DOI:10.19476/j.ysxb.1004.0609.2019.03.23

稳态浓密机全尾砂脱水规律物理模拟

李公成1,王洪江1,焦华喆2,孙 伟3,吴爱祥1

(1. 北京科技大学 土木与资源工程学院,北京 100083;

2. 河南理工大学 土木与环境工程学院,焦作 454150;

3. 昆明理工大学 国土资源工程学院,昆明 650093)

摘 要:结合沉降和压滤实验研究浓密机内全压力范围下尾砂脱水性能,考察网状结构形成体积分数、压缩屈服应力、干涉沉降系数等参数的变化规律。结果表明:网状结构形成体积分数随絮凝剂单耗增加先升高后降低,单耗20 g/t时网状结构形成体积分数达到最大值;压缩屈服应力随体积分数变化呈幂和指数增长,在低压力区域,絮凝剂单耗对底流体积分数影响较大,在高压力区域,絮凝剂作用逐渐弱化;干涉沉降系数随体积分数变化呈幂增长,在低压力区域,絮凝剂单耗对料浆渗透性影响较大,单耗80 g/t时渗透性良好,在高压力区域,絮凝剂单耗对料浆渗透性影响逐渐弱化。实验范围内,膏体料浆存在脱水拐点,其体积分数为38%~42%。

关键词:稳态浓密机;脱水性能;压缩屈服应力;干涉沉降系数

文章编号:1004-0609(2019)-03-0649-10 中图分类号:TD853;TD861 文献标志码:A

随着对矿产资源需求量的增加和浅部资源的不断消耗,国内外大量矿山转入深部开采。矿山开采深度的增大,导致高地应力、高地温、高渗透压和开采扰动问题日益明显[1-3],高浓度充填技术是缓解“三高一扰动”的有效途径。基于絮凝沉降技术的浓密机可获得较高底流浓度,逐渐成为提高充填浓度的重要手段,因此,研究浓密机内尾砂脱水规律显得尤为重要。时至今日,国内学者多以沉降速率、底流浓度[4-9]、达西渗透系数[10]及流变性质[11]等参数描述尾砂脱水规律。然而,以上参数并未形成尾砂脱水行为的评价体系,沉降速率无法表征压密区域渗透性,底流浓度难以描述絮团行为过程,达西渗透定律并不一定适用于研究絮团及絮团群之间的相互作用,流变性质研究则更多的集中于耙架的合理设计。

BUSCALL等[12]基于絮团网状结构,将脱水性能分为压缩性和渗透性两个部分,并以网状结构形成体积分数 、压缩屈服应力Py表征压缩性,干涉沉降系数

、压缩屈服应力Py表征压缩性,干涉沉降系数 表征渗透性,提出脱水性能数学模型,实现浓密性能预测[13-17]。浓密机内随着沉降和压缩过程的进行,物料体积分数逐渐升高至某临界值,从该值起,床层内部絮团相互联结并形成网状结构,其结构强度可抵抗外部切力作用,此临界值称为网状结构形成体积分数,也即泥层最高点(hb)处的体积分数(见图1);压缩屈服应力反映的是在一定固体体积分数下,浆体网状结构屈服压缩,并使得浆体体积分数进一步提升所必须施加的应力,也即泥层压力;

表征渗透性,提出脱水性能数学模型,实现浓密性能预测[13-17]。浓密机内随着沉降和压缩过程的进行,物料体积分数逐渐升高至某临界值,从该值起,床层内部絮团相互联结并形成网状结构,其结构强度可抵抗外部切力作用,此临界值称为网状结构形成体积分数,也即泥层最高点(hb)处的体积分数(见图1);压缩屈服应力反映的是在一定固体体积分数下,浆体网状结构屈服压缩,并使得浆体体积分数进一步提升所必须施加的应力,也即泥层压力; 是指脱水速度影响下的颗粒流体动力相互作用影响关系,该系数的物理意义为单位面积上浆体的黏度,即黏度的面密度,与渗透性和自由沉降速度负相关。基于此表征体系,国外学者就泥浆等低密度材料展开广泛研究[13, 15-17],但针对高密度尾砂脱水特性的分析鲜有报道。

是指脱水速度影响下的颗粒流体动力相互作用影响关系,该系数的物理意义为单位面积上浆体的黏度,即黏度的面密度,与渗透性和自由沉降速度负相关。基于此表征体系,国外学者就泥浆等低密度材料展开广泛研究[13, 15-17],但针对高密度尾砂脱水特性的分析鲜有报道。

