DOI:10.19476/j.ysxb.1004.0609.2019.04.10

形变退火态Ti-50.8Ni-0.1Nb合金的相变和形状记忆行为

贺志荣1,刘康凯1,王 芳2,冯 辉1,杜雨青1

(1. 陕西理工大学 材料科学与工程学院,汉中 723001;

2. 陕西理工大学 图书馆,汉中 723003)

摘 要:用XRD、光学显微镜、示差扫描量热仪和拉伸实验研究退火温度(ta)对冷拉Ti-50.8Ni-0.1Nb(摩尔分数,%)合金组织、相变和形状记忆行为的影响。结果表明:350~700 ℃退火态Ti-50.8Ni-0.1Nb合金由马氏体M(B19′,单斜结构)和母相A(B2,CsCl型结构)组成。随ta升高,合金组织形貌由纤维状变为等轴状,再结晶温度约为580 ℃;合金冷却/加热相变类型由A→R→M/M→R→A型向A→R→M/M→A型向A→M/M→A型转变(R-R相,菱方结构),R相变温度降低,M相变温度和热滞先升高后降低,R相变热滞为6.7~9.8 ℃。350~550 ℃退火态合金的抗拉强度高于600~700 ℃退火态合金的,伸长率则远低于后者的。400~550 ℃退火态合金呈形状记忆效应,350 ℃退火态和600 ℃及以上温度退火态合金呈超弹性。随应力-应变循环次数增加,合金应力-应变曲线的平台应力下降。400~550 ℃退火态合金的形状记忆效应和600 ℃及以上温度退火态合金的超弹性稳定性良好。

关键词:Ti-Ni-Nb合金;形状记忆合金;退火;相变;形状记忆行为

文章编号:1004-0609(2019)-04-0742-07 中图分类号:TG113.25 文献标志码:A

Ti-Ni基形状记忆合金(SMA)是集感知和驱动于一体的功能材料[1]。处于马氏体相状态的SMA具有良好的形状记忆效应(SME),即特定成分合金在马氏体相状态下加载变形,卸载后仍能保持变形后的形状,然后将变形后的合金加热到母相状态时能恢复到加载前的形状的现象[2];处于母相状态的SMA具有良好的超弹性(SE),即特定成分合金在外力作用下产生的应变超过其弹性极限应变量,卸载后合金可自发恢复到原来的形状[3-4],其应力 -应变曲线呈现非线性。此外,SMA还具有良好的高阻尼性、生物相容性和耐腐蚀性,已在航空航天、机械制造、交通运输、土木建筑、能源工程、生物医学及日常生活等领域得到应用[5]。为改善Ti-Ni SMA的性能,可通过在二元Ti-Ni SMA中添加Fe、Cu、Nb、Cr、V等元素进行合金化,比如,所得Ti-47Ni-3Fe SMA的相变温度较低,可制作管接头[6];Ti-30Ni-20Cu SMA的相变温度滞后较小,可制作弹簧和作动器[7-8];Ti-50.8Ni-0.3Cr和Ti-50.8Ni-0.5V SMA具有良好的超弹性,可用于制作弹性及减震元件[9];Ti-47Ni-9Nb SMA具有宽相变温度滞后效应,可制作联接器[10]。目前对Ti-Ni-Nb的研究主要集中在Ti-Ni-9Nb上,对Nb含量较少的Ti-Ni-Nb合金研究的较少。因为Nb含量较低的合金能克服Nb含量较高合金恢复力不足的缺点,同时也能保持Nb含量高的相变滞后宽的优点[11-12],已成为研究热点之一。本文作者在相变温度较低的Ti-50.8Ni SMA基础上,通过掺杂0.1%Nb(摩尔分数),得到Ti-50.8Ni-0.1Nb合金并加工成丝材,进而研究退火对Ti-50.8Ni-0.1Nb合金相变行为、显微组织、形状记忆效应和超弹性的影响,为开发性能优异的多元Ti-Ni基SMA及其热处理工艺提供理论依据和实验支撑。

