文章编号:1004-0609(2011)07-1504-09

Ag对Al-Cu-Mg合金Ω相析出行为的影响

蔡金伶, 易丹青, 王宏伟, 王 斌

(中南大学 材料科学与工程学院,长沙,410083)

摘 要:用硬度测试、差热分析(DSC)以及透射电镜(TEM)研究Al-Cu-Mg-(Ag)合金时效过程中组织和性能的演变;根据不同升温速率的DSC曲线,采用Kissinger法计算Ω相和θ′相的激活能,探讨Ag对Al-Cu-Mg合金Ω相和θ′相析出行为的影响。结果表明:Al-Cu-Mg合金经185 ℃时效后,时效硬化曲线呈双阶段硬化特征,生成少量Ω相;添加Ag后,合金的时效硬化能力显著提高,经170、185和200 ℃时效时,对应的峰值时效时间分别为10、5和2 h,峰值硬度随着时效温度的升高而下降;Ag能促进Ω相析出,使θ′相的激活能提高,从而抑制θ′相的 析出。

关键词:Al-Cu-Mg-(Ag)合金;Ω相;析出行为;微观组织;激活能

中图分类号:TG146.2 文献标志码:A

Effect of Ag on precipitation behavior of Ω phase in Al-Cu-Mg alloy

CAI Jin-ling, YI Dan-qing, WANG Hong-wei, WANG Bin

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract:The effect of Ag on the microstructure and mechanical properties of Al-Cu-Mg-(Ag) alloy during artificial aging was studied by Vickers hardness measurement, differential scanning calorimetry (DSC) and transmission electron microscopy (TEM). The analysis of DSC curves at various heating rates was carried out to evaluate the activation energies of Ω and θ′ phases by Kissinger method. The effect of Ag on the precipitation behavior of Ω and θ′ phases in Al-Cu-Mg alloy was investigated. The results show that the aging hardening curve of Al-Cu-Mg alloys is of two-stage hardening at 185 ℃ with a small amount of Ω phase precipitated. When Ag is added to Al-Cu-Mg alloy, the aging hardening ability is greatly improved. The aging time of Al-Cu-Mg-Ag alloy corresponding to the peak value of hardening is 10, 5 and 2 h, respectively, when the alloy is aged at 170, 185 and 200 ℃, while the peak hardness decreases with the increase of the aging temperature. The addition of Ag in Al-Cu-Mg alloy promotes the formation of Ω phase and increases the activation energy of θ′ phase, resulting in the suppression precipitation of θ′ phase.

Key words: Al-Cu-Mg-(Ag) alloy; Ω phase; precipitation behavior; microstructure; activation energy

Al-Cu-Mg系铝合金属于热处理可强化型合金,具有良好的综合性能,被广泛地应用于航空航天等领域。该合金适合在室温环境下使用,而当用于飞机结构材料时,由于飞机在空中飞行时与空气发生摩擦,使飞机表面温度上升,当温度超过100 ℃时,强化相(θ′或S)急剧粗化而使性能显著下降,严重影响该合金的实际应用。 20世纪80年代,POLMEAR和COUPER[1]及POLMEAR和CHESTER[2]研究发现,向位于 (α+θ+S)或(α+θ)相区高Cu/Mg比的Al-Cu-Mg合金中加入微量Ag能使合金析出一种新的时效强化相Ω。该析出相在较高的温度下(≤200 ℃)具有优异的抗粗化性能[3],可显著改善合金的高温力学性能和抗蠕变 性能[4-5]。

各国研究者对Al-Cu-Mg-Ag合金微观组织的研究主要集中在Ω相的化学成分和晶体结构,时效初期,Ω相的形核机理、微观组织演变以及Ω相的高温析出行为[6]。CHANG和HOWE[7]研究表明,Ω相是平衡相θ相的一种过渡相,其化学组成与θ-Al2Cu相同。随后,HONO等[8]用原子探针场离子显微镜(APFIM)证实Ω相的成分与Al2Cu接近,同时发现Ag和Mg在α/Ω界面富集。研究者们对Ω相的晶体结构提出种种设想,有单斜结构[9]、六方结构[10]及正交结构[11-12],其中,被广泛接受的是面心正交结构(空间群为Fmmm, a=0.496 0 nm,b=0.859 0 nm,c=0.848 0 nm[13])。由于缺乏实验依据以及存在广泛的争议,许多研究者对时效初期Ω相的形核机理和微观组织演化提出各自的理论。TAYLER等[14]、COUSLAND和TATE[15]以及ABIS[16]等分别提出以Mg3Ag、MgAg和Ω′为先驱相的形核理论,这些都是以先驱相为形核核心的不均匀形核。HONO等[8]和RINGER等[17]分别研究Al-Cu-Mg-Ag在130和180 ℃时效初期析出相的演化过程,认为时效时并无先驱相,而Ag-Mg共聚原子团为Ω相的析出提供了有利的形核位置。

