DOI: 10.11817/j.issn.1672-7207.2016.02.020

螺旋钻机变幅时机液耦合动力学的键合图建模

胡均平,李科军

(中南大学 机电工程学院,湖南 长沙,410083)

摘要:为了从理论上研究螺旋钻机变幅机构内在的复杂动态特性,建立较精确的变幅机构数学模型。首先,分析螺旋钻机变幅机构的工作原理和结构特点,运用键合图理论对转动铰、油缸及立柱进行模块化建模,构建变幅机构基础单元的多体动力学模型;然后,建立变幅机构液压系统驱动力的键合图模型。通过分析各子模型的动态特性及相互作用规律,根据功率流传递路径,以统一方式建立变幅机构机液耦合动力学的键合图模型。研究结果表明:变幅油缸2腔压力的数值模拟结果与试验结果较吻合,表明该模型能预测机液耦合作用下系统的动态特性,可为分析和提高变幅机构的动力学性能提供参考。

关键词:螺旋钻机;变幅机构;动态特性;键合图;耦合

中图分类号:TP202 文献标志码:A 文章编号:1672-7207(2016)02-0495-08

Dynamics model of mechanical-hydraulic coupling of auger driller during luffing motion by bond graph

HU Junping, LI Kejun

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: In order to describe the inherent complex dynamic characteristics of luffing mechanism of auger driller, the accurate mathematic model of the luffing mechanism was established. The working principle and structural characteristics of the luffing mechanism were firstly analyzed, the bond graph model of revolute joint, cylinder and column were bulit, and the multi-body dynamics model for the basis unit was also constructed. Then the bond graph of hydraulic system was obtained. Through the analysis of the dynamic characteristics and interaction rules of each sub model, according to the transmission path of power flow, the mechanical-hydraulic coupling dynamic bond graph model of luffing mechanism was developed in a unified way. The results show that the two chamber pressure simulation results of the luffing cylinder agree well with the experimental results, which indicates that the system dynamic characteristics can be forecasted by this model, which provides a theoretical basis for improving the dynamic performance of the luffing mechanism.

Key words: auger driller; luffing mechanism; dynamic characteristics; bond graph; coupling

螺旋钻机是一种适合建筑基础工程中成孔作业的施工机械,因施工时噪音低、污染少、作业速度快、作业人员少而得到广泛应用和发展。螺旋钻机的结构主要由纵移机构、额头、回转平台、变幅机构、动力头等组成。而变幅机构是螺旋钻机1个非常重要的工作装置,主要起变幅和支撑作用,其动力学性能对螺旋钻机主要性能指标如铰点约束力、变幅油缸压力和动力头最大输出扭矩等有很大影响。变幅机构的结构形式不同,其动力学性能也不同。目前,对变幅机构工作装置的研究多侧重于单方面特性如变幅机构动力学[1-4]、参数优化设计[5]、运动轨迹优化[6]和构件强度[13-14]等机械方面的特性的研究并对油缸负载特性[15-16]、变幅作业平稳性[17]等进行了研究。但由于螺旋钻机变幅机构具有典型的机械、液压一体化特征,必须综合考虑机液耦合对整机性能的影响,用统一的方式建立变幅机构的数学模型。以分析力学及弹性力学为基础解决该问题的方法对于多能域并存的系统具有局限性,因为建模时总会对某一能域进行简化并进行相应忽略处理,从而影响结果的精度,无法真实地反映系统的性能[1-2]。键合图法为解决该问题提供了有效的途径,它是一种基于功率流图形化表达的系统动力学仿真方法[12],能统一描述多能域并存复杂系统的动态特性。与其他方法相比,该建模方法更适用于构建螺旋钻机变幅时机液耦合的完备动力学模型。

1 变幅机构多体动力学建模

螺旋钻机变幅机构简图如图1所示,由变幅油缸(2个)、机身、立柱组成,通过铰点(A,C和P)连接组成1个曲柄摇块机构。由电机驱动泵输入压力油到油缸推动立柱绕铰点A转动,立柱从水平位置开始运动,到竖直位置终止,完成立柱举升动作。因变幅时机身固定不动,在机身上设立惯性坐标系。为便于建模,将变幅系统机械部分分为3个子系统:1) 转动铰子系统;2) 立柱子系统;3) 油缸子系统。分别建立各子系统的键合图模型,进而建立变幅机构的多体动力学键合图模型。