研究尾砂脱水性能的实验方法众多,如沉降实验、重力渗透实验、离心实验及压滤实验[13],单一实验方法只能研究一定压力范围内的脱水性能。现场实际工作中,全尾砂浓密机泥层压强可达100 kPa以上,室内量筒沉降实验可获得低压力区域(<500 Pa)表征参数,压滤实验可获得高压力区域(≥5 kPa)表征参数。物料的压缩屈服应力及干涉沉降系数与体积分数满足一定的数学关系[18],为此,本文作者结合沉降和压滤实验,对某铜矿尾砂开展絮凝剂单耗对尾砂脱水性能的影响研究,探索浓密机全压力范围内尾砂脱水性能与规律。

图1 稳态浓密机模型

Fig. 1 Model of steady state thickener

1 脱水性能表征参数计算理论

1.1 低压力区域表征参数计算

1.1.1 网状结构形成体积分数及压缩屈服应力获取

稳态浓密机内不同高度,浆体网状结构压力等于该体积分数下的压缩屈服应力[13]。溶液内的压力梯度可以表示为固液密度差Δρ、固体体积分数 和重力加速度g三个因素的方程:

和重力加速度g三个因素的方程:

(1)

(1)

式中:p为固体网状压力,Pa。

将式(1)进行积分可得式(2):

(2)

(2)

如图1所示,当料浆初始体积分数低于网状结构形成体积分数时,一旦颗粒沉降至底部平衡状态,沉降床层上部z=hb的固体网状结构压力为0。在悬浮液底部,z=0,底部泥层压力Pbase由上部悬浮液数量决定:

(3)

(3)

根据物料守恒,料浆平均体积分数 可用式(4)获得:

可用式(4)获得:

(4)

(4)

量筒沉降实验中,变化沉降高度,绘制平均体积分数与压缩屈服应力( , Pbase,i)关系曲线(见图2),将图中拟合线延长交至竖轴,其截距即为网状结构形成体积分数。同时可获得低压力条件下压缩屈服压力与体积分数数据(

, Pbase,i)关系曲线(见图2),将图中拟合线延长交至竖轴,其截距即为网状结构形成体积分数。同时可获得低压力条件下压缩屈服压力与体积分数数据( ,

, )。

)。

1.1.2 干涉沉降系数获取

图2 网状结构形成体积分数求解示意图

Fig. 2 Method of obtaining gel point

经理论分析及实践修正,相关学者提出悬浮颗粒力学平衡方程[12, 19],其认为颗粒受力形式包括流体阻力、网状结构压力和重力,表达式如式(5)所示:

(5)

(5)

式中:uSt为斯托克斯沉降速率,m/s; 为干涉沉降因子;u为固体沉降速率,m/s;v为液体上浮速率,m/s; z为竖向位移,m。

为干涉沉降因子;u为固体沉降速率,m/s;v为液体上浮速率,m/s; z为竖向位移,m。

斯托克斯沉降速率由式(6)给出:

(6)

(6)

式中:dp为颗粒直径,m;η为液体黏度,Pa·s;

斯托克斯速率也与颗粒体积Vp有关:

(7)

(7)

式中:λ为斯托克斯拖曳系数,干涉沉降因子用来表征脱水速度影响下的颗粒流体动力相互作用影响关系,干涉沉降系数可由式(8)表述:

(8)

(8)

根据质量守恒,沉降固体通量与上浮液体通量之和为0,如式(9)所示:

(9)

(9)

结合式(5)可得

(10)

(10)

根据以上分析,量筒沉降实验中初始体积分数为 的固体沉降速率u0如式(11)所示:

的固体沉降速率u0如式(11)所示:

(11)

(11)

压力梯度可由式(12)表示:

(12)

(12)

则可获得干涉沉降系数如式(13)所示:

(13)

(13)

当初始体积分数小于网状结构形成体积分数时,网状结构压力为0,式(13)可装换为式(14):

(14)

(14)

因此,在量筒沉降实验中,其他条件不变,变化初始体积分数( <

< ),即可获得自由沉降区域体积分数与干涉沉降系数(

),即可获得自由沉降区域体积分数与干涉沉降系数( ,

, )。

)。

1.2 压缩实验模型建立

尾砂脱水的关键在于流体通过多孔固体结构时的流动阻力,压滤实验可模拟浓密机内高压力行为方式,其多段压力模式可在一次实验中施加多个压力。实验初始对料浆施加初始压力,水分开始析出,当此压力下料浆水分不再析出时进入下一段压力测试,依次完成所有阶段压力测试。压滤过程分为滤饼形成、压缩及生长3个阶段[20](见图3)。

