文章编号: 1004-0609(2006)09-1563-07

连续等径角挤压制备超细晶铜

运新兵1, 2, 宋宝韫2, 陈 莉2

(1. 东北大学 材料与冶金学院, 沈阳 110004;

2. 大连交通大学 材料科学与工程学院, 大连 116028)

摘 要: 介绍一种制备超细晶材料的新技术——连续等径角挤压, 它将连续挤压技术应用于制备超细晶材料的等径角挤压工艺, 解决了传统等径角挤压不能制备大尺寸超细晶材料的问题, 该技术对超细晶材料的推广应用具有重要意义。 通过DEFORM3D对铜的连续等径角挤压过程的数值模拟, 得到变形过程中金属的流动、 应变场和温度场情况, 并对不同变形速度和摩擦条件下的变形过程进行比较, 得到优化的工艺参数, 并以此参数进行实验。 实验结果表明, 连续等径角挤压后铜的硬度明显上升, 连续等径角挤压3道次后, 硬度趋于饱和; 连续等径角挤压12道次后, 铜的平均晶粒尺寸为400nm。

关键词: 铜; 连续等径角挤压; 超细晶; 有限元模拟 中图分类号: TG379; TG376

文献标识码: A

Ultra-fine grain copper prepared by

continuous equal channel angular press

YUN Xin-bing1, 2, SONG Bao-yun2, CHEN Li2

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. School of Materials Science and Engineering, Dalian Jiaotong University, Dalian 116028, China)

Abstract: The continuous equal channel angular pressing introduced is a new method to produce ultra-fine grain(UFG) materials, which applies continuous extrusion technology in ECAP technology to manufacture UFG materials and solves the problem that cant manufacture large bulk UFG materials by traditional ECAP. Through simulating continuous ECAP process of copper by DEFORM-3D, the metal flow, strain field and temperature field are obtained. The deformation processes are compared under the conditions of various speeds and different friction factors, the optimum process parameters are obtained. The experiments are performed by optimum process parameters, the results indicate that the hardness increases clearly during the first 2 passes of continuous ECAP, and the hardness is saturated after 2 passes, the grain size of about 400nm is achieved after 12 passes.

Key words: copper; continuous equal channel angular press; ultra-fine grain; finite element simulation

超细晶粒材料因其独特的微观组织结构而具有优异的力学和物理性能, 使其成为材料研究领域的热点之一。 众所周知, 在低温条件下, 传统的塑性变形(如轧制、 挤压、 拉拔等)都能细化材料的晶粒尺寸。 然而, 这些方法只能产生具有小角度晶界的亚结构, 要获得500nm以下的超细晶粒尺寸, 必须获得具有大角度晶界的晶粒结构。 近年来发展起来的大塑性变形(Severe plastic deformation, SPD)技术[1-4] 就是通过一些特殊的成形方法将金属粗大的晶粒细化为具有亚微米甚至纳米级的晶粒结构, 获得超细晶金属材料。 而等径角挤压(Equal channel angular pressing, ECAP)是其中最引人注目的一种方法, 它利用由两个相交的等径通道组成的挤压模具来使金属获得很大的塑性剪切应变, 试样变形前后的形状和尺寸不发生改变, 因而可进行多次反复挤压, 并由此改善材料的性能[5-7]。 ECAP法可以制备出致密、 界面洁净的块体超细晶材料, 为超细晶材料的科学研究提供了必要条件。 然而, 当前的ECAP法很难制备出尺寸超过20mm×20mm×100mm的试样, 这使得该技术的推广应用受到很大限制。 Raab等[8]将ECAP与CONFORM进行结合, 提出了一种实用的大尺寸块体超细晶材料制备技术——连续等径角挤压, 并对铝的连续等径角挤压成形进行了研究。 本文作者结合大连交通大学自主研制的TLJ300连续挤压机的实际生产特点, 优化了连续等径角挤压工艺, 并对铜的连续等径角挤压过程进行了理论和工艺实验研究。

