文章编号:1004-0609(2012)08-2289-06

靶电流对磁控溅射AlSn20/C镀层耐蚀性的影响

郭巧琴1, 2,蒋百灵1,李建平2

(1. 西安理工大学 材料科学与工程学院,西安 710048;

2. 西安工业大学 材料与化工学院,西安 710032)

摘 要:采用非平衡磁控溅射技术在铝基轴承合金表面制备AlSn20/C复合镀层,通过扫描电镜形貌观察、交流阻抗和极化曲线的测量研究石墨靶电流对镀层组织与耐蚀性能的影响。结果表明:在电流0.2~0.8 A范围内,薄膜均以层状结构生长,且电流越小,薄膜组织越致密;镀膜后试样的电化学阻抗比基体的高5~6个数量级,石墨靶电流为0.2 A时,可将基体的自腐蚀电位由-1.42 V提高到-1.18 V,石墨靶电流是影响AlSn20/C复合镀层耐蚀性的一个重要因素,石墨靶电流越小,其耐蚀性越好。

关键词:轴承合金;AlSn20/C镀层;耐蚀性;自腐蚀电位

中图分类号:TB43 文献标志码:A

Effect of target current on corrosion resistance of AlSn20/C coating deposited by magnetron sputtering

GUO Qiao-qin1, 2, JIANG Bai-ling1, LI Jian-ping2

(1. Institute of Materials Science and Technology, Xi’an University of Technology, Xi’an 710048, China;

2. School of Materials and Chemical Engineering, Xi’an Technological University, Xi’an 710032, China)

Abstract: The AlSn20/C composite films were deposited on the surface bearing alloy by non-equilibrium magnetron sputtering. The influence of carbon target current on the structure and corrosion resistance were studied by scanning electron microscopy (SEM), electrochemical impedance spectroscopy (EIS) and polarization curves. The results indicate that when the current is in the range of 0.2-0.8 A, the film is in layer structure, and the lower the current is, the compacter the film structure is. The composite coating can improve the electrochemical impedance by 5-6 order of magnitude. When the carbon target current is 0.2 A, the self-corrosion potential can be improved from -1.42 V to -1.18 V. The carbon target current is an important factor to affect the corrosion resistance of AlSn20/C composite coating, the lower the target current is, the better the corrosion resistance is.

Key words: bearing alloy; AlSn20/C composite coating; corrosion resistance; self-corrosion potential

随着近几年来高速发动机的发展,新设计的柴油机都要求轴承承载极限比油膜最大压力(400 N/mm2)还要高出很多,同时使用寿命的期望值也急剧增加,即使细槽轴承也不能满足抗疲劳强度和耐磨性的要求,因此,要求轴承表面镀层在机械特性和性能指标方面有 重大的改进[1-2]。目前,世界各国都把主要精力集中在镀层的选材上,因为他们直接决定了轴承的工作稳定 性和使用寿命[3-4]。本文作者采用磁控溅射技术在轴承合金材料表面制备AlSn20/C镀层,该镀层是硬质点基体上分布软质点型镀层,且其间分布具有自润滑作用的石墨,具有极高的耐磨性、抗疲劳强度和减震能力,常用于高速大功率的重型机床、内燃机车,拖拉机等的轴承上[5-10]。另外,由于轴承长期处在润滑油的工作环境,因此,其耐蚀性好坏直接影响到轴承的使用寿命,针对这一生产实际,本文作者采用磁控溅射技术制备AlSn20/C镀层,并研究碳靶电流对AlSn20/C镀层耐蚀性的影响,为溅镀轴轴承提供理论和实践基础。

1 实验

试验选用AlZn4.5Mg铝基轴承合金,试样规格为d 40 mm×5 mm。

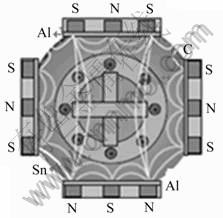

采用闭合场非平衡磁控溅射镀膜设备UDP450(见图1)制备AlSn20/C镀层,设备真空室内径为425 mm,试验中采用2个铝靶、1个锡靶和1个石墨靶的四靶配置,铝靶用于离子轰击清洗以及往渡层上引入合金元素Al。

图1 镀层设备靶材分布示意图

Fig. 1 Schematic diagram of target materials distribution of coating apparatus

镀前将试样进行预磨、抛光处理,然后用乙醇和丙酮超声波清洗10 min,经冷风吹干后放入真空室。本底真空度为1.1 mPa,氩气为溅射气体,靶基距保持为70 mm,当氩气压为0.3 Pa时,开始靶材预溅射以清除靶材表面存在的化合物,时间为10 min,然后分别通过调整石墨靶电流为0.2、0.4、0.6和0.8 A,进行镀膜处理,涂层沉积厚度为2~4 μm。