1.2.1 滤饼形成

底流料浆受压后,水分通过滤纸析出,自下而上形成体积分数为 的滤饼,脱水体积V随时间t变化如下式:

的滤饼,脱水体积V随时间t变化如下式:

(15)

(15)

式中:P1为初始过滤压力,Pa;B为滤饼厚度,m;A1为比阻,m-2;t为过滤时间,s。

根据物料守恒,滤饼厚度与脱水体积之间的关系为

(16)

(16)

式中: 为初始体积分数,%。

为初始体积分数,%。

将式(16)代入式(15),建立时间从t0至t,脱水体积从V0至V的关系式:

(17)

(17)

(18)

(18)

而在滤饼初始形成阶段时(t0,V0)=(0,0),具有以下数学模型:

(19)

(19)

(20)

(20)

随压力递增,滤饼体积分数进一步提升;一旦前期滤饼完全压缩至高体积分数,则上部悬浮液将会在已经形成的滤饼上部产生新的滤饼。

图3 压滤实验的模型

Fig. 3 Model of filtration tests

1.2.2 滤饼压缩

当时间t=t1时,脱水体积V=V1,滤饼厚度如式(21)所示:

(21)

(21)

式中:B1为压力P1、时间t1时的滤饼厚度。此时,压力由P1增加至P2,滤饼开始压缩。新滤饼厚度为 ,其平均体积分数为

,其平均体积分数为 。新滤饼是从体积分数为

。新滤饼是从体积分数为 的原滤饼底部开始生长,滤饼比阻为A2,体积梯度如式(22)所示:

的原滤饼底部开始生长,滤饼比阻为A2,体积梯度如式(22)所示:

(22)

(22)

根据物料守恒,滤饼厚度转换如式(23)所示:

(23)

(23)

式中:体积分数 为压力P2时对应的滤饼体积分数。将式(23)代入式(22)中,建立从时间t1至t,脱水体积V1到V的关系式(24)所示:

为压力P2时对应的滤饼体积分数。将式(23)代入式(22)中,建立从时间t1至t,脱水体积V1到V的关系式(24)所示:

(24)

(24)

在滤饼形成过程中,如以下数学模型所示:

(25)

(25)

(26)

(26)

1.2.3 滤饼生长

当时间t=(t1+t2),脱水体积V=(V1+V2)时如式(27)所示:

(27)

(27)

滤饼厚度B2表达式为式(28):

(28)

(28)

利用各阶段滤饼中固体质量相等可得

(29)

(29)

(30)

(30)

在滤饼生长阶段,P2持续作用,原始悬浮液( )继续压缩,二阶段滤饼厚度(体积分数

)继续压缩,二阶段滤饼厚度(体积分数 )继续增加至

)继续增加至 。因此,在滤饼生长阶段,脱水体积随时间变化如式(31)所示:

。因此,在滤饼生长阶段,脱水体积随时间变化如式(31)所示:

(31)

(31)

根据质量守恒,滤饼厚度如式(32)所示:

(32)

(32)

计算时间从(t1 + t2)至 t,脱水体积从(V1 + V2) 到V的变化过程如式(33)所示:

(33)

(33)

滤饼生长过程数学模型如下所示:

(34)

(34)

(35)

(35)

1.3 高压力区域表征参数获取

1.3.1 压缩屈服应力计算

基于压缩实验数据和质量守恒,每一阶段压力下的体积分数 可由式(36)计算:

可由式(36)计算:

(36)

(36)

同理,计算得到最终阶段压力后的体积分数 ,取出试样通过烘干法测量其体积分数

,取出试样通过烘干法测量其体积分数 ,通常情况下,烘干法所得体积分数更加真实,为消除实验误差,每一阶段压力下最终体积分数

,通常情况下,烘干法所得体积分数更加真实,为消除实验误差,每一阶段压力下最终体积分数 由式(37)修正:

由式(37)修正:

(37)

(37)

初始体积分数 采用同样方法进行修正:

采用同样方法进行修正:

(38)

(38)

为烘干法获得的初始体积分数,每一阶段的压应力即为压缩屈服应力:

为烘干法获得的初始体积分数,每一阶段的压应力即为压缩屈服应力:

(39)

(39)

因此,压滤实验可获得多组体积分数和压缩屈服应力数据( ,

, )i。

)i。

1.3.2 干涉沉降系数计算

LANDMAN等[21]提出干涉沉降系数计算公式:

(40)

(40)

式中: 为过滤参数,m2/s,是过滤梯度t/V-V倒数,在多压力过滤实验中,可以由t-V2计算:

为过滤参数,m2/s,是过滤梯度t/V-V倒数,在多压力过滤实验中,可以由t-V2计算:

(41)

(41)

2 实验原料

取新疆某选厂铜尾砂烘干待用,测定全尾砂基本物理性质和粒级组成。测定结果见表1和图4。

表1 全尾砂物理性能参数

Table 1 Physical performance parameters of tailings

图4 全尾砂粒级组成曲线

Fig. 4 Grain size curves of unclassified tailings

絮凝剂类型属于聚丙烯酰胺(PAM)阴离子型,型号为XT9020,呈白色粉末状,无臭,无毒,其分子量为1.2×108。

3 实验方法

通过室内量筒沉降实验,研究不同絮凝剂添加量条件下全尾砂沉降速度和泥层压力的变化规律。配置体积分数相同(7.78%)的全尾砂料浆,为增强体积分数效果差异性,采用等比误差确定絮凝剂添加量(10、20、40、80 g/t),沉降24 h后,记录初始沉降高度和固液分离界面高度,以研究低应力区域压缩性,即网状结构形成体积分数和压缩屈服应力;配置体积分数不同的全尾砂料浆,同一体积分数分别添加不同剂量(10、20、40、80 g/t)的絮凝剂,沉降实验开始后,测固液分离界面在不同时间的沉降高度,以研究低应力区域渗透性,即干涉沉降系数。

图5 压滤实验装置

Fig. 5 Filtration rig experimental sets

压缩性沉降实验完成后,一部分底流采用烘干法测定其体积分数,一部分用于压滤实验(装置如图5所示)。该装置可进行压缩性和渗透性测试,压力范围5~1500 kPa,包括控制和压滤两个模块,控制软件基于压滤模型编程,气动控制活塞实现不同阶段压力切换,收集脱水体积、时间及压力等数据,进而计算压缩性及渗透性等相关参数;压滤模块承载料浆的圆筒直径40 mm,圆筒底部布置滤纸,滤纸孔隙尺寸2×10-6 μm,可确保水分析出,避免尾砂颗粒析出。根据实践经验,设定阶段压力如下:5、10、20、50、100、150、200、300 kPa。

4 结果及分析

4.1 絮凝剂单耗对压缩性能的影响

4.1.1 絮凝剂单耗对网状结构形成体积分数的影响

网状结构形成体积分数与絮凝剂单耗关系分如图6所示。由图6可看出,网状结构形成体积分数随絮凝剂单耗增加先升高后降低,表明在一定范围内,絮凝剂单耗的增加有利于得到较大的网状结构形成体积分数,絮团结构逐渐增强,在20 g/t时获得最大网状结构形成体积分数30%;随着絮凝剂添加量继续增加,溶液黏度升高,降低了床层渗透性,增加了絮团排水阻力,絮团结构逐渐变弱,网状结构形成体积分数逐渐降低。因此,相同规格的浓密机内,絮凝剂单耗20 g/t时泥层最高点处体积分数最高,同一泥层高度下,体积分数变化范围较窄、稳定性较好,尾砂絮团压缩效果较好,浓密机储存能力最大。

图6 网状结构形成体积分数与絮凝剂单耗关系

Fig. 6 Relationship between gel point and flocculant dosage

4.1.2 絮凝剂单耗对压缩屈服应力的影响

结合沉降和压滤实验数据,不同絮凝剂单耗下压缩屈服应力随体积分数变化如图7。同一压缩屈服应力,随絮凝剂单耗增加底流体积分数先升高后降低,单耗20 g/t时取得最大体积分数;在低应力区域(<500 Pa),絮凝剂单耗对体积分数影响较大,表明絮团网状结构力相对压应力较强,絮团内水分无法有效排出,絮团尺寸差异性较大,致使体积分数变化较大;在高应力区域(>5 kPa),随应力增加,絮凝剂单耗对体积分数变化逐渐变小,压缩屈服应力大于100 kPa时,絮凝剂单耗对体积分数影响较少,此时压应力较大,使絮团内水分排出,絮团尺寸趋于一致,体积分数变化较小。同一底流体积分数,随絮凝剂单耗增加所需压缩屈服应力先减小后增加,单耗20 g/t时,相同体积分数下需要的压缩屈服应力最小。

