文章编号:1004-0609(2013)07-1812-07

Mg含量对Al-Cu-Mg-Ag合金组织与力学性能的影响

宋艳芳1,潘清林1,2,丰 雷1,王 迎1,李 晨1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用维氏硬度、室温拉伸性能测试、金相显微分析技术、透射电子显微分析等手段,研究Mg含量对Al-Cu-Mg-Ag耐热铝合金的组织和性能的影响。结果表明:随着Mg含量的增加,合金的时效响应速率加快,峰时效时间提前,且峰值硬度先增大后减小,在Cu/Mg摩尔比接近6时峰值硬度达到极大值;合金的抗拉强度和屈服强度先上升后下降,塑性则先降低后提高,但总体保持在较高水平;Mg含量(质量分数)为0.4%和0.8%时,合金的主要强化相为Ω相和少量θ′相,Mg含量为1.2%的合金主要强化相为Ω相和S′相,随着Mg含量的增加,Ω相的体积分数增大,尺寸减小,分布更加均匀,但当Mg含量增大到1.2%时,Ω相的体积分数有所减小。

关键词:Al-Cu-Mg-Ag合金;显微组织;力学性能

中图分类号:TG146.2 文献标志码:A

Effects of Mg content on microstructure and mechanical properties of Al-Cu-Mg-Ag alloy

SONG Yan-fang1, PAN Qing-lin1, 2, FENG Lei1, WANG Ying1, LI Chen1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: The effects of Mg content on the mechanical properties and microstructures of Al-Cu-Mg-Ag alloy were studied by Wicker hardness test (HV), room temperature tensile properties, optical microscopy (OM) and transmission electron microscopy (TEM). The results show that with the increase of Mg content, the aging response rate is accelerated, the peak aging is advance, and whereas the peak hardness increases at first and then decreases which reaches its maximum when the Cu/Mg ratio closes to 6. With the increase of Mg content, the yield strength and the tensile strength increase first and then decrease, while the plasticity is just the opposite, but it maintains at a high level. The main strengthening phases are Ω phase and a bit of θ ′ phase when the Mg content (mass fraction) is 0.4% or 0.8%, but translate to Ω phase and S′ phase when the Mg content is 1.2%. The volume fraction of Ω phase increases with the increase of Mg content, the size decreases and it distributes more uniform. However, the volume fraction of Ω phase decreases to some extent when the Mg content is 1.2%.

Key words: Al-Cu-Mg alloy; microstructure; mechanical property

Al-Cu-Mg系合金具有良好的抗拉强度、疲劳强度和良好的韧性及耐热性等特点,具有非常广阔的应用前景,目前广泛应用于航空领域,是重要的航空结构材料[1-5]。但该合金主要用于不超过100 ℃的工作环境中,超过此温度时,主要强化相将发生粗化,导致力学性能下降[6-8]。添加Ag的Al-Cu-Mg合金可以在更高的温度(150 ℃)下使用,这主要是由于合金时效析出序列发生了改变,其强化相可能包括θ′相、S′相和Ω相,主要强化相的类型主要是由Cu/Mg质量比来决 定[9-13]。目前对Al-Cu-Mg-Ag合金的研究主要集中在微合金化及热处理方面,而Mg元素对其组织和力学性能的影响却少见报道。本文作者设计和制备了3种不同Mg含量的Al-Cu-Mg-Ag合金,系统地研究该合金的时效特性与微观组织演变,并期望在Mg元素在铝合金中的存在形式和作用机理探索的基础上,优化Al-Cu-Mg-Ag耐热铝合金的成分,开发出性能优越的新型铝合金。

1 实验

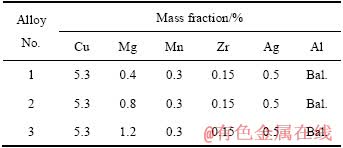

实验原料为工业纯铝、纯镁、纯银以及A1-Cu、A1-Mn和A1-Zr中间合金。采用铸锭冶金方法制备了Al-Cu-Mg-Ag合金铸锭。该合金的化学成分见表1,试样经500 ℃均匀化退火24 h,再进行铣面。在箱式电阻炉中加热至470 ℃,保温2 h,热轧至6 mm,经中间退火冷轧至3 mm的板材。合金在515 ℃固溶处理1.5 h,水淬,之后于185 ℃进行时效处理。