近期BAKAVOS等[18]研究发现,高Cu/Mg比的Al-Cu-Mg合金在T8态时,有少量Ω相析出。宋旼 等[19-20]从热力学角度分析合金不需要Ag存在,只需要有Mg即可在基体的{111}α面上形成GP区,且在随后的时效过程中逐渐演变为Ω相。

然而,关于Ag对Al-Cu-Mg合金中Ω相和θ′相时效析出激活能的影响尚未见报道,为此,本文作者利用差热分析(DSC)法研究Ag对Al-Cu-Mg合金中Ω相和θ′相析出激活能的影响,并结合硬度法和TEM观察对其时效析出行为进行分析。

1 实验

用铸锭冶金法制备合金A和B,其化学成分列于表1。合金铸锭经(420 ℃,6 h)+(515 ℃,18 h)均匀化处理、铣面、热轧及中间退火后,冷轧成2.16 mm厚的板材。合金经525 ℃、2 h固溶,室温水淬后进行人工时效。时效处理温度为170、185和200 ℃,时效时间为0.5~44 h。人工时效后立即在HV-10B型小载荷维氏硬度计上进行硬度测试,载荷为19.6 N,加载时间为15 s,每个试样至少测试3个点,取其平均值作为测量值。 用Universal V4.1-TA型热分析仪进行差热分析,选纯铝作为参比样,升温速率为5、10和20 K/min,升温范围为50~450 ℃,实验采用N2气氛保护;选取合金A和B的淬火态试样(约20 mg,0.2 mm厚) 进行DSC分析。TEM试样首先机械减薄至约0.1 mm,冲裁成直径为3 mm的圆片,然后在MTP-1A型双喷电解减薄仪上减薄,减薄时电压为15~20 V,电流控制在50 mA左右,双喷液为30%硝酸+70%甲醇混合溶液,用液氮冷却至-25 ℃以下,试样在穿孔后用酒精清洗至少10 min。在TecnaiG220型透射电子显微镜上进行微观组织观察,加速电压为200 kV。

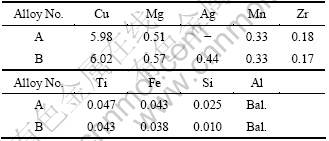

表1 实验合金的化学成分

Table 1 Chemical composition of experimental alloys (mass fraction, %)

2 结果

2.1 不同时效制度下合金的硬化曲线

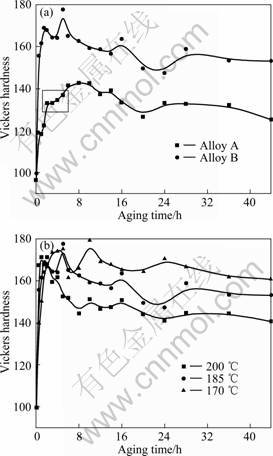

图1(a)所示为合金A和B经固溶处理后于185 ℃时效不同时间的硬度变化曲线。由图1(a)可以看出,两种合金具有很强的时效强化效应,两种合金的维氏硬度随时效时间的变化规律大致类似,均经历了欠时效、峰时效和过时效3个阶段。时效初期,合金硬度均迅速上升,且随时效时间的延长而增大。合金A的欠时效过程中有一平缓阶段(如图1(a)方框所示),即硬度平台,呈现双阶段硬化特征,这是GP区的析出所 致[21];合金B的初始硬化速率明显加快,硬化水平提高,平缓阶段基本消失。合金A达到峰时效的时间为8 h,峰值硬度为142 HV;而合金B达到峰时效的时间缩短为5 h,峰值硬度为177 HV。图1(b)所示为合金B在不同时效温度下的硬化曲线。170 ℃时效时,其峰值时间和相应硬度分别为10 h和179 HV;200 ℃时效时,其峰值时间和硬度分别为1 h和171 HV。由图1(b)可知,随着时效温度的进一步提高,达到峰值时效的时间大大缩短,峰值硬度下降,并且合金快速进入过时效阶段。