1连续等径角挤压

连续挤压是20世纪70年代发展起来的一种新的塑性加工技术。 该方法利用一个带轮槽的连续旋转的挤压轮, 通过轮槽与坯料之间的摩擦力, 将坯料连续不断地拽入模腔, 并在模腔内发生塑性变形, 最后从挤压模孔挤出连续的挤压产品。 改变挤压模孔的形状, 就可以生产各种线材、 管材及型材等产品。 由于这种工艺方法巧妙地将通常在压力加工中做无用功的摩擦力转化为变形的驱动力和使坯料升温的发热源, 且可连续挤出几千米乃至上万米的成卷制品, 使其成为一种高效的加工新技术。

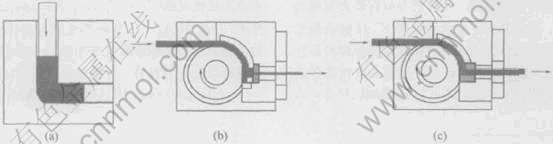

把连续挤压技术和ECAP技术结合起来, 也就是将连续挤压技术应用于金属晶粒超细化变形, 即连续等径角挤压变形(Continuous equal channel angular pressing, Continuous ECAP)(见图1), 它是除带料连续剪切成形(Continuous confined strip shearing, CCSS)工艺之外的又一项新技术[9, 10]。 基于连续挤压技术的等径角挤压不但具备了ECAP的工艺特点, 同时还有其它独特的优越性: 1) 工艺简单, 可连续操作。 连续等径角挤压变形是靠旋转的挤压轮对坯料的摩擦来驱动的, 其操作不受最大行程的限制, 可以不间断地连续成形; 2) 传统的ECAP工艺中若加热坯料需要用电炉, 而连续等径角挤压变形是通过坯料与导料板的摩擦生热来控制金属的变形温度, 大大降低了能耗; 3) 产品的长度不受限制, 既可以加工用于组织和性能研究的试样, 也可以生产线材产品。

由此可见, 连续等径角挤压是对ECAP方法的发展与创新, 它为超细晶粒材料的制造技术开辟了一条新途径。 为了研究连续等径角挤压成形细化晶粒的机理, 首先要对其成形过程进行深入的理论研究。 ECAP的研究资料表明[11-15], 影响晶粒细化的因素除了变形温度和变形速度之外, 还有挤压路线、 模具内外角、 模具圆角半径以及摩擦条件等参数。 而连续等径角挤压的主要影响因素是挤压轮转速、 摩擦条件和模具结构。 本文作者通过对铜的连续等径角挤压过程的有限元模拟, 研究了其塑性变形行为, 分析工艺参数对变形的影响, 并以优化的参数进行工艺实验。

2 有限元模型

在连续等径角挤压过程中, 坯料温度由室温逐渐升高, 因此该过程是非等温的, 属于变形与传热的耦合问题。 本研究采用商业有限元软件DEFORM3DTM对成形过程进行模拟。 根据连续挤压和ECAP工艺特点, 选取截面为12.5mm×12.5mm的长杆料, 材料为纯铜(99.99%), 其流动应力为温度和应变速率的函数:

图1 ECAP、 连续挤压及连续等径角挤压的原理图

Fig.1 Principle diagrams of ECAP(a) and continuous extrusion(b) and continuous ECAP(c)

连续等径角挤压成形的有限元几何模型如图2所示。 单元网格划分所遵循的原则是在确保模拟精度的前提下, 尽量减少单元数以缩短运算时间。 在各模具与坯料相接触的区域, 细化模具单元, 则其它区域单元相对稀疏。 同时由于该模型的对称性, 取其1/2作为模拟对象。 坯料的初始单元数为12745, 挤压轮单元数为76713, 压实轮单元数为6844, 腔体单元数为71670。

图2 有限元几何模型

Fig.2 Geometry model of FEM

3 模拟结果分析

首先对挤压轮转速v为3r/min, 模具内角为90°, 摩擦因子m为0.6时的变形过程进行了模拟。

图3所示为连续等径角挤压有限元模拟的金属变形情况图。 从图3的整个过程中的变形网格可以看出, 连续等径角挤压过程中的金属变形主要集中在挤压模孔附近, 说明此处的金属塑性变形比较剧烈。