表1 Al-Cu-Mg-Ag合金化学成分

Table 1 Chemical composition of Al-Cu-Mg-Ag alloys

合金不同时效态下的硬度值在401MVDTM数显显微维氏硬度计下测定,加载载荷1.96 N,加载时间10 s。合金的室温力学性能在CSS-44100电子万能材料实验机上完成,拉伸速率为2 mm/min。金相显微分析在XJZ-A3金相显微镜下进行。DSC分析在差示扫描量热仪(DSC-5p)上进行,扫描速度为10 ℃/min。TEM分析在TECNAIG2 20型透射电镜上进行,加速电压为200 kV。透射电镜样品经机械预减薄后双喷穿孔而成,双喷液采用硝酸、甲醇混合液(1:3)(体积比),温度控制在-30 ℃以下。

2 结果与分析

2.1 时效硬化曲线

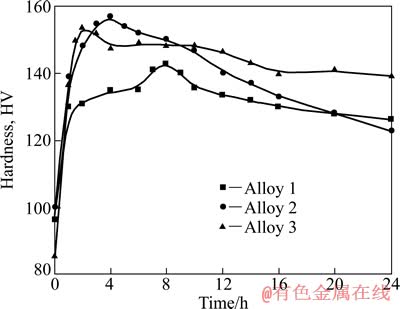

图1所示为合金在185℃时的等温时效硬化曲线。由图1可见,Mg含量的变化并不改变Al-5.3Cu-Mg- 0.5Ag合金的时效过程。3种合金的时效过程均包括了3个阶段,即欠时效、峰时效和过时效,表现出显著的时效硬化特性。3种合金在时效初期的时效响应速率均很快,且在达到峰时效之后较长时间内合金的硬度值下降不大,出现了一个较长的时效平台,说明在时效过程中,晶内析出相粗化缓慢,热稳定性较好。合金1在欠时效过程中有一平缓阶段,这是GP区析出所致。随着合金中Mg含量的增加,这一平缓阶段逐渐消失,初始硬化速率明显加快,欠时效过程缩短,合金的峰值硬度先上升后下降,在Cu/Mg摩尔比接近6时达到极大值。由此,可制定出各合金的峰时效处理制度如表2所列。

图1 Al-Cu-Mg-Ag合金在185 ℃的等温时效硬化曲线

Fig. 1 Vickers hardness versus ageing time at 185 ℃ for Al-Cu-Mg-Ag alloys

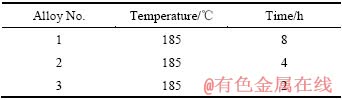

表2 Al-Cu-Mg-Ag合金峰时效处理制度

Table 2 Peak aging treatment condition of Al-Cu-Mg-Ag alloys

2.2 合金的室温拉伸性能

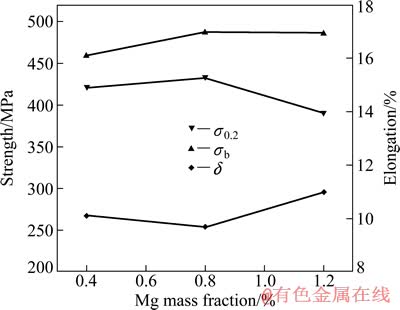

图2所示为4种合金进行如表2的峰时效处理后,在室温下进行拉伸测试的结果。由图2可知,在室温下,Mg含量的增加在一定程度上可提高Al-Cu-Mg-Ag合金的屈服强度和抗拉强度,但随着Mg含量的进一步增加,合金的屈服强度和抗拉强度则有所下降。而延伸率则是随着Mg含量的增加先降低后提高,但总体保持在较高水平。