2.2 DSC分析

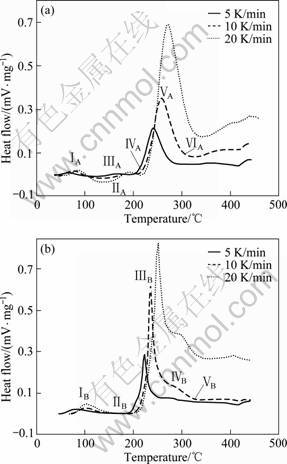

图2所示为淬火态合金A和B在不同升温速率下的DSC曲线。图2中,曲线的放热峰代表析出相的形成,吸热峰为析出相的溶解。从图2可知,随着升温速率的提高,对应的热效应峰漂移到更高的温度,表明合金反应是由热激活的。图2(a)所示为升温速率为10 K/min时合金A的DSC曲线,放热峰ⅠA的峰值温度为75.3 ℃,对应GP区的形成[22];吸热峰ⅡA的温度范围比较宽(120~156 ℃),对应GP区的溶解;放热峰ⅢA的峰值温度为185 ℃,对应θ″的形成;吸热峰ⅣA的温度范围为195~210 ℃,对应θ″相的溶解;放热峰ⅤA的峰值温度为258.8 ℃,对应θ′相的形成;吸热峰ⅥA的温度范围为310~336 ℃,对应θ′相的溶解。图2(b)所示为合金B的DSC曲线,放热峰ⅠB的峰值温度为101.1 ℃,对应Ag-Mg原子团簇和GP区的形成[23];吸热峰ⅡB发生在186~190 ℃,对应GP区的溶解,而Ag-Mg原子团簇并没有随着GP区的溶解而溶解,该峰比较平坦,这可能是因为Mg-Ag原子团簇形成所释放的热量部分抵消了GP区溶解所吸收的热量;放热峰ⅢB的峰值温度为235.4 ℃,对应Ω相的形成[20, 24];放热峰ⅣB的峰值温度为286.2 ℃,对应θ′相的形成;吸热峰ⅤB的温度范围很宽,对应Ω相和θ′相的溶解。

图1 合金A和B经固溶处理后时效不同时间的硬度变化曲线

Fig.1 Hardness—time curves of alloys A and B solid-solution treated and aged at 185 ℃ (a) and alloy B aged at different temperatures (b)

图2 淬火态合金A和B在不同升温速率下的的DSC曲线

Fig.2 DSC curves of alloys A (a) and (b) B at different heating rates in quenched condition

根据DSC曲线热效应峰值温度以及不同的升温速率,可以运用热分析动力学分析微分法中最常用的Kissinger法计算合金不同析出相的激活能[25]。

析出速率:

(1)

(1)

式中:α为合金中的相在时间t时的转变百分数;k为反应速率常数;f(α)为反应机理函数的微分形式。

Κ与反应温度T(热力学温度)的关系可用Arrhenius方程表示:

k=Aexp[-E/(RT)] (2)

式中:A为表观指前因子;E为表观活化能(激活能);R为理想气体常数。

Kissinger法中,假设反应机理函数为f (α)=(1-α)n,相应的动力学方程表示为

(3)

(3)

对方程(3)两边微分,在DSC曲线的顶峰,即T=Tp处,其一阶导数为0,即

(4)

(4)

将微分方程处理后得

(5)

(5)

式中:αp为合金中的相在T=TP时的转变百分数。

升温速率为

(6)

(6)

Kissinger认为,n(1-α)n-1与β无关,其值近似等于1,因此,式(5)可变换为

(7)

(7)

对式(7)两边取对数,得Kissinger方程:

(8)

(8)

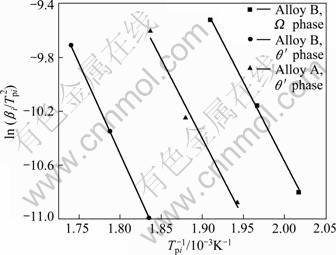

式(8)表明, 与1/Tpi成线性关系,将二者作图可以得到一条直线(见图3),由直线斜率可求得Ek。

与1/Tpi成线性关系,将二者作图可以得到一条直线(见图3),由直线斜率可求得Ek。

图3 析出相ln(βi/Tpi2)和1/Tpi的关系

Fig.3 Relationship between ln(βi/Tpi2) and 1/Tpi for precipitates

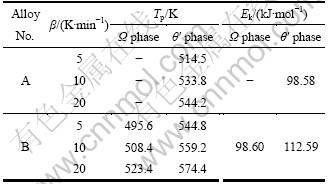

计算结果如表2所列。在合金A的DSC曲线中没有观察到Ω相生成或溶解的热效应峰,这可能是由于合金中析出Ω相的数量太少,而被其他峰叠加。因此,在计算析出相时无法计算合金A中Ω相的激活能,

但这并不影响后续的讨论。从表2可知,合金A中θ′相的激活能为98.58 kJ/mol,添加Ag的合金B的θ′相的激活能则提高到112.59 kJ/mol,与合金A相比,合金B的θ′相的激活能提高了13.7%,这说明生成θ′相的阻力变大,使θ′相更难析出,在DSC曲线上表现为放热峰偏移到更高的温度。合金B的Ω相激活能为98.60 kJ/mol,与合金A的θ′相激活能非常接近,这说明添加微量Ag具有促进Ω相析出的作用。