图3(a)所示为金属接触堵头前的单元网格图。 [CM)] 图3(b)所示为金属刚接触堵头时的单元网格图。 由图3(a)和(b)可看出, 金属的网格比较均匀, 网格形状无较大变化, 仅在转角外角区域有不太大的变化, 说明金属在这两个阶段尚未发生很大变形。 图3(a)中的外角部位有几个单元发生明显的畸变, 一方面是该部位是主要变形区; 更主要的是因为挤压轮槽底与腔体堵头有一定的间隙, 当坯料随挤压轮槽旋转, 其前端与不动的堵头刚刚接触时, 部分单元有向间隙里流动的趋势, 但由于此处阻力太大, 阻止其向里变形, 于是使部分单元产生畸变, 也会使此处产生很大的应变值。 坯料流经此处转向模具出口后情况就有所改善。 由图3(c)和(d)可看出, 金属在挤入模孔后, 单元网格在转角附近明显变细, 这是由于转角处的金属发生了剧烈变形, 且此系统对此区域的网格进行了细化。 由图3(c)可以明显地看出, 金属在内角与外角附近区域的变形最剧烈, 金属的主要变形就发生在这两处。 而当金属在完全通过模具转角后, 金属的变形就不太剧烈了, 但在此时金属出现了轻微上翘的现象, 这是由于金属在此阶段受到的挤压轮给它的摩擦驱动力作用使它的下部流动速度快, 上部流动速度慢所致。

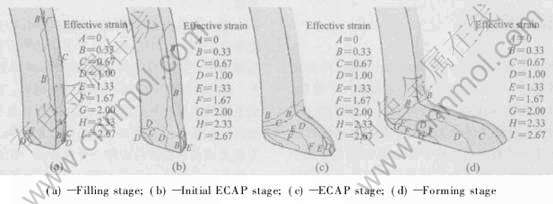

图4所示为连续等径角挤压模拟过程中的等效应变分布情况。 由图4(a)可看出, 在变形金属未接触堵头前, 靠近腔体内边缘部分金属等效应变较大, 且越靠近腔体的部分等效应变越大。 而等效应变最高处发生在外角附近, 且越接近外角等效应变越大。 由图4(b)可看出, 金属刚接触堵头, 等效应变最大处仍在腔体内边缘与外角附近。 在金属刚进入模孔时的等效应变值与图4(b)中的情况差别不大, 但当金属已经进入模孔时, 等效应变急剧上[CM(22]升。 同时, 由于金属发生弯曲变形, 内角处也产生了应变。 说明此阶段金属发生很大的变形, 外角与内角处的变形尤为剧烈(如图4(c))。 产生这种现象的原因是由于此时金属受到了很大的向着模孔入口方向的推动力, 同时又受到内角与外角给予的附加拉应力与压应力, 内外角阻碍着金属向模孔流动, 在内外角处金属又受到很大的剪应力, 在这些力的共同作用下, 金属发生很大的塑性变形。 图4(d)所示为金属变形体从大部分进入挤压模孔到被挤出模孔过程中的等效应变。 由图4(d)可看出, 在这个阶段, 金属变形体靠近模孔下模壁区域的等效应变明显高于靠近上模壁区域的等效应变, 金属的等效应变大于图4(c)阶段的。 此现象说明, 金属靠近模孔下模壁区域的变形大于靠近上模壁区域的变形, 这就是导致金属向上翘曲的原因。 从整个变形过程来看, 坯料从接触堵头开始便发生明显变形; 金属在转角处由于受到多个力的共同作用而发生剧烈的变形; 当金属通过转角进入模孔中时, 各部分的变形相对比较均匀, 金属被挤出模孔时变形才结束。

图3 坯料网格的变形

Fig.3 Deformation of billet mesh

连续等径角挤压不同于ECAP的一个突出特点是其成形过程中因摩擦而使坯料的温度由室温逐渐升高, 变形区的具体温度随挤压轮转速的变化而变化, 同时坯料与模具间还存在着热传导。