图2 Al-Cu-Mg-Ag合金峰时效拉伸性能

Fig. 2 Tensile properties of peak-aged Al-Cu-Mg-Ag alloys

2.3 合金的金相组织

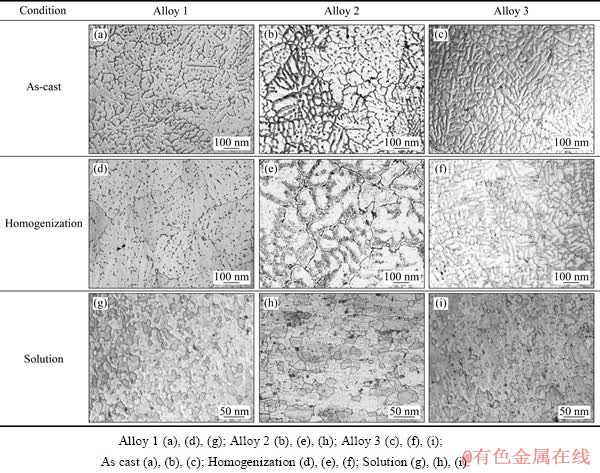

3种合金铸态、均匀化态和固溶态的金相组织如图3所示。由图3可见,3种合金的铸态组织中都存在明显的树枝状晶,枝晶偏析严重,需要通过后续热处理工艺来消除。但与合金1和合金2相比,合金3中的树枝状晶较为细小,组织更加均匀。经均匀化退火后,合金晶内枝晶偏析基本消除,枝晶网胞及晶界上网状化合物也部分溶解。

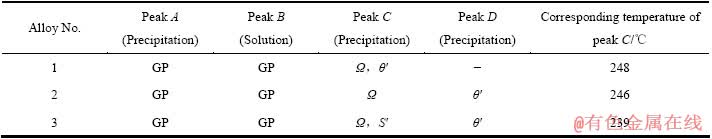

2.4 差示扫描量热法分析结果(DSC)

图4所示为3种淬火态合金的DSC曲线。由图4可见,3种合金的DSC曲线中各峰所对应的相变如表3所列。随着合金中Mg含量的增加,峰C向低温方向移动。峰C左移,表明Ω相的析出速率加快,峰时效时间缩短,这与时效硬化过程所显示的结果(见图1)一致。另外,合金2的峰C最为尖锐,所对应的面积最大,表明析出相的体积分数最大,且Ω相的强化效果最好,因而合金2的强度最高,这也与时效硬化过程所显示的结果一致。DSC分析结果表明,Mg含量的增加有利于Ω相的快速析出,但合金强度则先上升后下降。

图3 3种合金不同状态的金相组织

Fig. 3 Optical microscopes of three alloys under different conditions

表3 3种淬火态合金DSC曲线各峰对应相变

Table 3 Phase versus peaks in DSC analyses of three modified austemper alloys

图4 3种淬火态合金的DSC曲线

Fig. 4 DSC curves of three modified austemper alloys (sweep rate of 10 ℃/min)