表2 Kissinger法计算得到的Ω和θ′相的激活能

Table 2 Activation energies of Ω and θ′ phases obtained by Kissinger method

2.3 TEM分析

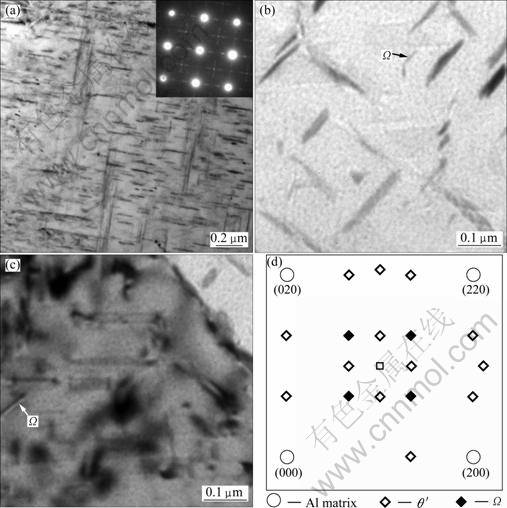

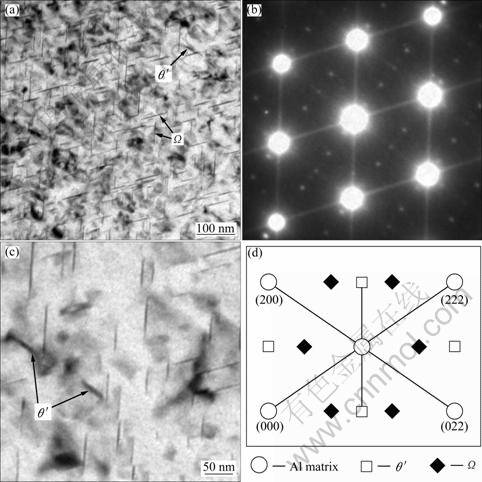

图4(a)所示为合金A经185 ℃时效2 h的TEM明场像以及对应á100?α方向的SAED谱和示意图。从图4(a)可以看出,经时效处理后,晶内析出大量的片状相,析出相在选区衍射谱中表现为较弱的衍射斑点,表明此时晶内的主要强化相为θ′相。θ′相为正方结构,其空间群是I M2,晶格参数为a=c=0.404 nm、b=0.580 nm,呈片状,在Al基体的{100}α面上析出,该相与基体的位向关系为(100)θ′//(100)α和[010]θ′//[010]α[25]。尽管在图4(a)的明场相中没有显示Ω相的形貌特征,但是在相应的选区电子衍射谱中显示了Ω相较弱的斑点,这表明合金A中也有少量Ω相生成。为了考察析出相Ω,进一步放大倍数观察Al-Cu-Mg合金在185 ℃时效2 h的明场像,其结果如图4(b)和(c)所示。由图4(b)和(c)可以观察到少量的Ω相。图4(d)所示为对图4(a)镶嵌的衍射谱进行模拟得到的Al基体、θ′和Ω相衍射斑点的分布示意图。由图4(d)可见,在高Cu/Mg比的Al-Cu-Mg合金中有少量Ω相析出。

M2,晶格参数为a=c=0.404 nm、b=0.580 nm,呈片状,在Al基体的{100}α面上析出,该相与基体的位向关系为(100)θ′//(100)α和[010]θ′//[010]α[25]。尽管在图4(a)的明场相中没有显示Ω相的形貌特征,但是在相应的选区电子衍射谱中显示了Ω相较弱的斑点,这表明合金A中也有少量Ω相生成。为了考察析出相Ω,进一步放大倍数观察Al-Cu-Mg合金在185 ℃时效2 h的明场像,其结果如图4(b)和(c)所示。由图4(b)和(c)可以观察到少量的Ω相。图4(d)所示为对图4(a)镶嵌的衍射谱进行模拟得到的Al基体、θ′和Ω相衍射斑点的分布示意图。由图4(d)可见,在高Cu/Mg比的Al-Cu-Mg合金中有少量Ω相析出。

图5所示为合金A经185 ℃、8 h峰时效的TEM明场像及对应的á111?α方向的SAED谱。根据文献[10, 26],该合金峰时效的主要析出相为θ′相。SAED谱表明,在基体衍射斑1/2处的斑点来自θ′相。进一步放大图像,图5(c)箭头所指析出相为Ω相,可以观察到Ω相在{111}α面上为不规则的六角形形貌[9-10],这与文献[19]的研究结果一致。随着时效时间的延长,合金的析出相更加弥散;当达到峰时效时,主要析出相为θ′相,同时伴随少量的Ω相,此时,合金的硬度达到最大(见图1(a))。

图4 合金A在185 ℃时效2 h后的TEM明场像以及对应的SAED谱

Fig.4 TEM images and corresponding SAED patterns of alloy A after aging at 185 ℃ for 2 h: (a) TEM image in bright field and SAED pattern of [001]α; (b), (c) Enlargement of (a); (d) Simulated SAED pattern corresponding to (a)