采用JSM-6700F型场发射扫描电子显微镜对镀层表面与截面形貌进行观察。

电化学分析采用LK98C型电化学工作站,进行交流阻抗测量(EIS)、塔菲尔曲线测量以及相关的数据处理。在电化学池中采用三电极体系,将基体试样和经过磁控溅射镀膜处理的试样作为工作电极,铂片作为辅助电极,饱和甘汞电极作为参比电极。

2 结果与分析

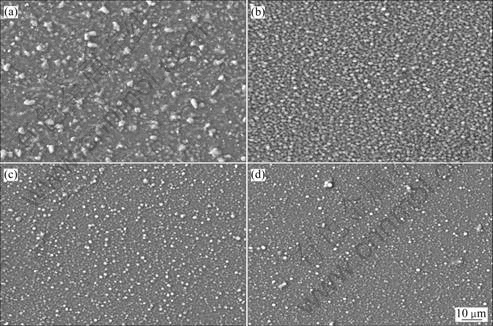

不同碳靶电流下镀层的表面和截面形貌如图2和3所示。由图2可以看出,石墨靶电流对AlSn20/C镀层的表面形貌有明显的影响。在不同的石墨靶电流 下,镀层表面都是由晶粒较为细小的铝相、锡相和在其表面均匀分布的石墨相组成,当石墨靶电流较大 时,所得试样表面始终可以看到析出的石墨相呈大块状,尺寸大约为1~2 μm,而在石墨靶电流较小时(小于0.6 A),析出的石墨相均未出现明显的块状,而与铝相、锡相有相对均匀的“混合”,有相当好的匹配关系,石墨有利于改善润滑条件,但添加量过多会影响韧性[11]。增大石墨靶电流,即增加了轰击石墨靶的 Ar+的轰击能量,所以在一定范围内,增加石墨靶电流,从石墨靶上溅出的原子数就会增多,这样撞击基体表面的粒子数就会增多,又因为镀层在基体上的沉积速率与单位时间内撞击基体表面的粒子数成正比,所以增大石墨靶电流会提高石墨的沉积速率,在相同的沉积时间里,镀层厚度随沉积速率的增大而增加[12-13]。当石墨靶电流较大时,石墨的沉积速率较大,单位面积上的石墨原子数较多,不利于吸附的石墨原子在基片表面的迁移,发生“偏聚”现象,所以形成较大的石墨块;当石墨靶电流小于0.6 A时,从石墨靶上溅射的石墨原子数量较少,有足够的时间在基片表面进行形核、迁移,因此,在基片表面形成均匀细小的石墨相,并与铝相和锡相均匀混合。

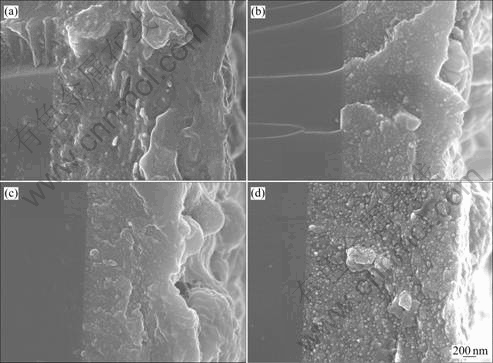

由图3所示的不同碳靶电流下镀层截面可见,镀层截面呈层状结构生长。在溅射过程中,溅射的材料从靶面到达基体后,是以原子团,又称岛状方式生长。随石墨靶电流的增加和溅射时间的延长,岛状原子团会结合新溅射过来的原子逐渐长大,且岛的数目也会逐渐饱和,孤立的小岛相互连接为层状形式[14]。而在实验过程中,通过控制4个靶的溅射时间,就可以使不同靶材溅射形成的小岛状原子团紧密均匀地交叉连接,而不会形成单一材料的层状形式[15]。

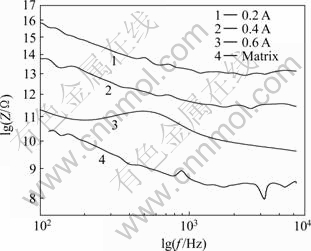

2.1 交流阻抗测量(EIS)