图1 变幅机构示意图

Fig. 1 Schemic diagram for luffing mechanism

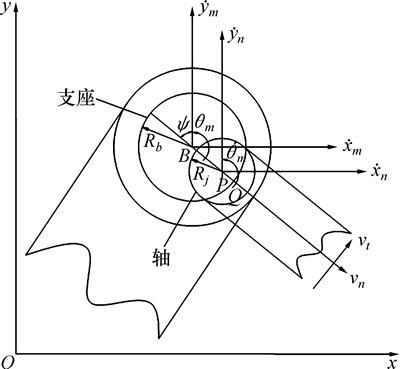

1.1 转动铰建模

转动铰是平面机构键合图建模的基础单元之一,如图2所示。连杆与连杆之间通过转动铰连接,支座和轴之间只有存在间隙和柔性才能保证运动的平稳,尤其当不断转动摩擦产生热量使轴膨胀时,必须保证一定间隙,确保支承和轴不至于发生过盈配合。但另一方面,关节间隙经常引起冲击载荷、迅速磨损、噪音等不良影响。支承和轴之间存在2个方向的力:正压力和切向力。正压力作用在中心线上,切向力垂直中心线,这些力有不同的数学表达形式[7]。本文研究的是无间隙的弹性转动铰,忽略干摩擦,此时切向力为0 N,正向力(铰点的约束力)可按下式计算:

(1)

(1)

式中: ;

; 和

和 分别为支座和轴中心点的绝对坐标;支座和轴接触的弹性系数K可通过试验或有限元法来确定;阻尼系数和弹性系数成正比,即B=λK。

分别为支座和轴中心点的绝对坐标;支座和轴接触的弹性系数K可通过试验或有限元法来确定;阻尼系数和弹性系数成正比,即B=λK。

图2 转动铰

Fig. 2 Schema for revolute joint

FILIPPOV[8]讨论了不同材料时λ的取值。为便于用键合图表达,式(1)可表示成如下标量形式:

(2)

(2)

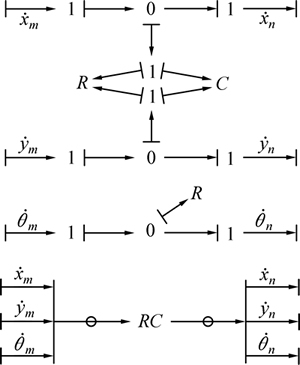

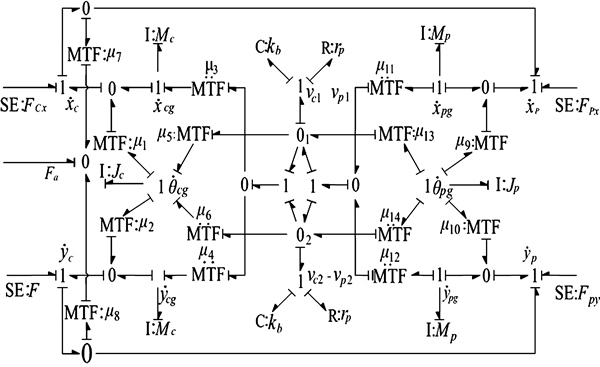

转动铰键合图模型如图3所示,可利用C场和R场上的势流变量约束关系式推导出构件在铰点处的弹性力、阻尼力和转动摩擦力矩(因切向力为0 N,本文忽略不计),得到转动铰键合图模型,也可用RC场以向量形式更紧凑地表达铰点键合图模型(图3)。

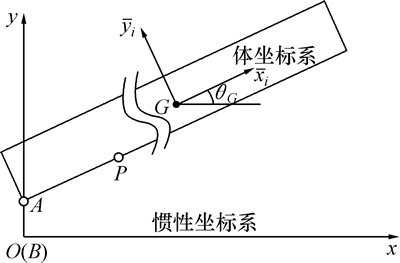

1.2 立柱建模

因立柱转动速度小,抗弯刚度大,可以将之视为刚体单元,如图4所示。将体坐标系原点固定在立柱的重心G上, 轴沿着立柱轴向方向。在已知立柱重心坐标、铰点的局部坐标及体坐标系相对惯性坐标系的转角