1 实验

实验材料是直径1 mm的冷拉Ti-50.8Ni-0.1Nb(摩尔分数,%)形状记忆合金丝材。合金原料是纯度分别为99.7%、99.9%和99.9%的海绵Ti,电解Ni和Nb粉。经熔炼、旋锻、拉丝等工序制成合金丝,每道次变形量为20%。用SK-GO6J23K型真空管式电阻炉对合金丝进行350、400、450、500、550、600、650、700 ℃退火处理,保温时间为30 min,炉冷。用Rigaku Ultima IV型X射线衍射仪(XRD)分析合金薄带的相组成。用TA-Q2000型示差扫描热分析仪(DSC)分析合金的相变行为,冷却/加热温度范围为-150~100 ℃,冷却/加热速率为10 ℃/min。用XJL-300型金相显微镜分析合金的显微组织,腐蚀剂配比为V(HF): V(HNO3):V(H2O)=1:4:5。用CMT5105型微机控制电子万能试验机测定合金在室温下的形变行为、形状记忆效应、超弹性和应力-应变循环特性,标距为50 mm,加载/卸载速率为2 mm/min,应力-应变循环试验应变量取6%。

2 结果及讨论

2.1 合金的相组成

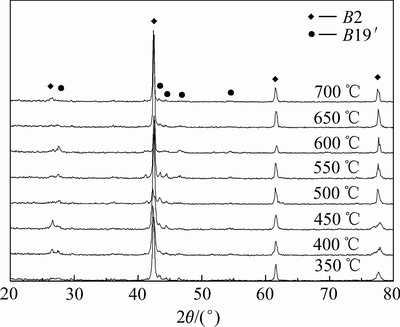

退火温度(ta)对冷拉态Ti-50.8Ni-0.1Nb合金相组成的影响如图1所示,由图1可以看出,退火态Ti-50.8Ni-0.1Nb合金由CsCl结构的母相(A)B2和单斜结构的马氏体(M)相B19′组成,衍射峰强度表明,合金组织中A相较多,M相较少。由于A相与SE对应,M相与SME对应[13],故该合金室温下呈SE+SME特性,以SE为主。

图1 退火温度对Ti-50.8Ni-0.1Nb合金相组成的影响

Fig. 1 Effect of annealing temperature on phase compositions of Ti-50.8Ni-0.1Nb alloy

2.2 合金的显微组织

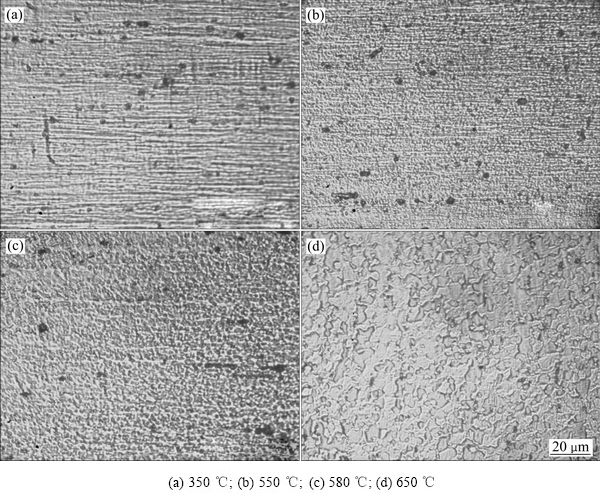

图2 退火温度对Ti-50.8Ni-0.1Nb合金显微组织形态的影响

Fig. 2 Effect of different annealing temperatures on microstructure morphology of Ti-50.8Ni-0.1Nb alloy