图7 不同絮凝剂单耗压缩屈服应力与体积分数关系

Fig. 7 Relationship between compressive yield stress and concentration for different flocculant dosage

有关学者提出同一材料的压缩屈服应力与体积分数具有相应的数学模型[18, 22],据此将实验数据进行线性拟合得浓密机全应力范围内压缩屈服应力随体积分数变化规律如图8,不同絮凝剂单耗情况下,压缩屈服应力随体积分数变化规律一致,都呈幂函数及指数函数复合增长。体积分数38%~42%为全尾砂脱水阻力突变起始区域,即体积分数大于该区域,压缩屈服应力迅速上升,表明若获得较高体积分数,则必须提供较大的压力,重塑絮团网状结构。

图8 不同絮凝剂单耗压缩屈服应力与体积分数拟合曲线

Fig. 8 Fitting curves between compressive yield stress and concentration for different flocculant dosages

4.2 絮凝剂单耗对渗透性能的影响

结合沉降和压滤实验数据,不同絮凝剂单耗下干涉沉降系数随底流体积分数变化如图9。随着体积分数的升高,干涉沉降系数以数量级速度增加,渗透性由强变弱。在低体积分数区域,絮凝剂单耗对渗透性影响较大,单耗80 g/t时渗透性最好,40 g/t时次之,这是由于絮团较大,料浆单位体积内密度更大,干涉阻力影响较小,固体沉降速率及液体上浮速率较快,渗透性较强;在高体积分数区域,干涉沉降系数较大,表明浓密机内压密区域渗透性较差,尾砂絮团沉降速率逐渐变小,絮凝剂单耗对渗透性影响逐渐弱化,这是由于料浆受高应力影响,絮团结构破坏,缩小了含水率差异,尾砂絮团沉降速率及液体上浮速率趋于一致。

图9 不同絮凝剂单耗干涉沉降系数与体积分数关系

Fig. 9 Relationship between hindered settling function and solid volume fraction for different flocculant dosages

同一材料的干涉沉降系数与体积分数也具有相应的数学模型[18, 22],将实验数据进行线性拟合得浓密机全应力范围内干涉沉降系数随体积分数变化规律(见图8),不同絮凝剂单耗情况下,干涉沉降系数随体积分数变化规律一致,都呈幂增长。渗透性变化过程可分为3个阶段,以絮凝剂单耗20 g/t的压滤实验为例描述如下:1) 网状结构形成体积分数(30%)前,尽管干涉沉降系数逐渐变大,但尾砂絮团未触及压密区域,除液体浮力干扰外,不受下部絮团网状结构的影响,渗透性较好;2) 在体积分数30%~42%范围内,干涉沉降系数较为平稳,表明一定絮团结构强度下,压应力不足以迫使水分大量析出,絮团形状及尺寸趋于稳定,渗透性变化较小;3) 继续施加应力,絮团结构强度不足以支撑压应力,絮团更加密实,同时絮团尺寸及形状趋于一致,体积分数进一步提高,渗透性迅速变差,液体上升极度困难。与压缩屈服应力结果相同,絮凝剂单耗20 g/t时,体积分数42%成为干涉沉降系数的拐点。

图10 不同絮凝剂单耗干涉沉降系数与体积分数拟合曲线

Fig. 10 Fitting curve between hindered settling function and solid volume fraction for different flocculant dosages

4.3 全尾砂脱水过程分析

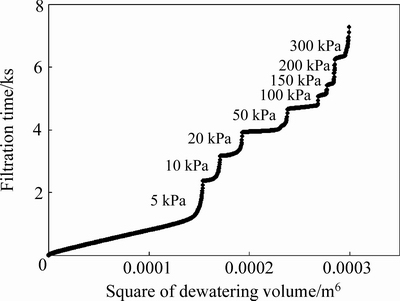

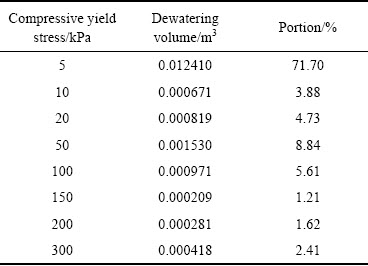

絮凝剂单耗20 g/t时,尾砂脱水性能较好,以此实验条件下的数据分析全尾砂脱水规律。 相关研究人员[5-9]基于量筒沉降试验,对全尾砂低压应力下的脱水特性进行了大量分析,此处不再赘述。基于压缩性压滤实验分析全尾砂在高压缩屈服应力下的脱水程度,收集压缩性实验中不同阶段应力(5、10、20、50、100、150、200、300 kPa)下压缩时间与脱水体积数据(见图11)。