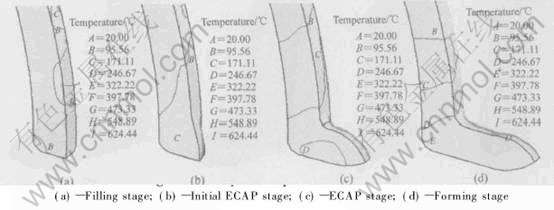

图5所示为连续等径角挤压模拟过程中的温度场分布变化。 由图5(a)可看出, 接触堵头前, 金属变形体的温度较未接触腔体前有所上升, 平均在66℃左右, 只有局部区域(外角处和腔体内边缘附近)温度很高, 约100℃左右。 这一现象产生的原因是由于此时变形热相对于摩擦热所起的作用很小, 因此温度的变化相对来说不十分显著。 图5(b)和(c)显示了金属从刚进入模孔到进入大部分时的温度变化情况。 此时变形热对金属温度的升高起着很大的作用。 因此, 在变形热和摩擦热的共同作用下, 此阶段金属的温度升高得很快, 且进入模孔区域的金属温度相对其它部位较高, 温度由120℃上升到240℃。 温度的快速升高表明, 此阶段的金属变形是最剧烈的, 剧烈的变形使金属产生很高的温度。 同时, 在此时开始出现金属的变形体与各接触模具间的热传导作用, 模具的温度也开始有所上升。 由图5(d)可以看出, 当变形金属完全挤出模孔时, 在模孔内的金属温度已趋于稳定, 平均在280℃左右。 温度的最高区在挤压模孔靠近进口区域的金属的下部, 局部最高达300℃。 且此区域为外角区域, 变形较大, 摩擦力较大, 在变形热和摩擦热的共同作用下导致该区温度很高。

图4 等效应变的分布变化

Fig.4 Variety of effective strain of billet

图5 温度场分布变化

Fig.5 Variety of temperature field of billet

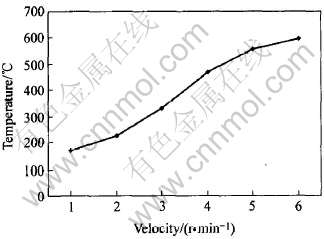

挤压轮转速变化时, 变形区最高温度变化情况如图6所示。 当挤压轮转速增加时, 经过挤压模孔附近的金属温度升高明显, 且由于受摩擦驱动力与阻力的共同作用, 在金属进入模孔到被挤出模孔的整个过程中, 金属产生的摩擦和变形热效应增强, 金属的温度逐渐升高。 这一现象说明在其他条件不变的情况下, 挤压轮转速越大, 金属变形体的温度就越高。 由图6可以看出, 当挤压轮转速为6r/min时, 变形区最高温度已接近600℃, 坯料会因发生再结晶而使晶粒长大, 从而失去剧烈塑性变形细化晶粒的作用, 因此, 该工艺不宜采用如此快的速度, 一般应在3r/min以下。

当腔体与坯料间的摩擦条件发生变化时, 变形区最高温度的变化情况如图7所示。 由图7可看出, 腔体与坯料间的摩擦因子越大, 则坯料的温度越高。 因此, 对摩擦条件的有效控制也直接影响成形结果, 腔体与坯料间的摩擦因子越低越适合于连续等径角挤压。

图6 挤压轮转速与变形温度的关系

Fig.6 Relationship between wheel angular velocity and temperature(m=0.3)

图7 摩擦因子与变形温度的关系

Fig.7 Relationship between friction factor and temperature(v=3r/min)

4 实验结果

根据上述有限元模拟的优化结果, 对连续等径角挤压成形进行了实验研究。 实验坯料为12.5mm×12.5mm的纯铜杆料, 是由d12.5mm的上引铸杆经连续挤压制备的。 实验在TLJ300连续挤压机上进行, 模具采用90°转角结构。 为了降低坯料温度, 实验过程中进行了通水冷却, 使变形温度控制在160℃以下。