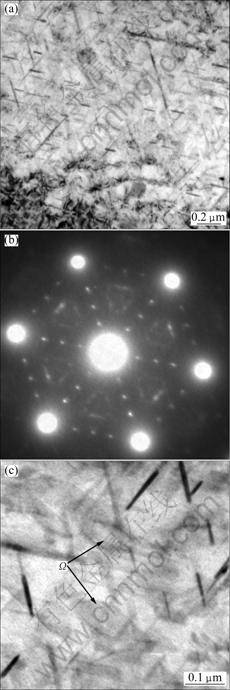

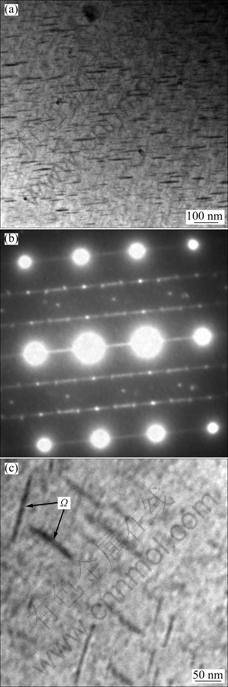

图6所示为合金B经185 ℃、2 h时效的TEM明场像以及对应á110?α方向的SAED谱和示意图。从图6中可以看出,合金B经时效处理后析出细小的片状Ω相和少量的θ′相。

Ω相与α(Al)基体的位向关系为(111)α//(001)Ω、[010]Ω//[10 ]α和[100]Ω//[1

]α和[100]Ω//[1 1]α。Ω相两个方向的变体呈约70°的角度交错排列,且Ω相与Al基体呈半共格的关系。由图6(b)的SAED谱以及图6(d)的SAED示意图可知,Ω相分布在基体斑点的1/3和2/3处,θ′相分布在基体斑点的1/2处。明场像中观察到的析出相主要为Ω相,θ′相很少,几乎观察不到。但是,衍射斑点显示θ′相是存在的。进一步放大倍数,由图6(c)可以观察到少量θ′相,该相比Ω相粗大。

1]α。Ω相两个方向的变体呈约70°的角度交错排列,且Ω相与Al基体呈半共格的关系。由图6(b)的SAED谱以及图6(d)的SAED示意图可知,Ω相分布在基体斑点的1/3和2/3处,θ′相分布在基体斑点的1/2处。明场像中观察到的析出相主要为Ω相,θ′相很少,几乎观察不到。但是,衍射斑点显示θ′相是存在的。进一步放大倍数,由图6(c)可以观察到少量θ′相,该相比Ω相粗大。

图7所示为合金B经185 ℃、5 h峰时效的TEM明场像及其对应á112?α方向的SAED谱。由图7可知,经峰时效后,Ω析出相分布均匀,且数量比欠时效态的多。对应的SAED谱中析出相的衍射斑点变得清晰。合金B的主要析出相为Ω相并伴随少量的θ′相。主要析出相Ω使得该合金的时效硬化效果明显,且时效响应极快。对比图4可以看出,Ω相的尺寸较θ′相的细得多,这有利于合金强度和韧性的提高。

3 讨论

在铝合金的固溶过程中,不仅合金元素溶入α固溶体,而且也会形成大量的晶格空位。淬火后,溶质原子呈过饱和状态,且留在固溶体里,空位也被冻结在晶格内。铝合金的时效过程就是将固溶处理获得的过饱和固溶体在室温或高于室温的条件下逐步脱溶的过程,通过一系列脱溶相如GP区、过渡相及平衡相的出现、形核及长大来实现的。

图5 合金A经185 ℃时效8 h(峰时效)后的TEM明场像及相应的SAED谱

Fig.5 TEM images and corresponding SAED patterns of alloy A after aging at 185 ℃ for 8 h: (a) TEM image in bright field; (b) á111?α SAED pattern; (c) Enlargement of (a)

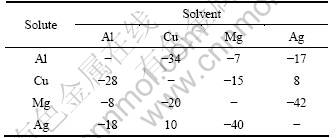

本研究中的Al-Cu-Mg和Al-Cu-Mg-Ag合金属于高Cu/Mg比合金,位于(α+θ)或(α+θ+S)相区。微量元素对合金时效析出相形核过程以及时效析出序列的影响主要有如下两个因素:溶质原子之间的相互作用;溶质原子与空位之间的相互作用。溶质原子之间的相互作用大小可以由无限稀释固溶体中溶质的自由焓?hΘ推测[27],如表3所列,无限稀释固溶体中两元素之间的自由焓为负值,且绝对值越大,表明该原子对在热力学上越稳定,越容易形成,它们之间的相互作用越强烈。

表3 不同元素形成固溶体 (无限稀释) 时的形成焓[29]

Table 3 Formation enthalpy of solid solution (infinite dilution) formed between different elements (?hΘ(kJ/mol))