冷拉Ti-50.8Ni-0.1Nb合金经350、550、580和650 ℃退火处理后的显微组织形态如图2所示。从图2可以看出,ta对冷拉合金丝的显微组织有显著影响,350 ℃(见图2(a))和550 ℃(见图2(b))退火态合金的显微组织皆呈纤维状,ta=580 ℃时,合金的纤维组织特征消失,形成了细小等轴晶粒(见图2(c)),随着ta 进一步升高,再结晶晶粒相互吞并逐渐长大,最后形成粗大等轴晶组织(见图2(d))。上述结果表明,在本实验条件下,该合金的再结晶温度(tr)约为580 ℃。当然,tr并非物理常数,当合金冷变形程度增加、晶粒细化时,tr会因冷变形储能增加、再结晶驱动力增大而降低。当加热速度过慢或极快时,tr会升高,原因是加热速度过慢时,变形金属在加热过程中有足够时间回复,使点阵畸变度降低,储能减小,再结晶驱动力减小,故tr升高;加热速度极快时,变形金属在各温度停留时间过短,再结晶晶粒来不及形核和长大,致使Tr升高。

2.3 合金的相变行为

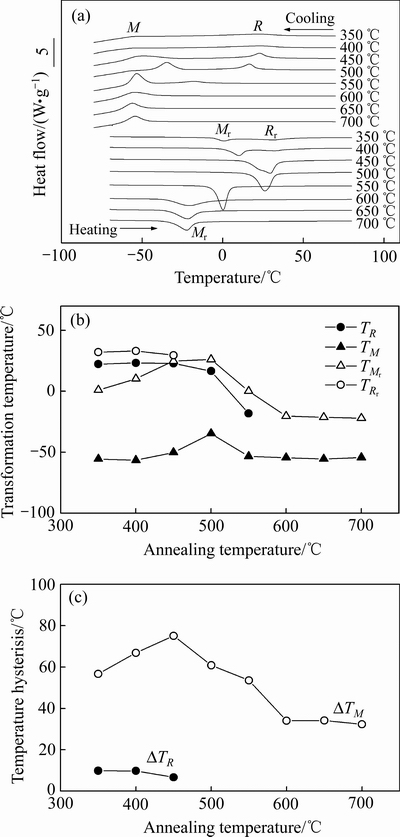

ta对冷拉态Ti-50.8Ni-0.1Nb合金相变类型和R、M正、逆相变峰温度及热滞(正、逆相变峰温度差)的影响如图3所示。图3(a)中R和Rr分别代表正、逆R相变峰,M和Mr分别代表正、逆马氏体相变峰。可以看出,当350 ℃≤ta≤450 ℃时,合金在冷却/加热过程中发生A→R→M/M→R→A(R-R相,菱方结构)型可逆相变,即合金冷却发生A→R和R→M两阶段正相变,加热时发生M→R和R→A两阶段逆相变;当500 ℃≤ta≤550 ℃时,合金发生A→R→M/M→A型相变,即合金冷却发生A→R和R→M两阶段正相变,而加热时因R和M相变峰重叠,合金仅呈现M→A一阶段马氏体逆相变,R相变未单独呈现。R和M相变峰重叠的原因是,随ta升高,合金丝中冷加工组态回复的比较彻底,形变内应力得到释放,形变位错通过滑移、攀移,密度降低,对M相变阻碍作用减弱,M峰向高温方向移动;而随ta升高,合金丝中残留缺陷密度减小,组织均匀性改善,有利于R相形核的有效位置减少,R相变被阻抑,故R峰向低温方向移动。由于R、M峰移动方向相反,因此当ta =500~550 ℃时,二者相遇并重叠。当ta≥600 ℃时,合金完成再结晶,组织均匀化,R相因失去形核位置而不再出现,故只发生A→M/M→A型一阶段正/逆马氏体相变[14]。

图3 退火温度对Ti-50.8Ni-0.1Nb合金相变类型、相变温度和相变热滞的影响

Fig. 3 Effect of annealing temperature on transformation types(a), transformation temperature(b) and temperature hysteresis(c) of Ti-50.8Ni-0.1Nb alloy