图11 不同压力时间与脱水体积平方关系

Fig. 11 Relationship between compressive time and square of dewatering volume for different pressure

如图11所示,实验内料浆脱水体积呈阶梯式上升,每一阶段压力不再析出水分时,转至下一阶段压滤。根据压缩性实验结果,脱水总体积为0.017309 m3, 各压力下脱水体积比例见表2。随着压力递增,水分析出体积整体呈递减趋势,5 kPa时脱水体积分数最大为71.7%;50 kPa时析出体积出现明显增长,表明压应力打破原絮团结构,迫使水分排出,重塑絮团结构;240、300 kPa时脱水体积再次出现微弱增长,表明絮团结构进一步密实。

表3 各阶段压力脱水体积

Table 3 Dewatering volume for different pressures

结合4.1及图8,絮凝剂单耗20 g/t、料浆初始体积分数7.8%时,可得压缩屈服应力与体积分数数学模型(R2=0.94):

(42)

(42)

根据1.3及式(28)~(29)知,若量化干涉沉降系数与体积分数关系,需确定渗透参数β2与体积分数对应关系,体积分数可由脱水体积推测得到。基于渗透性压滤实验,获得过滤参数β2随脱水体积变化规律,由压缩性压滤实验知,压应力>100 kPa时脱水体积较小,此处只列出≤150 kPa时的压滤过程数据(见图12),在滤饼形成阶段(5 kPa时),过滤参数随脱水体积单调递增,滤饼压缩和生长阶段(≥10 kPa),每一阶段压力过滤参数随体积变化规律基本一致,均经历恒定-上升-下降过程。

图12 不同压力过滤参数与脱水体积关系

Fig. 12 Relationship between filtration parameter and dewatering volume at different pressures

脱水体积是在一定压力下获得的,据此可推断出β2与压缩屈服应力的关系(见图13),随着压缩屈服应力的增加,过滤参数越来越大,并呈幂函数增长,结合沉降区域数据拟合可得式(43)。

图13 渗透参数与压缩屈服应力关系

Fig. 13 Relationship between filtration and compressive yield stress

(43)

(43)

体积分数由压应力决定,结合4.2分析,絮凝剂单耗20 g/t、料浆初始体积分数7.8%时,可得干涉沉降系数与体积分数数学模型(R2=0.97):

(44)

(44)

5 结论

1) 网状结构形成体积分数度、压缩屈服应力可表征稳态浓密机尾砂脱水压缩性,干涉沉降系数可表征其渗透性;沉降实验可获取低压力(<500 Pa)条件下表征参数,压滤实验可获取高压力(>5 kPa)表征参数,两者实验结合可分析稳态浓密机全压力范围下尾砂脱水规律。

2) 絮凝剂单耗对尾砂压缩脱水性能有较大影响,当絮凝剂单耗20 g/t时,压缩效果最佳;随絮凝剂单耗增加,网状结构形成体积分数先升高后降低;随絮凝剂单耗增加,同一压缩屈服应力底流体积分数先增加后减少;同一底流体积分数,随絮凝剂单耗增加所需压缩屈服应力先减小后增加。

3) 干涉沉降系数随体积分数升高以幂函数速度增长,渗透性由强变弱;在低压力区域,絮凝剂单耗对渗透性影响较大,单耗80 g/t时渗透性最好;在高压力区域,絮凝剂单耗对渗透性影响逐渐弱化。

4) 实验范围内,尾砂料浆存在脱水拐点,絮凝剂20 g/t时脱水拐点体积分数为42%,超过该体积分数,需更加较大的压应力才能提高其压缩性及渗透性。

REFERENCES

[1] 何满潮, 谢和平, 彭苏萍, 姜耀东. 深部开采岩体力学研究[J]. 岩石力学与工程学报, 2005, 24( 16): 2803-2813.

