of metals, ceramics, and other materials. US 5400633[P]. 1995.

[4] 索 涛, 李玉龙. 等径通道挤压中晶粒细化影响因素的研究进展[J]. 材料科学与工程学报, 2004, 22(1): 132?137.

SUO Tao, LI Yu-long. Progress in influence factor of grain refinement during equal channel angular pressing[J]. Journal of Materials Science and Engineering, 2004, 22(1): 132?137.

[5] 刘 英, 陈维平, 张大童, 张卫文, 李元元. 不同路径等通道转角挤压镁合金的结构与力学性能[J]. 华南理工大学学报: 自然科学版, 2004, 32(10): 10?14.

LIU Ying, CHEN Wei-ping, ZHANG Da-tong, ZHANG Wei-wen, LI Yuan-yuan. Structure and mechanical property of the magnesium alloy prepared by the equal channel angular pressing via different processing routes[J]. Journal of South China University of Technology: Natural Science Edition, 2004, 32(10): 10?14.

[6] 刘 英, 陈维平, 张卫文, 朱权利, 赵海东. 等通道转角挤压后AZ31镁合金的微观结构与性能[J]. 华南理工大学学报: 自然科学版, 2004, 32(9): 50?53.

LIU Ying, CHEN Wei-ping, ZHANG Wei-wen, ZHU Quan-li, ZHAO Hai-dong. Microstructure and properties of AZ31 magnesium alloy with ECAP[J]. Journal of South China University of Technology: Natural Science Edition, 2004, 32(9): 50?53.

[7] 赵国群, 徐淑波. 等通道弯角多道次挤压工艺累积变形均匀性研究[J]. 机械工程学报, 2005, 41(5): 177?181.

ZHAO Guo-qun, XU Shu-bo. Study of material, accumulated deformation uniformity of equal channel angular multi-pass pressing process[J]. Chinese Journal of Mechanical Engineering, 2005, 41(5): 177?181.

[8] 刘 英, 李元元, 张大童. 金属材料的等通道转角挤压研究进展[J]. 材料科学与工程, 2002, 20(4): 613?617.

LIU Ying, LI Yuan-yuan, ZHANG Da-tong. Development of equal channel angular pressing on metals[J]. Materials Science & Engineering, 2002, 20(4): 613?617.

[9] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation[J]. Progress in Materials Science, 2000, 45: 103?189.

[10] IWAHASH Y, HOFITA Z, NEMOTO M, LANGDON T G. The process of grain refinement in equal-channel angular pressing[J]. Acta Mater, 1998, 46(9): 3317?3331.

[11] 张忠明, 王锦程, 唐文亭, 郭学锋, 杨根仓. 等通道转角挤压(ECAP)工艺的研究现状[J]. 铸造技术, 2004, 25(1): 10?12.

ZHANG Zhong-ming, WANG Jin-cheng, TANG Wen-ting, GUO Xue-feng, YANG Gen-cang. Status of equal channel angular pressing (ECAP)[J]. Foundry Technology, 2004, 25(1): 10?12.

[12] CHENG Xu, DIXON W, FURUKAWA M, HORITA Z, LANGDON T G. Developing superplasticity in a spray-cast aluminum 7034 alloy through equal-channel angular pressing[J]. Materials Letters, 2003, 57: 3588?3592.

[13] ZHENG L J, LI H X, HASHMI M F, CHEN C Q, ZHANG Y, ZENG M G. Evolution of microstructure and strengthening of 7050 Al alloy by ECAP combined with heat-treatment[J]. Journal of Materials Processing Technology, 2006, 171: 100?107.

[14] 黄俊霞, 曹小芳, 杜忠泽, 赵西成, 王经涛. 等径弯曲通道变形法及其晶粒细化机制[J]. 金属材料研究, 2002, 28(4): 1?6.

HUANG Jun-xia, CAO Xiao-fang, DU Zhong-ze, ZHAO Xi-cheng, WANG Jing-tao. Equal channel angular pressing and the mechanisms of grain refinement[J]. Research in Metallic Materials, 2002, 28(4): 1?6.

[15] 毕见强, 孙康宁, 刘 睿, 王素梅, 范润华. 等效应变量对等径角挤压2A12铝合金力学性能的影响[J]. 塑性工程学报, 2005, 12(6): 42?45.

BI Jian-qiang, SUN Kang-ning, LIU Rui, WANG Su-mei, FAN Run-hua. Effect of the effective strain value on mechanical properties of 2A12 alloy pressed by ECAP[J]. Journal of Plasticity Engineering, 2005, 12(6): 42?45

[16] NAGASEKHAR A V, YIP T H, SEOW H P. Deformation behavior and strain homogeneity in equal channel angular extrusion/pressing[J]. Journal of Materials Processing Technology, 2007, 192/193: 449?452.

基金项目:教育部新世纪优秀人才支持计划资助项目(NCET-06-0701);湖南省重点实验室资助项目(06FJ3041)

收稿日期:2008-03-10;修订日期:2008-07-18

通讯作者:严红革,教授,博士;电话:0731-8821648;E-mail: yanhg68@163.com

(编辑 龙怀中)