由图3(b)可以看出,随ta升高,R正、逆相变峰温度tR、tRr均降低,当ta从350 ℃升至550 ℃时,tR从22.31 ℃降至-18.23 ℃;马氏体正、逆相变峰温度tM、tMr先升高后降低,当Ta=500 ℃时,TM和TMr先分别达到极大值-34.71 ℃和26.11 ℃。由图3(c)知,R相变热滞△tR较小,当ta从350 ℃升至450 ℃时,△tR在6.7~9.8 ℃间变化;随ta升高,M相变热滞△tM先升高后降低,当ta=450 ℃时,△tM达到极大值75.1 ℃,若想得到较小的△tM,ta温度应取600 ℃以上。相变温度决定了形状记忆合金元件的开关温度,高、低相变温度合金可分别用于制作在高、低温场合使用的控温形状记忆元件或超弹性减震、阻尼元件。相变热滞反映了SMA元件动作温度范围的宽窄,Δt越小,动作温度范围越窄,亦即元件对温度的反应越灵敏[15]。小热滞SMA可用于制作传感器,大热滞SMA可用于制作连接元件。

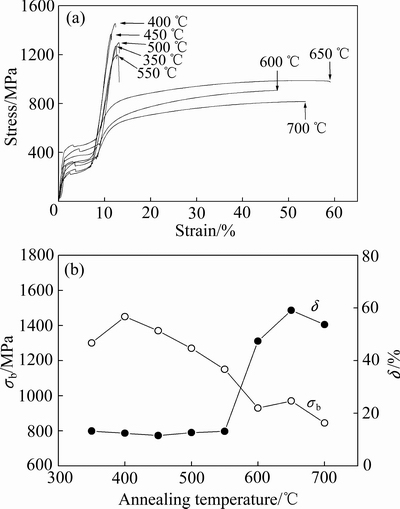

2.4 合金的形变行为

ta对冷拉Ti-50.8Ni-0.1Nb合金室温拉伸曲线及抗拉强度σb和断裂伸长率δ的影响如图4所示。由图4(a)可以看出,合金拉伸时经历了母相的弹性变形、马氏体再取向或应力诱发M相变、应力诱发M的弹性变形、塑性变形和断裂等阶段[11]。350~550 ℃退火态合金的强度高于600~700 ℃退火态合金,但塑性远低于后者的,这与600~700 ℃退火态合金的形变组织发生再结晶、形成无畸变等轴晶粒,使合金塑性恢复有关[16-17]。由图4(b)知,随ta升高,σb先升高后降低,400 ℃退火态合金的σb最大,为1450 MPa,700 ℃退火态合金的σb降为815 MPa。350~550 ℃退火态合金的δ较小(11.5%~13.2%),当ta高于550 ℃后,随ta升高,δ迅速升高,650 ℃退火态合金的δ高达59.1%。因此,要想获得高强度Ti-50.8Ni-0.1Nb合金,合金的退火温度应选取350~550 ℃;要想对Ti-50.8Ni-0.1Nb合金进行大应变塑性加工,合金应在600~700 ℃退火处理。

图4 退火温度对Ti-50.8Ni-0.1Nb合金拉伸曲线、抗拉强度σb和伸长率δ的影响

Fig. 4 Effect of annealing temperature on tensile curves (a), tensile strength σb and percentage elongation δ (b) of Ti-50.8Ni-0.1Nb alloy