HE Man-chao, XIE He-ping, PENG Su-ping, JIANG Yao-dong. Study on mechanics in deep mining engineering[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(16): 2803-2813.

[2] 李启月, 刘 恺, 李夕兵. 基于协同回采的深部厚大矿体分段充填采矿法[J]. 工程科学学报, 2016, 38(11): 1515-1521.

LI Qi-yue, LIU Kai, LI Xi-bing. Sublevel filling method for a heavy orebody in deep mining based on collaborative stoping[J]. Chinese Journal of Engineering, 2016,38 (11): 1515-1521.

[3] 李公成, 王洪江, 吴爱祥, 于少峰, 陈 辉, 王晓宁, 严庆文. 基于倾斜管实验的膏体自流输送规律. 中国有色金属学报, 2014, 24(12): 3162-3168.

LI Gong-cheng, WANG Hong-jiang, WU Ai-xiang, YU Shao-feng, CHEN Hui, WANG Xiao-ning, YAN Qin-wen. Gravity transport law of paste based on inclined pipe experiment[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 3162-3168.

[4] 吴爱祥, 周 靓, 尹升华, 王雷鸣. 全尾砂絮凝沉降的影响因素[J]. 中国有色金属学报, 2016, 26(2): 439-446.

WU Ai-xiang, ZHOU Jing, YIN Sheng-hua, WANG Lei-ming. Influence factors on flocculation sedimentation of unclassified tailings[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 439-446.

[5] 王新民, 柯愈贤, 张钦礼, 杨 建. 磁化处理全尾砂料浆沉降规律及其参数优化[J]. 中国矿业大学学报, 2017, 46(4): 803-808.

WANG Xin-ming, KE Yu-xian, ZHANG Qing-li, YANG Jian. Rule and optimum magnetization parameters of sedimentation of pre-magnetized crude tailings slurry[J]. Journal of China University of Mining & Technology, 2017, 46(4): 803-808.

[6] 柯愈贤, 王新民, 张钦礼. 全尾砂料浆磁化絮凝沉降特性[J]. 中国有色金属学报, 2017, 27(2): 392-398.

KE Yu-xian, WANG Xin-ming, ZHANG Qing-li. Flocculating sedimentation characteristic of pre-magnetized crude tailings slurry[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(2): 392-398.

[7] 王新民, 赵建文, 张德明. 全尾砂絮凝沉降速度优化预测模型[J]. 中国有色金属学报, 2015, 25(3): 793-798.

WANG Xin-ming, ZHAO Jian-wen, ZHANG De-ming. Optimal prediction model of flocculating sedimentation velocity of unclassified tailings[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 392-398.

[8] 焦华喆, 吴爱祥, 王洪江, 刘晓辉, 杨盛凯, 肖云涛. 全尾砂絮凝沉降特性实验研究[J]. 北京科技大学学报, 2011, 33(12): 1437-1441.

JIAO Hua-zhe, WU Ai-xiang, WANG Hong-jiang, LIU Xiao-hui, YANG Sheng-kai, XIAO Yun-tao. Experiment study on the flocculation settlement characteristic of unclassified tailings[J]. Journal of University of Science and Technology Beijing, 2011, 33(12): 1437-1441.

[9] 王洪江, 陈琴瑞, 吴爱祥, 翟永刚, 张新普. 全尾砂浓密特性研究及其在浓密机设计中的应用[J]. 北京科技大学学报, 2011, 33(6): 676-681.

WANG Hong-jiang, CHEN Qin-rui, WU Ai-xiang, ZHAI Yong-gang, ZHANG Xin-pu. Study on the thickening properties of unclassified tailings and its application to thickener design[J]. Journal of University of Science and Technology Beijing, 2011, 33(6): 676-681.

[10] 吴爱祥, 王洪江. 金属矿膏体充填理论与技术[M]. 北京: 科学出版社, 2015: 52.

WU Ai-xiang, WANG Hong-jiang. The theory and technology of paste filling in metal mines[M]. Beijing: Metallurgical Industry Press, 2015: 52.

[11] 李 辉, 王洪江, 吴爱祥, 焦华喆, 刘晓辉. 基于尾砂沉降与流变特性的深锥浓密机压耙分析[J]. 北京科技大学学报, 2013, 35(12): 1553-1558.