合金A的典型时效析出序列如下:SSSS→GP 区→θ″→θ′ →θ。淬火后存留的过饱和空位为时效初期形成的偏聚区(GP区)提供了溶质原子扩散和富集的条件。在高Cu/Mg比的Al-Cu-Mg合金中,Mg原子与空位的结合能很高[28],足以形成大量的Mg-空位对,而Cu和Mg原子之间的相互作用很强(-20 kJ/mol),导致Mg-空位对很容易捕获Cu原子,形成Cu-Mg-空位团。此外,Cu的原子半径比Al的小,当Cu原子在Al基体的晶面偏聚时会产生正的晶格畸变;而Mg的原子半径比Al的大,Cu-Mg-空位团的形成降低了这两种与Al基体的晶格畸变能,随后,空位即可被释放或者空位坍塌形成位错环,为Cu原子的扩散与富集提供条件,因此,在时效初期快速形成GP区,并产生典型的硬度平台,呈双阶段硬化特征;随着时效时间的延长,合金的硬度逐渐增大,这是因为GP区逐渐被过渡相θ″和θ′相取代;当达到峰时效时,主要析出相为θ′相;进入过时效后,θ′相逐渐粗化并转化为平衡相θ。在DSC分析中,可能由于峰与峰之间叠加,导致一些析出相的放热峰没能在DSC曲线中显示,但是,DSC热分析仍然能给时效析出序列提供可靠的依据。通过SAED谱以及高倍TEM像发现,高Cu/Mg比的Al-Cu-Mg合金(合金A)也会析出Ω相,该结果与文献[18]的结果一致。宋旼等[19-20]在对Al-Cu-Mg合金中Ω相的形核机制研究时发现,Al-Cu-Mg合金中,Mg-Cu原子对对Cu原子簇沿基体{100}α和{111}α面偏聚有一定的促进作用[20-21]。少量小尺寸的Cu原子簇沿基体{111}α面偏聚所引起的晶格畸变能是可以容纳的,因此,合金中只要有Mg存在即可在基体的{111}α面形成GP区,随后,逐渐演变为Ω相。

图6 合金B经185 ℃时效2 h后的TEM明场像及相应的SAED谱

Fig.6 TEM images and corresponding SAED pattern of alloy B after aging at 185 ℃ for 2 h: (a) TEM images in bright field; (b) SAED pattern of á110?α; (c) Enlargement of (a); (d) Simulated SAED pattern corresponding to (b)

添加微量Ag的Al-Cu-Mg合金(合金B)的时效析出序列改变为 ,合金峰时效

,合金峰时效

时的主要析出相为Ω相,伴随少量的θ′相。合金A的 θ′相析出激活能和合金B的Ω相析出激活能相近(见表2),但是,添加Ag合金B的θ′相的析出激活能与合金A的相比提高了13.7%,所以,合金B优先析出Ω相。可见,添加微量Ag能抑制Al-Cu-Mg合金θ′相的析出,但能促进Ω相的形成,因此,Ag元素成为Al-Cu-Mg合金中析出Ω相的动力学条件。这可能是由于Ag原子与Mg原子的相互作用比Cu原子与Mg原子之间的相互作用强烈(见表3),因此,合金淬火后快速形成Mg-Ag原子团簇。Mg的原子半径比Al的大,而Ag的原子半径与Al的相当,因此,Mg-Ag原子团簇倾向于{111}α面偏聚,以减小弹性应变能,并为Cu原子沿{111}α面偏聚提供有利条件。MURAYAMA和HONO[30]利用三维原子探针(3-DAP)分析Al-1.9Cu-0.3Mg-0.2Ag(摩尔分数,%)合金时效初期的原子分布状态,表明在180 ℃时效15 s后,出现Mg-Ag原子团簇;时效120 s时,Cu原子以摩尔分数约为30%向Mg-Ag原子团簇聚集,并认为这是Ω相形成的初始阶段,而Mg-Ag原子团簇是Ω相的有利形核地点。随着时效的进行,少量的Cu原子也会在{100}α面偏聚,并转化为θ″相,而后形成θ′相;而Mg-Ag原子团簇此时分布在Ω相与α(Al)基体界面处,Ag和Mg的原子半径大于Cu原子的,其扩散速度小于Cu原子的,因此,分布在界面处的Mg-Ag原子团簇能延缓Ω相的长大与粗化,这有利于提高合金的力学性能;随着时效时间的延长,合金B的硬度仍然维持在一个较高的水平,说明Ω相具有良好的热稳定性。

图7 合金B经185 ℃峰时效5 h后的TEM明场像及对应á112?α方向的SAED谱

Fig.7 TEM images and corresponding SEDA patterns of alloy B after peak aging at 185 ℃ for 5 h: (a) TEM image in bright field; (b) SAED pattern along á112?α; (c) Enlargement of (a)