图4所示为石墨靶电流分别为0.2、0.4和0.6 A时镀膜试样和基体试样的电化学阻抗谱。由图4可知,经过镀膜处理的1~3号试样的电化学阻抗比未经处理原始试样的电化学阻抗高5~6个数量级,这说明轴承合金的电化学阻抗越高,其耐蚀性越好。采用非平衡磁控溅射技术制备镀层,其分子、原子量级的沉积保证在基体表面形成了一层低孔隙率和高致密性的保护层。因此,所有的镀层都很好地保护了基体[16]。同时,对于不同石墨靶电流下的镀膜试样,其电化学阻抗也表现出一定的差异:当石墨靶电流由0.2 A逐渐增大到0.6 A时,试样的电化学阻抗逐渐增大。这说明靶电流越低,镀层的电化学阻抗值越大,耐蚀性越好。这是由于对于如图3所示的截面结构,当靶电流较低时,膜组织更致密,孔隙率更低,而且与基体之间具有较高的结合强度,因而生成的镀层阻抗值较大,能更好地提高基体的耐蚀性。

图2 不同石墨靶电流下镀层的表面形貌

Fig. 2 Surface morphologies of coatings deposited at different carbon target currents: (a) 0.8 A; (b) 0.6 A; (c) 0.4 A; (d) 0.2 A

图3 不同石墨靶电流下镀层的截面形貌

Fig. 3 Cross-section morphologies of coating deposited at different carbon target currents: (a) 0.8 A; (b) 0.6 A; (c) 0.4 A; (d) 0.2 A

图4 不同石墨靶电流下镀膜试样的交流阻抗谱

Fig. 4 EIS of coating deposited at different carbon target currents

2.2 极化曲线测量

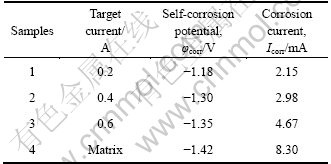

图5所示为不同靶电流下镀层和基体试样在25 ℃、3.5%的NaCl溶液中的塔菲尔曲线。由图5可知,体系中发生的腐蚀属电化学腐蚀,且随着靶电流的增大,其自腐蚀电位发生负移。表1所列不同真空度下试样在体系中的自腐蚀电位及用塔菲尔曲线外推法求取的腐蚀电流。由表1可知,不同石墨靶电流下的镀膜试样均比基体的自腐蚀电位高,而腐蚀电流都比基体的腐蚀电流小。这说明轴承合金表面镀AlSn20/C复合镀层可以提高基体的耐蚀性,其原因主要是通过磁控溅射技术在轴承合金表面形成了一层AlSn20/C复合镀层,该镀层在腐蚀介质中保护了基体。石墨靶电流为0.6 A时,自腐蚀电位为-1.35 V, 腐蚀电流为4.67 mA,其耐蚀性最差。而当石墨靶电流为0.2 A时,自腐蚀电位提高到-1.180 V,电流减小到2.15 mA时,其耐蚀性最佳。这说明随着石墨靶电流的增大,其耐蚀性变差。

图5 不同石墨靶电流下试样在25 ℃、3.5%的NaCl溶液中的塔菲尔曲线

Fig. 5 Tafel curves of samples in 3.5% NaCl solution at different carbon target currents and 25 ℃

表1 不同石墨靶电流下试样在25 ℃、3.5% NaCl溶液中的自腐蚀电位和腐蚀电流

Table1 Self-corrosion potential and corrosion current of samples in 3.5% NaCl solution at different carbon target currents and 25 ℃

2.3 AlSn20/C镀层的微观形貌

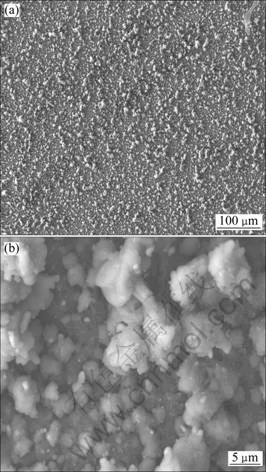

对经磁控溅射镀膜处理后的试样作腐蚀前后的表面形貌观察,结果如图6所示。

图6 AlSn20/C镀层的SEM像

Fig. 6 SEM images of AlSn20/C coatings: (a) Surface before corrosion; (b) Surface eroded in 3.5% NaCl solution for 120 h