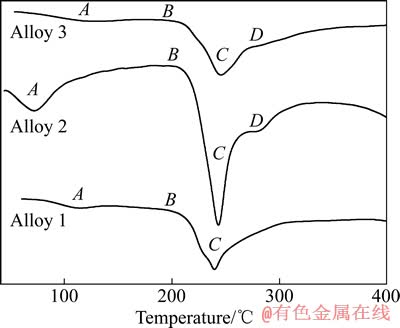

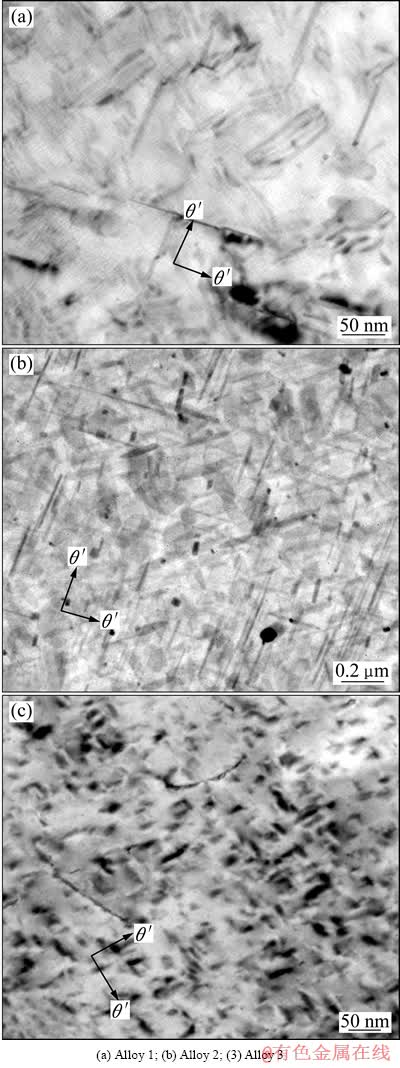

2.5 TEM显微组织

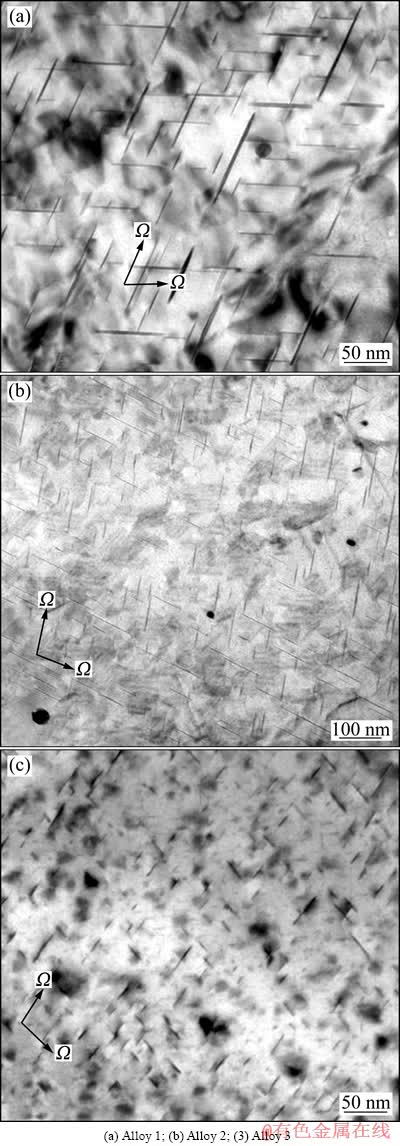

为了研究Mg含量对合金沉淀析出相的影响,以及力学性能和显微组织的关系,对峰时效态的3种合金进行了透射电子显微观察,结果如图5和6所示。图5中入射电子束方向为<100>方向,由图5可见,3种合金在峰时效态下沿基体[001]和[010]方向均有片状θ′相析出,合金3中还析出了少量针状的S′相。图6中入射电子束方向均为<110>Al方向。由图6可看出,3种合金峰时效态下均沿{111}α面析出大量片状Ω相,合金2中Ω相较合金1中的更为细小弥散,片状析出相厚度明显减小,体积分数明显增加。合金3的Cu/Mg摩尔比接近4,位于S+Ω相区,所以此时的主要强化相为Ω相和S′相,但由于此时形貌相的入射电子束方向为<110>Al方向,S′相在这个方向的形貌不规则,无法分辨,只能看到非常细小弥散的Ω相分布于基体中,且析出相侧向长度明显缩短,但总体积分数相比合金2略有下降。另外,由于4种合金所采用的时效时间不同,时效时间较长的合金中,Ω相可能发生了侧向长大和增厚,这还有待后续的进一步研究做出判断。

图5 3种合金峰时效态的TEM像(入射电子束方向均为<100>方向)

Fig. 5 TEM images of three peak-aged alloys (The election beam is close to <100>α)

图6 3种合金峰时效态的TEM像(入射电子束方向均为<110>Al方向)

Fig. 6 TEM images of three peak-aged alloys (The election beam is close to <110>Al)