脱溶相的析出需要溶质原子的扩散,而温度则是影响原子扩散的一个重要因素,因此,时效温度对析出过程的形核和长大具有重要影响。本文作者测定了3个温度下的时效硬化曲线,时效温度越高,达到峰值时效的时间越短,而峰值硬度则随着温度的升高而下降。这是由于在170和185 ℃时效时,原子扩散速率比200 ℃的慢,过饱和溶质原子有足够的时间形成Ag-Mg原子团簇和GP区,并为Ω相的析出提供形核位置。而在200℃高温时效时,原子扩散速率加快,预脱溶阶段和过渡相(即Ag-Mg原子团簇、GP区以及θ″相和Ω相)可能出现的过渡相结构较少,而是很快形成平衡相,因此,达到峰值时效的时间较短,且预脱溶相和过渡相的减少使峰值硬度下降。

4 结论

1) 高Cu/Mg比的Al-Cu-Mg合金在185 ℃时效后的主要强化相为θ′相,其析出激活能为98.58 kJ/mol,合金中也有少量的Ω相析出,并且合金呈双阶段硬化特征。

2) 添加Ag的Al-Cu-Mg合金人工时效硬化效果加强,响应速度加快,且进入过时效后仍能保持较高的硬度;Ag能够促进Ω相的析出,使θ′相的激活能提高到112.59 kJ/mol,从而抑制θ′相的析出。

3) 添加微量Ag的Al-Cu-Mg合金在185 ℃时效后的强化析出相由片状Ω相和少量θ′相组成。

REFERENCES

[1] POLMEAR I J, COUPER M J. Design and development of an experimental wrought aluminum alloy for use at elevated temperatures[J]. Metallurgical Transactions A, 1988, 19(4): 1027-1035.

[2] POLMEAR I J, CHESTER R J. Abnormal age hardening in an Al-Cu-Mg alloy containing silver and lithium[J]. Scripta Metallurgica, 1989, 23(7): 1213-1217.

[3] RINGER S P, YEUNG W, MUDDLE B C, POLMEAR I J. Precipitate stability in Al-Cu-Mg-Ag alloys aged at high temperatures[J]. Acta Metallurgica et Materialia, 1994, 42(5): 1715-1725.

[4] LUMLEY R N, MORTON A J, POLMEAR I J. Enhanced creep performance in an Al-Cu-Mg-Ag alloy through underageing[J]. Acta Materialia, 2002, 50(14): 3597-3608.

[5] LUMLEY R N, POLMEAR I J. The effect of long term creep exposure on the microstructure and properties of an underaged Al-Cu-Mg-Ag alloy[J]. Scripta Materialia, 2004, 50(9): 1227-1231.

[6] 张 坤, 戴圣龙, 杨守杰, 黄 敏, 颜鸣皋. Al-Cu-Mg-Ag系新型耐热铝合金研究进展[J]. 航空材料学报, 2006, 26(3): 251-257.

ZHANG Kun, DAI Sheng-long, YANG Shou-jie, HUANG Min, YAN Ming-gao. Development of a new creep resistant Al-Cu-Mg-Ag type alloy[J]. Journal of Aeronautical Materials, 2006, 26(3): 251-257.

[7] CHANG Y C, HOWE J M. Composition and stability of Ω phase in an Al-Cu-Mg-Ag alloy[J]. Metallurgical Transactions A, 1993, 24(7): 1461-1470.

[8] HONO K, SANO N, BABU S S, OKANO R, SAKURAI T. Atom probe study of the precipitation process in Al-Cu-Mg-Ag alloys[J]. Acta Metallurgica et Materialia, 1993, 41(3): 829-838.

[9] AULD J H. Structure of metastable precipitate in some Al-Cu-Mg-Ag alloys[J]. Materials Science and Technology, 1986, 2(8): 784-787.

[10] KERRY S, SCOTT V D. Structure and orientation relationship of precipitates formed in Al-Cu-Mg-Ag alloys[J]. Metal Science, 1984, 18: 289-294.

[11] SUN L P, IRVING D L, ZIKRY A M, DRENNER D W. First-principles investigation of the structure and synergistic chemical bonding of Ag and Mg at the Al/Ω interface in a Al-Cu-Mg-Ag alloy [J]. Acta Materialia, 2009, 57(2): 3522-3528.

[12] MUDDLE B C, POLMEAR I J. The precipitate Ω phase in Al-Cu-Mg-Ag alloys[J]. Acta Metallurgica, 1989, 27(3): 777-789.

[13] KNOWLES K M, STOBBS W M. The structure of {111} age-hardening precipitates in Al-Cu-Mg-Ag alloys[J]. Acta Crystallographica Section B, 1988, 44: 207-227.

[14] TAYLER J A, PARKER B A, POLMEAR I J. Precipitation in Al-Cu-Mg-Ag casting alloy[J]. Metal Science, 1978, 12: 478-482.

[15] COUSLAND S M, TATE V. Structural changes associated with solid-state reactions in Al-Ag-Mg alloys[J].Journal of Applied Crystallography, 1986, 19: 174-180.