2.5 合金的形状记忆行为

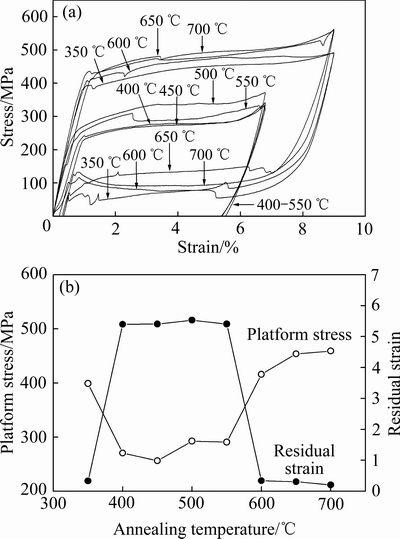

ta对冷拉态Ti-50.8Ni-0.1Nb合金形状记忆行为及加载/卸载应力-应变曲线的平台应力和残余应变的影响如图5所示。由图5(a)可知:1) 350 ℃退火态Ti-50.8Ni-0.1Nb合金丝呈超弹性,原因是350 ℃退火温度较低,形变合金组织中位错等晶体缺陷残留较多,合金丝的加工硬化残余较多,屈服强度较高,有利于产生超弹性;2) 400~550 ℃退火态合金加载时产生应力平台,卸载后应力回零,应变残余,加热至母相状态后,该残余应变回零,即合金呈现典型的形状记忆效应,与此对应的应力平台的物理意义为马氏体再取向,原因是400~550 ℃退火态合金相变温度较高,室温下合金处于马氏体状态,加载时处于马氏体状态的合金发生马氏体再取向;3) 600~700 ℃退火态合金加载时产生应力平台,卸载后应力、应变回零,即合金呈现超弹性,与此对应的应力平台的物理意义为应力诱发马氏体相变,原因是600~700 ℃退火态合金相变温度较低,室温下合金处于母相状态,加载时处于母相状态的合金发生应力诱发A→M相变,卸载发生M→A相变[18]。此外,图5(a)给出的加载/卸载应力平台中出现了锯齿状变化现象,这与SMA合金孪生变形方式有关。因为孪生变形产生孪晶是形核、长大过程,孪晶形核所需的应力远高于其长大所需的应力,故当孪晶出现时伴随载荷突然下降现象,在变形过程中孪晶不断形成,从而形成了锯齿状应力应变曲线[19]。

图5 退火温度对Ti-50.8Ni-0.1Nb合金形状记忆行为和应力-应变曲线平台应力、残余应变的影响

Fig. 5 Effect of annealing temperature on shape memory behavior (a) and platform stress, residual strain in stress-strain curves (b) of Ti-50.8Ni-0.1Nb alloy

由图5(b)知,随ta升高,合金加载/卸载应力-应变曲线的平台应力先降低后升高再趋于稳定,分别在450 ℃和700 ℃时取得最小值(256 MPa)和最大值 (459 MPa);残余应变先升高后降低。当退火温度为400~550 ℃时,卸载后,合金的残余应变高达5.4%~ 5.5%,加热后该残余应变降为0,即合金的形状恢复,表现出优异的SME;当退火温度为350 ℃和600~700 ℃时,卸载后,合金的残余应变仅为0.2%~ 0.3%,呈现优异的SE。可见,要使Ti-50.8Ni-0.1Nb合金具有优异的SME,ta应取400~550 ℃;要使该合金具有优异的SE,ta应取350 ℃和600~700 ℃。