3 讨论

Al-Cu-Mg-Ag合金的主要强化相是Ω相,由合金峰时效态的TEM像可知,合金1的析出强化相为Ω相和少量的θ′相,合金2的析出强化相为Ω相,合金3的析出强化相为Ω相和S′相。

当Al-Cu-Mg合金中同时存在Mg和Ag时,合金经过固溶处理并淬火后,形成了过饱和固溶体,其中存在着大量的自由空位,Mg、Ag原子和空位(Vacancy)发生强烈的相互作用,形成Mg/Ag/vacancy聚合体。这种聚合体在随后的时效过程中,通过Cu、Mg及Ag原子的共同扩散,促进Ω相的形成[13-14]。当Cu/Mg摩尔比较高时,Cu原子浓度比其他合金元素高,自由空位除用于形成Mg/Ag/vacancy聚合体的需要外,过量的空位基本上与Cu原子相结合,促进Cu原子的扩散,从而加速Ω相的析出。同时,Cu原子与空位形成的Cu/vacancy聚合体也可以作为GP区的形核核心,促进GP区的析出,在随后的时效过程中形成θ′相。

从时效硬化曲线中可以看出,3种合金在时效初期均表现出很高的时效响应速率,且随着Mg含量的增加,时效响应速率越快,峰时效明显。分析其原因,主要是因为在淬火过程中,Mg、Ag原子与淬火中形成的大量过饱和空位发生强烈相互作用而迅速团聚,形成Mg/Ag/vacancy聚合体,在时效初期,Mg/Ag/vacancy聚合体为Ω相的形核提供了核心,加速沉淀相的析出,使合金强度迅速提高。同时,在Ag含量不变的情况下,随着合金中Mg含量的增加,形成的Ag-Mg原子团越多,越有利于Ω相的析出,进而缩短了达到峰时效的时间。

同时,从合金的时效硬化曲线可以看出,合金的峰值硬度随着合金中Mg含量的增加而先上升后下降。这点在合金的拉伸性能测试结果中也有体现,随着合金中Mg含量的增加,合金的抗拉强度、屈服强度并没有一直升高,而是先上升后下降。分析其原因,主要是因为θ′(Al2Cu)相和Ω(Al2Cu)相在析出的过程中都需要消耗Cu原子,而S′(Al2CuMg)相不仅需要消耗Cu原子,同时需要消耗Mg原子,当合金中其他元素含量不变,Mg含量增加时,合金3析出S′相会消耗一部分Mg原子和Cu原子,使得合金中Cu原子含量减少,一定程度上阻碍了Ω相的大量析出;而相比于Ω相,S′相的强化效果又较弱,所以合金3的强度在一定程度上会有所下降。随着时效的进行,合金中的θ′相会由于溶质原子向Ω相转移而受到阻碍,所以出现了合金2中析出大量细小弥散的Ω相,且在3种合金中强度最高的现象。

由3种合金峰时效态的TEM像可知,随着合金中Mg含量的增加,合金峰时效态组织中Ω相的体积分数先增加后减少,更为细小弥散,且侧向长度和厚度逐渐减小。这是由于随着合金中Mg含量的增加,Ω相形核所需要的Mg/Ag/vacancy聚合体的数量增加,主要强化相Ω相的形核位置增多,使其相互之间发生碰撞的几率增大,从而降低其长大速率,尺寸减小。由文献[8, 15-17]可知,Mg/Ag/vacancy聚合体会在随后的时效过程中逐步演变为Ω相,Cu/vacancy聚合体会演变为θ′相,Mg/Cu/vacancy聚合体会演变成为含Cu、Mg的GP区,进而转化成为S′相。所以当合金中Mg含量较低,Cu/Mg摩尔比较大时,少量的Mg原子与Ag原子及空位结合成为少量的Ω相形核的核心,多余的Cu原子就会与空位结合成为Cu/vacancy聚合体,并转化成为θ′相;随着合金中Mg含量的增加,所形成的Mg/Ag/vacancy聚合体增加,Ω相的形核率增加,所以在合金2中析出了大量细小弥散的Ω相;当Mg含量继续增加时,Mg原子除了与Ag原子和空位结合成为Mg/Ag/vacancy聚合体外,还会与Cu原子和空位结合成为Mg/Cu/vacancy聚合体,促进含Cu、Mg的GP区的形成,在随后的时效过程中,GP区即转化成为S′相,这也是合金中析出相的转化和数量随着Mg含量的变化而变化的原因。