轴沿着立柱轴向方向。在已知立柱重心坐标、铰点的局部坐标及体坐标系相对惯性坐标系的转角 时,根据体坐标与惯性坐标的转换规律,立柱上任何1点(第i个点)的绝对坐标可以通过如下关系式计算得到:

时,根据体坐标与惯性坐标的转换规律,立柱上任何1点(第i个点)的绝对坐标可以通过如下关系式计算得到:

图3 转动铰键合图模型

Fig. 3 Bond graph model of revolute joint

图4 立柱简图

Fig. 4 Schema for column

(3)

(3)

式中: 和

和 为立柱上第i(铰点A和P)个点在体坐标系中的坐标,xG和yG为立柱的质心在惯性坐标系中的坐标。

为立柱上第i(铰点A和P)个点在体坐标系中的坐标,xG和yG为立柱的质心在惯性坐标系中的坐标。

对式(3)求导得:

(4)

(4)

设 ,

,

,将之代入式(4)可得

,将之代入式(4)可得

(5)

(5)

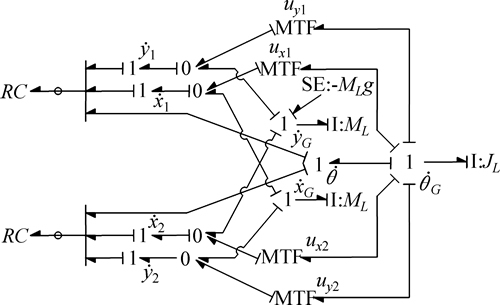

通过式(5)表示速度、角速度约束关系,可得图5所示的立柱键合图模型。模型中只绘制了2个铰点(铰点A和P),但可根据构件的复杂程度增减铰点数目。通过铰点可以与其他刚体铰接,建立构件之间的约束关系。图5中:键元1上的变量ML,JL分别代表体系坐标中立柱的质量和转动惯量,键元1结上的变量 ,

, ,

, ,

, 分别表示惯性坐标系中刚体质心的线速度及体坐标系相对惯性坐标系的转动速度。功率键中间位置的小圆圈表示此键为向量键,而较长的因果划表示可将向量键拆成标量键,也可将标量键合成向量键。可以在刚体上施加外力和转矩,只需把力和转矩等效到刚体的质心上,即将代表力的势源加在键合图中相应的1结上,如将立柱所受重力以势源SE:-MLg添加到1(

分别表示惯性坐标系中刚体质心的线速度及体坐标系相对惯性坐标系的转动速度。功率键中间位置的小圆圈表示此键为向量键,而较长的因果划表示可将向量键拆成标量键,也可将标量键合成向量键。可以在刚体上施加外力和转矩,只需把力和转矩等效到刚体的质心上,即将代表力的势源加在键合图中相应的1结上,如将立柱所受重力以势源SE:-MLg添加到1( )结上。

)结上。

通过构件运动约束关系建立的键合图模型同时体现了动力学特征。由图5可得立柱重心处力和力矩的平衡方程:

(6)

(6)

式中:Fxi和Fyi为第i个节点x和y方向上的力;FxG,FyG和MzG分别为质心上x,y方向上力及z轴方向的力矩。式(6)的动力学方程与直接对图4应用牛顿—欧拉动力学方程所得的结果是一致的。可见:图5所示的键合图模型基于功率守恒,简单、紧凑地表达了立柱重心和铰点的运动约束及动力学关系。

图5 立柱键合图模型

Fig. 5 Bond graph model of stand column

1.3 油缸建模

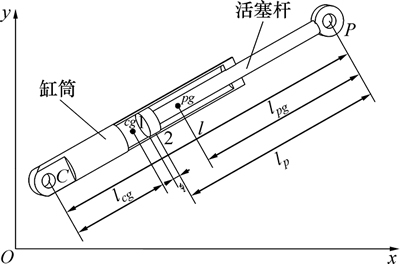

移动铰的建模和仿真是多体动力学中最难分析的问题之一。油缸就是典型的移动铰,是联系机械和液压能域的枢纽,在工程机械液压系统中应用广泛。图6所示为油缸结构原理图,主要由缸筒和活塞杆2部分组成,通过两端的耳环和相邻构件铰接。