LI Hui, WANG Hong-jiang, WU Ai-xiang, JIAO Hua-zhe, LIU Xiao-hui. Pressure rake analysis of deep cone thickeners based on tailings’ settlement and rheological characteristics[J]. Journal of University of Science and Technology Beijing, 2013, 35(12): 1553-1558.

[12] BUSCALL R, WHITE L R. The consolidation of concentrated suspensions[J]. Journal of Chemical Society, 1987: 873-891.

[13] USHER S P, SCALES P J. Steady state thickener modelling from the compressive yield stress and hindered settling function[J]. Chemical Engineering Journal, 2005, 111(2/3): 253-261.

[14] van DEVENTE B B G, USHER S P, KUMAR A, RUDMAN M, SCALES P J. Aggregate densification and batch settling[J]. Chemical Engineering Journal, 2011, 171(1): 141-151.

[15] ZHANG Y, GRASSIA P, MARTIN A D, USHER S P, SCALES P J. Mathematical modelling of batch sedimentation subject to slow aggregate densification[J]. Chemical Engineering Science, 2015, 128: 54-63.

[16] ZHANG Y, MARTIN A, GRASSIA P. Mathematical modelling of time-dependent densified thickeners[J]. Chemical Engineering Science, 2013, 99: 103-112.

[17] ZHANG Y, MARTIN A, GRASSIA P. Prediction of thickener performance with aggregate densification[J]. Chemical Engineering Science, 2013, 101: 346-358.

[18] USHER S P. Suspension dewatering: Characterisation and optimization[D]. Melbourne: The University of Melbourne, 2002: 347.

[19] GREEN M D. Characterisation of suspensions in settling and compression[D]. Melbourne: The University of Melbourne, 1997: 246.

[20] USHER S P, de KRETSER R G, SCALES P J. Validation of a new filtration technique for dewaterability characterization[J]. AIChE Journal, 2001, 47(7): 1561-1570.

[21] LANDMAN K A, STANKOVICH J M, WHITE L R. The measurement of filtration diffusivity D(f) of a flocculated suspension[J]. AIChE Journal, 1999, 45(9): 1875-1882.

[22] LANDMAN K A, WHITE L R, BUSCALL R. The continuous flow gravity thickener: Steady state behavior[J]. AIChE Journal, 1988, 34 (2): 239-252.

Physical simulation of dewaterability law of unclassified tailings in steady state thickener

LI Gong-cheng1, WANG Hong-jiang1, JIAO hua-zhe2, SUN Wei3, WU Ai-xiang1

(1. School of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Civil and Environment Engineering, Henan Polytechnic University, Jiaozuo 454150, China;

3.Faculty of Land Resources Engineering , Kunming University of Science and Technology, Kunming 650093, China)

Abstract: The dewaterability of tailings was investigated under the condition of all pressure zone in thickener by combining settling and filtration experiments. The dewatering parameters, such as gel point, compressive yield stress and hindered settling function, were statistically calculated. The results indicate that the gel point increases firstly and then decreases with flocculant dosage increasing, the maximum value of gel point is obtained at dosage of 20g/t. The compressive yield stress increases combining power function and exponential function with the concentration. The flocculant dosage has a big effect on concentration at the low pressure zone relatively, and the effect decreases gradually at the high pressure zone. The hindered settling function grows with a power function of concentration. The flocculant dosage has a big effect on concentration at the low pressure zone relatively with obtaining the optimum permeability at the flocculant dosage of 80g/t, and decreases gradually at the high pressure zone. An obvious turning point of volume fraction being from 38% to 42% is observed in the experiments.

Keywords: steady state thickener; dewaterability; compressive yield stress; hindered settling function

Foundation item: Project(2017YFC0602903) supported by the 13th Five-year National Key Research and Development Program of China; Projects(51374034, 51304011) supported by the National Natural Science Foundation of China; Project(Z161100001216002) supported by the Beijing Science and Technology Plan, China

Received date: 2018-03-19; Accepted date: 2018-05-22

Corresponding author: WANG Hong-jiang; Tel: +86-15901196527; E-mail: wanghj1988@126.com

(编辑 王 超)

基金项目:国家“十三五”重点研发计划资助项目(2017YFC0602903);国家自然科学基金资助项目(51374034, 51304011);北京市科技计划资助项目(Z161100001216002)

收稿日期:2018-03-19;修订日期:2018-05-22

通信作者:王洪江,教授,博士;电话:15901196527;E-mail:wanghj1988@126.com