4 结论

1) Al-Cu-Mg-Ag合金在185℃时效时,随着Mg含量的增加,合金的时效响应速率加快,达到峰时效的时间提前,但合金的硬化水平则是先上升后下降。

2) Mg含量影响Al-Cu-Mg-Ag合金的力学性能。增加合金中的Mg含量,抗拉强度和屈服强度先上升后下降。但塑性的变化趋势则与之相反,即随着Mg含量的增加,合金的塑性先降低后升高,但总体保持在较高水平。

3) 含0.4%Mg和0.8%Mg的Al-Cu-Mg-Ag合金的主要强化相是Ω相和少量θ′相,当Mg含量为0.8%时,Ω相的体积分数增大,尺寸减小,分布更加均匀。当Mg含量增加到1.2%时,合金的主要强化相是Ω相和S′相,Ω相的体积分数有所减少。

REFERENCES

[1] 刘克明, 陆德平, 杨 滨, 陆 磊, 陈志宝, 谌 昀. 快速凝固耐热铝合金的现状与进展[J]. 材料导报, 2008, 22(2): 57-60.

LIU Ke-ming, LU De-ping, YANG Bin, LU Lei, CHEN Zhi-bao, CHEN Yun. Present status and development of rapid-solidified heat resistant aluminum alloys[J]. Materials Review, 2008, 22(2): 57-60.

[2] 雷彬彬, 周志明, 黄伟九, 唐丽文. Al-Cu-Mg高强铝合金的研究进展[J]. 材料热处理技术, 2012, 41(2): 41-45.

LEI Bin-bin, ZHOU Zhi-ming, HUANG Wei-jiu, TANG Li-wen. Development of high-strength Al-Cu-Mg alloy[J]. Material and Heat Treatment, 2012, 41(2): 41-45.

[3] 贾祥磊, 朱秀荣, 陈大辉, 费良军. 耐热铝合金研究进展[J]. 兵器材料科学与工程, 2010, 33(2): 108-112.

JIA Xiang-lei, ZHU Xiu-rong, CHEN Da-hui, FEI Liang-jun. Research development of heat-resistant aluminium alloys[J]. Ordnance Material Science and Engineering, 2010, 33(2): 108-112.

[4] 米国发, 董翠粉. 快速凝固耐热铝合金的研究进展[J]. 金属铸锻焊技术, 2010, 39(13): 4-6.

MI Guo-fa, DONG Cui-fen. Research development of rapid-solidified heat resistant aluminum alloys[J]. Hot Working Technology, 2010, 39(13): 4-6.

[5] 陈志国, 杨文玲, 王诗勇, 舒 军. 微合金化铝合金的研究进展[J]. 稀有金属材料与工程, 2010, 39(8): 1499-1504.

CHEN Zhi-guo, YANG Wen-ling, WANG Shi-yong, SHU Jun. Research progress of microalloyed Al alloys[J]. Rare Metal Materials and Engineering, 2010, 39(8): 1499-1504.

[6] 蔡金伶, 易丹青, 王宏伟, 王 斌. Ag对Al-Cu-Mg合金Ω相析出行为的影响[J]. 中国有色金属学报, 2011, 21(7): 1504-1512.

CAI Jin-ling, YI Dan-qing, WANG Hong-wei, WANG Bin. Effect of Ag on precipitation behavior of Ω phase in Al-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(7): 1504-1512.

[7] 肖代红, 黄伯云, 宋 旼, 陈康华. Al-Cu-Mg-(Ag,La)合金的显微组织与力学性能[J]. 中国有色金属学报, 2008, 18(4): 571-576.

XIAO Dai-hong, HUANG Bai-yun, SONG Min, CHEN Kang-hua. Microstructures and mechanical properties of Al-Cu-Mg-(Ag, La) alloys[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(4): 571-576.