图6 油缸结构原理

Fig. 6 Schema for cylinder

根据图6中几何机构关系及油缸运动规律,两端点C和P的速度可以用缸筒与活塞杆各自重心位置的速度及角速度表示:

(7)

(7)

(8)

(8)

(9)

(9)

(10)

(10)

式中: 和

和 分别为缸筒和活塞杆的转角;其余几何参数意义见图6。对EC和EP点距离进行求导,可得

分别为缸筒和活塞杆的转角;其余几何参数意义见图6。对EC和EP点距离进行求导,可得

(11)

(11)

图6中,缸筒与活塞的接触点1的法向速度可分别表示为:

(12)

(12)

(13)

(13)

将虚拟的容性元件和阻性元件添加在接触点处,根据相对速度vc1-vp1的变化规律,可计算出接触点1的法向力。文献[9]证明了该处理方法的可行性和有效性。在缸筒和活塞上接触点2的法向速度可分别表示为:

(14)

(14)

(15)

(15)

类似计算接触点1的法向力,在图6的接触点2处加一虚约束,同样通过相对运动速度vc2-vp2计算点2的接触力。由运动约束关系式(7)~(15)可得图7所示的由移动铰连接的平面运动刚体缸筒和活塞杆的键合图模型,各容性、惯性元件全部具有积分因果关系。图7中: ;

; ;

; ;

;  ;

; ;

;  ;

; ;

;

;

; ;

; ;

; ;

; ;

; ;

; ;左右两端的势源表示铰点处的约束力;各1结分别表示缸筒、活塞杆重心的运动速度和各接触点的相对运动速度。将虚拟的容性元件和阻性元件添加在1

;左右两端的势源表示铰点处的约束力;各1结分别表示缸筒、活塞杆重心的运动速度和各接触点的相对运动速度。将虚拟的容性元件和阻性元件添加在1 结处,计算接触法向力;缸筒与活塞杆的相对运动速度通过模数为μ7与μ8的TF变换器之间的0结表示;压力油对活塞的作用力Fa也通过此结引入;Kb和rb分别为活塞和缸筒接触点的等效刚度系数、等效阻尼系数;rf为活塞和缸筒相对运动的阻尼系数。

结处,计算接触法向力;缸筒与活塞杆的相对运动速度通过模数为μ7与μ8的TF变换器之间的0结表示;压力油对活塞的作用力Fa也通过此结引入;Kb和rb分别为活塞和缸筒接触点的等效刚度系数、等效阻尼系数;rf为活塞和缸筒相对运动的阻尼系数。

图7 油缸键合图模型

Fig. 7 Bond graph model of cylinder

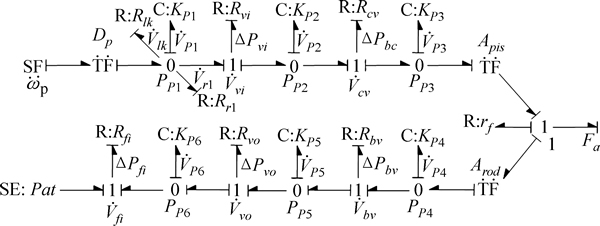

2 变幅机构液压系统建模

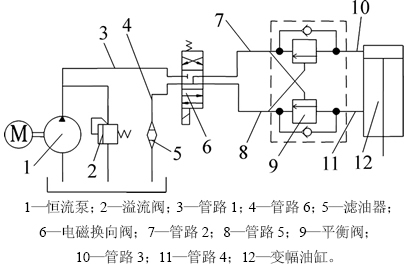

螺旋钻机变幅机构液压系统原理图如图8所示,由一恒流泵经具有Y型中位机能的电磁换向阀给变幅油缸提供流量。油缸和电磁换向阀之间的连接油路上安装平衡阀,其作用是在泵停止供油时,使立柱可靠地停在任意位置;或在立柱下落时,提供足够的背压,防止立柱在重力负载作用下超速下降,起到安全保护的作用。在建模前对液压系统进行必要简化:1) 液压件的容性、阻性作为集中参数进行处理;2) 泵输出工作流体稳定,忽略其脉动特性;3) 电磁阀开启过程视为瞬态过程;4) 泵输入转速恒定。由此建立了如图9所示的变幅机构液压系统立柱举升阶段的键合图模型。图9中:Dp为恒流泵每转排量;Kp1为泵出口到电磁换向阀进口之间工作容腔的等效液压刚度;Rlk为泵的泄漏液阻,泄漏量为 ;Rrl为溢流阀溢流时的液阻,溢流量为