[16] ABIS S, MENGUCCI P, RIONTINO G. A study of the high-temperature ageing of Al-Cu-Mg-Ag alloy 201[J]. Philosophical Magazine B, 1993, 67(4): 465-484.

[17] RINGER S P, HONO K, POLMEAR I J, SAKURAI T. Nucleation of precipitates in aged Al-Cu-Mg-(Ag) alloys with high Cu: Mg ratios[J]. Acta Materialia, 1996, 44(5): 1883-1898.

[18] BAKAVOS D, PRANGNELL P B, BES B, EBERL F. The effect of silver on microstructural evolution in two 2xxx series Al-alloys with a high Cu:Mg ratio during ageing to a T8 temper[J]. Materials Science and Engineering A, 2008, 491: 214-223.

[19] 宋 旼, 陈康华, 黄兰萍. Al-Cu-Mg-(Ag)合金中时效析出相的析出及生长动力学[J]. 中国有色金属学报, 2006, 16(8): 1313-1319.

SONG Min, CHEN Kang-hua, HUANG Lan-ping. Precipitation and growth dynamics of precipitates in Al-Cu-Mg-(Ag) alloy during aging[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(8): 1313-1319.

[20] 宋 旼, 肖代红. Mg和Ag元素对二元Al-Cu合金时效析出的影响[J]. 中国科学(E辑): 科学技术, 2006, 36(11): 1283-1290.

SONG Min, XIAO Dai-hong. Effect of Mg and Ag on ageing precipitation of binary Al-Cu alloy[J]. Science in China Series. (E): Technological Sciences, 2006, 36(11): 1283-1290.

[21] WANG S C, STARINK M J, GAO N. Precipitation hardening in Al-Cu-Mg alloys revisited[J]. Scripta Materialia, 2006, 54(2): 287-291.

[22] 肖代红, 陈康华, 宋 旼, 王健农. 微量Ag对Al-Cu-Mg-Mn合金时效析出及组织热稳定性的影响[J]. 金属热处理, 2007, 32(10): 17-23.

XIAO Dai-hong, CHEN Kang-hua, SONG Min, WANG Jian-nong. Effects of Ag addition on ageing precipitation and microstructure thermal stability of an Al-Cu-Mg-Mn alloy[J]. Heat Treatment of Metals, 2007, 32(10): 17-23.

[23] HOU Yan-hui, GU Yan-xia, LIU Zhi-yi, LI Yun-tao, CHEN Xu. Modeling of whole process of ageing precipitation and strengthening in Al-Cu-Mg-Ag alloys with high Cu-to-Mg mass ratio[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 863-869.

[24] RINGER S P, MUDDLE B C, POLMEAR I J. Effects of cold work on precipitation in Al-Cu-Mg-(Ag) and Al-Cu-Li-(Mg-Ag) alloys[J]. Metallurgical and Materials Transactions A, 1995, 26: 1659-1671.

[25] 胡荣祖, 史启祯. 热分析动力学[M]. 北京: 科学出版社, 2008: 79-80.

HU Rong-zu, SHI Qi-zhen. Thermal analysis kinetics[M]. Beijing: Science Press, 2008: 79-80.

[26] 马秀梅. Al-Cu-Mg-Ag-Ce合金析出相的电子显微研究[D]. 北京: 北京工业大学, 2006: 19-26.

MA Xiu-mei. Electron microscopy investigation of precipitates in Al-Cu-Mg-Ag-Ce alloys[D]. Beijing: Beijing University of Technology, 2006: 19-26.

[27] 陈志国. 微合金化铝合金的微观组织演变与性能研究[D]. 长沙: 中南大学, 2004: 107-134.

CHEN Zhi-guo. Microstructural evolution and properties in microalloyed aluminium alloys[D]. Changsha: Central South University, 2004: 107-134.

[28] HUANG B P, ZHEN Z Q. Independent and combined roles of trace Mg and Ag additions in properties precipitation process and precipitation kinetics of Al-Cu-Li-(Mg)-(Ag)-Zr-Ti alloys[J]. Acta Materialia, 1998, 46(12): 4381-4393.

[29] NIESSEN A K, de BOER F R, BOOM R, de CHATEL P F, MATTENS W C M, MIEDEMA A R. Model predictions for enthalpy of transition metal alloys (Ⅱ)[J]. Calphad, 1983, 7(1): 51-70.

[30] MURAYAMA M, HONO K. Three dimensional atom probe analysis of pre-precipitate clustering in an Al-Cu-Mg-Ag alloy[J]. Scripta Materialia, 1998, 38(8): 1315-1319.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划资助项目(2005CB623705);中国铝业公司科技发展基金资助项目(CHALCO-2007-KJ-09)

收稿日期:2010-08-25;修订日期:2010-11-22

通信作者:易丹青,教授,博士;电话:0731-88830263;E-mail: danqing@mail.csu.edu.cn