[8] RAVIPRASAD K, HUTCHINSON C R, SAKURAI T, RINGER S P. Precipitation processes in an Al-2.5Cu-1.5Mg(wt.%) alloy microalloyed with Ag and Si[J]. Acta Materialia, 2003, 51: 5037-5050.

[9] XIAO D H, WANG J N, DING D Y, CHEN S P. Effect of Cu content on the mechanical properties of an Al-Cu-Mg-Ag alloy[J]. Journal of Alloys and Compounds, 2002, 343: 77-81.

[10] 刘志义, 李云涛, 刘延斌, 夏卿坤. Al-Cu-Mg-Ag合金析出相的研究进展[J]. 中国有色金属学报, 2007, 17(12): 1905-1915.

LIU Zhi-yi, LI Yun-tao, LIU Yan-bin, XIA Qing-kun. Development of Al-Cu-Mg-Ag alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1905-1915.

[11] BER L B, TELESHOV V V, UKOLOVA O G. Phase composition and mechanical properties of wrought aluminum alloys of the system Al-Cu-Mg-Ag-Xi[J]. Metal Science and Heat Treatment, 2008, 50(5/6): 220-227.

[12] 马飞跃, 刘志义, 侯延辉, 夏卿坤, 柏 松, 罗 虎. Ag含量对Al-Cu-Mg-Ag合金高温力学性能及耐热性的影响[J]. 稀有金属材料与工程, 2010, 39(3): 482-485.

MA Fei-yue, LIU Zhi-yi, HOU Yan-hui, XIA Qing-kun, BAI Song, LUO Hu. Effect of Ag content on evaluated-temperature mechanical properties and thermal stability of Al-Cu-Mg-Ag alloys[J]. Rare Metal Materials and Engineering, 2010, 39(3): 482-485.

[13] FENG Z Q, YANG Y Q, HUANG B, HAN M, LUO X and RU J G. Precipitation process along dislocations in Al-Cu-Mg alloys during artificial aging[J]. Materials Science and Engineering A, 2010, 528: 706-714.

[14] HOU Y H, GU Y X, LIU Z Y, LI Y T, CHEN X. Modeling of whole process of ageing precipitation and strengthening in Al-Cu-Mg-Ag alloys with high Cu-to-Mg mass ratio[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 863-869.

[15] MURAYAMA M, HONO K. Role of Ag and Mg on precipitation of T phase in an Al-Cu-Li-Mg-Ag alloy[J]. Scripta Materialia, 2001, 44: 701-706

[16] 雷文平, 沈 建, 毛柏平, 李俊鹏, 严亮明. Al-5.2Cu-0.4Mg- 1.02Ag合金的时效析出行为研究[J].金属学报, 2009, 45(5): 579-584.

LEI Wen-ping, SHEN Jian, MAO Bai-ping, LI Jun-peng, YAN Liang-ming. Study on aging precipitation behavior of Al-5.2Cu-0.4Mg-1.02Ag alloy[J]. Acta Metallurgica Sinica, 2009, 45(5): 579-584.

[17] 朱宝宏, 熊柏青, 张永安, 张建波, 李志辉, 李锡武. 高Cu/Mg比Al-Cu-Mg-Ag(2139)合金时效析出行为研究[J]. 稀有金属, 2011, 35(3): 317-321.

ZHU Bao-hong, XIONG Bai-qing, ZHANG Yong-an, ZHANG Jian-bo, LI Zhi-hui, LI Xi-wu. Research on precipitation behavior of Al-Cu-Mg-Ag(2139)alloy with high Cu/Mg ratio[J]. Chinese Journal of Rare Metals, 2011, 35(3): 317-321.

(编辑 何学锋)

基金项目:中南大学中央高校基本科研业务费专项资金资助项目(2012zzts067)

收稿日期:2012-10-19;修订日期:2013-04-11

通信作者:潘清林,教授,博士;电话:0731-88830933;E-mail:pql@mail.csu.edu.cn