;Rrl为溢流阀溢流时的液阻,溢流量为 ;Rvi和Rvo分别为电磁换向阀的进油、回油液阻,流过的流量分别为

;Rvi和Rvo分别为电磁换向阀的进油、回油液阻,流过的流量分别为 和

和 ;Kp2为电磁换向阀与平衡阀之间工作容腔的等效液压刚度;Rcv为平衡阀中的单向阀打开时的等效液阻,流过的流量为

;Kp2为电磁换向阀与平衡阀之间工作容腔的等效液压刚度;Rcv为平衡阀中的单向阀打开时的等效液阻,流过的流量为 ;Rbv为平衡阀中顺序阀打开时的等效液阻,流过的流量为

;Rbv为平衡阀中顺序阀打开时的等效液阻,流过的流量为 ;Kp3为平衡阀到变幅油缸无杆腔的等效液压刚度;Apis为无杆腔作用面积;Arod为有杆腔作用面积;rf为活塞与油缸之间的相对运动阻尼系数;Kp4为油缸有杆腔到平衡阀的等效液压刚度;Kp5为平衡阀到电磁换向阀的等效液压刚度;Kp6为电磁换向阀到滤油器的等效液压刚度;Rfi为滤油器的液阻,流过的流量为Vfi。由此键合图可以建立立柱举升时液压系统的状态方程。

;Kp3为平衡阀到变幅油缸无杆腔的等效液压刚度;Apis为无杆腔作用面积;Arod为有杆腔作用面积;rf为活塞与油缸之间的相对运动阻尼系数;Kp4为油缸有杆腔到平衡阀的等效液压刚度;Kp5为平衡阀到电磁换向阀的等效液压刚度;Kp6为电磁换向阀到滤油器的等效液压刚度;Rfi为滤油器的液阻,流过的流量为Vfi。由此键合图可以建立立柱举升时液压系统的状态方程。

管路1~6的工作容腔油液体积变化率分别为

(16)

(16)

(17)

(17)

(18)

(18)

(19)

(19)

图8 变幅机构液压系统

Fig. 8 Hydraulic system of luffing mechanism

图9 液压系统立柱举升键合图模型

Fig. 9 Bond graph model of hydraulic system during luffing motion

(20)

(20)

(21)

(21)

式中: ;

; ;

;

;

; ;

;

;

; ;

; 。

。

管道6活塞杆上的作用力为

(22)

(22)

管路1工作容腔的压力为

其他容腔压力的计算类似。

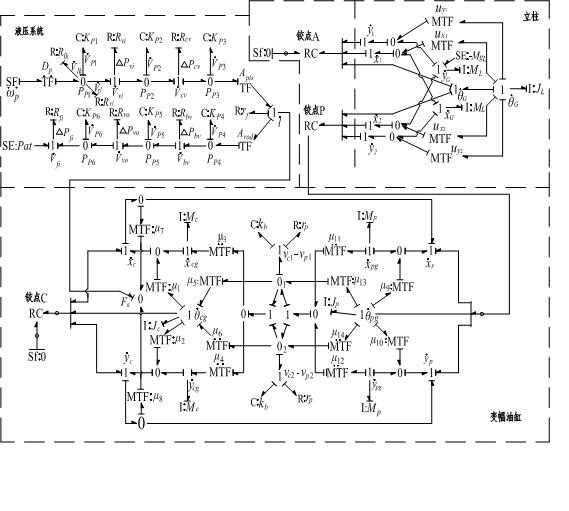

3 变幅机构键合图模型

根据功率流传递路径和各子系统相互作用原理,联合前面构建的平面机构基础单元的多体动力学模型和液压系统驱动力模型,建立如图10所示的变幅机构机液一体化的键合图模型。各构件通过铰点相连,因机身固定不动,说明立柱、变幅油缸缸筒与机身相连的铰点A和C的键合图模型RC场一端输入速度为0,即在RC场一端加上1个零流源。压力油对油缸活塞的作用力可以通过液压系统键合图模型中的1(i)结和变幅油缸键合图模型中的0(Fa)结相连的路径传递,同时,活塞杆对立柱的作用力,通过铰点P的RC场传递。立柱举升过程中的转速变化也通过铰点P的RC场传递给变幅油缸,然后传递到液压系统。通过此功率流路径直观地揭示了变幅机构机液耦合的变化规律,也明确了系统所包含的所有变量,真实反映了变幅机构的能量分配、传递、消耗和储存的情况。