2.6 循环变形行为

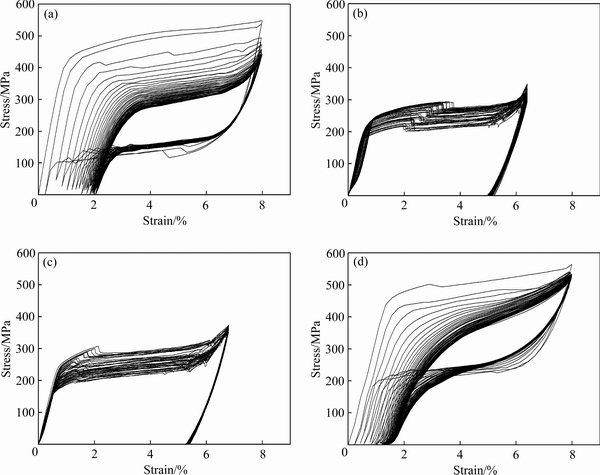

图6给出了应力-应变循环对350 ℃(见图6(a))、 400 ℃(见图6(b))、550 ℃(见图6(c))和600 ℃(见图 6(d))退火态Ti-50.8Ni-0.1Nb合金形状记忆行为的影响,应力-应变循环总次数为50次。可以看出,随应力-应变循环次数增加:1) 350 ℃退火态(见图6(a))和600 ℃及以上温度退火态(见图6(d))合金保持超弹性行为,且由部分超弹性(残留应变不为零)转变为完全超弹性(残余应变为零)[20-21];2) 350 ℃退火态合金的应力-应变曲线平台应力下降幅度比600 ℃及以上温度退火态合金的大(比较图6(a)和(d)),即350 ℃退火态合金的超弹性稳定性不如600 ℃及以上温度退火态合金的;3) 400~550 ℃退火态合金保持形状记忆行为,合金的应力-应变曲线平台应力随应力-应变循环次数增加而下降(见图6(b)和(c))。要使Ti-50.8Ni-0.1Nb合金获得稳定的SME和SE,ta应分别取400~550 ℃和600~700 ℃。

图6 应力-应变循环对350 ℃,400 ℃,550 ℃和600 ℃退火态Ti-50.8Ni-0.1Nb合金形状记忆行为的影响

Fig. 6 Effect of stress-strain cycle on shape memory behavior of Ti-50.8 Ni-0.1Nb alloy annealed at 350 ℃(a), 400 ℃(b), 550 ℃(c), 600 ℃(d)

3 结论

1) 350~700 ℃退火态Ti-50.8Ni-0.1Nb合金由马氏体M和母相A组成。随ta升高,Ti-50.8Ni-0.1Nb合金冷却/加热时的相变类型由A→R→M/M→R→A型向A→R→M/M→A型再向A→M/M→A型转变;R相变温度降低,M相变温度和热滞先升高后降低,R相变热滞在6.7~9.8 ℃间变化;合金的组织形貌由纤维状变为等轴状,合金的再结晶温度约为580 ℃。

2) 350~550 ℃退火态合金的抗拉强度高于600~ 700 ℃退火态合金的,伸长率远低于后者的;400~ 550 ℃退火态合金呈SME,350 ℃退火态和600 ℃及以上温度退火态合金呈SE。

3) 随应力-应变循环次数增加,合金的应力-应变曲线平台应力下降,400~550 ℃退火态合金的SME和600 ℃及以上温度退火态合金的SE稳定性良好。

REFERENCES

[1] SAIKRISHNA C N, RAMAIAH K V, PAUL D, BHAUMIK S K. Enhancement in fatigue life of NiTi shape memory alloy thermal actuator wire[J]. Acta Materialia, 2016, 102: 385-396.

[2] HE Z, LIU M. Effect of heat treatment on transformation behavior of Ti-Ni-V shape memory alloy[J]. Materials Science and Engineering A, 2011, 528(22): 6993-6997.

[3] DAGHASH S M, OZBULUT O E. Characterization of superelastic shape memory alloy fiber-reinforced polymer composites under tensile cyclic loading[J]. Materials and Design, 2016, 111: 504-512.

[4] 贺志荣, 刘曼倩, 王 芳, 张永宏, 王永善. 时效工艺对Ti-Ni-V形状记忆合金组织和超弹性的影响[J]. 中国有色金属学报, 2013, 23(5): 1301-1306.

HE Zhi-rong, LIU Man-qian, WANG Fang, ZHANG Yong-hong, WANG Yong-shan. Effect of aging process on microstructure and superelasticity of Ti-Ni-V shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1301-1306.

[5] JANI J M, LEARY M, SUBIC A, GIBSON M A. Review of shape memory alloy research, applications and opportunities[J]. Materials and Design, 2014, 56: 1078-1113.

[6] KANG X, LI Y, YIN X, XIE H, MI X. The microstructure and properties of Ti50Ni47Fe3and Ti50Ni46.75Fe3Cr0.25 shape memory alloy[J]. Advanced Materials Research, 2013, 631/632: 326-330.