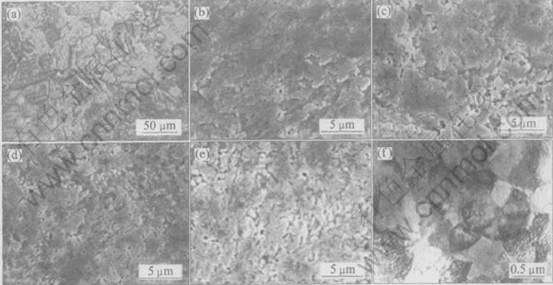

图8所示为纯铜坯料和经Bc路线2道次、 4道次、 6道次、 12道次的连续等径角挤压变形的微观结构以及12道次的TEM照片。 由图8可以看出: 坯料是经过常规连续挤压加工出来的, 变形温度在600℃左右, 是完全退火态的等轴状孪晶组织(图8(a)), 其平均晶粒尺寸约为20μm; 经1~2道连续等径角挤压加工后(图8(b)), 原始态的晶粒在剪应力作用下被拉长, 晶粒内部形成了剪切带, 在剪切带内, 位错密度迅速增高, 位错相互缠结, 形成了网状结构, 位错的形态错综复杂, 位错分布很不均匀, 形成了大量的位错胞, 胞壁上的位错密度大大高于胞内; 随加工道次的进一步增加(图8(c)), 位错胞的数量急增, 尺寸减小, 逐渐形成了取向差较小的亚晶; 随着加工道次的进一步增加(图8(d)和(e)), 小角度晶界通过吸收位错等方式长大成大角度晶界, 亚晶逐渐转变成更细小、 均匀的等轴晶; 经12道次的连续等径角挤压变形后(图8(f)), 平均晶粒尺寸已经减小到400nm左右。

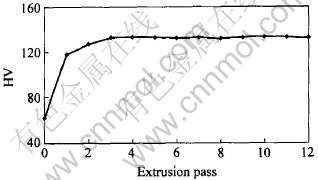

图9所示为材料连续等径角挤压道次与硬度之间的关系曲线。 由图9可看出: 随着挤压道次的增加, 材料硬度的增加越来越缓慢, 1道次连续等径角挤压后硬度迅速增加, 3道次后硬度趋于饱和。 产生这种现象的原因主要是由于加工硬化所致[16], 而加工硬化是与材料储存能成正比的, 储存能随变形量的增加而增加, 但其增加速率逐渐减慢, 有趋于饱和的趋势。 在前几道次的ECAP加工过程中, 由于材料的晶粒尺寸较大, ECAP变形的主要机制是晶内的位错运动, 材料内部位错不断增殖, 位错密度和空位密度明显升高, 形成大量的胞状结构以及亚晶界、 孪晶界等, 使得材料继续塑性变形的抗[CM(22]力增加, 出现加工硬化。 根据Baily-Hirsch关系式H=H0+αGbρ1/2, 可知材料此时的硬度将明显增加。 但随着ECAP道次的增加, ECAP变形的机制逐渐从晶内位错运动转变为细小的晶界滑移, 这必然导致位错密度增加变慢, 其结果是晶粒细化变慢, 此时, 加工硬化作用与回复作用同时存在, 同时起作用, 使其硬度增加趋于平缓。

图8 铜连续等径角挤压前后的微观结构

Fig.8 Microstructures of billet copper(a) and copper extruded by continuous equal

channel angular press after 2 passes(b), 4 passes(c), 6 passes(d), 12 passes(e) and TEM image(f) after 12 passes

图9 显微硬度与挤压道次的关系

Fig.9 Relationship between Vickers hardness and extrusion passes

5 结论

1) 连续等径角挤压过程中金属的剧烈变形主要集中在腔体模具转角部位, 这是晶粒实现超细化的关键部位。

2) 随着挤压轮转速增加, 变形体的温度逐渐升高, 达到甚至超过再结晶温度, 会使已经细化的晶粒长大。 为了避免晶粒长大, 在TLJ300挤压机上进行连续等径角挤压时挤压轮的转速应低于3r/min。