由图6可以看出,AlSn20/C镀层在腐蚀前膜层成分均匀,且镀层呈岛团状结构,石墨相弥散分布于Al基体中,试样经腐蚀后,在试样表面布满腐蚀产物,且出现了微裂纹。这是由于镀层表面的Al和Sn与溶液中的活性氧原子[O]发生了反应。其腐蚀产物为Al2O3和SnO2。具体过程如下:2Al+3[O]→Al2O3,Sn+2[O]→SnO2,其形成原因与薄膜的生长方式有关。由图3可知,镀层是以层状结构生长,但是,在孤立的小岛相互连接成为层状形式的过程中,岛与岛之间不能很好地连接,从而产生空隙,又因为在NaCl溶液中,由于Al与Sn之间存在电位差,产生电偶腐蚀,加快了基体的腐蚀,从而由电偶腐蚀转化为均匀腐蚀。轴承合金的溶解过程和腐蚀产物的覆盖过程同时存在,最终使得体系的腐蚀电位和阻抗值达到一个相对稳定的值[17]。

3 讨论

在讨论碳靶电流对镀层组织结构及耐蚀性的影响时应该从如下两个方面来考虑:一是溅射石墨粒子的能量,二是石墨粒子的沉积速率。入射离子能量大时,溅射原子的出射能量也大,从而使到达基体的高能量原子增多,进而影响沉积镀层的性能。溅射粒子能量的提高能改善镀层表面原子的扩散能力,使得组织内部和边界出现明显的致密化倾向。粒子在扩散过程中若遇到了其它的粒子或聚集体就凝聚起来,这样逐步形成稳定的核、岛、沟道和连续镀层,若粒子能量较大就不容易凝聚,或者即使凝聚在一个聚集体上它也能沿着其边沿迁移,甚至再次脱离聚集体成为单个粒子,这样就更容易形成致密的镀层[18]。因此,石墨靶电流的增大能提高溅射石墨粒子的能量从而改善其在镀层表面的扩散能力。

然而,随着靶电流的增大,不仅溅射粒子能量提高,单位时间内到达工件的溅射粒子数量也随之增多。溅射粒子能量的提高改善了镀层表面原子的扩散能力,有利于镀层生长过程中岛的合并与组织细化,相反地,溅射粒子沉积速率的加快却使先到达工件表面的粒子来不及扩散便被后来的粒子覆盖,在这种条件下,镀层有向异性地向上生长的趋势。由于到达工件表面粒子的沉积方向不可能和衬底严格地垂直,其轨迹一般和垂直方向形成一个小的角度,这样长得快的岛会挡住粒子,引起所谓的阴影效应[19],阴影效应不仅是导致镀层表面粗糙化的一个主要原因,也是造成镀层组织中含有大量孔洞的根本原因。在靶电流较大时,石墨层出现较为粗大的层状组织,而且图3分析结果显示靶电流较大时镀层致密度变差,这应该是由于沉积速率过大加剧了镀层沉积过程中的阴影效应所致。因此,这种组织结构决定了随着靶电流的增大,其电化学阻抗减小,自腐蚀电位降低,耐蚀性变差。

4 结论

1) 当石墨靶电流在0.2~0.8 A范围内,薄膜与基体润湿性好,以层状方式生长,电流越小,薄膜组织越致密。AlSn20/C复合镀层可将基体的电化学阻抗提高5~6个数量级。

2) 当石墨靶电流为0.2 A时,基体的自腐蚀电位由-1.42 V提高到-1.18 V,显著提高了轴承合金的耐蚀性。

3) 石墨靶电流是影响AlSn20/C复合镀层耐蚀性的一个重要因素,石墨靶电流越小,其耐蚀性越好。

REFERENCES

[1] 郭亚军. 轴瓦磁控溅射镀膜技术及其材料力学性能研究[D].哈尔滨: 哈尔滨工程大学, 2002: 1-5.

GUO Ya-jun. Study for bearing in magnetron sputtering deposition technology and mechanical behavior of the material[D]. Harbin: Harbin Engineering University, 2002: 1-5.

[2] 宣天鹏. 材料表面功能镀覆层及其应用[M]. 北京: 机械工业出版社, 2008: 200-206.

XUAN Tian-peng. Material surface function layers and their application[M]. Beijing: Mechanical Industry Press, 2008: 200-206.

[3] 马 婕, 蒋百灵, 张永宏. Cr靶电流对Cr改性类石墨薄膜摩擦磨损性能的影响[J]. 摩擦学学报, 2007, 27(5): 437-440.

MA Jie, JIANG Bai-ling, ZHANG Yong-hong. Influence of Cr target current on friction and wear performance of Cr modified graphite film[J]. Tribological Journal, 2007, 27(5): 437-440.