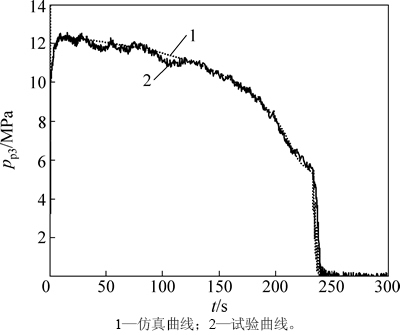

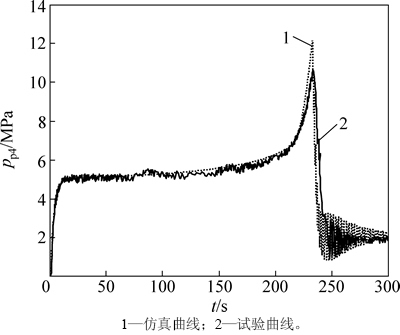

4 试验和仿真结果

以某型螺旋钻机为研究对象,主要结构参数设定如下:r1,r2,r3和r4分别为1.050,2.997,3.700和1.400 m;立柱的质量ML为9.500 t,转动惯量JL为27.389 t·m2。同时,为验证该建模方法的可行性与准确性,将两压力传感器安装在变幅油缸进出油口位置,通过数据采集卡和计算机对变幅油缸两腔油压进行采集、存储和绘图。测试时,立柱处于水平位置,开始给系统供油,当立柱举升到竖直位置时,停止供油。

图11和图12所示为立柱举升过程中变幅油缸两腔压力响应的试验和仿真曲线。分析图12和图12可知:

1) 实际完成立柱举升的时间比仿真时间约多5 s,而且试验曲线有一定程度的压力抖动。这是由于泵输出流量的脉动与管路的振动相互耦合作用,又存在平衡阀阀芯的振动,最终导致油缸两容腔压力的脉动。而在数学模型中,泵的输出流量为一定值,各阀芯工作位置稳定,且各仿真参数的取值误差也造成了对仿真精度的实际影响。

图10 变幅机构键合图模型

Fig. 10 Bond graph model of luffing mechanism

图11 无杆腔压力试验结果与仿真结果对比

Fig. 11 Comparison between experimental results and simulation results of chamber pressure without rod

图12 有杆腔压力试验与仿真数据对比

Fig. 12 Comparison between experimental results and simulation results of chamber pressure with rod

2) 立柱完成举升动作瞬间,有杆腔压力的仿真值比实测值约高1.2 MPa。这是因为实际系统所采用的换向阀和平衡阀,其启闭动作有延时,而仿真过程中没有考虑各阀的动作延时,所以,忽略各阀动作影响时,系统的冲击更大。

3) 完成立柱举升后,无杆腔压力基本为0,有杆腔压力稳定在2 MPa左右,但实际系统的稳定性要好,最终稳定的时间只需30 s左右。而在仿真结果中,系统趋于稳定的持续时间较长,大约需要65 s,两者的区别可能在于实际系统中的黏性阻尼较大,增强了系统的稳定性。

从以上两者的对比结果可知:两者的初始点和终点值基本相同,而且变化趋势及曲线的宏观形状一致性较好,验证了所建模型的准确性,可以用来对系统动态特性进行分析和预测。除了模拟变幅油缸工作油口压力外, 利用该模型, 可以仿真分析系统的变幅角速度、角度和铰点受力等状态变量的动态响应。