[7] RONG L, MILLER D A, LAGOUDAS D C. Transformation behavior in a thermomechanically cycled TiNiCu alloy[J]. Metallurgical and Materials Transactions A, 2001, 32(11): 2689-2693.

[8] 商泽进, 王忠民, 李新波, 郑碧玉. 冷加工变形量对TiNiCu形状记忆合金棒材形状记忆效应的影响[J]. 机械科学与技术, 2010, 29(7): 902-905.

SHANG Ze-jin, WANG Zhong-min, LI Xin-bo, ZHENG Bi-yu. Effects of cold deformation on the shape memory effect of TiNiCu alloy bars[J]. Mechanical Science and Technology for Aerospace Engineering, 2010, 29(7): 902-905.

[9] HE Z, LIU M. Effects of annealing and deforming temperature on microstructure and deformation characteristics of Ti-Ni-V shape memory alloy[J]. Materials Science and Engineering B, 2012, 177: 986-991.

[10] 李贵发, 孙益阳, 洪起虎. 热处理温度对NiTiNb5相变温度和组织的影响[J]. 特种铸造及有色合金, 2012, 32(3): 15-18.

LI Gui-fa, SUN Yi-yang, HONG Qi-hu. Influence of heat treatment temperature on phase transformation temperature and microstructure of NiTiNb5 alloy[J]. Special Casting and Nonferrous Alloys, 2012, 32(3): 15-18.

[11] ZHAO Xin-qing. Mechanical properties and transformation behavior of NiTiNb shape memory alloys[J]. Chinese Journal of Aeronautics, 2009, 22(5): 540-543.

[12] XIAO Fu, MA Guo-jun, ZHAO Xin-qing. Effects of Nb content on yield strength of NiTiNb alloys in martensite state [J]. Chinese Journal of Aeronautics, 2009, 22(6): 658-662.

[13] SHARIAT B S, MENG Qing-lin, MAHMUD A S, WU Zhi-gang, BAKHTIARI R, ZHANG Jun-song, MOTAZEDIAN F, YANG Hong, RIO G, NAM T H, LIU Yi-nong. Functionally graded shape memory alloys: Design, fabrication and experimental evaluation[J]. Materials and Design, 2017, 124: 225-237.

[14] 贺志荣, 王 芳. 热处理对Ti-49.8Ni-1.0Co超弹性合金相变行为的影响[J]. 金属学报, 2008, 44(1): 23-28.

HE Zhi-rong, WANG Fang. Effect of heat treatment on transformation behavior of superelastic alloy Ti-49.8Ni- 1.0Co[J]. Acta Metallurglca Sinica, 2008, 44(1): 23-28.

[15] 贺志荣. Ti-50.8Ni-0.3Cr超弹性合金的相变与形变特性[J]. 金属学报, 2008, 44(9): 1076-1080.

HE Zhi-rong. Transformation and deformation characteristics of Ti-50.8Ni-0.3Cr superelastic alloy[J]. Acta Metallurglca Sinica, 2008, 44(9): 1076-1080.

[16] JIANG F, LIU Y, YANG H, LI L, ZHENG Y F. Effect of ageing treatment on the deformation behavior of Ti-50.9at.% Ni [J]. Acta Materialia, 2009, 57(16): 4773-4781.

[17] SEMBA H, OKABE N, YAMAJI T, OKITA K, YAMAUCHI K. Effects of applied strain and subsequent heat treatment at intermediate temperature on mechanical properties of a thin plate Ti-51at% Ni shape memory alloy[J]. Materials Transactions, 2006, 47(3): 772-779.

[18] 贺志荣, 王 芳. Ti-Ni-V形状记忆合金的循环形变特性[J]. 中国有色金属学报, 2013, 23(7): 1866-1872.

HE Zhi-rong, WANG Fang. Cyclic deformation characteristics of Ti-Ni-V shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1866- 1872.

[19] ATLI K C. The effect of tensile deformation on the damping capacity of NiTi shape memory alloy[J]. Journal of Alloys and Compounds, 2016, 679: 260-267.