[4] 郭巧琴, 蒋百灵, 李建平, 吴 兵. 铝靶电流对磁控溅射AlSn20镀层耐蚀性的影响[J]. 特种铸造及有色合金, 2010, 30(12): 1150-1152.

GUO Qiao-qin, JIANG Bai-ling, LI Jian-ping, WU Bing. Effects of Al target current on the corrosion resistance of AlSn20 coating deposited by magnetron sputtering[J]. Special Casting & Nonferrous Alloys, 2010, 30(12): 1150-1152.

[5] 邹国庆. 滑动轴承的应用和发展趋势[J]. 柴油机, 1996(1): 14-15.

ZOU Guo-qing. Application and development trend of bush bearing[J]. Diesel, 1996(1): 14-15.

[6] OGITA Y, 梁巨仁. 采用新的方法改善铝基轴瓦性能[J]. 国外内燃机, 2003, 15(6): 25-30.

OGITA Y, LIANG Ju-ren. New methods of improvement of aluminum base bearing properties[J]. Diesel Engine, 2003, 15(6): 25-30.

[7] 尹树桐, 李庆芬. 滑动轴承磁控溅射镀层技术的应用研究[J]. 中国表面工程, 2002, 50(21): 39-42.

YIN Shu-tong, LI Qin-fen. Application research of bush bearing magnetron sputtering technology[J]. China Surface Engineering, 2002, 50(21): 39-42.

[8] ZENG X T, ZHANG S, DING X Z, TEER D G. Comparison of three types of carbon composite coatings with exceptional load-bearing capacity and high wear resistance[J]. Thin Solid Films, 2002, 420(12): 366-370.

[9] HOLMBERG K, RONKAINEN H, MATTHEWS A. Review tribology of thin coatings[J]. Ceramics International, 2000, 26(7): 787-795.

[10] BULL S J. Modelling the hardness response of bulk materials, single and multilayer coatings [J]. Thin Solid Film, 2001, 398(11): 291-298.

[11] TAN J N, HSIEH J H. Deposition and characterization of (Nb,Cr)N thin films by unbalanced magnetron sputtering[J]. Surface and Coatings Technology, 2003, 167(2/3): 154-160.

[12] BULIR J, NOVOTRY M, JEL?NEK M, KOCOUREK T, STUDNI?KA V. Plasma study and deposition of DLC/TiN/Ti multilayer structures using technique combining pulsed laser deposition and magnetron sputtering[J]. Surface and Coatings Technology, 2005, 200(1/4): 708-711.

[13] LI Mu-guo, Miyake Shoji, WU Yi-xiong. Effects of copper doping on structure and properties of TiN films prepared by magnetron sputtering assisted by low energy ion flux radiation[J]. Japanese Journal of Applied Physics, 2006, 45( ): 5178-5182.

[14] HU J, HAN J, MENG S. Correlations between substrate bias, microstructure and surface morphology of tetrahedral amorphous carbon films[J]. Vacuum, 2004, 72(3): 285-290.

[15] BUGAEV S P, PODKOVYROV V G, OSKOMOV K V, SMAYKINA S V, SOCHUGOV N S. Ion-assisted pulsed magnetron sputtering deposition of ta-C films[J]. Thin Solid Films, 2001, 89(20): 16-26.

[16] YANG S, CAMINO D, JONES A H S, TEER D G. Deposition and tribological behavior of sputtered carbon hard coating[J]. Surface and Coating Technology, 2000, 124(2/3): 110-116.

[17] KELLY P J, ARNELL R D. Magnetron sputtering: A review of recent development and applications[J]. Vacuum, 2000, 56(3): 159-172.

[18] ZAFER DURUSOY H, OZLEM D, ATILLA A. Influence of substrate temperature and bias voltage on the optical transmittance of TiN films[J]. Vacuum, 2003, 70(1): 21-28.

[19] HAMPSHIRE J, KELLY P J, TEER D G. The structure of Co deposited aluminum/titanium alloy coatings[J]. Thin Solid Films, 2004, 447/448(1): 418-424.

(编辑 龙怀中)

基金项目:陕西省教育厅专项科研计划项目(09JK481);陕西省薄膜技术与光学检测重点实验室开放基金;西安工业大学材料与化工学院培育基金

收稿日期:2011-05-23;修订日期:2011-10-20

通信作者:郭巧琴,博士研究生;电话:029-83208080;E-mail: qiaoqin.guo@gmai.com