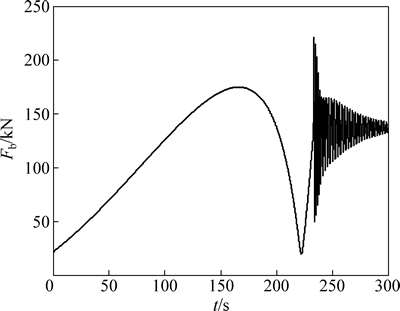

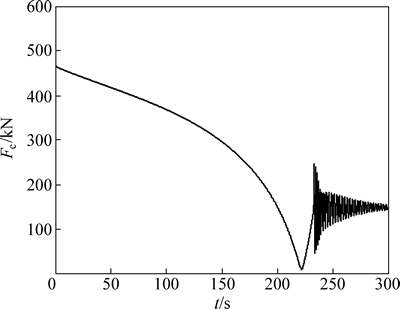

图13和图14所示分别为铰点A和C的约束反力响应曲线。立柱举升作业完成时,因立柱的大惯性和油缸两腔封闭油液的弹簧效应,立柱较长时间地进行低频衰减振动。最后,铰点A的约束力稳定在140 kN左右,铰点C的约束力稳定在145 kN左右。

图13 铰点A约束力响应

Fig. 13 Cconstraint force response of revolute point A

图14 铰点C约束力响应

Fig. 14 Constraint force response of revolute point C

5 结论

1) 功率键合图法是一种对多能域统一建模的方法。采用该方法对变幅机构建模使得建模过程规则化,模块化,直观地揭示了各构件之间的约束关系及机液耦合作用,变幅油缸两腔压力的数值模拟结果较好地反映了实际工作特性,表明该模型可用于分析和提高变幅机构的动态性能。

2) 转动铰、移动铰和刚体是平面机构多体动力学建模的基础单元,用图形方式进行建模,使得各单元间的能量关系和负载关系清晰明了,模型易于理解,修改简单,具有良好的扩展性和通用性,在此基础上添加相应的子模型,可以快捷地实现同类型机构的键合图建模和分析。

参考文献:

[1] 康辉梅, 何清华, 朱建新.旋挖钻机变幅机构的动力学建模与仿真[J]. 中南大学学报(自然科学版), 2010, 41(2): 532-538.

KANG Huimei, HE Qinghua, ZHU Jianxin. Dynamic modeling and simulation of mast link frame system of rotary drilling rig[J]. Journal of Central South University (Science and Technology), 2010, 41(2): 532-538.

[2] 杨华. ZY-220型旋挖钻机钻挖支撑系统动力分析[D]. 长春: 吉林大学机械科学与工程学院, 2007: 1-37.

YANG Hua. Dynamic analysis on tunneling Support system of the ZY-220 rotary drilling rig[D]. Changchun: Jilin University. College of Mechanical Science and Engineering, 2007: 1-37.

[3] 王鹏程, 方勇纯, 相吉磊, 等. 回转旋臂式船用起重机的动力学分析与建模[J]. 机械工程学报, 2011, 47(20): 34-40.

WANG Pengju, FANG Yongchun, XIANG Jilei, et al. Dynamics analysis and modeling of ship-mounted boom crane[J]. Journal of Mechanical Engineering, 2011, 47(20): 34-40.

[4] 姜涛, 游义平, 杨虎, 等. 旋挖钻机调桅机构动态特性的一体化建模分析[J]. 同济大学学报, 2012, 40(5): 729-734.

JIANG Tao, YOU Yiping, YANG Hu, et al. Integrated Model-based analysis of mast mechanism of rotary drilling rig and its dynamic characteristics[J]. Journal of Tongji University, 2012, 40(5): 729-734.

[5] 徐雪松, 胡吉全. 基于混合神经网络的门座起重机变幅机构参数优化设计[J]. 机械工程学报, 2005, 41(4): 220-224.

XU Xuesong, HU Jiquan. Hybrid neural networks based portal cranes’ luffing system optimal design[J]. Chinese Journal of Mechanical Engineering, 2005, 41(4): 220-224.

[6] 林晓辉, 黄卫生, 林晓通, 等. 平面连杆机构变幅机构轨迹综合遗传退火优化算法的研究[J]. 计算机辅助设计与图形学学报, 2001, 13(8): 724-729.

LIN XiaoHui, HUANG Weisheng, LIN Xiaotong, et al. Study of synthetical genetics annealing optimization for the luffing mechanism locus of a plane link[J]. Journal of Computer-Aided Design & Computer Graphics, 2001, 13(8): 724-729.