[20] 商泽进, 王忠民, 尹冠生, 郑碧玉. 循环加载条件下TiNi形状记忆合金棒材的超弹性行为[J]. 实验力学, 2008, 23(4): 305-310.

SHANG Ze-jin, WANG Zhong-min, YIN Guan-sheng, ZHENG Bi-yu. Superelastic behavior under cyclic loading for TiNi shape memory alloy bars[J]. Journal of Experimental Mechanics, 2008, 23(4):305-310.

[21] 贺志荣. Ti-Ni-V形状记忆合金超弹性研究[J]. 稀有金属材料与工程, 2015, 44(7): 1639-1642.

HE Zhi-rong. Superelasticity of Ti-Ni-V shape memory alloys[J]. Rare Metal Materials and Engineering, 2015, 44(7): 1639-1642.

Transformation and shape memory behaviors of deformed and annealed Ti-50.8Ni-0.1Nb alloy

HE Zhi-rong1, LIU Kang-kai1, WANG Fang2, FENG Hui1, DU Yu-qing1

(1. School of Materials Science and Engineering, Shaanxi University of Technology, Hanzhong 723001, China;

2. Library, Shaanxi University of Technology, Hanzhong 723003, China)

Abstract: The effects of annealing temperature (Ta) on the microstructure, phase transformation and shape memory behavior of cold drawing Ti-50.8Ni-0.1Nb (mole fraction, %) shape memory alloy were investigated by XRD, optical microscopy, differential scanning calorimetry and tensile test. The results show that the phase compositions of Ti-50.8Ni-0.1Nb alloy annealed at 350-700 ℃ are martensite M (B19′, monoclinic) and parent phase A (B2, CsCl). With increasing Ta, the microstructure morphology of the alloy changes from fibrous to equiaxed grain, the recrystallization temperature is about 580 ℃; the transformation types of the alloy change from A→R→M/M→R→A to A→R→M/M→A to A→M/M→A (A-parent phase B2, CsCl; R-R phase, rhombohedral; M-martensite B19′, monoclinic) upon cooling/heating, the R transformation temperature of the alloy decreases, the M transformation temperature and temperature hysteresis increases firstly and then decreases, the R transformation temperature hysteresis is 6.7-9.8 ℃. The tensile strength of the alloy annealed at 350-550 ℃ is higher than that of the alloy annealed at 600-700 ℃, while the percentage elongation of the former is lower than that of the latter. The alloy annealed at 400-550 ℃ shows shape memory effect, and the alloys annealed at 300 ℃ and 600-700 ℃ show superelasticity. With increasing stress-strain cycling number, the platform stress in the stress-strain curve of the alloy decreases. The stability of the shape memory effect in the alloy annealed at 400-550 ℃ and the superelasticity in the alloy annealed at 600-700 ℃ are well.

Key words: Ti-Ni-Nb alloy; shape memory alloy; annealing; transformation; shape memory behavior

Foundation item: Project(2016YFE0111400) supported by the National Program on Key Basic Research Project of China; Project(2017ZKC04-84) supported by the Scientific Research Program Foundation by Shaanxi Province, China; Project(HZGXW1602) supported by the Scientific Research Project Foundation by Hanzhong City of Shaanxi Province, China; Project(SLGYCX1823) supported by the Innovation Found for Postgraduate of Shaanxi University of Technology, China

Received date: 2018-03-09; Accepted date: 2018-05-22

Corresponding author: HE Zhi-rong; Tel: +86-916-2291193; E-mail: hezhirong01@163.com

(编辑 王 超)

基金项目:国家重点研发计划项目(2016YFE0111400);陕西省重大科技创新项目(2017ZKC04-84);汉中市科技计划项目(HZGXW1602);陕西理工大学研究生创新基金项目(SLGYCX1823)

收稿日期:2018-03-09;修订日期:2018-05-22

通信作者:贺志荣,教授,博士;电话:0916-2291193;E-mail:hezhirong01@163.com