3) 在工艺条件允许的条件下尽量减小摩擦因数, 以减少因摩擦引起的变形温度升高。

4) 只要控制好工艺参数, 尤其是变形温度, 采用连续等径角挤压技术是可以实现铜组织的超细化的, 经12道次后的平均晶粒尺寸细化到400nm。

5) 连续等径角挤压后材料的硬度明显增加, 3道次后硬度趋于饱和。

REFERENCES

[1]Valiev R Z, Islamgaliev R K, Alexandrov I V. Bulk nanostructured materials from severe plastic deformation[J]. Prog Mater Sci, 2000, 45: 103-189.

[2]Segal V M, Reznikov V I, Drobyshevkiy A E, et al. Plastic metal working by simple shear[J]. Russ Metally, 1981, 1: 99-104.

[3]Gleiter H. Nanocrystalline materials[J]. Progr Mater Sci, 1989, 33: 223-315.

[4]Valiev R Z, Krasilnikov N A, Tsenev N K. Plastic deformation of alloys with submicron-grained structure[J]. Mater Sci Eng A, 1991, 137: 35-40.

[5]Segal V M. Materials processing by simple shear[J]. Mater Sci Eng A, 1995, 197: 157-164.

[6]刘咏, 唐志宏, 周科朝, 等. 纯铝等径角挤压(Ⅱ)——变形行为模拟[J]. 中国有色金属学报, 2003, 13(1): 294-299.

LIU Yong, TANG Zhi-hong, ZHOU Ke-zhao, et al. Equal channel angular pressing process of pure aluminum(Ⅱ)—Simulation of deformation behavior[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 294-299.

[7]Valiev R Z. Structure and mechanical properties of ultrafine-grained metals[J]. Mater Sci Eng A, 1997, 234-236: 59-66.

[8]Raab G J, Valiev R Z, Lowe T C, et al. Continuous processing of ultrafine grained Al by ECAP-Conform[J]. Mater Sci Eng A, 2004, 382: 30-34.

[9]Lee J C, Seok H K, Han J H, et al. Controlling the textures of the metal strips via the continuous confined strip shearing(C2S2) process[J]. Materials Research Bulletin, 2001, 36: 997-1004.

[10]Han J H, Oh K H, Lee J C. Effect of accumulative strain on texture evolution in 1050 Al alloys processed by continuous confined strip shearing[J]. Mater Sci Eng A, 2004, 387-389: 240-243.

[11]Srinivasan R. Computer simulation of the equichannel angular extrusion (ECAE) process[J]. Scripta Mater, 2001, 44: 91-96.

[12]Kim H S, Seo M H, Hong S I. Plastic deformation analysis of metals during equal channel angular pressing[J]. J Mater Proc Technol, 2001, 113: 622-626.

[13]Kim H S. Finite element analysis of equal channel angular pressing using a round corner die[J]. Mater Sci Eng A, 2001, 315: 122-128.

[14]Luis-Pérez C J. On the correct selection of the channel die in ECAP processes[J]. Scripta Mater, 2004, 50: 387-393.

[15]Kim W J, Namkung J C. Computational analysis of effect of route on strain uniformity in equal channel angular extrusion[J]. Mater Sci Eng A, 2005, 412: 287-297.

[16]汪建敏, 许晓静, 石凤健, 等. 等径角挤压获得超细晶铜的研究[J]. 热加工工艺, 2004, 7: 6-7.

WANG Jian-min, XU Xiao-jing, SHI Feng-jian, et al. Investigation on ultra-fine grain copper by equal channel angular pressing[J]. Hot Working Technology, 2004, 7: 6-7.

基金项目: 辽宁省自然科学基金资助项目(20032106)

收稿日期: 2006-03-28; 修订日期: 2006-05-27

通讯作者: 运新兵, 副教授; 电话:0411-84109425; E-mail: yunxb@djtu.edu.cn

(编辑 李艳红)