[7] Flores P. Modeling and simulation of wear in revolute clearance joints in multibody systems[J]. Mechanism and Machine Theory, 2009, 44(6): 1211-1222.

[8] Filippov A. Vibrations of mechanical systems[M]. Yorkshire, England: National Lending Library for Science and Technology, 1971: 137-173.

[9] Bera T K, Samantaray A K. Consistent bond graph modelling of planar multibody systems[J]. World Journal of Modelling and Simulation, 2011, 7(3): 173-188.

[10] Marquis-favre W, Bideaux E, Scavarda S. A planar mechanical library in the AMESim simulation software. part i: Formulation of dynamics equations[J]. Simulation Modelling Practice and Theory, 2006, 14(1): 25-46.

[11] Ahmed S, Lankarani H, Pereira M. Frictional impact analysis in open-loop multibody mechanical systems[J]. Journal of Mechanical Design, Transactions of the ASME, 1999, 121(1): 119-127.

[12] Karnopp D C, Margolis D L, Rosenberg R C. System dynamics: Modeling, simulation, and control of mechatronic systems[M]. New York: John Wiley & Sons, 2012: 326-365.

[13] 何晓艳, 秦四成. 旋挖钻机钻桅三角形连接架的有限元分析[J]. 工程机械, 2007, 38(10): 34-36.

HE Xiaoyan, QIN Sicheng. Finite element analysis for the triangular connecting frame of drill mast on rotary pile drill[J]. Construction Machinery and Equipment, 2007, 38(10): 34-36.

[14] 朱金光, 陈敏革, 刘安宁, 等. 旋挖钻机工作装置有限元分析[J]. 农业装备与车辆工程, 2007(2): 24-27.

ZHU Jinguang, CHEN Minge, LIU Anning, et al. Finite element analysis for the working equipment of drilling rigs[J]. Agricultural Equipment & Vehicle Engineering, 2007(2): 24-27.

[15] 易炜, 周海生, 赵黎明, 等. 旋挖钻机动臂变幅油缸的负载分析[C]//2006年中国桩工机械行业年会. 长沙, 2006: 31-33.

YI Wei, ZHOU Haisheng, ZHAO Liming, et al. Load analysis of hydraulic cylinder of lift-arm of rotary drilling rig[C]//2006 Annua1 Conference of China Pile Machinery Industry. Changsha, 2006: 31-33.

[16] 朱建新, 谢嵩岳, 胡雄伟, 等. 以ADAMS为平台的旋挖钻机变幅机构变幅油缸举升力仿真分析[J]. 现代制造工程, 2009(11): 119-123.

ZHU Jianxin, XIE Songyue, HU Xiongwei, et al. Simulation analysis of the lifting force of parallelogram cylinder of the parallelogram system of rotary drilling rig based on ADAMS[J]. Modern Manufacturing Engineering, 2009(11): 119-123.

[17] 王子坡, 胡军科, 杨文彬, 等. 臂架变幅机构负载下降时的平稳性研究[J]. 合肥工业大学学报(自然科学版), 2013, 36(7): 783-787.

WANG Zipo, HU Junke, YANG Wenbin, et al. Research on the stability of boom luffing mechanism at decline stage[J]. Journal of Hefei University of Technology, 2013, 36(7): 783-787.

[18] 王同建, 陈晋市, 赵锋, 等. 全液压转向系统机液联合仿真及试验[J]. 吉林大学学报(工学版), 2013, 43(3): 607-612.

WANG Tongjian, CHEN Jinshi, ZHAO Feng, et al. Mechanical-hydraulic co-simulation and experiment of full hydraulic steering system[J]. Journal of Jilin University (Engineering and Technology), 2013, 43(3): 607-612.

(编辑 陈灿华)

收稿日期:2015-02-10;修回日期:2015-04-22

基金项目(Foundation item):国家自然科学基金资助项目(51175518);湖南省科技型中小企业技术创新基金立项项目(12C26214305029)(Project (51175518) supported by the National Natural Science Foundation of China; Project (12C26214305029) supported by the Small and Medium-sized Enterprise Technology Innovation Fund of Science and Technology of Hunan Province)

通信作者:李科军,博士研究生,从事液压机械与控制研究;E-mail:likejuncsu@126.com